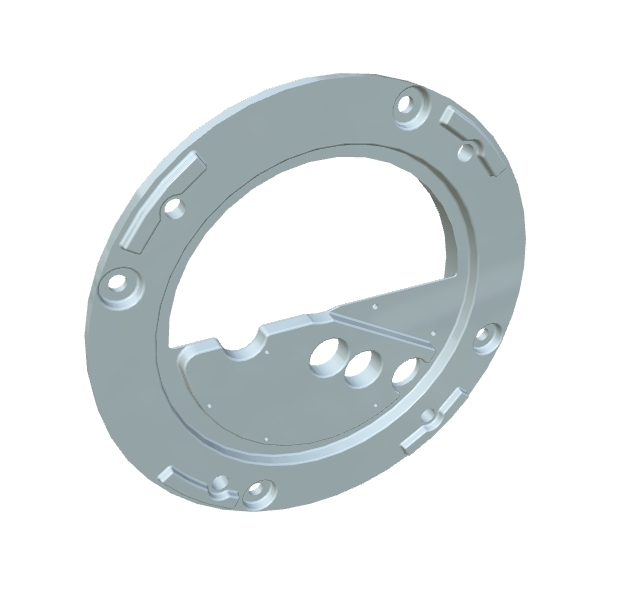

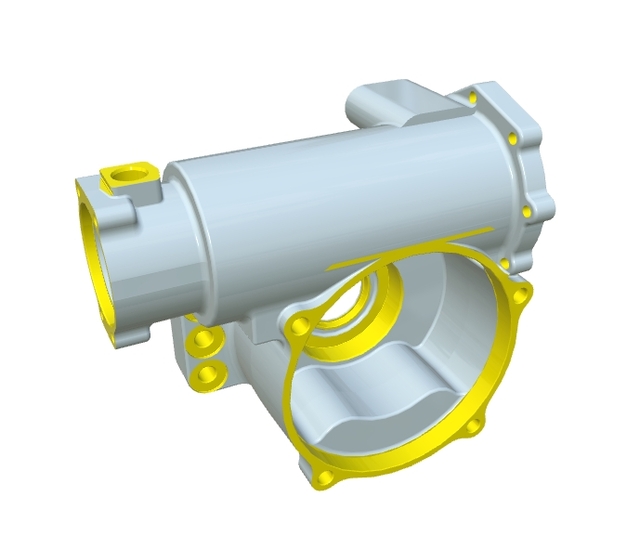

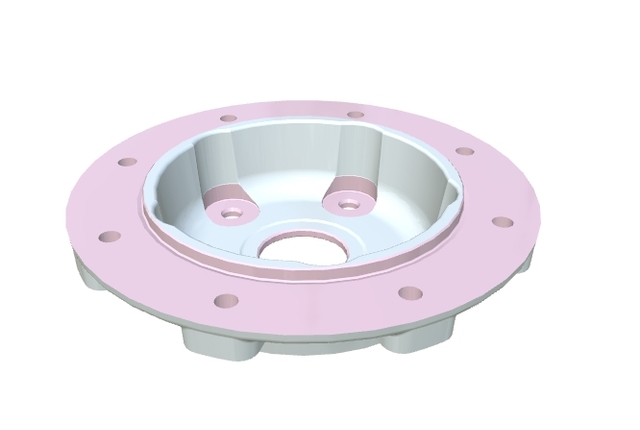

Low pressure casting is a highly efficient technique used in the metal casting industry that involves the filling of molds using lower pressure as opposed to traditional methods. This method is particularly beneficial for creating high-quality, durable components such as the Circular Mounting Plate, which is designed to meet the needs of modern engineering projects. This casting technique is instrumental in producing flawless components from metals like aluminum, leveraging the unique advantages of low pressure casting to ensure precise and robust products.

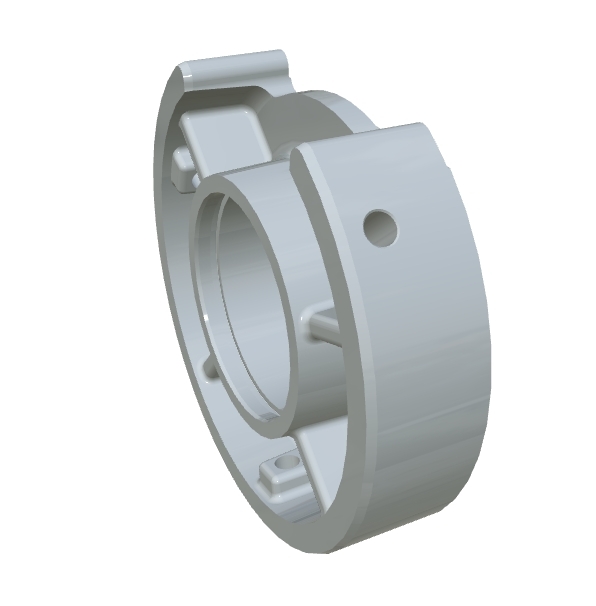

Low pressure die casting, often highlighted within the broader pressure casting method, allows for controlled filling of the mold, which is crucial in maintaining the integrity of complex geometries and thin-walled sections. The Circular Mounting Plate benefits significantly from this process, as it results in a product with minimal defects and superior surface finish, enhancing both its functionality and aesthetic appeal. Such attributes are essential for components integrated into high-demand industrial environments, requiring stability and reliability.

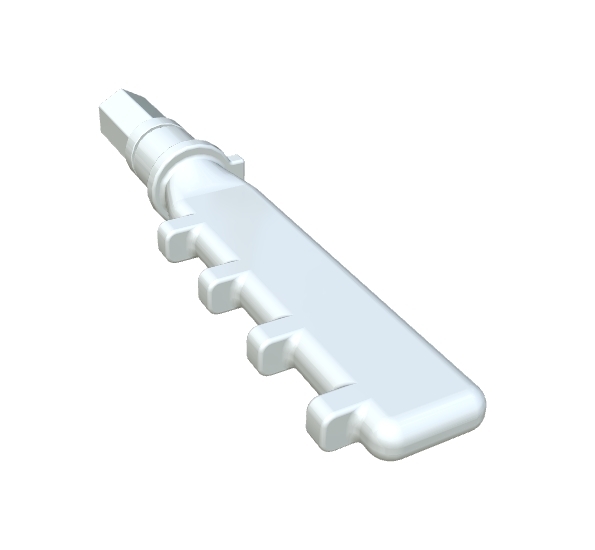

The advantages of low pressure casting include the ability to produce highly detailed parts economically. Unlike traditional sand casting, low pressure casting results in a denser and more precise product. This casting technology also enables material optimization, ensuring the Circular Mounting Plate is not only robust but also lightweight. When compared to other methods, the low pressure casting process offers reduced material wastage and enhanced design flexibility, particularly in designing intricate patterns and complex structures.

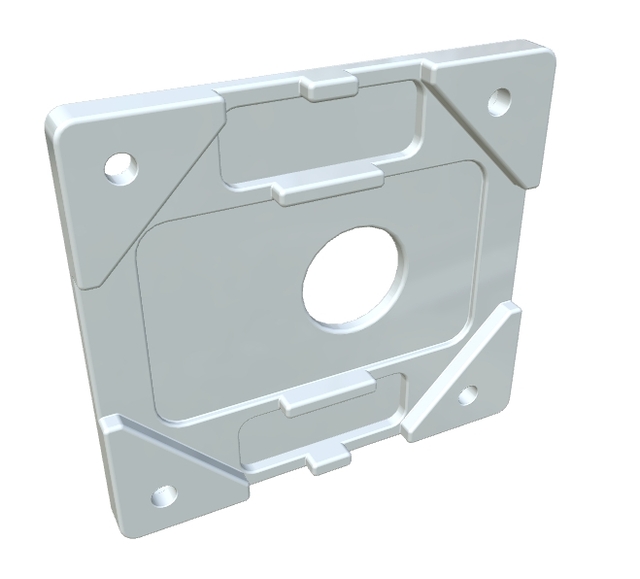

For industries aiming to achieve high precision in their manufactured components, such as aerospace or automotive sectors, low pressure casting technology is a preferred method due to its ability to produce consistent and reliable results. The adaptability of low pressure casting mold making is crucial when integrating components into contemporary engineering systems, where flawless design is non-negotiable. In applications where weight, accuracy, and durability are critical, the advantages of low pressure casting outweigh traditional methods, making it the technology of choice for modern manufacturing objectives.

In sum, understanding how low pressure casting works and selecting the appropriate materials for low pressure casting is essential for engineers looking to expand their capabilities with innovative solutions such as the Circular Mounting Plate. With its multiple pre-drilled holes for versatility and ease of installation, this component exemplifies the success and precision achievable with low pressure casting, emphasizing the method's growing applications across various industries and its role in transforming design possibilities.

Low Pressure Casting: Advantages, Process & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Low Pressure Casting: Advantages, Process & Applications

Mastering the Low Pressure Casting Process for Durability

Low Pressure Casting: Precision, Efficiency & Applications

Low Pressure Casting: Transforming Metal Foundry Services

Low Pressure Casting Process: Enhancing Precision & Quality

Low Pressure Casting: Precision in Engineering

Exploring the Benefits of Low Pressure Casting Techniques

Revolutionizing Automotive Parts: Low Pressure Casting Process