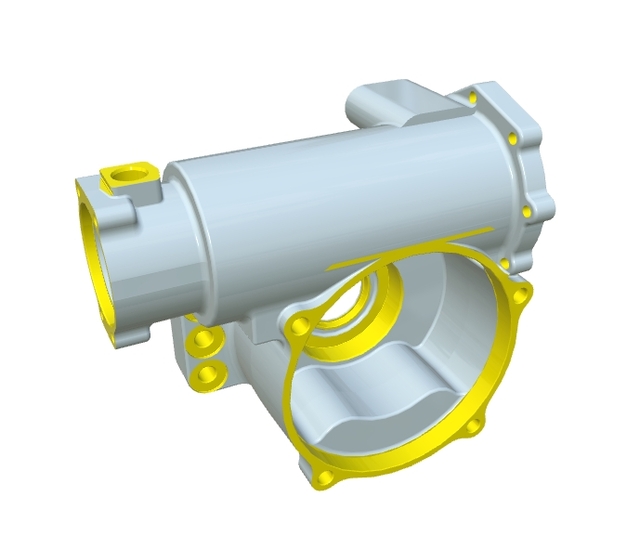

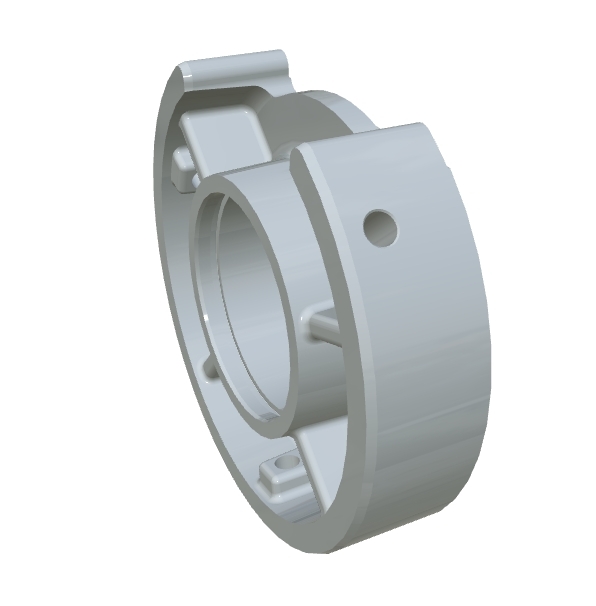

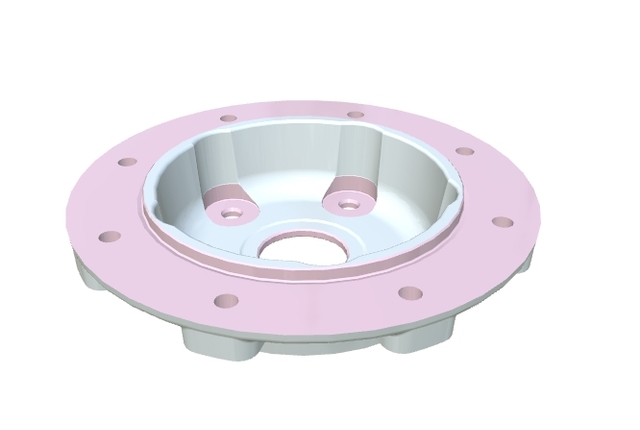

Low pressure casting has emerged as a prominent technique in the manufacturing industry, known for its precision and efficiency. At the heart of this method is the efficient production of aluminum components, a sector significantly benefiting from advancements in low pressure die casting. The process involves filling a mold with liquid metal using minimal force, ensuring high accuracy and minimal defects.

One of the key advantages of low pressure casting is its ability to produce high-quality aluminum parts, making it a favored choice among industries that demand lightweight but robust products, such as automotive and aerospace. This technique not only enhances the structural integrity of aluminum components but also reduces waste, making it an environmentally friendly option. Low pressure casting equipment plays a crucial role here, providing consistent results through controlled processes.

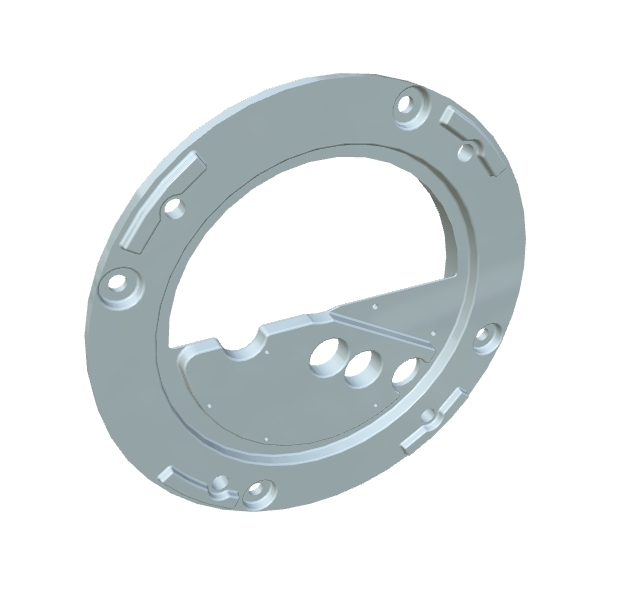

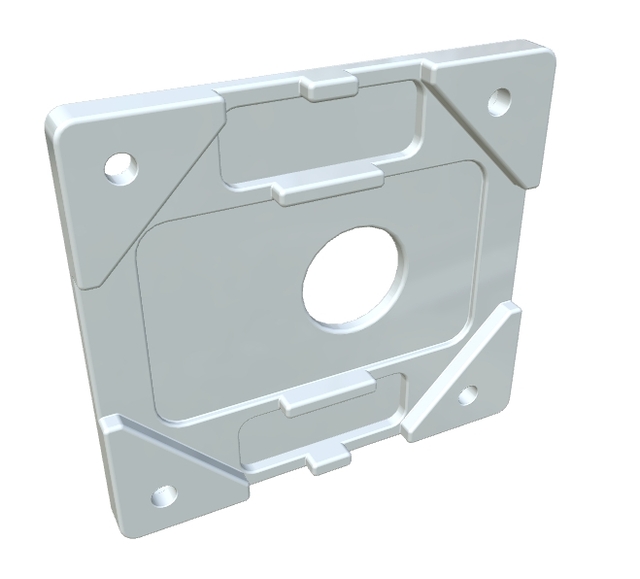

The low pressure casting process itself is highly regarded for its advantages over traditional casting methods. Unlike high pressure die casting, which is more suited for producing larger volumes of smaller parts, low pressure casting excels in creating complex and larger structures with fewer imperfections. The method's precision lands it a variety of applications, including producing intricate machine parts and high-quality industrial components. Moreover, industries benefit from low pressure casting technology due to its ability to enhance product durability and performance.

Despite its many advantages, it's important to be mindful of potential defects in low pressure casting. Factors such as gas porosity or improper temperature control can lead to issues; however, these are generally mitigated through advanced technology and stringent quality checks. As manufacturers continue to refine pressure casting techniques, the occurrence of such defects is diminishing, bolstering reliability across low pressure casting industries.

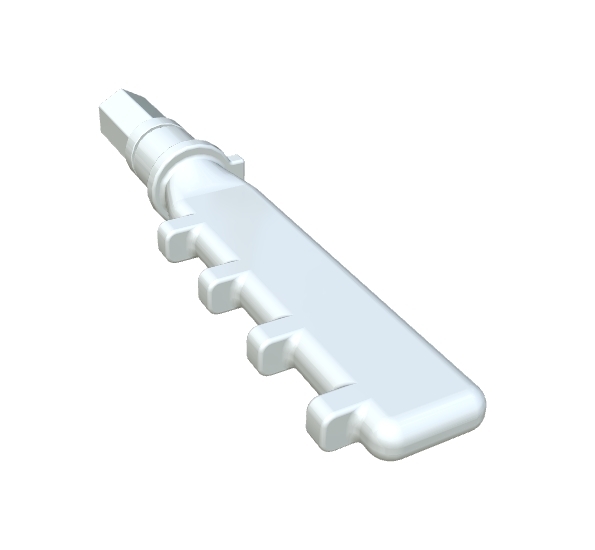

The introduction of innovative products like the Hex Key Holder illustrates the versatility of components produced through low pressure casting techniques. This elegantly designed, minimalist product exemplifies the high-quality output achievable through advanced aluminum low pressure casting processes. Crafted from durable materials, the Hex Key Holder underscores the precision casting's ability to combine functionality with aesthetic appeal, fitting comfortably in both professional and home settings to enhance organizational efficiency.

Embrace the transformation that low pressure casting can bring to your manufacturing needs. With its expanding presence across various industries, supported by continuous technological progress and equipment improvements, low pressure aluminum die casting remains a cornerstone of modern manufacturing. Its advantages are not only reshaping the way products are crafted but also paving the way for sustainable, high-performing components that meet the ever-growing demands of today's market.

Low Pressure Casting: Precision, Efficiency & Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Low Pressure Casting: Advantages, Process & Applications

Mastering the Low Pressure Casting Process for Durability

Low Pressure Casting: Precision, Efficiency & Applications

Low Pressure Casting: Transforming Metal Foundry Services

Low Pressure Casting Process: Enhancing Precision & Quality

Low Pressure Casting: Precision in Engineering

Exploring the Benefits of Low Pressure Casting Techniques

Revolutionizing Automotive Parts: Low Pressure Casting Process