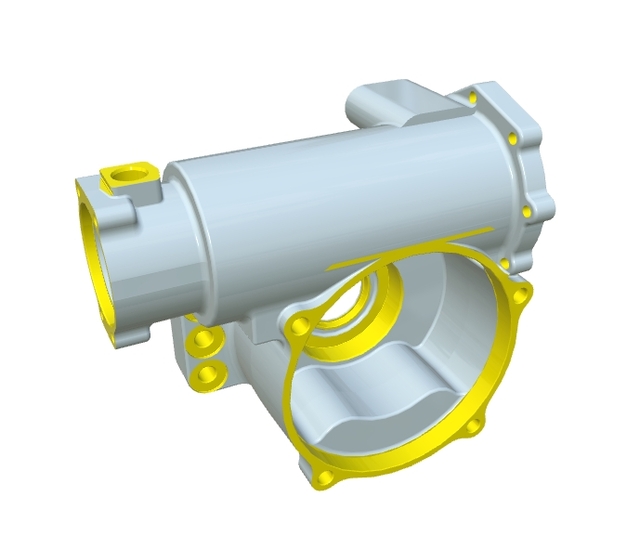

The **low pressure casting process** is a pivotal technique in modern manufacturing, notably enhancing the production of high-quality components by utilizing low pressure to fill molds. Unlike other casting methods, low pressure die casting ensures that molten material, typically aluminum or magnesium, is precisely introduced into the mold with minimal turbulence and air entrapment, resulting in superior surface finish and dimensional accuracy.

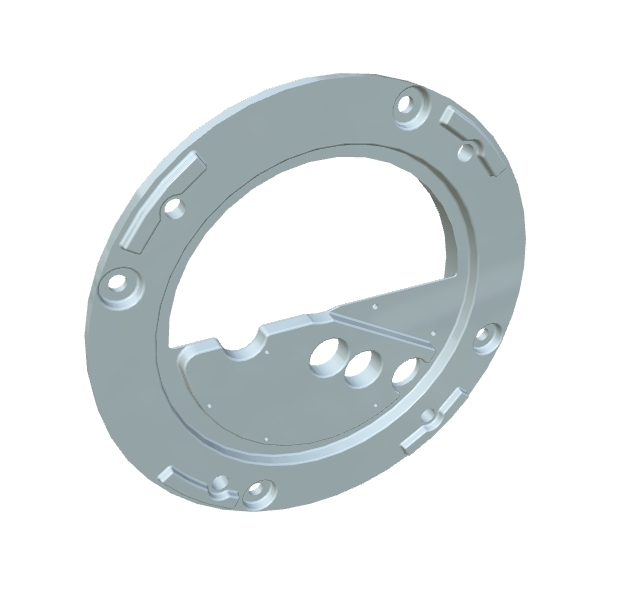

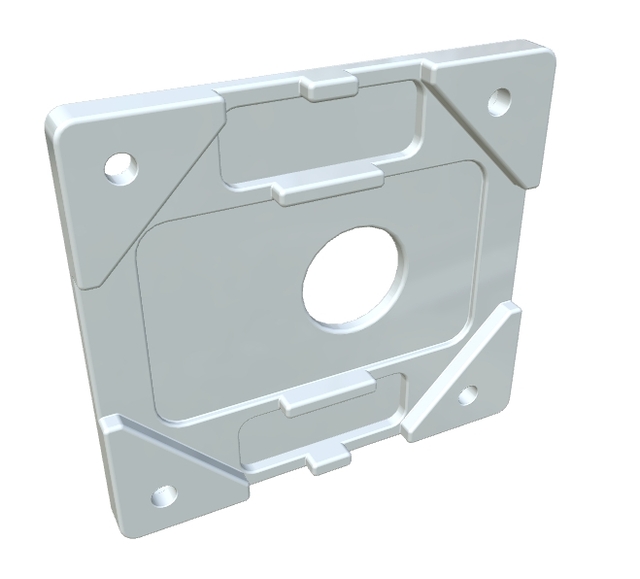

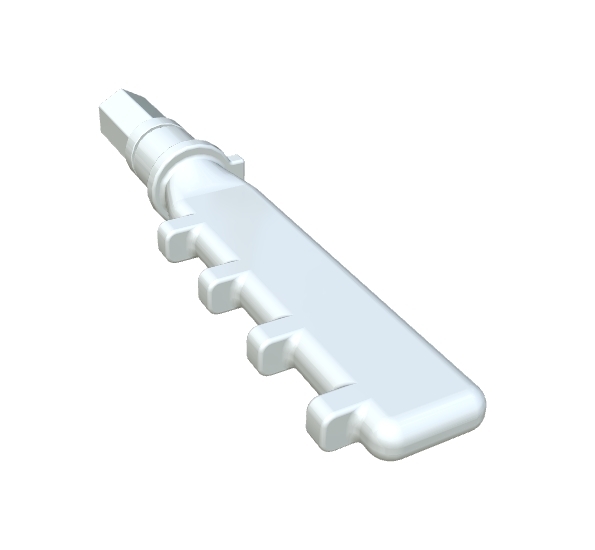

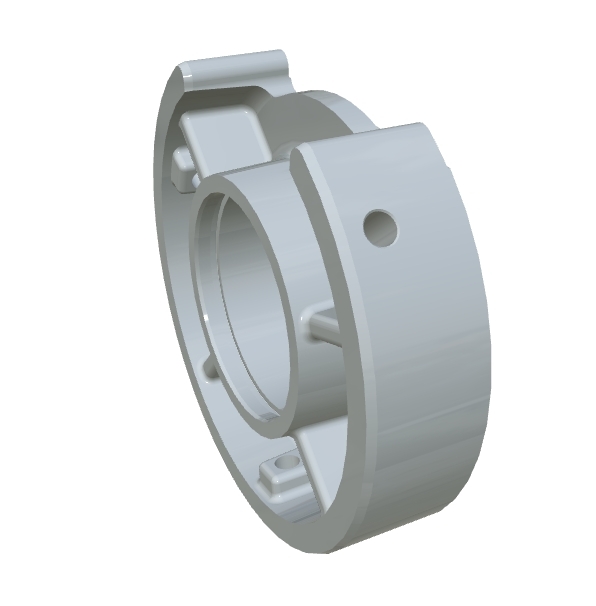

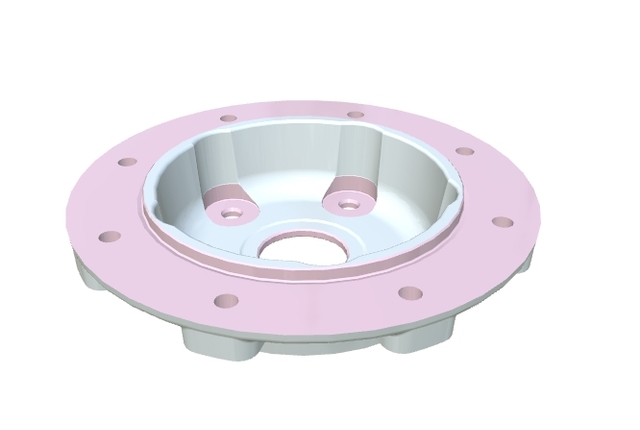

One of the core benefits of low pressure casting is its ability to produce complex geometries with exceptional precision. This makes it especially popular in the automotive sector where components such as engine blocks, suspension arms, and the innovative Precision Mounting Bracket are fabricated. The Precision Mounting Bracket exemplifies this process's advantages, boasting a robust metallic build and refined finish suitable for various mechanical systems. Its versatility in installations further underscores the adaptability of low pressure casting techniques in accommodating diverse industrial demands.

A significant advantage of low pressure casting compared to high pressure casting is the reduced incidence of casting defects, such as porosity and inclusions. This is crucial for applications requiring high structural integrity. Furthermore, the technology's adaptability allows it to handle a range of materials, broadening its appeal across different industries. By minimizing defects, low pressure aluminum casting extends the durability and lifespan of components, ensuring reliability in both industrial and consumer contexts.

The applications of low pressure casting are vast, spanning across the automotive, aerospace, and electronics industries. In these fields, the technology's ability to produce lightweight yet sturdy parts is invaluable. In addition, with advancements in low pressure casting equipment, manufacturers are now able to achieve even higher levels of precision and efficiency. This process's technological strides have made it a cornerstone of modern manufacturing, driving forward innovation in design and application.

In comparison to high pressure casting, low pressure casting offers smoother flow of metal, resulting in fewer critical flaws and a more streamlined production process. Thus, the superiority of low pressure casting in terms of ease of use and quality output makes it an increasingly preferred choice for manufacturers focused on delivering top-tier products like the Precision Mounting Bracket.

Overall, low pressure casting technology stands out for its manufacturing efficiency and quality assurance. It plays a crucial role in producing essential components with high accuracy and detail, supporting industries that demand reliability and performance. The low pressure casting process remains a testament to the triumphs of modern engineering and its continuous evolution in meeting the ever-changing demands of global industry.

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.