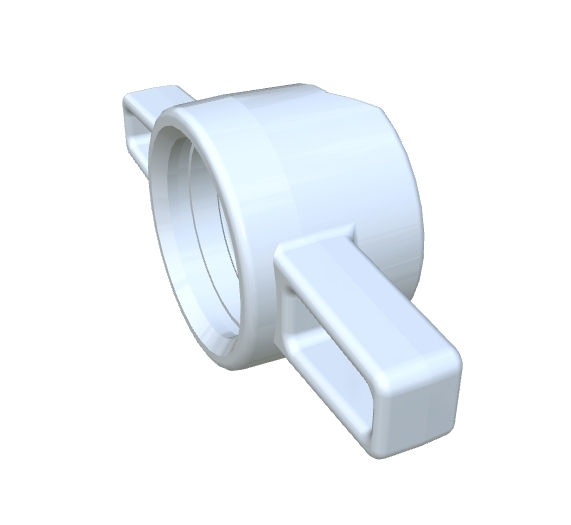

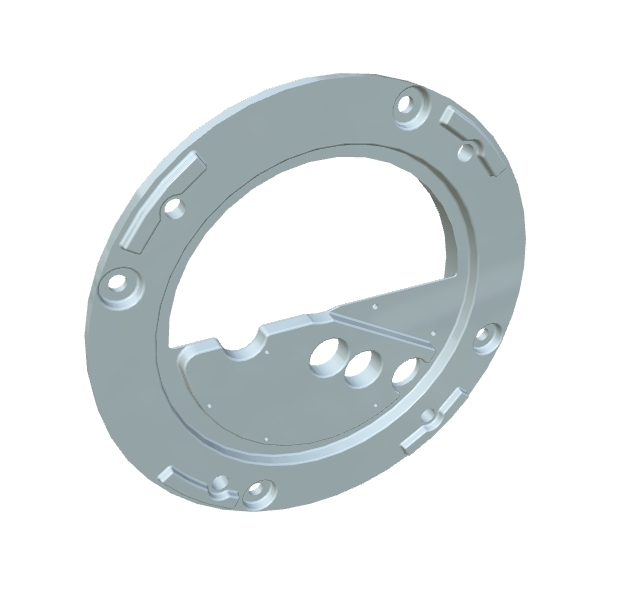

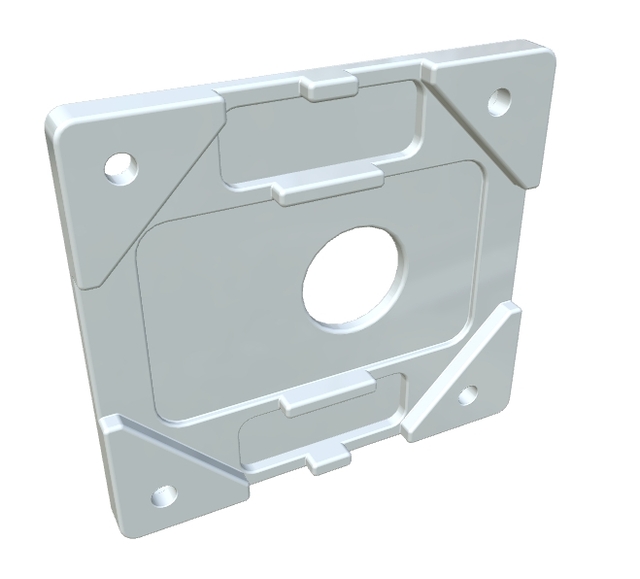

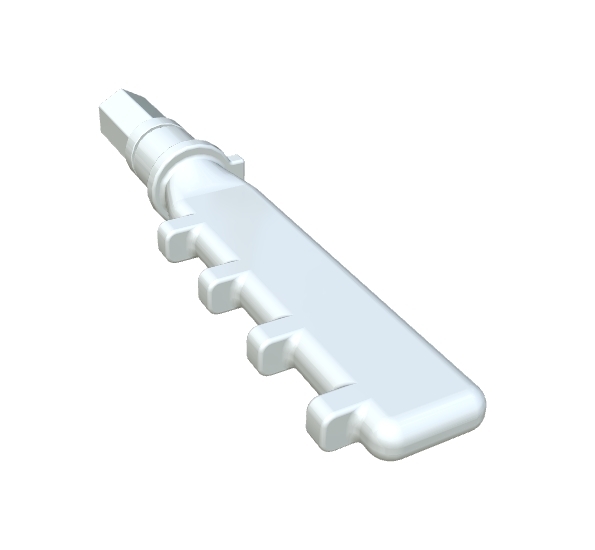

The investment casting process, a pivotal technology in modern manufacturing, offers a blend of precision and versatility that is unmatched in the industry. Investment casting techniques have revolutionized the way components like the Circular Valve Plate are manufactured, ensuring high standards of precision and durability. So, what is investment casting? It is a meticulous process whereby a wax pattern is coated with a refractory ceramic material to create a mold. Upon heating, the wax melts away, leaving a cavity that is then filled with molten metal to form a solid component once cooled.

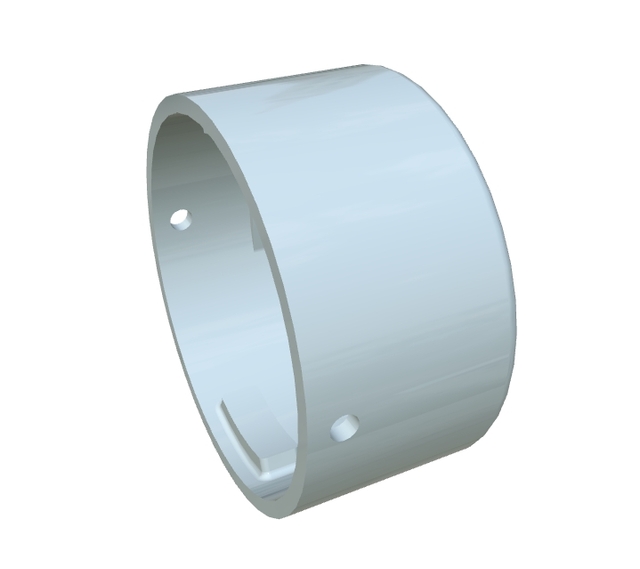

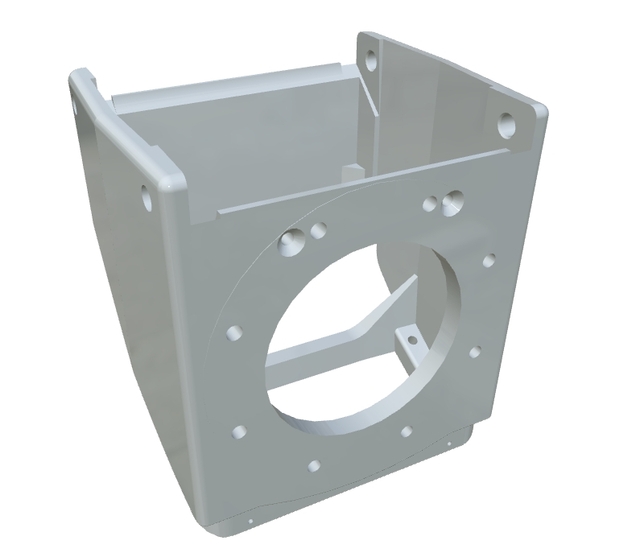

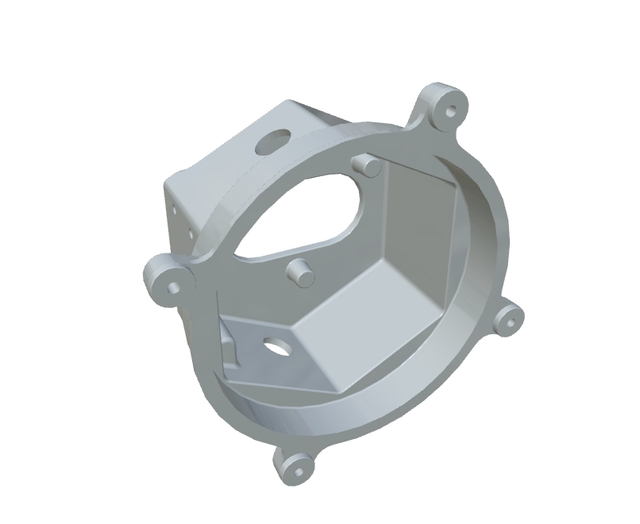

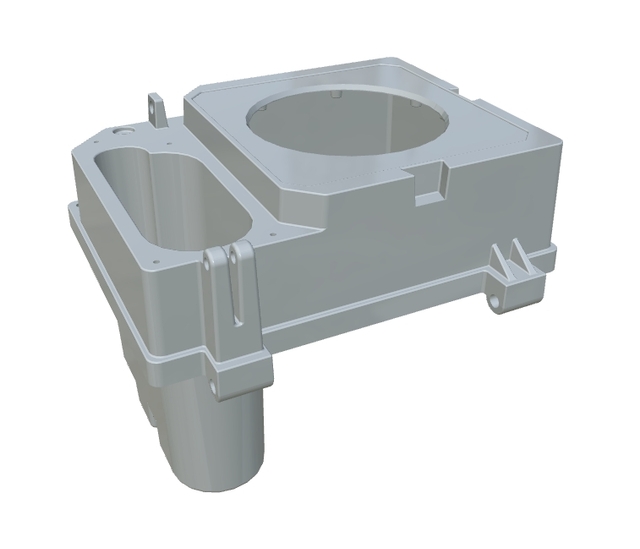

One of the key investment casting advantages is its ability to produce components with intricate geometries and tight tolerances that rival those found in machining or other manufacturing processes. This impeccable precision ensures that components like the Circular Valve Plate, crafted from high-quality stainless steel, offer exceptional resistance to corrosion and wear. Such durability is crucial, especially in demanding environments where these components must remain robust and reliable.

Moreover, investment casting materials are diverse, allowing for a wide range of metals, including stainless steel, to be used. These materials are paramount to producing components that are both durable and versatile, such as the Circular Valve Plate's sleek design. Its multiple apertures facilitate various configurations, which are indispensable in fluid dynamics and pneumatic systems. Furthermore, the precision-engineered holes for secure mounting underscore the adaptability of custom investment casting. This adaptability is essential for seamless integration into different mechanical assemblies while optimizing operational fluidity.

Investment casting companies continue to innovate by embracing precision investment casting, which aligns perfectly with the engineering of dynamic components. The Circular Valve Plate, for instance, exemplifies a product where innovation meets reliability, bringing heightened performance to industrial engineering. By utilizing precision investment casting, these plates maintain structural integrity and enhance the stability of the machinery they are part of, minimizing vibrations and wear over time.

In conclusion, investment casting is a cornerstone of modern manufacturing, particularly when it comes to producing intricate, durable components that meet the highest standards of quality and performance. Products like the Circular Valve Plate, made from high-quality stainless steel, demonstrate the critical role that investment casting plays in the world of industrial engineering. By incorporating cutting-edge design and materials, investment casting ensures that components are both innovative and reliable, offering industries an unparalleled level of craftsmanship and operational efficiency.

Investment Casting Process for Precision Engineering

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.