Investment casting is an age-old manufacturing process that has gained immense popularity in modern times due to its precision and versatility. This sophisticated technique, also known as lost wax casting, involves creating a wax pattern, which is then encased in a ceramic shell. Once the mold is formed, the wax is melted away, leaving a cavity to be filled with molten metal. The investment casting process is renowned for producing complex metal components with excellent surface finishes and intricate details.

Investment casting techniques have evolved significantly over the years, with advancements making the process more efficient and capable of handling a wide variety of metals. Precision investment casting has become a cornerstone in industries such as aerospace, automotive, and even healthcare, where high-quality components are imperative. Materials commonly used in investment casting include an array of metals such as stainless steel, aluminum, and titanium, each chosen for its specific properties to suit various applications. Investment casting foundries across the globe have refined these techniques to ensure the highest level of precision, meeting the demanding specifications of today’s market.

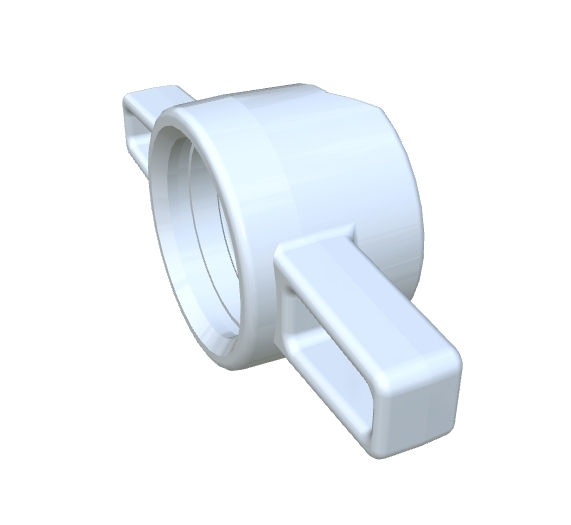

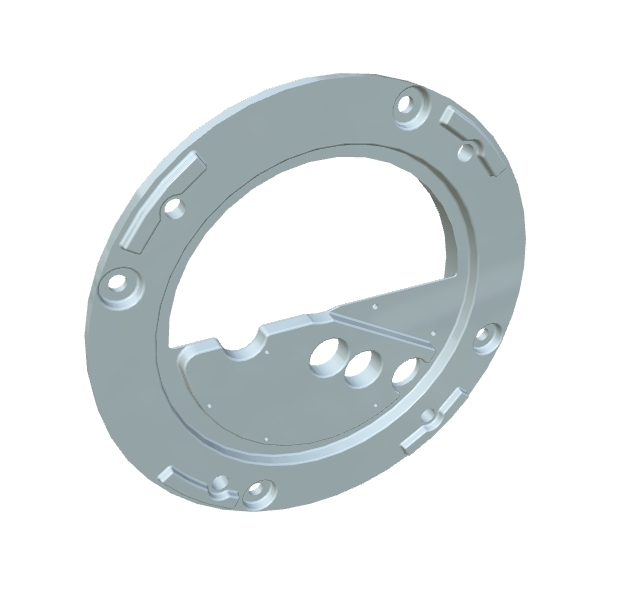

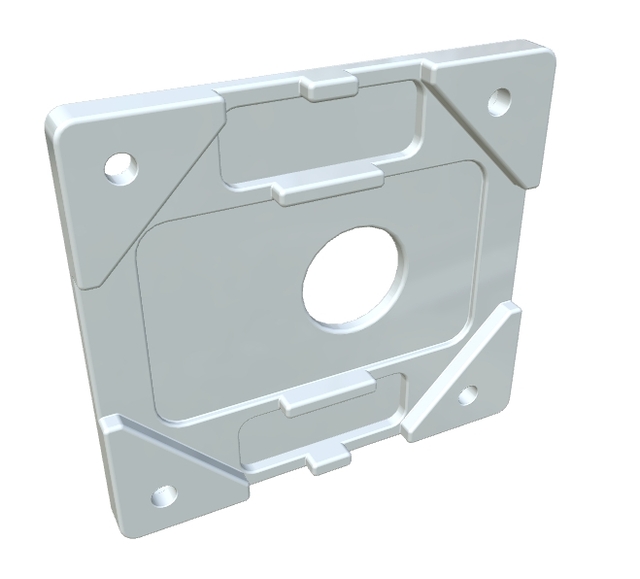

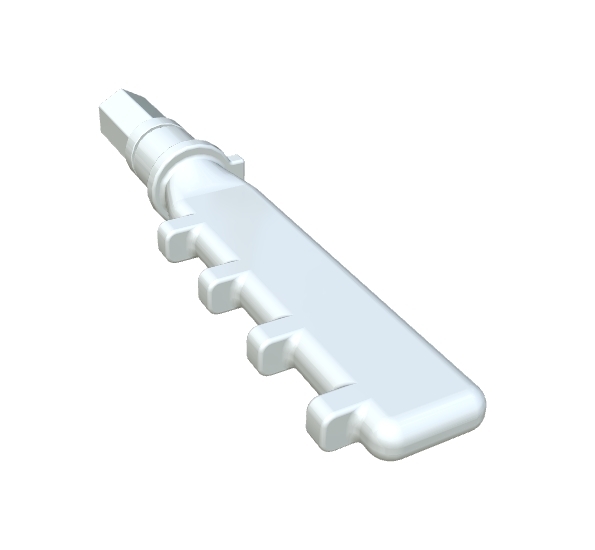

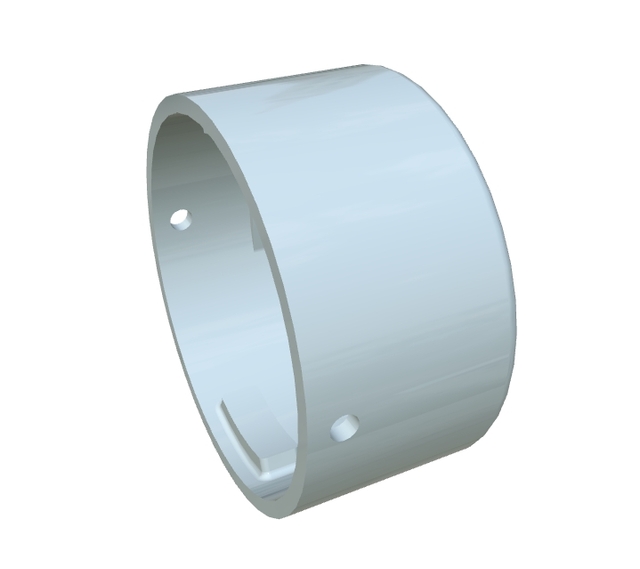

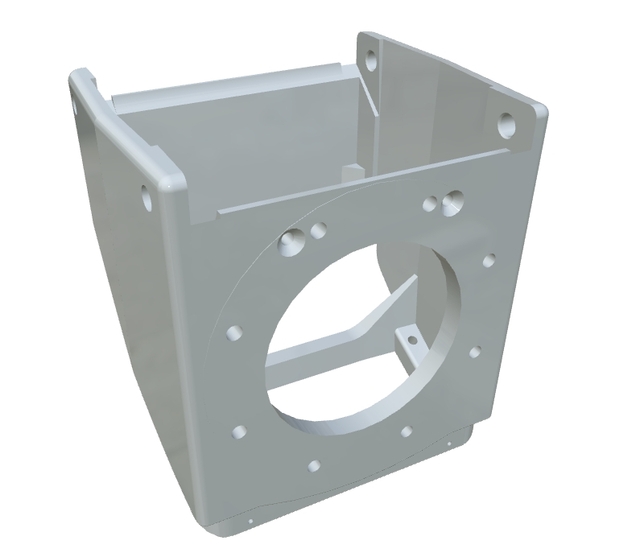

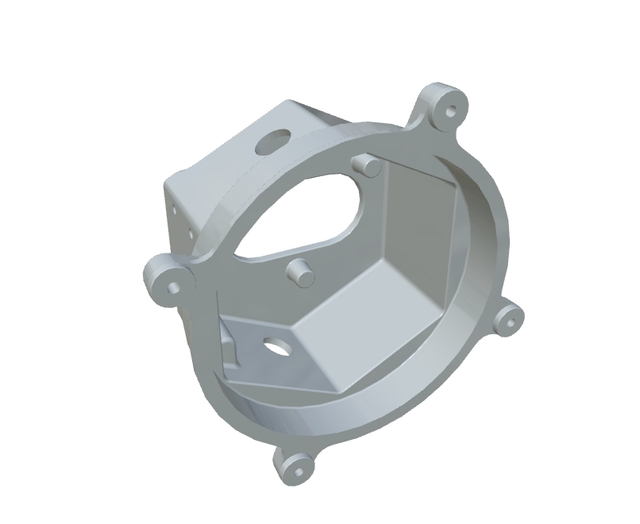

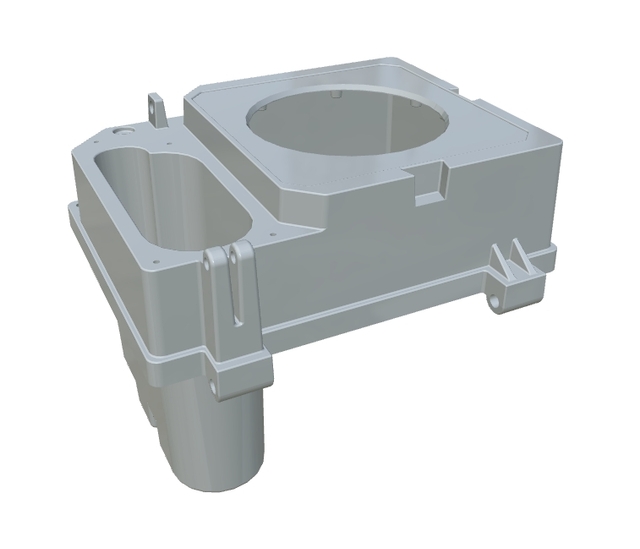

In recent years, investment casting companies have expanded their capabilities to accommodate the growing demand for multifunctional products. A prime example of this is the Multi-Function Holder, a product that stands out for its sleek design and practicality. Crafted from durable materials, the holder exemplifies the precision and detail that investment casting can achieve. The minimalist and modern design of the Multi-Function Holder, combined with its unique tooth-like grips, allows it to hold a variety of items securely. This versatility makes it a perfect addition to any home or office setting, demonstrating the adaptability and innovation within the investment casting industry.

The rise of metal casting has underscored the importance of finding efficient and cost-effective ways to produce high-quality components. Investment casting materials and techniques are continuously being developed to meet these needs, enabling manufacturers to create products that not only fulfill functional requirements but also enhance their aesthetic appeal. The investment cast Multi-Function Holder exemplifies this with its compact design that maximizes utility, blending functionality with elegance. Thus, as investment casting continues to evolve, its applications and benefits are likely to expand, fueling further growth in industries reliant on precision and high-quality metal components.

Investment Casting: Techniques and Modern Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, Investment Casting, High Pressure Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.