The investment casting process, also known as precision investment casting, is a sophisticated manufacturing technique used to create high-quality metal components, such as the newly introduced Precision Engineered Bearing Housing. As this technique continues to evolve, it remains a popular choice among investment casting manufacturers for its ability to produce intricate designs and complex geometries with minimal material waste. The advantages of investment casting over other methods, like sand casting, are clear, particularly when evaluating the precision and quality of the final product.

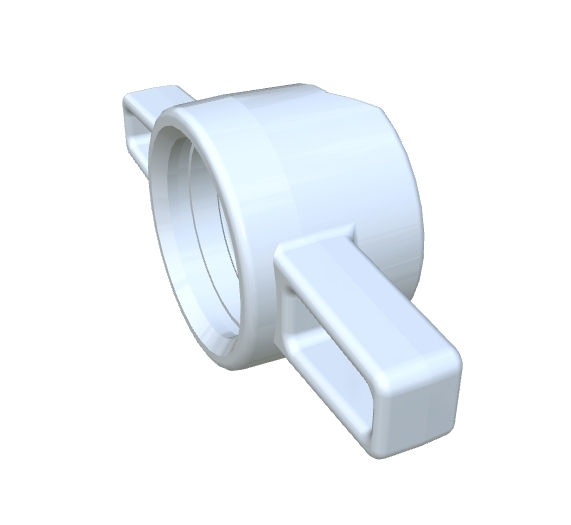

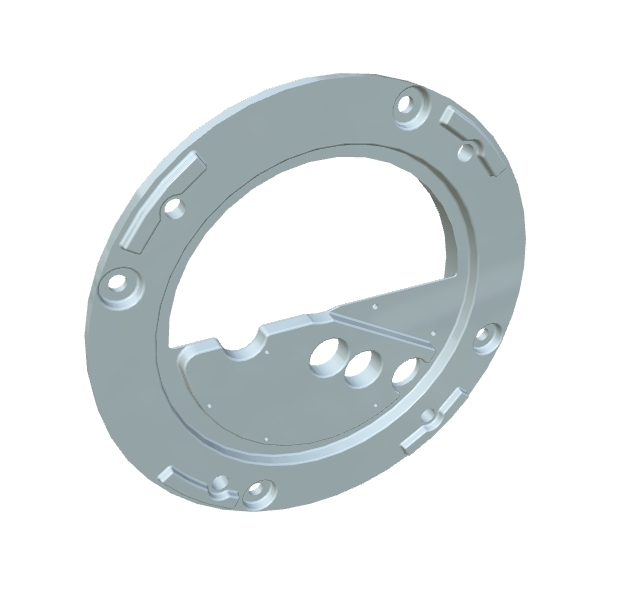

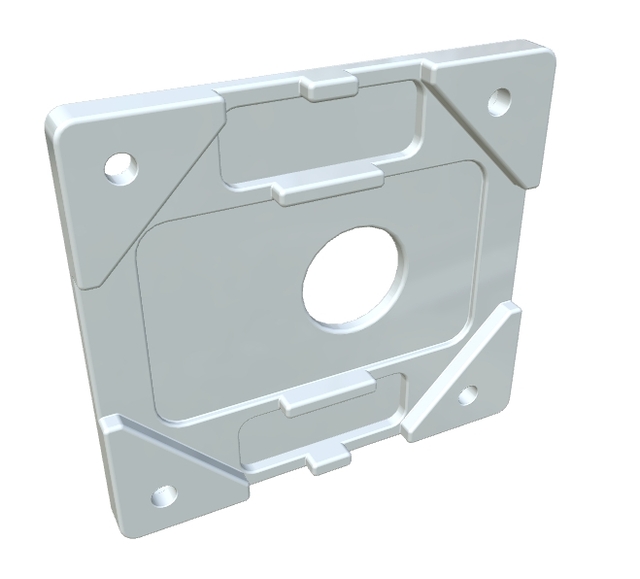

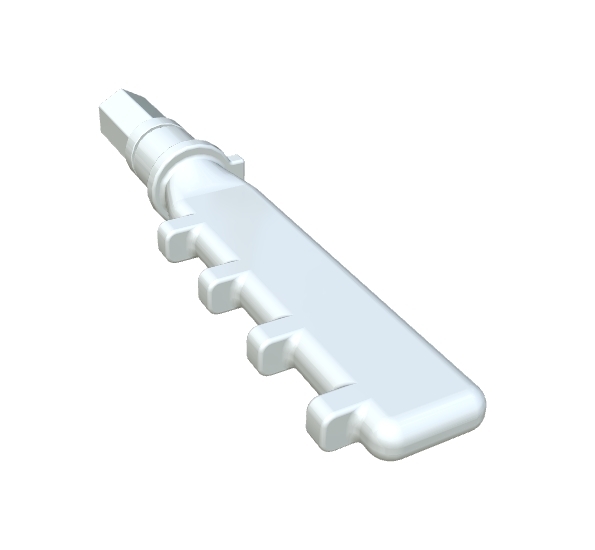

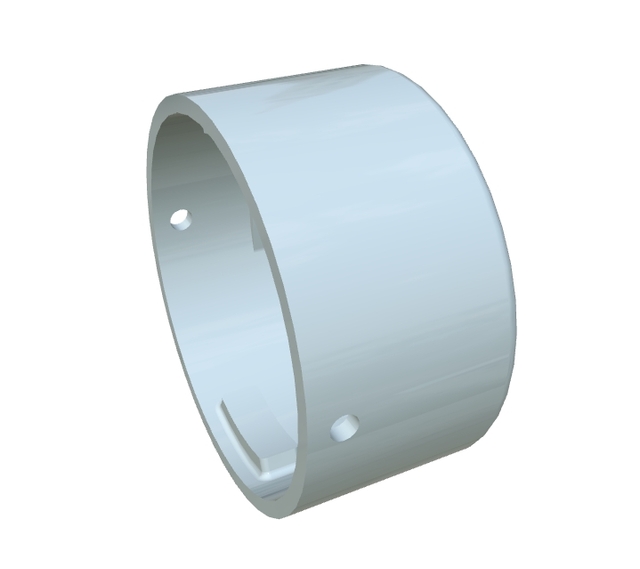

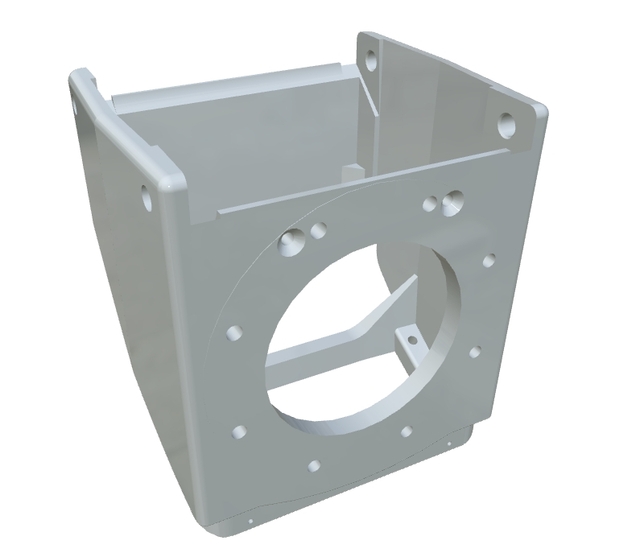

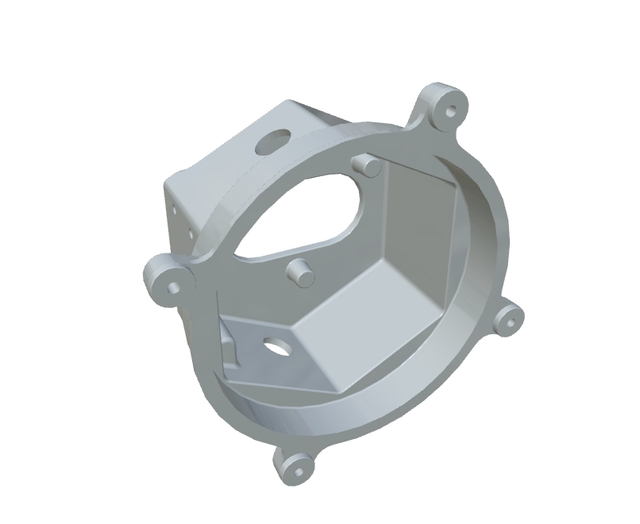

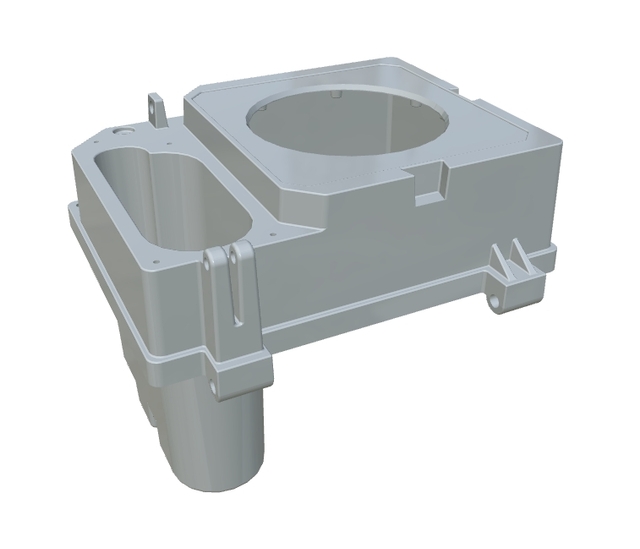

Investment casting materials play a significant role in the process, ensuring the production of components that are both sturdy and reliable. The Precision Engineered Bearing Housing, for instance, is crafted from high-strength materials that guarantee superior support and alignment for rotary components. These materials are carefully selected for their durability and their ability to withstand harsh conditions, making them ideal for industries that demand high-performance machinery. The design of the housing includes strategically placed mounting holes that ensure a secure fit, along with an open top that facilitates easy integration and maintenance within mechanical systems.

When comparing investment casting vs sand casting, it is evident that the former offers several significant advantages. Investment casting techniques allow for the precise replication of intricate details, which is particularly crucial for components like the Precision Engineered Bearing Housing, where every geometric curve and angle contributes to its functionality. Furthermore, investment casting advantages include the reduction of post-casting machining, reduced material wastage, and the potential for casting both ferrous and non-ferrous materials. However, it's important to also consider the investment casting disadvantages, such as the initial cost and the lengthy preparation time, which may not be suitable for all manufacturing budgets or schedules. Nonetheless, for companies seeking superior precision and an aesthetically pleasing, functionally robust product, investment casting remains a compelling choice.

In summary, the investment casting process offers a wide array of benefits that make it an attractive option for producing components like the Precision Engineered Bearing Housing. Its ability to create precise, high-quality parts with minimal material waste is unparalleled. For industries focused on precision machinery, this process affords an opportunity to achieve durable and reliable performance, which is an essential upgrade for any modern engineering setup. As investment casting techniques continue to advance, the potential for innovation and superior manufacturing remains vast, paving the way for future developments in high-performance component production.

Investment Casting Process: Precision & Advantages

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.