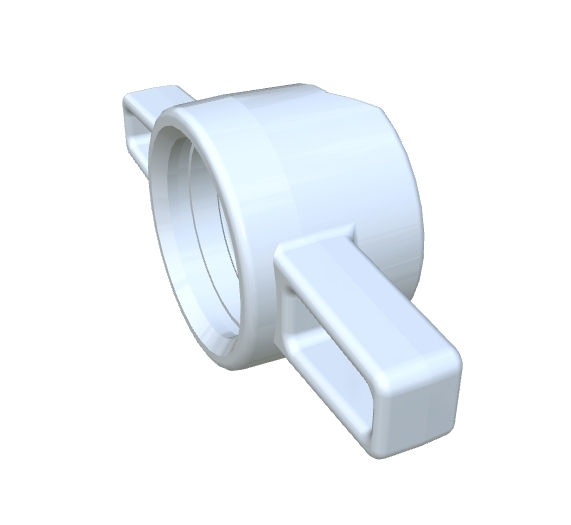

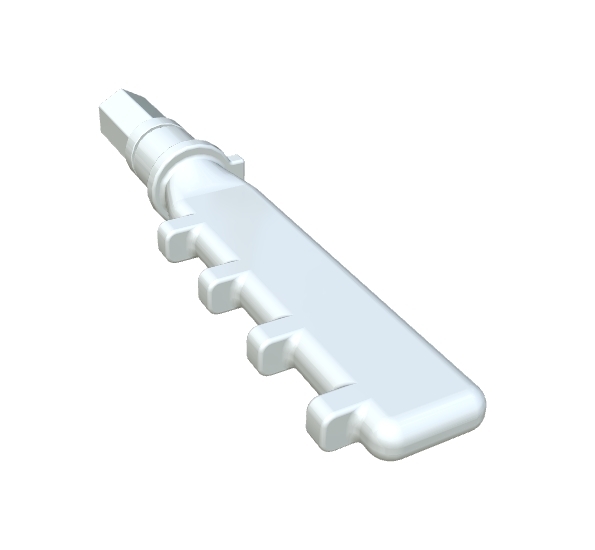

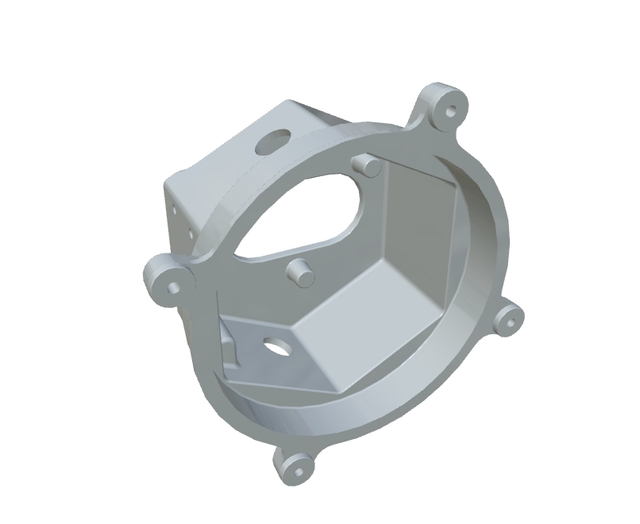

Investment casting manufacturers play a crucial role in providing high-quality components for a variety of industries, including the automotive sector. By leveraging the investment casting process, these manufacturers deliver precision parts with complex geometries and superior surface finishes. Investment casting, often known as lost wax investment casting, is a widely used method due to its ability to produce intricate shapes that are both precise and durable. This technique offers numerous advantages such as the use of diverse materials, precise dimensional control, and excellent repeatability in production.

The investment casting process begins with the creation of a wax pattern, which is then coated with a ceramic shell. Once the shell is cured, the wax is melted away, leaving a void into which molten metal is poured, forming the final part once cooled. Investment casting companies utilize this method to manufacture components that require high-performance characteristics and tight tolerances. These components are often found in sectors like aerospace, manufacturing, and automotive, where precision investment casting is valued for its cost-effectiveness and efficiency compared to alternative methods like sand casting.

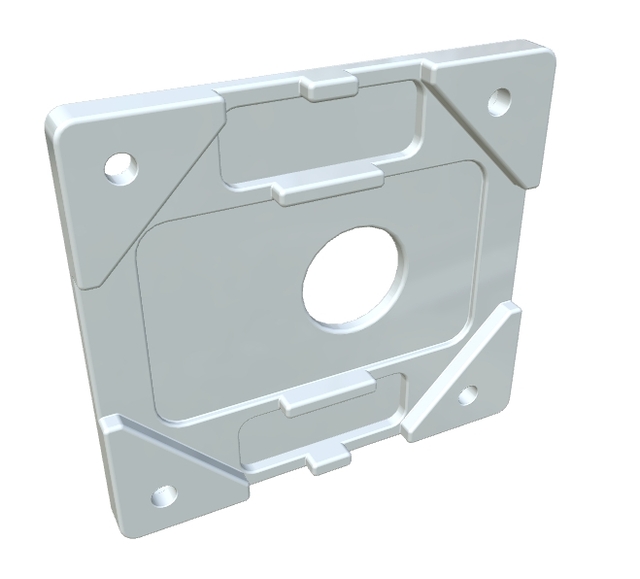

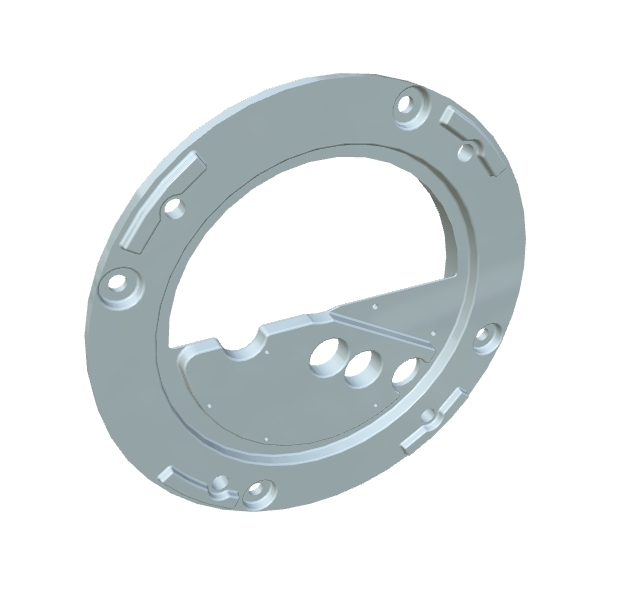

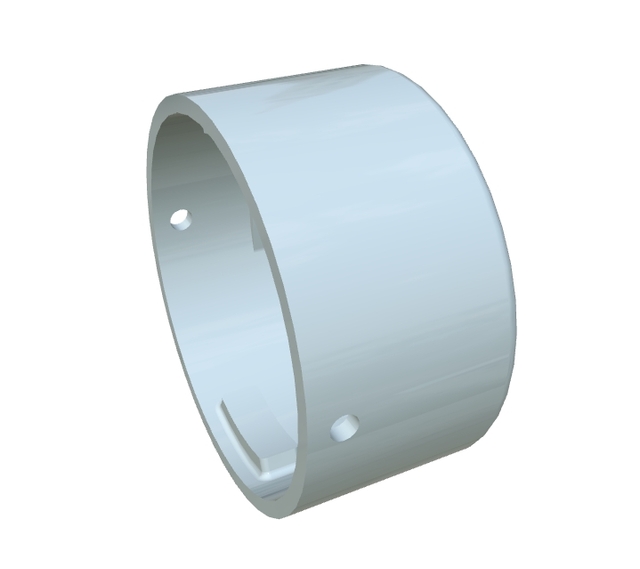

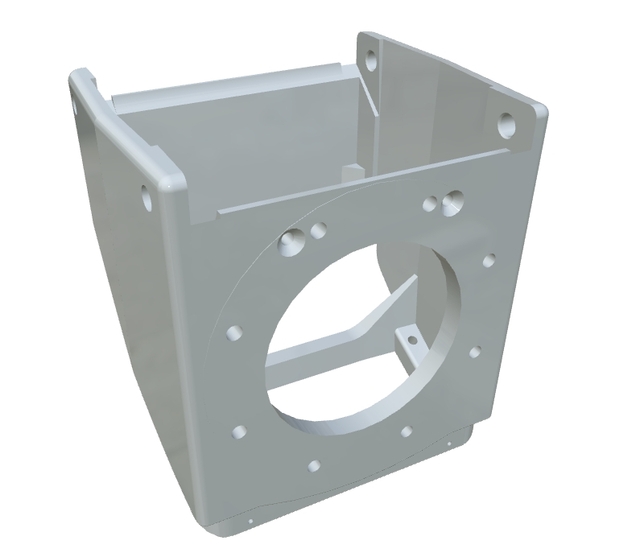

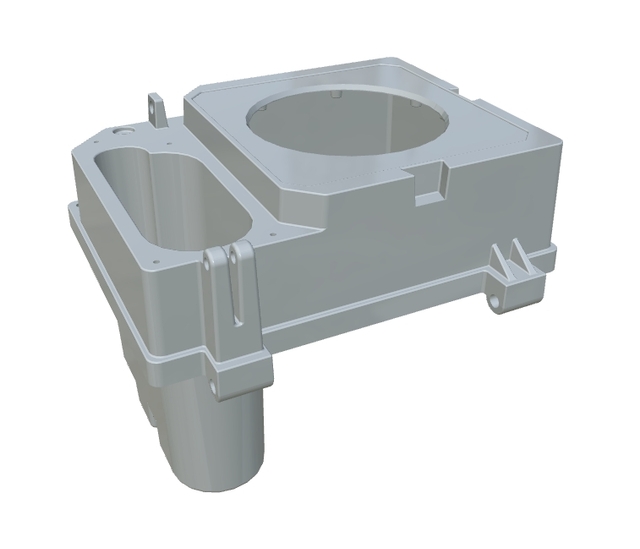

Investment casting offers several benefits over other manufacturing techniques. For one, it provides a higher degree of customization—investment casting manufacturers can tailor each component to meet specific customer needs, whether it's through custom investment casting services or using specialized materials. Particularly in the automotive industry, this method is pivotal in producing parts such as battery holders for advanced automotive battery technology. These casings, crafted from high-strength and corrosion-resistant materials, are designed to withstand extreme conditions and vibrations, offering reliability and enhanced performance. Additionally, the casing's design facilitates better airflow to manage temperature and efficiency effectively, contributing to the vehicle's overall performance.

Despite its advantages, investment casting does come with its own set of challenges, such as higher costs compared to other casting methods. However, the benefits of durability, precision, and the ability to utilize a variety of investment casting materials often outweigh the costs, especially in critical applications that necessitate high-quality parts. Investment casting technology continues to evolve, offering innovative solutions and broadening its applications across numerous industries. Through continuous advancements, investment casting manufacturers can offer solutions that not only meet but exceed industry standards, ensuring they remain indispensable providers of critical components.

Investment Casting Manufacturers: Precision & Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Investment Casting Benefits: Unlocking Precision & Durability

Investment Casting Process for Precision Engineering

Understanding the Investment Casting Process: Techniques and Benefits

Investment Casting: Techniques and Modern Applications

The Investment Casting Process: Precision & Advantage

Investment Casting Process: Precision & Advantages

Understanding the Investment Casting Process and Its Advantages

Investment Casting Manufacturers: Precision & Innovation