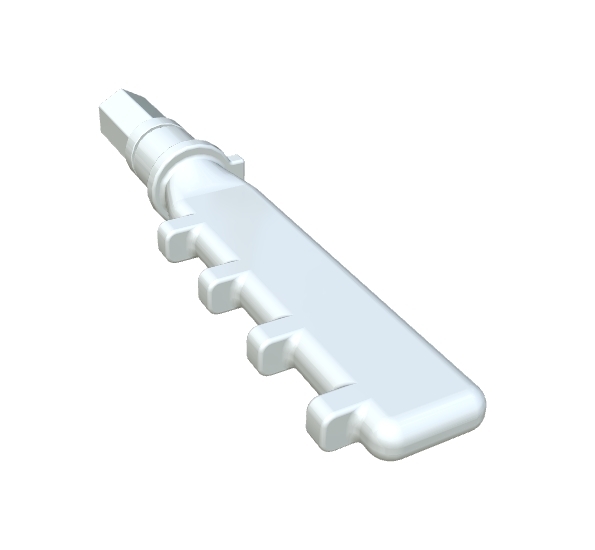

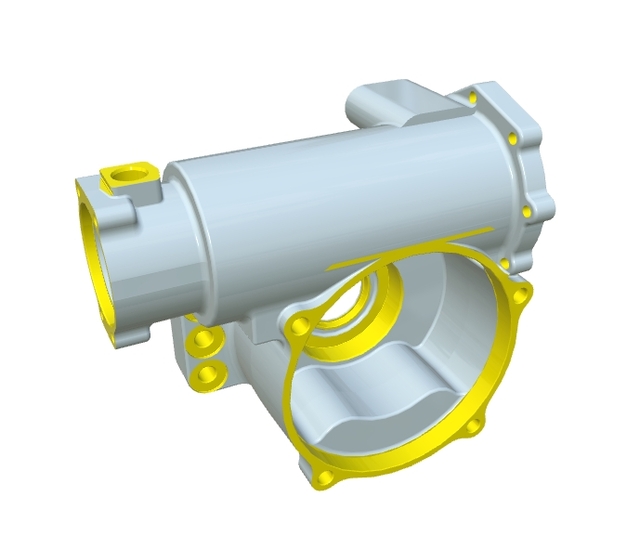

Metal casting techniques have been at the forefront of industrial manufacturing for centuries, shaping how we produce complex components with precision and efficiency. Among the myriad of metal casting processes, sand casting, die casting, investment casting, and lost foam casting stand out as pivotal methods. These techniques play a crucial role in the creation of various metal products, with each offering unique advantages suited to specific applications.

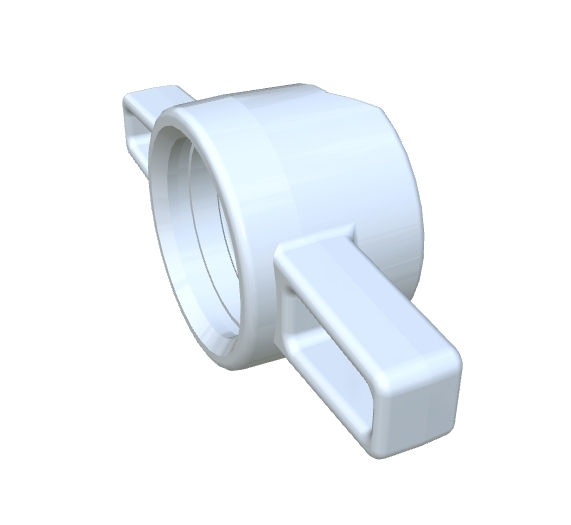

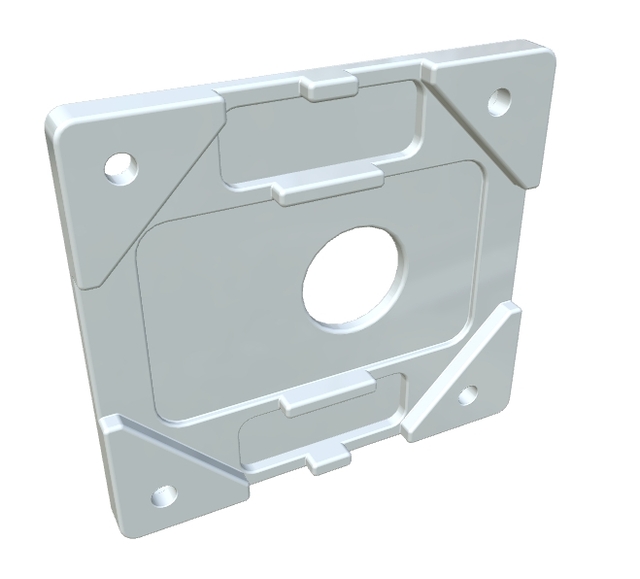

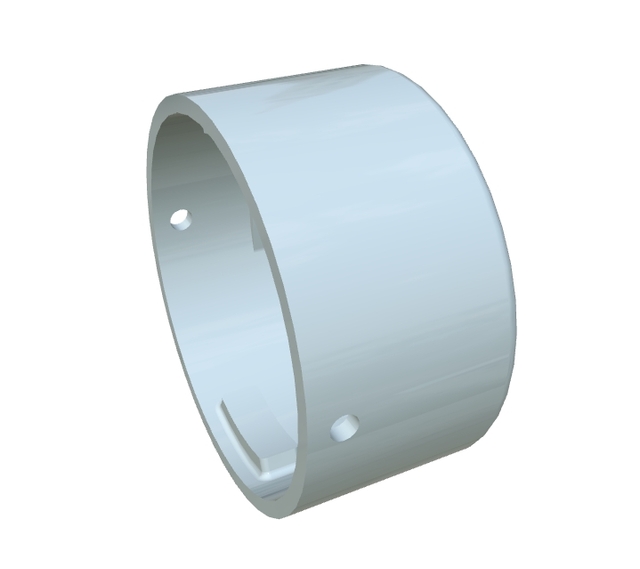

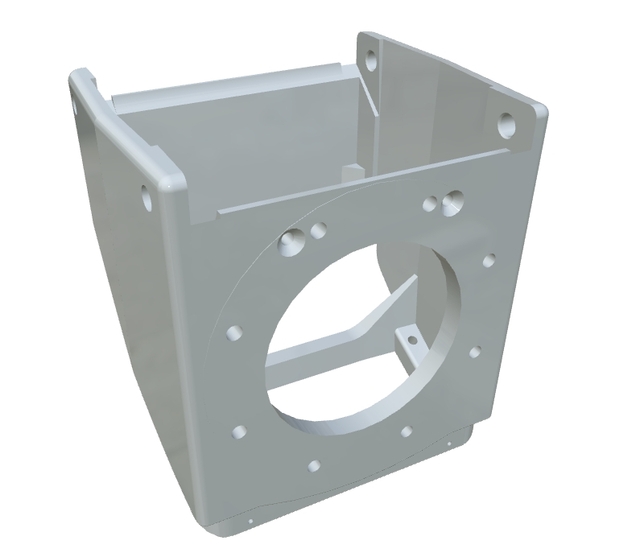

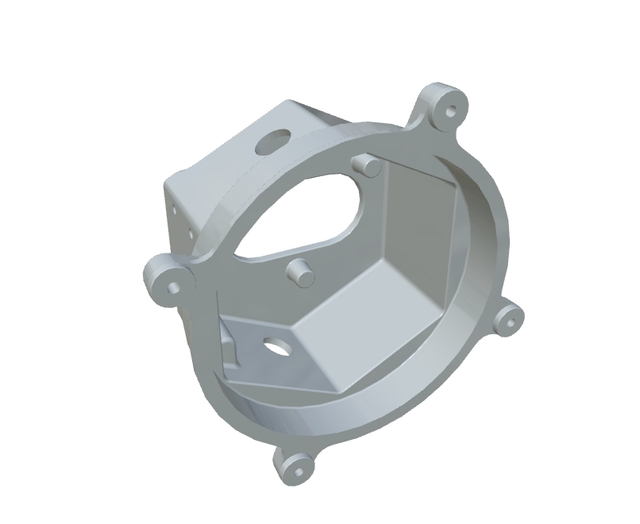

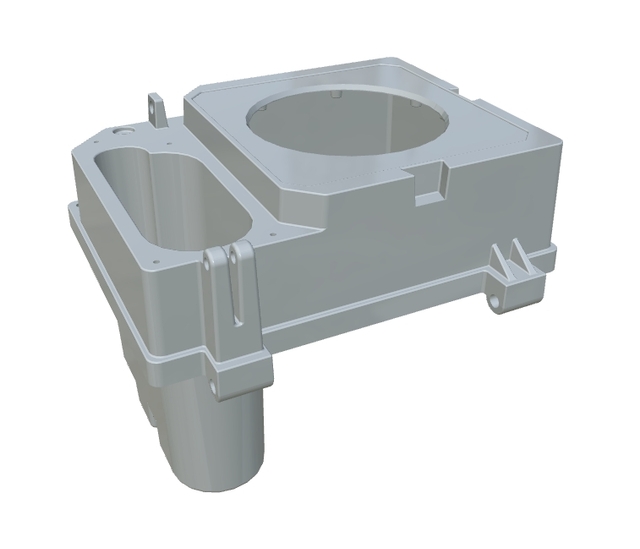

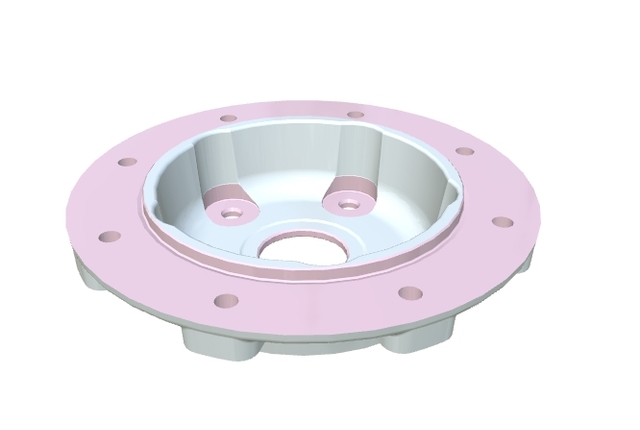

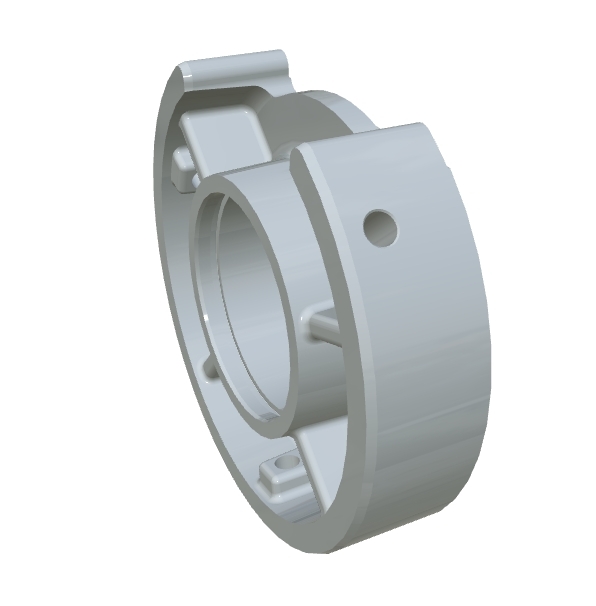

In the realm of metal casting materials, the selection is vast, including everything from softer alloys to high-strength metals. This diversity allows metal casting companies to produce an array of components that meet rigorous industrial standards. For example, the Precision Machined Bearing Housing demonstrates the perfect blend of technique and material. Crafted from high-grade metal, it boasts impressive durability, making it a robust solution for machinery and equipment that demand high efficiency and reliability.

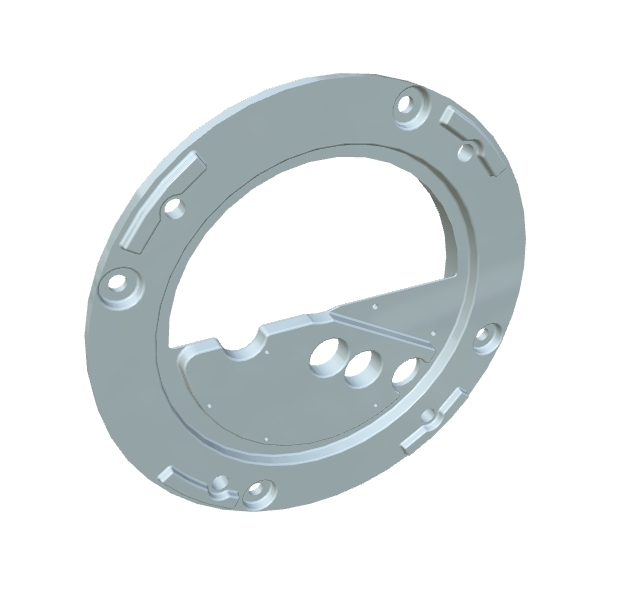

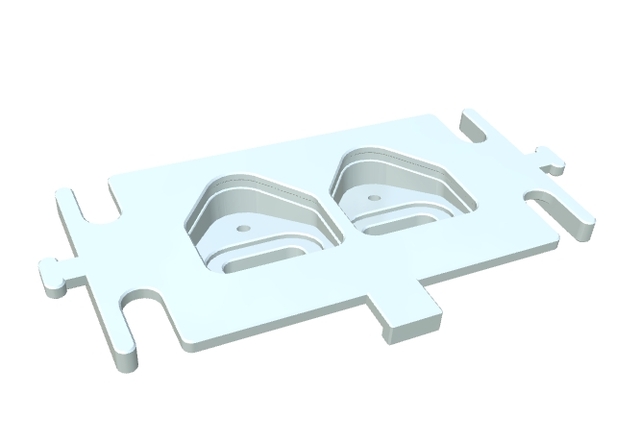

Investment casting, often called lost wax casting, is renowned for producing components with intricate details and excellent surface finishes, making it ideal for the high-quality production of parts like the Precision Machined Bearing Housing. Die casting, another popular method, excels in producing large volumes of precision parts with consistency, thanks to its rapid production capability and minimal secondary operations. Meanwhile, sand casting remains a versatile and economical process, perfect for creating large and complex shapes, although they may not require the fine intricacies that investment casting can achieve.

Moreover, the advancement of casting techniques continues to expand with methods like lost foam casting, which offers benefits such as reducing production costs and improving surface finishes. These advanced processes allow companies to tailor their manufacturing strategies according to the specific needs of their products, ensuring that they choose the best method for their project requirements.

Ultimately, metal casting techniques form the backbone of various industries, from automotive to aerospace and beyond. By understanding these processes and the materials involved, companies can make informed decisions that enhance the longevity and efficiency of their products. When a company utilizes top-tier metal casting processes for products like the Precision Machined Bearing Housing, they ensure that the end product not only meets but exceeds performance expectations. Whether through investment casting for precision or sand casting for size, metal casting techniques continue to evolve, offering innovative solutions for modern manufacturing challenges.

Exploring Metal Casting Techniques and Their Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.