High pressure casting represents a remarkable advancement in the field of manufacturing technology, prominently utilized in the production of complex and durable components for various industries, especially automotive. This sophisticated process, often referred to as die casting, involves forcing molten metal into a mold cavity under high pressure. This method is preferred for its ability to produce components with precise dimensions and superior surface finishes.

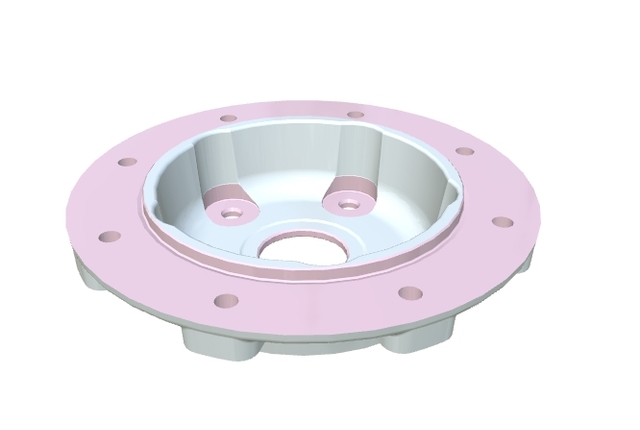

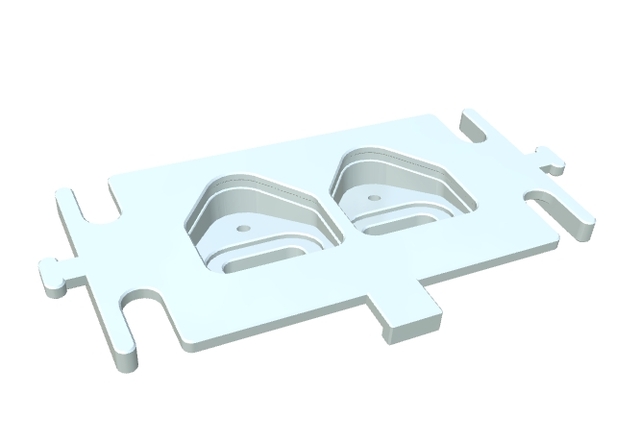

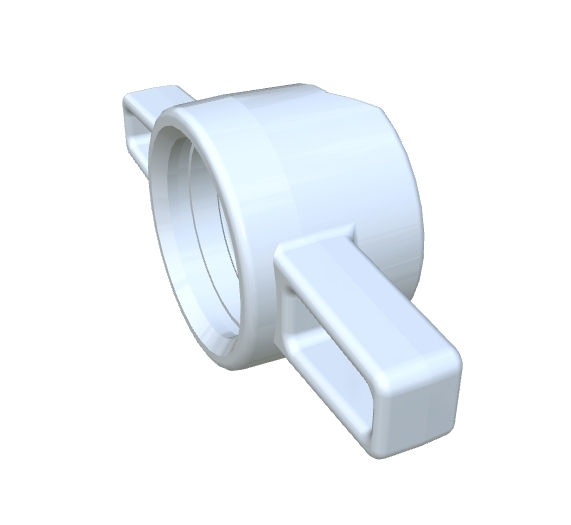

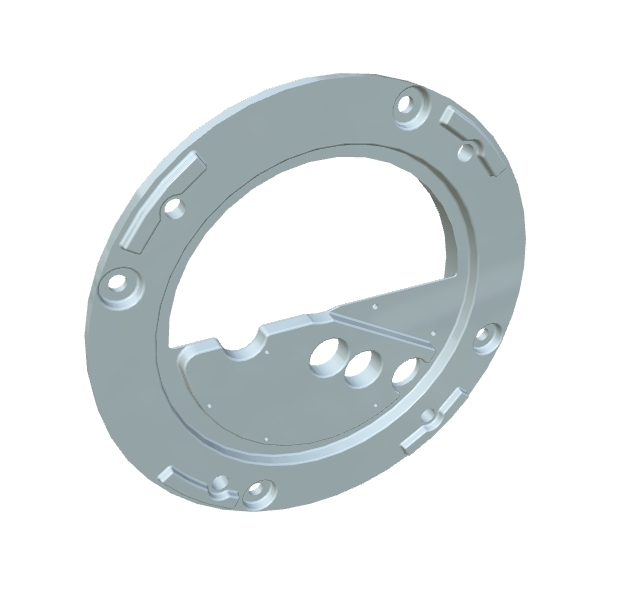

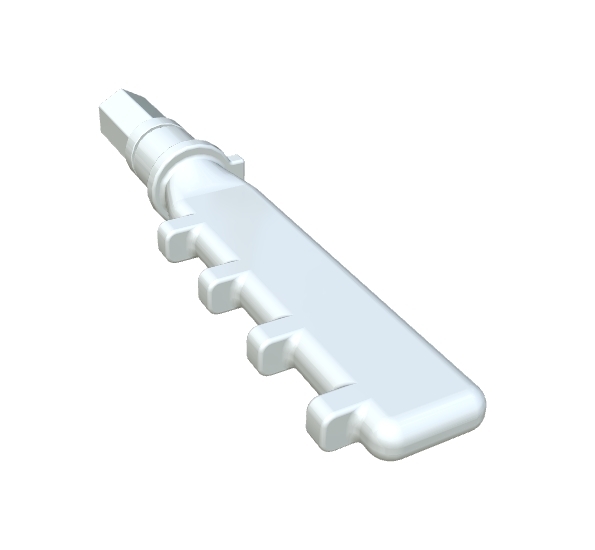

In the automotive industry, aluminum high pressure casting is highly valued due to its ability to create lightweight yet robust components, such as the suspension arm. This component, part of our precision engineering collection, is engineered using state-of-the-art casting methods to ensure it withstands high stress. Its lightweight characteristics contribute significantly to reducing overall vehicle weight, which in turn enhances fuel efficiency and improves ride comfort—key advantages that are integral to modern automotive manufacturing.

The appeal of high pressure die casting lies not only in its ability to fabricate sturdy components but also in the speed and efficiency of the process. Compared to traditional metal die casting processes, high pressure casting equipment is capable of producing intricate shapes with minimal machining required post-casting. This efficiency is further enhanced by the streamlined geometry of our components, which allow for seamless integration with existing systems while maximizing structural integrity. This means manufacturers can reduce production time and costs without compromising on component quality or reliability.

Additionally, high pressure casting manufacturers are continually innovating to push the boundaries of what this process can achieve. Our suspension arm exemplifies the high standards of durability and performance expected in today's automotive components, designed for both everyday use and high-demand scenarios. Through precision engineering, these components offer unparalleled reliability, helping to elevate engineering sophistication and meet the rigorous demands of modern-day transportation needs.

In conclusion, high pressure casting is not just a process; it is a pivotal driver of innovation in the manufacturing industry. It brings to life complex designs with unmatched precision, proving indispensable in sectors that demand performance and resilience. Embracing high pressure casting technologies promises a future of smarter, more efficient, and environmentally friendly production, aligning with the evolving requirements of the automotive industry and beyond.

High Pressure Casting: Revolutionizing Automotive Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

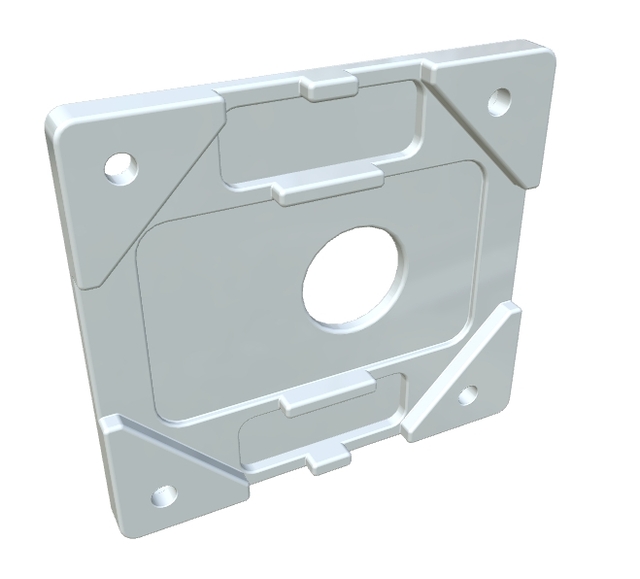

High Pressure Casting: Precision Engineering Flange Revolutionizes Industry

High Pressure Casting: Revolutionizing Automotive Manufacturing

High Pressure Casting in Modern Automotive Engineering

Casting Simulation Software: Revolutionizing Manufacturing

Die Casting: Precision Technology Revolutionizing Metalwork

High Pressure Die Casting: Advanced Manufacturing Solutions

High Pressure Casting: Revolutionizing Modern Manufacturing

High Pressure Casting: Revolutionizing Cable Management