High pressure die casting is a pivotal process in the world of manufacturing and engineering, renowned for its ability to produce high-quality components with precision and efficiency. This advanced manufacturing technique involves injecting molten metal into a mold under high pressure, creating complex metal parts with excellent structural integrity. Among the key advantages of high pressure casting is its capacity to produce components with smooth surfaces and precise dimensions, making it a favored choice for industries that demand high-quality metal parts.

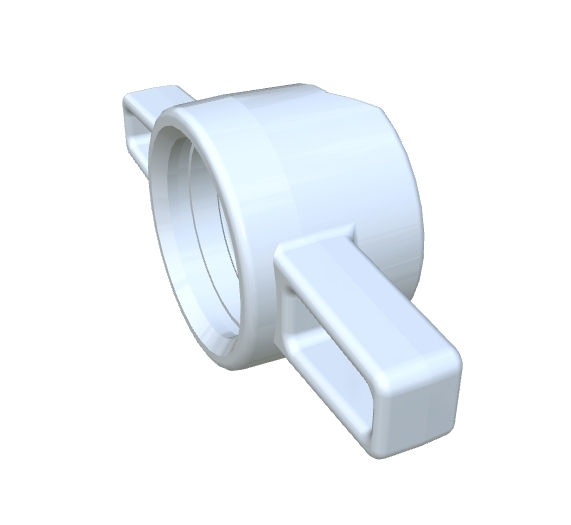

The HPDC process is particularly advantageous for producing parts in both aluminum and zinc, materials known for their excellent blend of strength, versatility, and resistance to corrosion. High pressure casting benefits are significant in automotive applications, where the light weight and strength of aluminum can dramatically improve fuel efficiency without compromising the safety and performance of vehicles. Aluminum high pressure casting is essential for creating lightweight automotive components that include engine blocks, transmission cases, and other critical parts. Similarly, zinc high pressure casting offers superior toughness and precision, making it ideal for smaller, intricate parts used across various industrial applications.

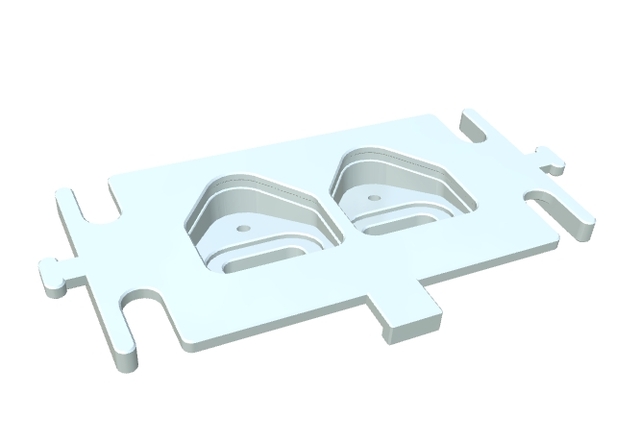

Custom high pressure casting is an innovative solution for manufacturers aiming to produce specific parts tailored to their requirements, providing flexibility and precision in design. This technology is supported by a sophisticated die casting technology that ensures each cast part meets the required specifications. High pressure die casting services extend beyond basic manufacturing; they involve collaborative processes in design, prototyping, and testing, ensuring an optimized production path for high-pressure casting parts. The availability of high pressure casting manufacturers with expertise in industrial and automotive applications further enhances the feasibility of obtaining precision high pressure casting solutions tailored to specific needs.

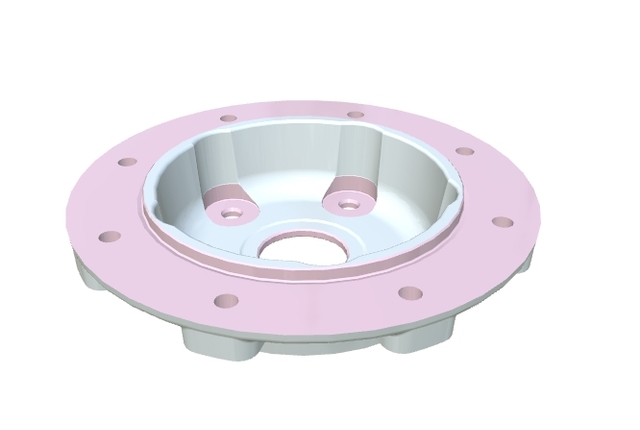

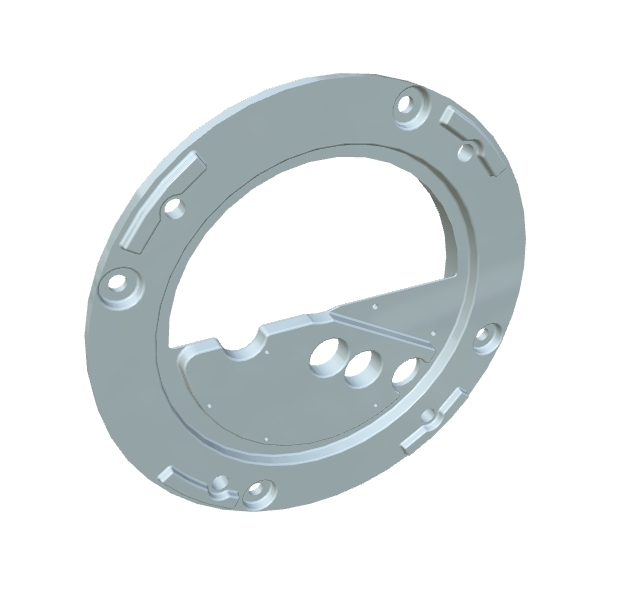

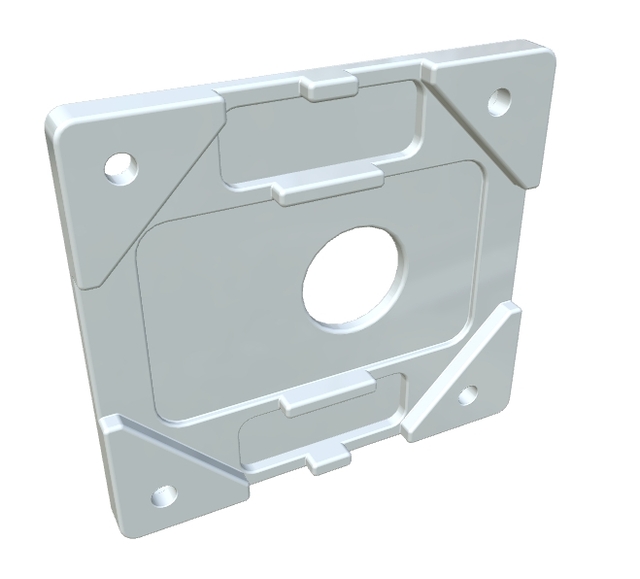

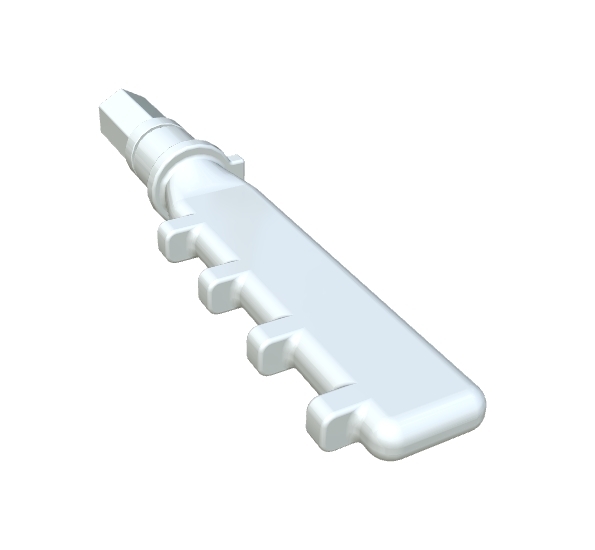

To complement these advanced casting techniques, our company introduces a precision machined flange, expertly crafted from premium-grade materials through cutting-edge die casting processes. This component exemplifies the pinnacle of quality and innovation, designed to thrive in high-pressure environments while maintaining structural integrity and durability. Its sleek design, featuring a polished surface and strategic cutouts, makes it an ideal choice for integration into various mechanical and industrial systems, achieving efficiency without compromising stability. With the combination of high pressure metal casting and meticulous engineering, this flange represents a new standard in performance and longevity.

In summary, the benefits of high pressure die casting are wide-ranging, encompassing the creation of complex, durable, and precise parts essential to multiple industries. By choosing advanced die casting solutions, you gain access to superior components that enhance the functionality and reliability of mechanical assemblies. Upgrade your operations with precision-engineered parts crafted with the expertise and innovation that high pressure die casting technology offers, redefining what's possible in modern manufacturing.

High Pressure Die Casting: Advanced Manufacturing Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

High Pressure Casting: Precision Engineering Flange Revolutionizes Industry

High Pressure Casting: Revolutionizing Automotive Manufacturing

High Pressure Casting in Modern Automotive Engineering

Casting Simulation Software: Revolutionizing Manufacturing

Die Casting: Precision Technology Revolutionizing Metalwork

High Pressure Die Casting: Advanced Manufacturing Solutions

High Pressure Casting: Revolutionizing Modern Manufacturing

High Pressure Casting: Revolutionizing Cable Management