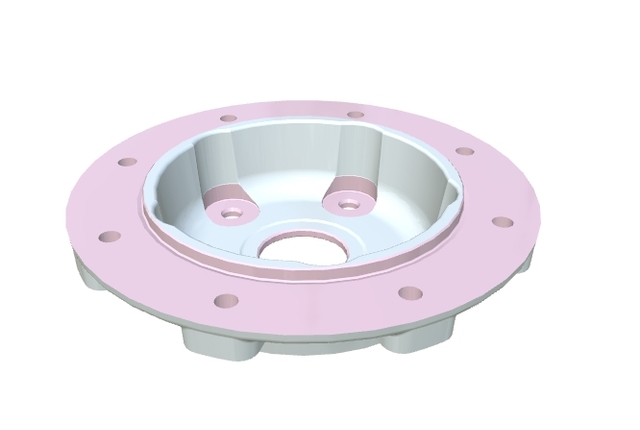

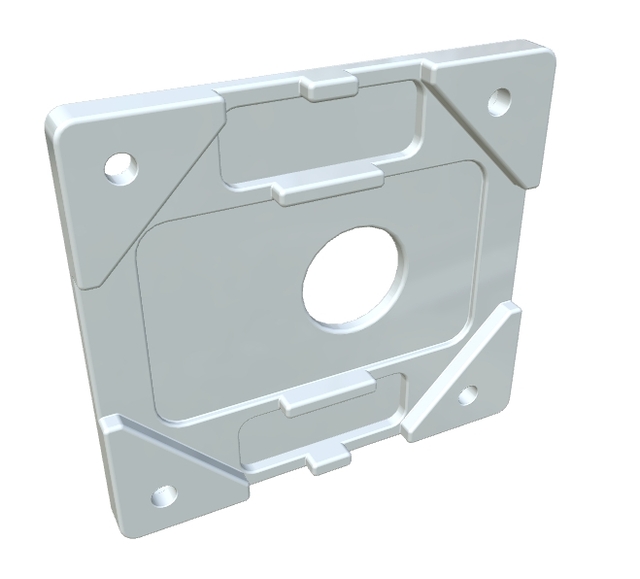

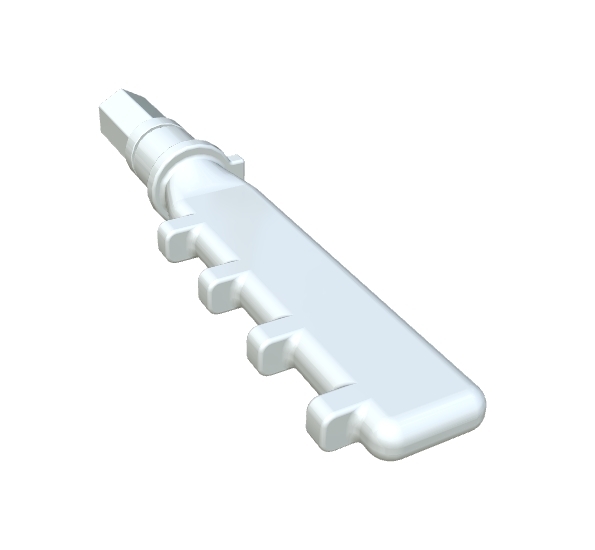

In the realm of modern automotive engineering, **high pressure casting** is a game-changer, enabling the production of components that are both durable and efficient. This innovative process is particularly transformative in crafting components like the Precision Steering Knuckle. Made from high-strength alloy, this steering knuckle utilizes high pressure aluminum casting to achieve remarkable durability and resistance to wear.

High pressure casting, closely related to die casting, including techniques like aluminum die casting and zinc die casting, is pivotal in the manufacturing of automotive parts such as the steering knuckle. In this advanced casting process, molten metal is forced into reusable metal molds, or dies, under high pressure. This method ensures precise dimensioning and a smooth finish, optimizing the integration of components like the Precision Steering Knuckle with modern suspension systems. Furthermore, by adopting die casting services, manufacturers can efficiently meet the increasing demand for complex components with consistent quality.

The advantages of using high pressure casting extend beyond just precision. This technique is integral to reducing unsprung weight in vehicles, which in turn enhances fuel efficiency—a key goal in today’s automotive industry. Custom die casting allows for the creation of specific design features within components that are pivotal for achieving aerodynamic efficiency, as seen in the sleek design of the Precision Steering Knuckle. The pressure die casting process ensures that each part meets stringent quality standards, and using high pressure casting machines, manufacturers are able to produce high-volume runs with minimal material waste.

Moreover, high pressure casting alloys play a significant role in determining the performance characteristics of automotive parts. By leveraging alloys tailored for strength and impact resistance, the Precision Steering Knuckle exemplifies how precision casting can enhance safety without compromising on weight or efficiency. Vacuum die casting may further enhance properties by reducing porosity, ensuring maximum structural integrity. As the automotive industry continues to evolve, the integration of these advanced metal casting techniques keeps pushing the boundaries, setting new standards in product excellence and sustainability.

High Pressure Casting in Modern Automotive Engineering

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Low Pressure Casting, Sand Casting, Investment Casting, High Pressure Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.