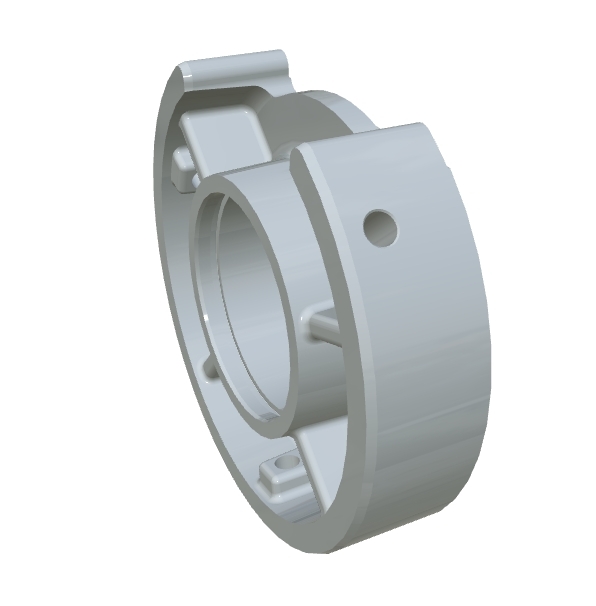

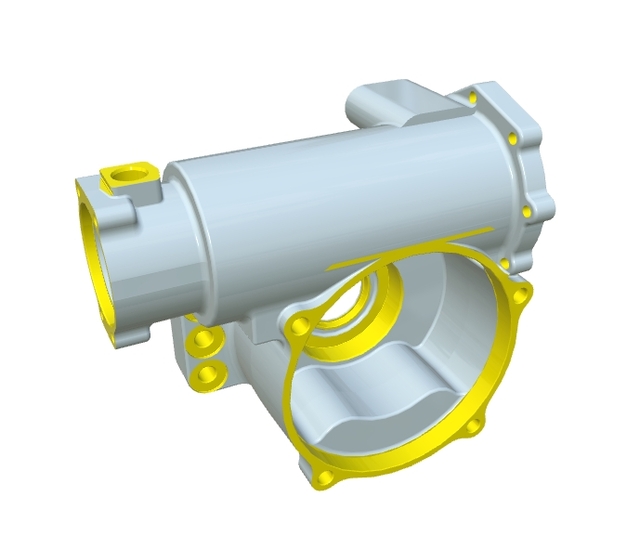

In the world of industrial manufacturing, foundry services hold a pivotal role. Providing essential components through various metal casting processes, foundries are the backbone of diverse sectors, including automotive, aerospace, and heavy machinery. *Foundry services* utilize advanced techniques such as bronze casting and *sand casting techniques* to produce intricate parts tailored to specific industrial needs.

The process of creating high-quality cast iron products often incorporates investment casting, a method renowned for its precision and ability to produce complex shapes with fine details. By leveraging this technology, manufacturers can achieve superior surface finishes and dimensional accuracy that meet stringent industry standards. Many foundries also specialize in aluminum casting, which offers lightweight solutions without compromising strength or durability—a critical advantage in sectors like aviation and automotive where weight savings translate to enhanced performance and efficiency.

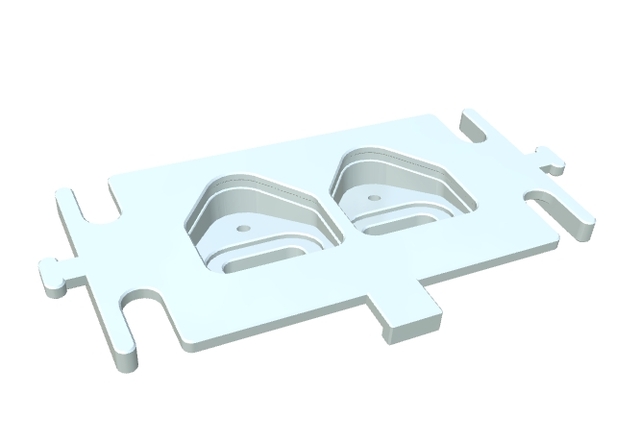

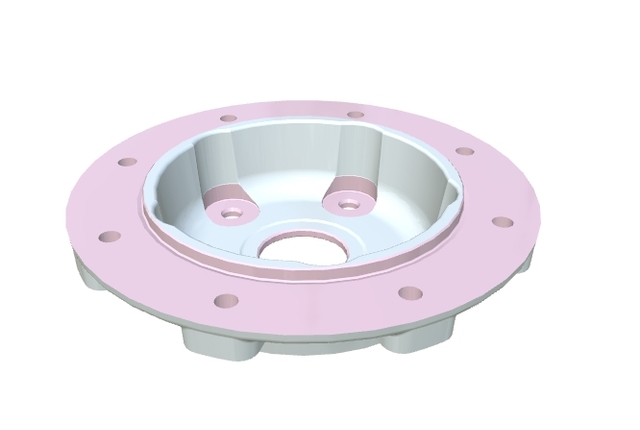

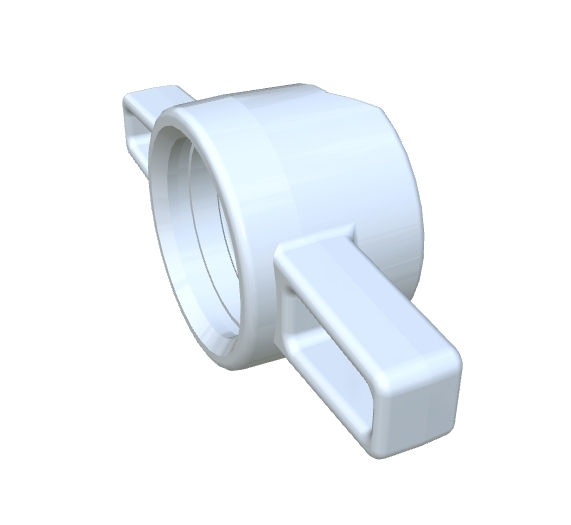

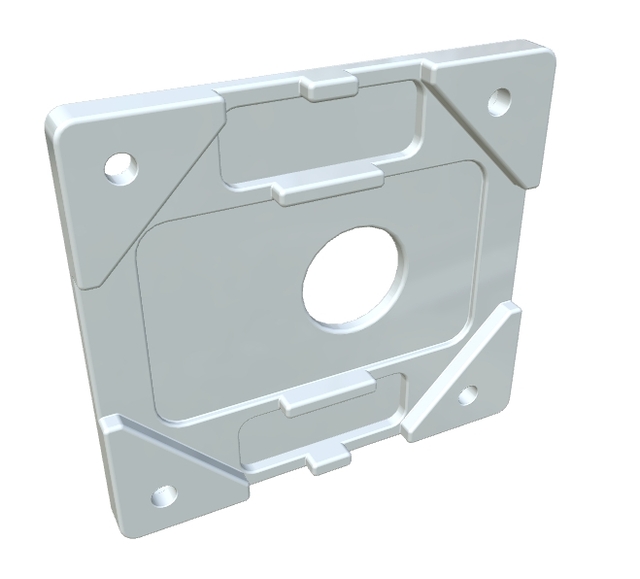

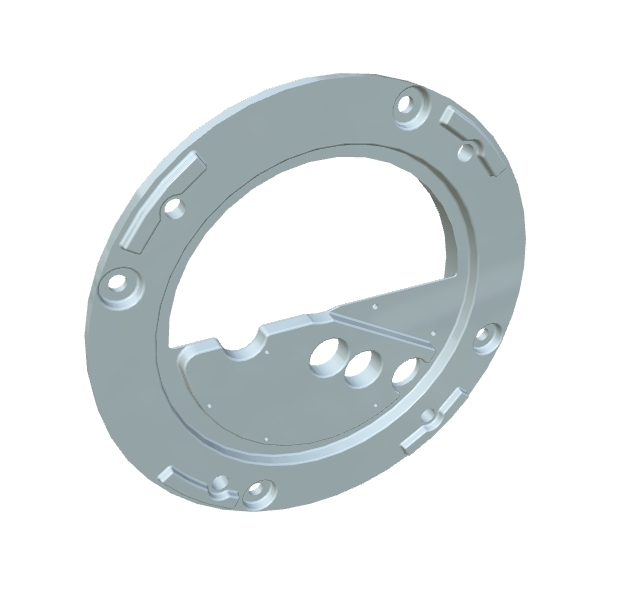

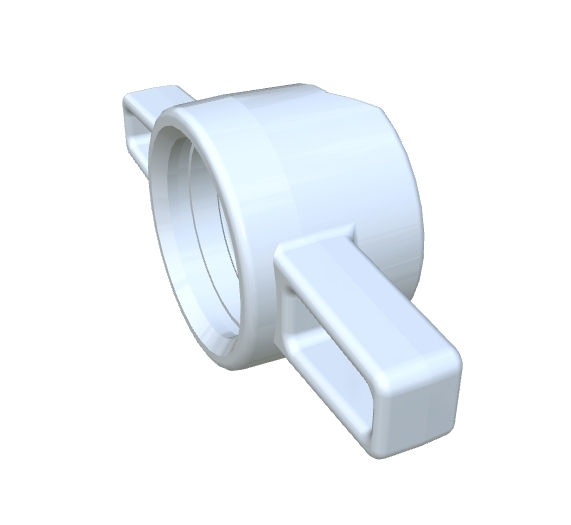

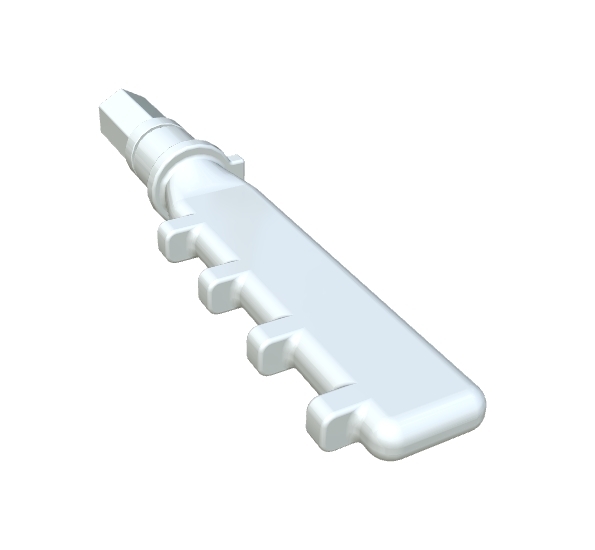

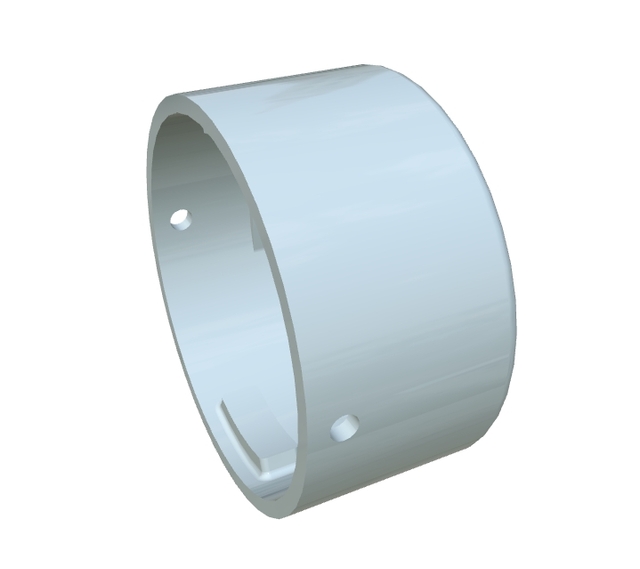

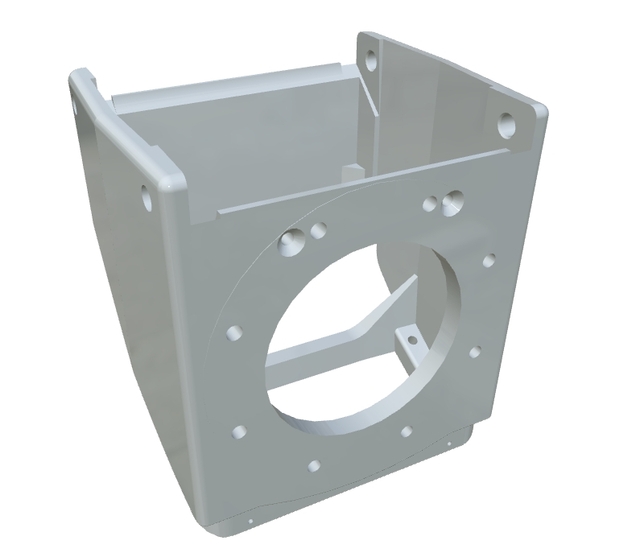

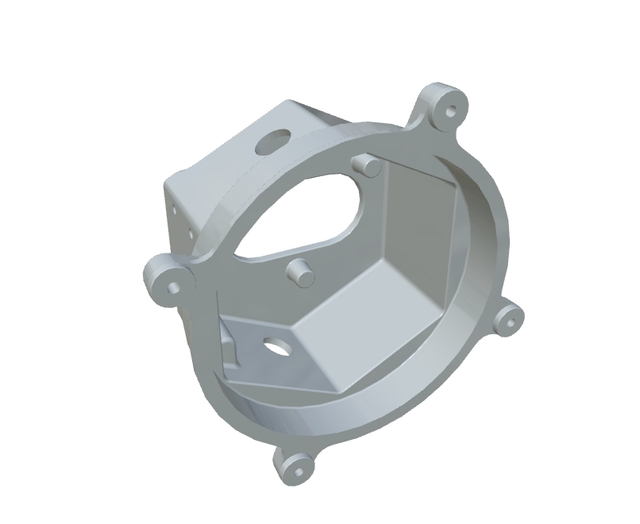

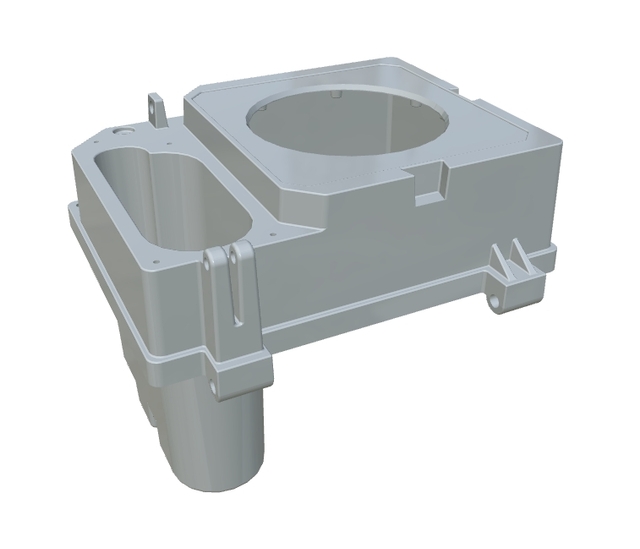

At the heart of innovative foundry services is a commitment to quality and versatility, exemplified by the latest *metal casting technology*. This advancement is crucial for producing components such as the Precision Engineering Hub Plate. This state-of-the-art component is crafted meticulously from high-grade materials, ensuring exceptional durability and performance in demanding environments. Its design is both functional and aesthetically appealing, featuring a sleek two-tone finish in soft pink and pristine white.

The *Precision Engineering Hub Plate* sets itself apart with its multiple precision-drilled holes, facilitating a seamless integration into various mechanical systems. Its engineered finely contoured inner chamber ensures optimal fit and support, emphasizing its role as a vital element in high-performance assemblies. Whether it's through the *die casting process* or other sophisticated methods, the creation of such a component underscores the essential role of foundry services in bringing engineering innovations to life.

Foundries continue to evolve, integrating new technologies that promise even greater precision and efficiency. By understanding and implementing these sophisticated casting methods, from the traditional to the cutting-edge, foundry services ensure they meet the diverse and ever-increasing demands of modern industries. They do not just provide components; they offer solutions that drive technological advancement, showcasing the continuing importance of this sector in the global manufacturing landscape.

Foundry Services: Bridging Industrial Innovation with Advanced Metal Casting Techniques

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring Metal Casting Techniques for CNC Precision

Investment Casting Benefits: Unlocking Precision & Durability

Investment Casting Process for Precision Engineering

Understanding the Investment Casting Process: Techniques and Benefits

Investment Casting: Techniques and Modern Applications

The Investment Casting Process: Precision & Advantage

Investment Casting Process: Precision & Advantages

Understanding the Investment Casting Process and Its Advantages

Investment Casting Manufacturers: Precision & Innovation

Sand Casting Process: Benefits and Techniques