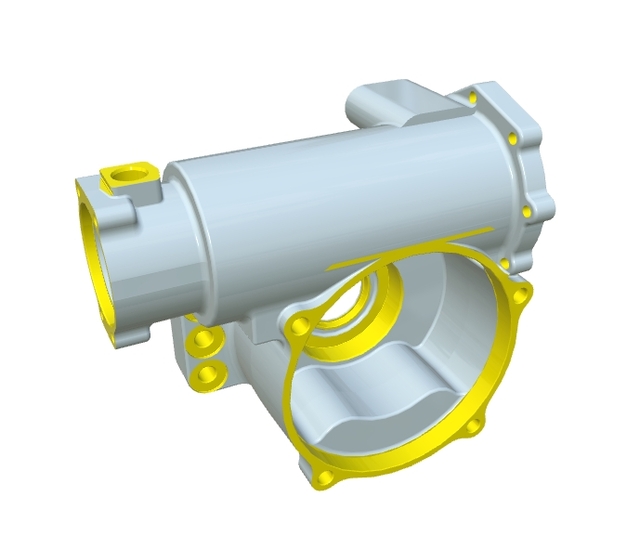

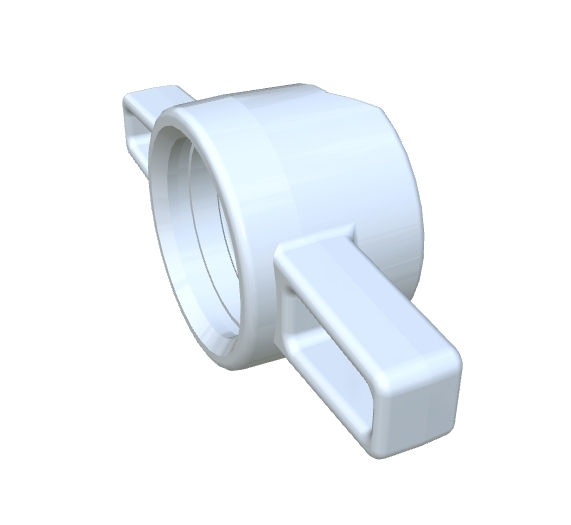

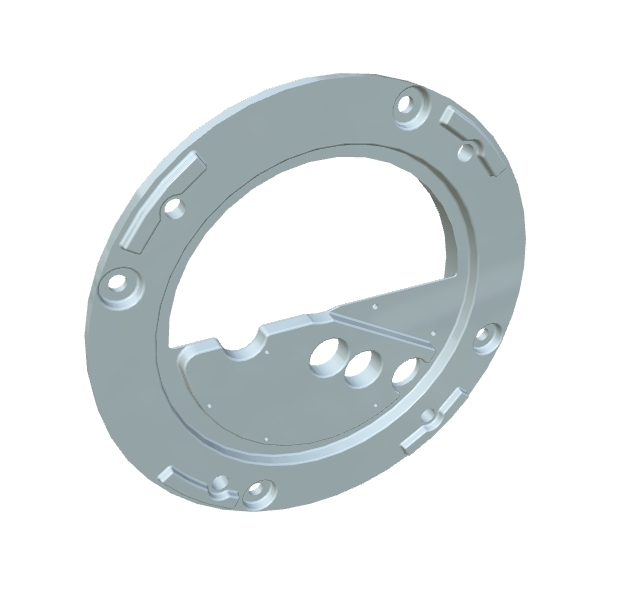

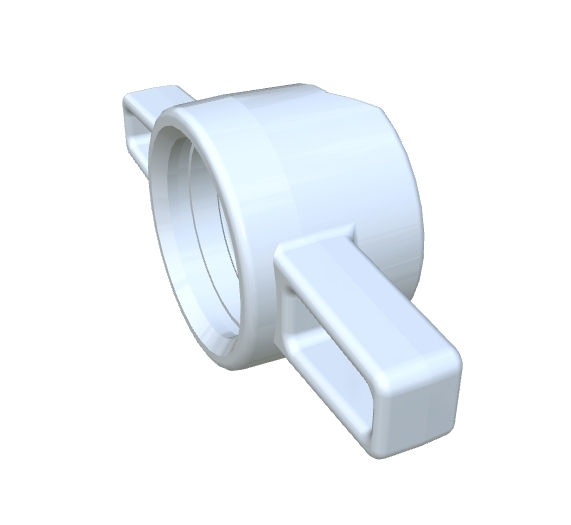

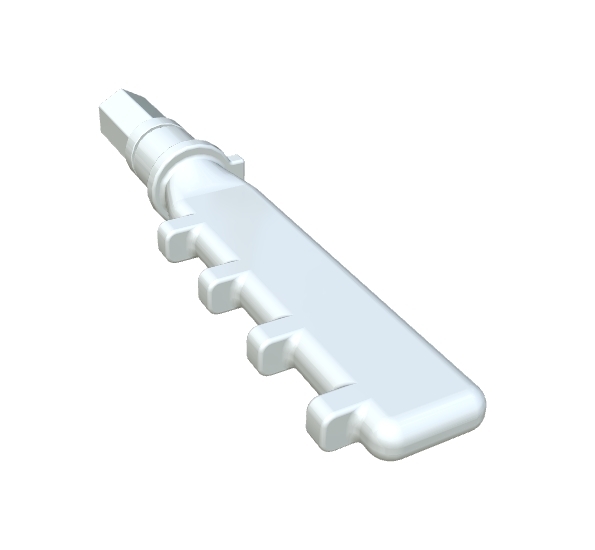

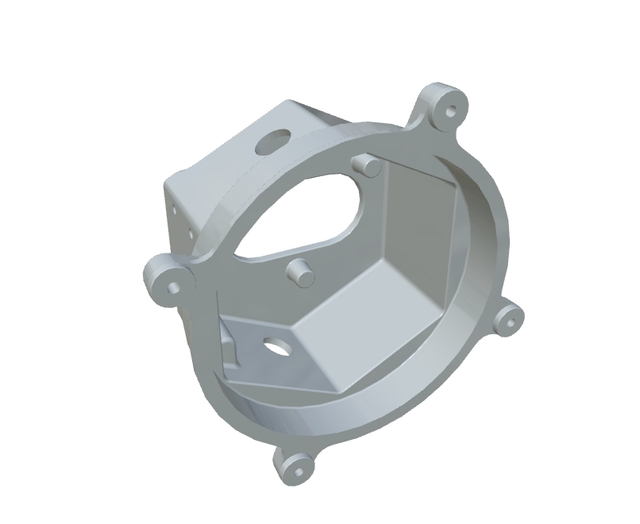

In the realm of automotive engineering, the science of **types of metal casting** plays a crucial role in shaping the components that contribute to vehicle performance and durability. Metal casting processes have been employed for centuries but are constantly evolving to enhance the mechanical properties and aesthetic qualities of automotive parts like the precision-crafted steering knuckle.

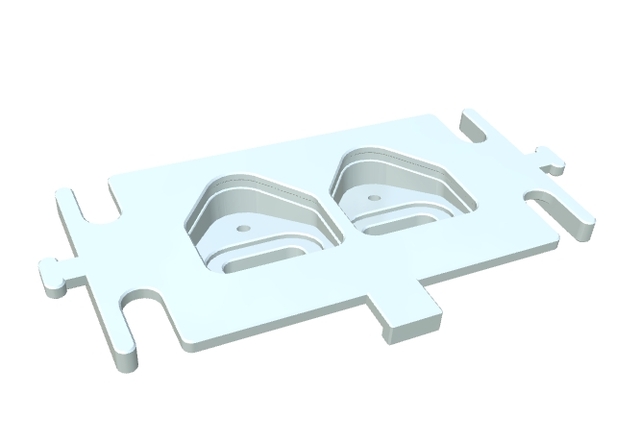

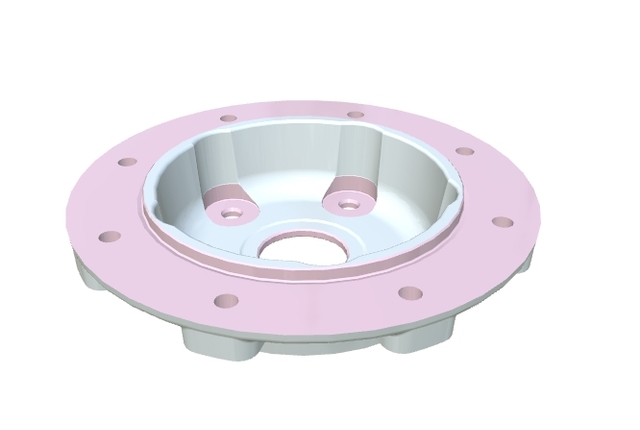

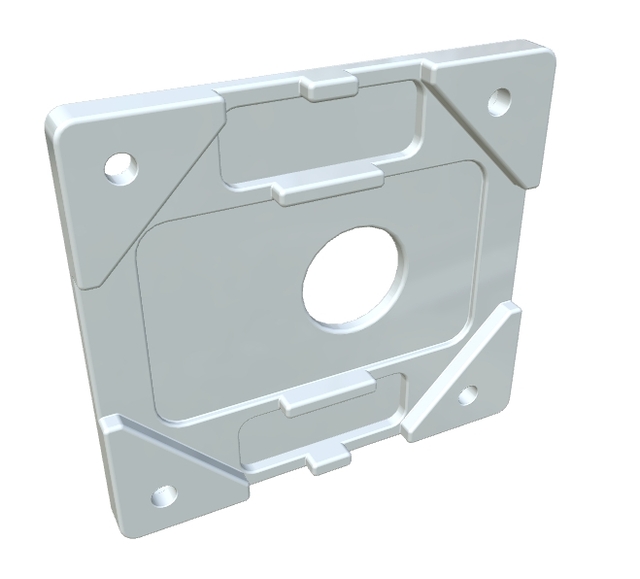

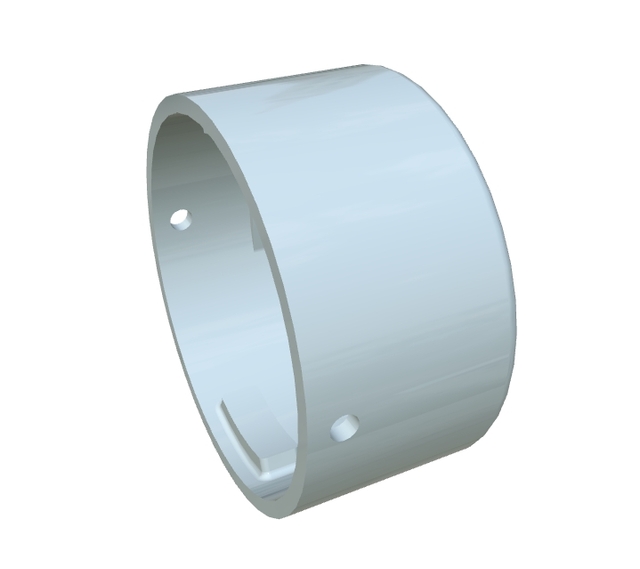

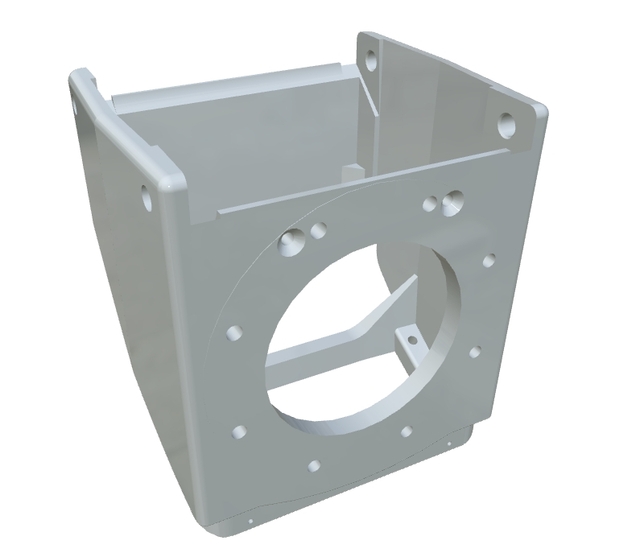

Metal casting involves several processes, each with unique advantages that make them suited for specific applications. Techniques such as steel casting, aluminum casting, and investment casting are popular in the manufacturing of automotive components. For instance, sand casting is a traditional method that involves creating a mold from sand and clay, making it ideal for large, complex parts. Investment casting, often referred to as lost-wax casting, allows for extremely detailed and precise components, making it perfect for high-strength materials used in modern vehicles.

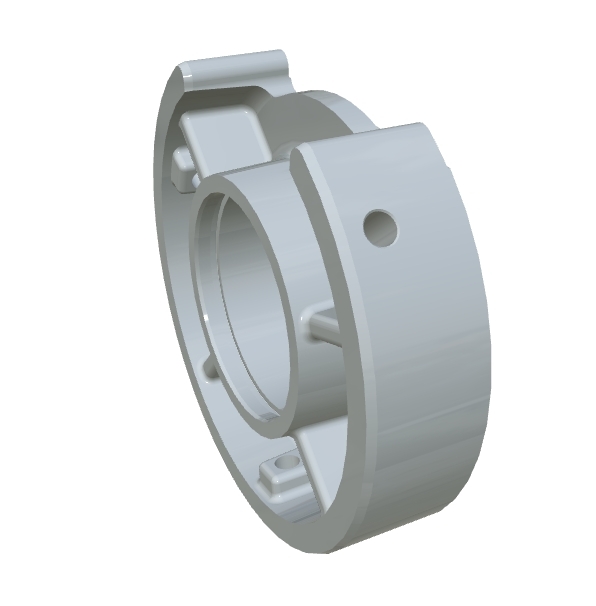

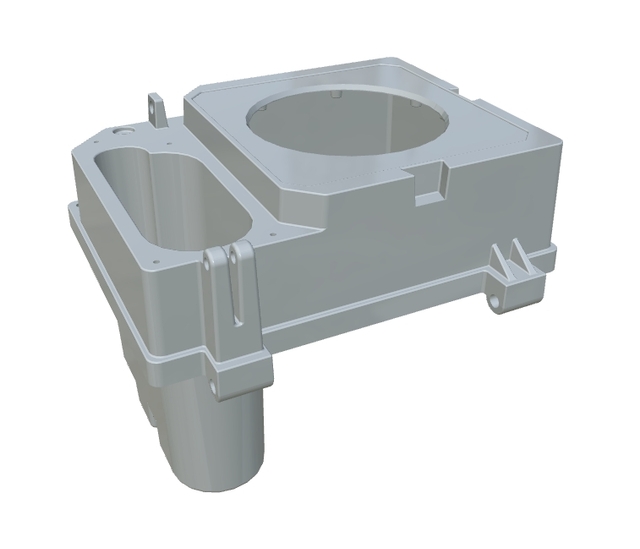

Die casting, known for its efficiency in high-volume production, utilizes a mold cavity to exert high pressure on molten metal, making it ideal for components that require a sleek, sophisticated design, such as automotive steering systems. For automotive engineers, choosing the most suitable casting technique from the various types is pivotal in crafting components like the steering knuckle, ensuring they maintain resilience under intense conditions and contribute to overall vehicle dynamics and driver confidence.

The latest steering knuckle innovation showcases how leveraging these casting processes can yield a product that boasts enhanced steering accuracy and stability. By strategically selecting the appropriate materials and methods, manufacturers are setting new standards in automotive technology. As each process contributes uniquely to the manufacturing chain, understanding their intricacies can lead to more durable, reliable, and efficient vehicle parts, driving the future of automotive engineering forward.

Exploring the Types of Metal Casting in Automotive Engineering

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Low Pressure Casting, High Pressure Casting, Investment Casting, Sand Casting, Metal Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Exploring Metal Casting Techniques for CNC Precision

Investment Casting Benefits: Unlocking Precision & Durability

Investment Casting Process for Precision Engineering

Understanding the Investment Casting Process: Techniques and Benefits

Investment Casting: Techniques and Modern Applications

The Investment Casting Process: Precision & Advantage

Investment Casting Process: Precision & Advantages

Understanding the Investment Casting Process and Its Advantages

Investment Casting Manufacturers: Precision & Innovation

Sand Casting Process: Benefits and Techniques