In recent years, the advances in **3D printing technology** have revolutionized the way we create, design, and manufacture products. From customized prosthetics to complex automotive parts, this groundbreaking technology has made a significant impact across numerous industries, pushing the boundaries of what is possible. At the core of the 3D printing revolution is the ability to transform digital designs into physical objects using a variety of **3D printing materials**, such as plastics, metals, and ceramics, rendering it a versatile and valuable tool for both hobbyists and industries alike.

LS Hardware Tech Co., Ltd, a leading expert in hardware and plastic parts manufacturing, is committed to advancing this technological frontier. Founded by the experienced Mr. Nick Zhang and his team of skilled engineers, LS Hardware Tech boasts over two decades of expertise, offering unparalleled **3D printing services** to a global clientele. The company prides itself on its high precision and quality, supported by over 100 advanced machining centers in their state-of-the-art factory in China. Thanks to their ISO 9001:2015 certification, they consistently deliver products that meet international standards, serving over 150 countries with innovative solutions.

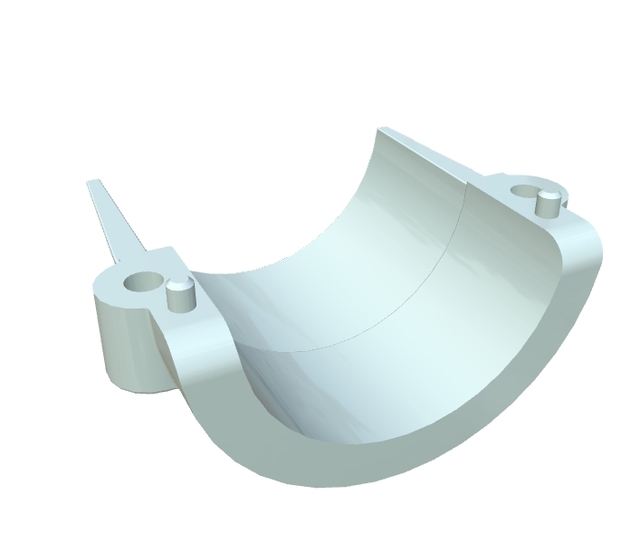

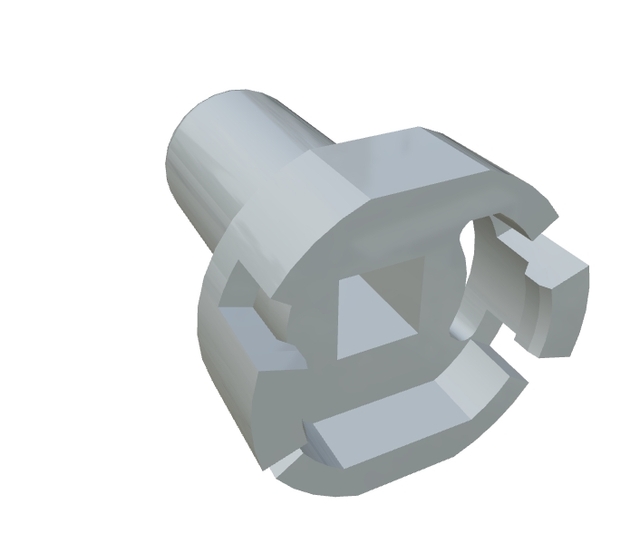

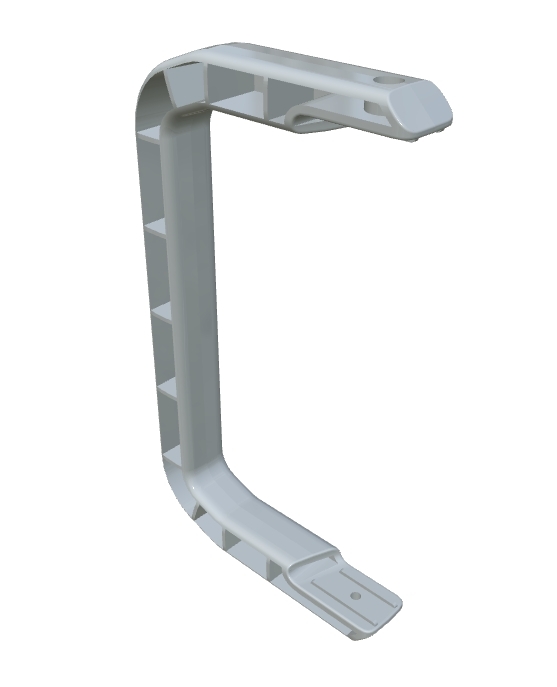

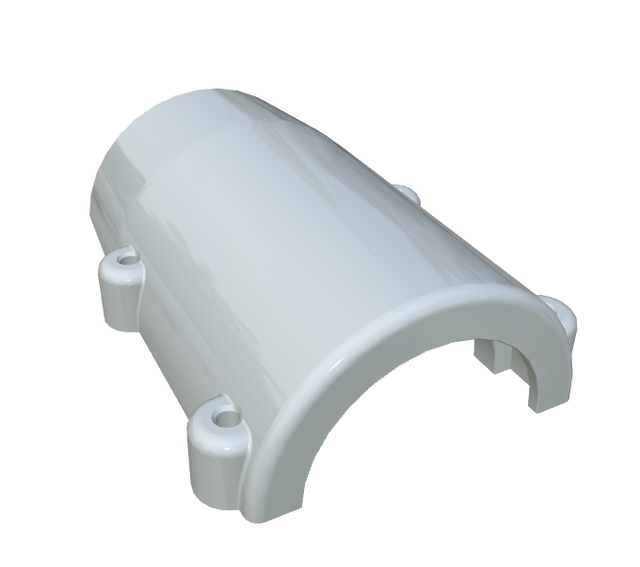

One of LS Hardware Tech's latest products leveraging the benefits of 3D printing is the sleek, glossy white Cable Management Clip. This elegantly designed clip is crafted to securely house and hide cables, providing a perfect blend of modern aesthetics and practical functionality. Constructed with strategic screw holes, it is easy to install on any surfaces, making it ideal for both home and office environments. Its smooth, rounded edges not only enhance its visual appeal but also ensure a fine integration with contemporary interiors. With its capability to maintain clean and organized spaces by reducing clutter, it not only enhances the efficiency of cable management but also improves overall cable safety.

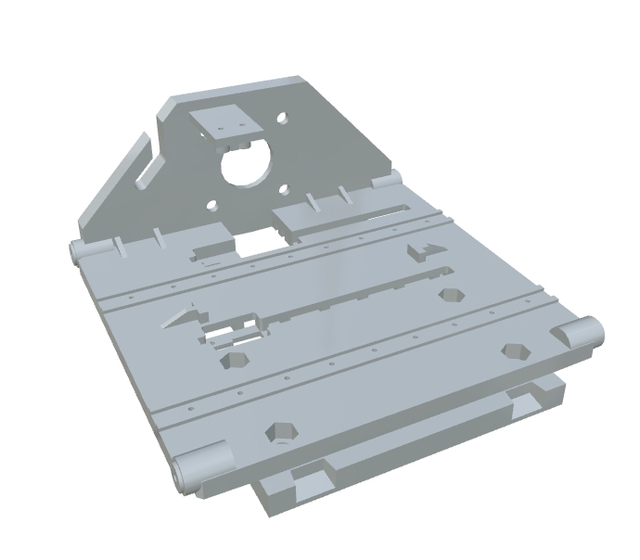

The rise of **industrial 3D printing** represents a trend that has the potential to reshape the future of production. As companies like LS Hardware Tech continue to innovate, the technology becomes more accessible and applicable to a wider audience. By providing robust and versatile 3D printing software, the company empowers businesses to easily conceptualize and create products that start from simple drawings or 3D models. These tools help beginners in the field to understand and harness the power of 3D printing technology. It is clear that as these tools evolve, they will open up even more possibilities for industries ranging from **automotive** to **aerospace**, healthcare, and beyond.

Aside from being an indispensable tool for prototyping and mass production, 3D printing is able to provide tailored solutions suited to personal needs. The versatility offered by **the best 3D printers** today enables the creation of highly customized and complex designs that were once considered impossible or economically unfeasible. These applications have a wide reach — from applying to the intricate designs needed in medical devices to the robust demands of the industrial equipment sector.

LS Hardware Tech’s approach to 3D printing is centered around empowering clients and driving innovation. Their mission is to provide manufacturing solutions that enable customers to bring their ideas to fruition. As they strive to remain at the forefront of technological advancements, they continuously improve their processes and capabilities, meeting evolving customer needs. By bridging the gap between digital concepts and physical reality, companies like LS Hardware Tech Co., Ltd are paving the way for a future where **3D printing technology** is an integral part of our everyday lives.

With the ongoing development of 3D printing technology and its applications, it's gratifying to witness how a company such as LS Hardware Tech continues to lead the industry in delivering precision and quality. The influence of 3D printing will undoubtedly continue to expand, further enhancing its role as a transformative force in the field of manufacturing. As more people and businesses adopt the technology, the possibilities it unlocks are limitless.

Revolutionizing Industries with 3D Printing Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Revolutionizing Manufacturing with Multi Jet Fusion Technology

Exploring Multi Jet Fusion Technology in Modern Manufacturing

Exploring Multi Jet Fusion Technology: Applications & Benefits

Advancements in Multi Jet Fusion Technology Transform Manufacturing

Multi Jet Fusion Technology: Advancements in 3D Printing and Its Industrial Applications

Revolutionizing Design with Multi Jet Fusion Technology

Multi Jet Fusion Technology: Revolutionizing 3D Printing Solutions

Exploring Multi Jet Fusion Technology: Applications & Advantages

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology