3D printing technology has revolutionized the way industries approach manufacturing and design, and LS Hardware Tech Co., Ltd is at the forefront of this innovation. The company, founded by Mr. Nick Zhang and a team of experienced engineers, has specialized in manufacturing high-precision hardware and plastic parts for over two decades. With an impressive record of delivering efficient solutions to over 5,000 clients worldwide, LS Hardware Tech continues to lead in the realm of 3D printing services and other cutting-edge technologies.

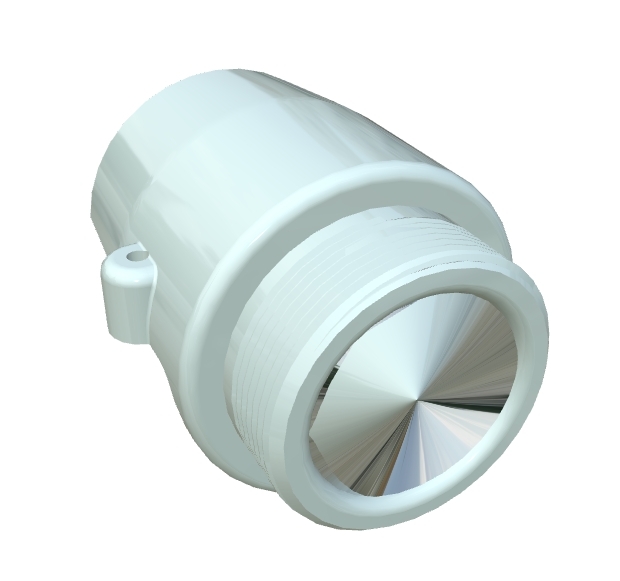

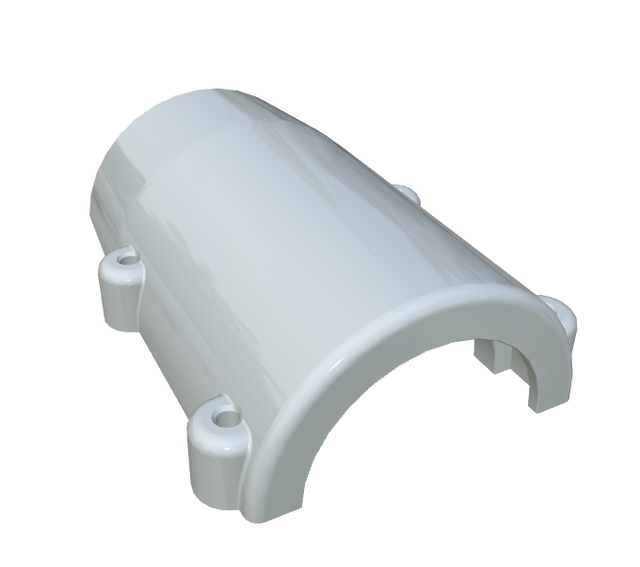

As industries evolve, 3D printing technology emerges as a game-changer in manufacturing by providing novel ways to use materials, lowering costs, and allowing for unprecedented design flexibility. Companies like LS Hardware Tech leverage 3D printing for prototyping, enabling rapid iterations and refinements in product designs. This innovation is particularly beneficial in fields such as consumer electronics, aerospace, and industrial equipment, where precision is paramount, and time-to-market can significantly impact competitiveness.

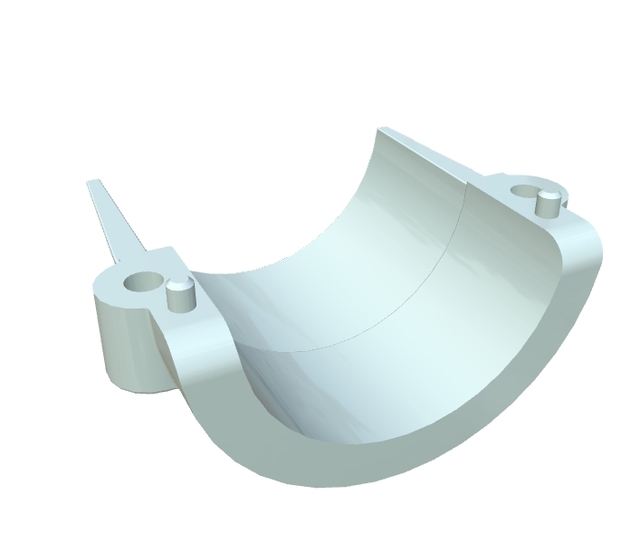

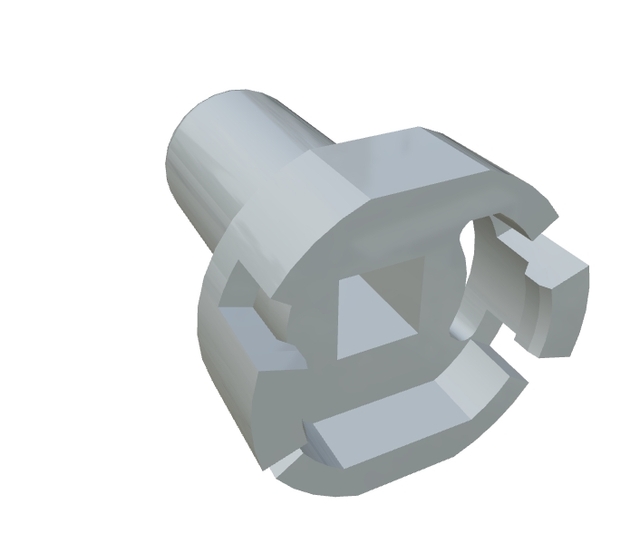

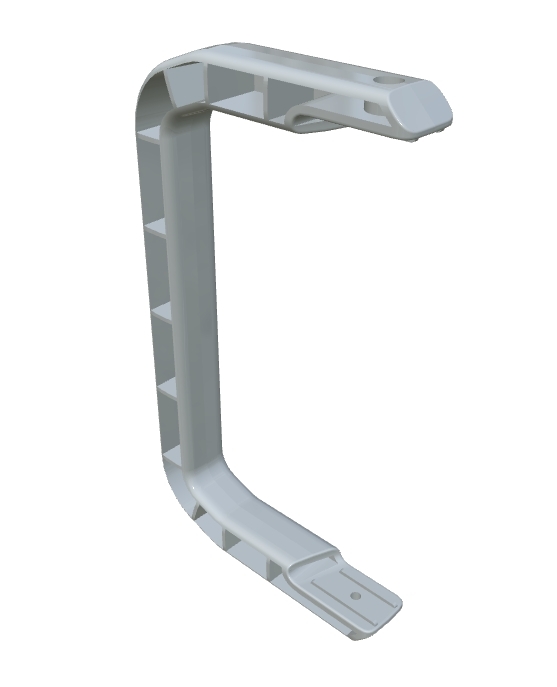

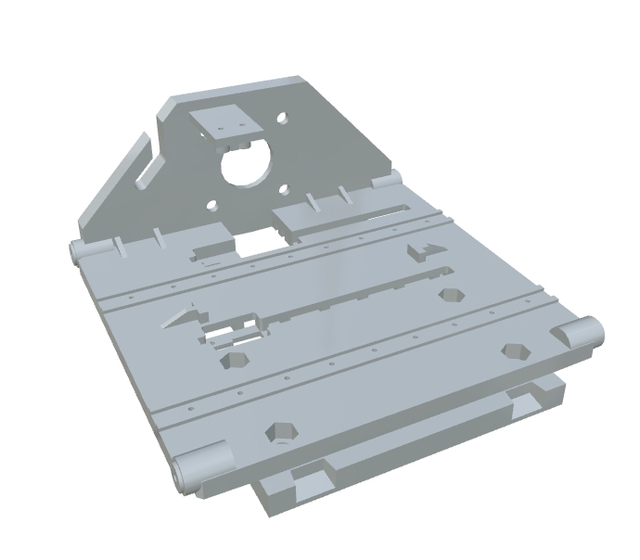

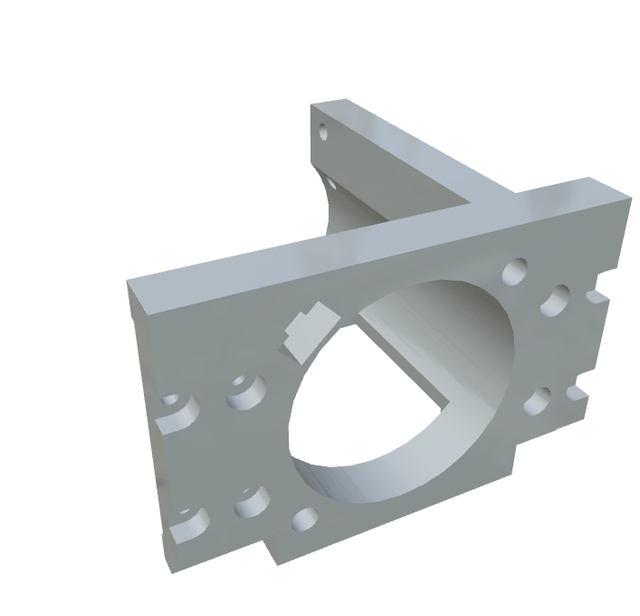

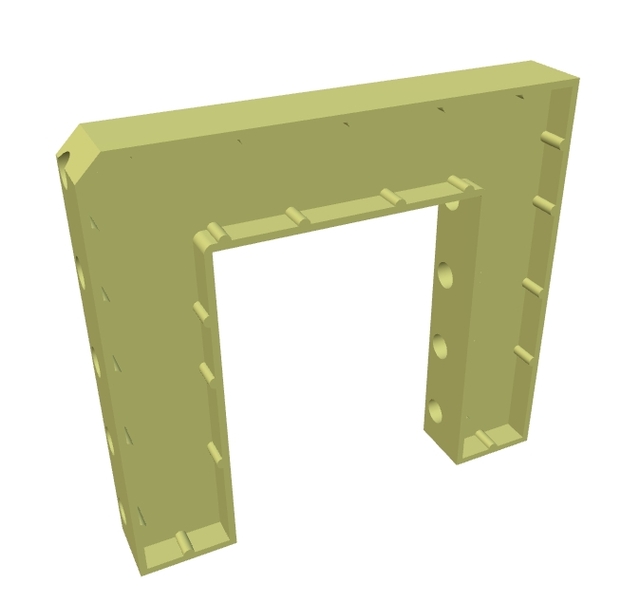

The advancements in 3D printing materials have further pushed the boundaries of what's possible. LS Hardware Tech employs cutting-edge materials to create parts that are not only lightweight and robust but also sustainable. This focus aligns with industry trends demanding eco-friendlier production processes without compromising on quality or structural integrity. Indeed, the Modular Reinforcement Bracket introduced by LS Hardware Tech showcases this ethos. Designed for durability and precision, the bracket exemplifies versatile 3D printing applications in modern construction, presenting a robust solution bolstered by advanced manufacturing techniques.

The rise of 3D printing technology also paves the way for beginners and hobbyists to explore creative possibilities in design and manufacturing. LS Hardware Tech recognizes this trend and offers solutions that cater not only to established industries but also to newcomers seeking to harness this technology for innovation. 3D printing in manufacturing holds significant promise for educators and students as well, providing hands-on learning experiences and fostering a new generation of engineers and designers.

Moreover, the adoption of 3D printing trends allows businesses to achieve greater customization in their offerings. With the Modular Reinforcement Bracket, LS Hardware Tech illustrates how 3D-printed components can be adapted for a variety of structural needs, giving architects and engineers the flexibility to incorporate these elements within their unique design frameworks. This adaptability is crucial in today's market, where personalized solutions are often key to meeting diverse client demands.

LS Hardware Tech, boasting an ISO 9001:2015 certification, prides itself on its ability to deliver high-quality parts for mass production, demonstrating the scalability of 3D printing in modern industry. The company's commitment to continually improving processes and expanding capabilities is evident in its sophisticated approach to integrating 3D printing into its manufacturing solutions. By maintaining a global presence and serving a broad array of industries, LS Hardware Tech ensures it remains a trusted partner for factories and businesses aiming to bring innovative products to the market.

In conclusion, 3D printing technology is not merely a trend but a transformative approach that impacts how products are conceptualized, designed, and produced. With companies like LS Hardware Tech leading the charge, this technology empowers businesses across varied sectors to not only enhance efficiency and precision but also to innovate without boundaries. Whether for beginners exploring 3D printing for the first time or seasoned manufacturers seeking enhanced capabilities, the future of 3D printing promises exciting developments that will shape the way we build, create, and imagine.

Revolutionizing Construction with 3D Printing Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Revolutionizing Manufacturing with Multi Jet Fusion Technology

Exploring Multi Jet Fusion Technology in Modern Manufacturing

Exploring Multi Jet Fusion Technology: Applications & Benefits

Advancements in Multi Jet Fusion Technology Transform Manufacturing

Multi Jet Fusion Technology: Advancements in 3D Printing and Its Industrial Applications

Revolutionizing Design with Multi Jet Fusion Technology

Multi Jet Fusion Technology: Revolutionizing 3D Printing Solutions

Exploring Multi Jet Fusion Technology: Applications & Advantages

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology