Fused Deposition Modeling: Pioneering the Future of 3D Printing

In recent years, additive manufacturing has drastically transformed the way we think about production and design. At the forefront of this technological revolution stands **fused deposition modeling** (FDM). As a cornerstone of 3D printing technology, FDM 3D printing offers a unique process that involves thermoplastic extrusion to create three-dimensional objects based on digital models.

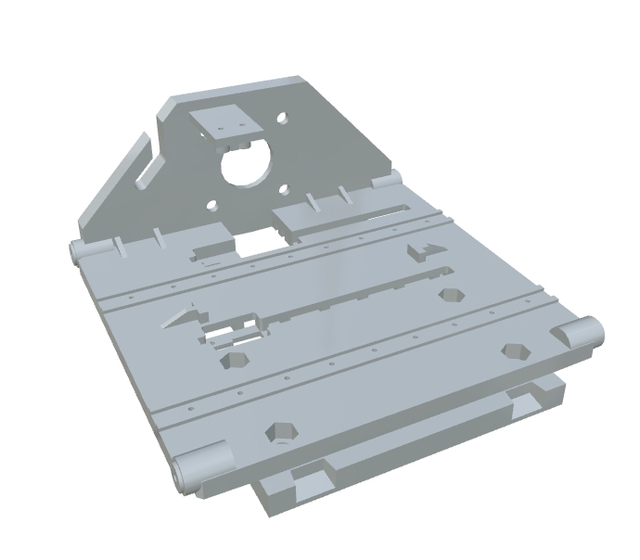

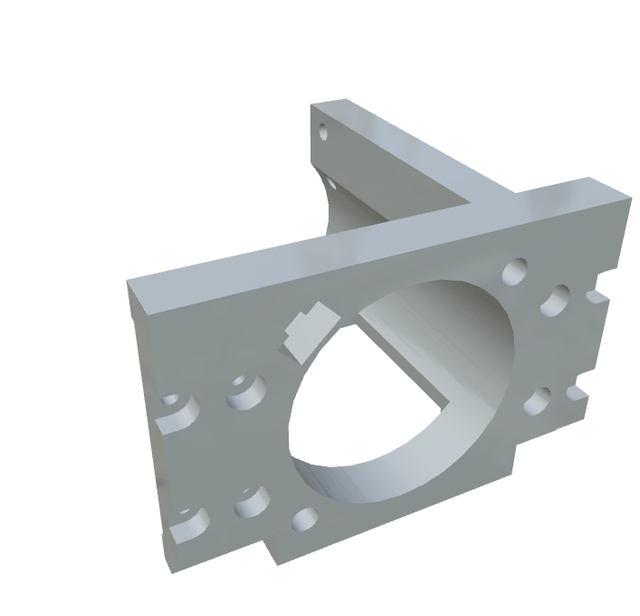

FDM, a method revered for its simplicity and efficiency, has found its place across various industries, from consumer electronics to aerospace. The core of the FDM process involves a digital model sliced into thousands of horizontal layers, which an FDM printer then reproduces layer by layer using a spool of thermoplastic filament. This technology opens doors to unlimited prototyping possibilities, fostering innovation and creativity by allowing rapid iteration.

LS Hardware Tech Co., Ltd: Proficiency in Precision

LS Hardware Tech Co., Ltd is a key player in the manufacturing domain, leveraging the power of 3D printing to offer robust, high-quality products. With over 20 years of experience, LS Hardware Tech, under the guidance of Mr. Nick Zhang, excels in the creation of both hardware and plastic parts. The company has empowered over 5,000 clients globally with tailor-made solutions that align with their unique manufacturing needs.

Their modern manufacturing facility is ISO 9001:2015 certified, housing over 100 high-end machining centers that ensure top-quality outputs with impressive production efficiency. These facilities are integral to their operations in producing high-precision parts catering to various industries, such as automotive, medical devices, and aerospace. LS Hardware Tech Co., Ltd is more than a service provider; they are partners to globally renowned factories across 150 countries, pushing the boundaries of what's possible with additive manufacturing.

Transforming Concepts into Reality

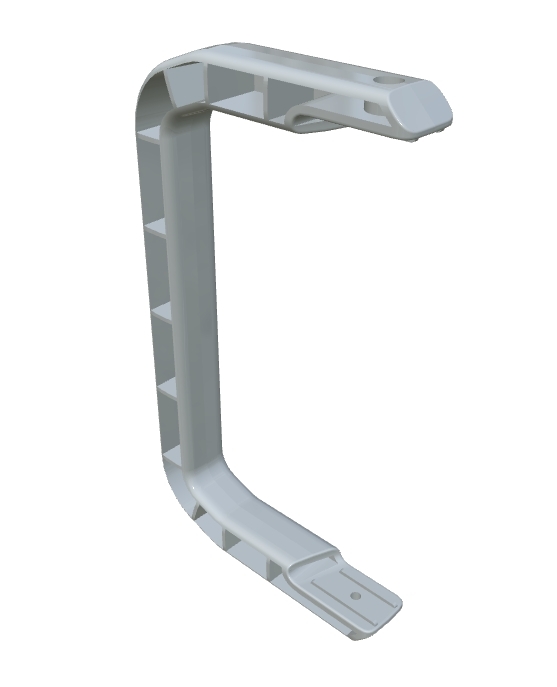

LS Hardware Tech Co., Ltd has a standout product, the sleek and modern multipurpose bracket, designed with both aesthetics and functionality in mind. Constructed with a minimalist approach, the C-shaped design is made from durable, high-quality materials ensuring both strength and longevity. This fashionable multipurpose bracket shines in its application versatility, proving itself ideal for organizing cables, supporting lightweight shelving units, or securely mounting devices.

The multipurpose bracket demonstrates the seamless synergy of form and function, where the two-hole design offers remarkable stability, making installation both secure and swift. Its understated sophistication allows for it to fit effortlessly within both home and office settings, enhancing any space with its polished appearance.

By integrating fused deposition modeling in their production processes, LS Hardware Tech Co., Ltd turns concepts into tangible, functional products. This demonstrates their commitment to spearheading innovative manufacturing solutions that not only serve current market demands but anticipate future needs as well.

Advantages of FDM 3D Printing

FDM 3D printing technology remains a protagonist in the realm of modern manufacturing due to its numerous advantages. It offers cost-effectiveness and accessibility compared to traditional manufacturing methods, especially beneficial during the prototyping phase. The ergonomic design potential this technology offers propels designers and engineers to experiment with complex geometries that conventional techniques would struggle to replicate.

Another powerful facet of the FDM process is its compatibility with a broad spectrum of 3D printing materials. From basic thermoplastics to specialized composites, manufacturers have the liberty to choose materials that suit the specific mechanical, thermal, and chemical properties required for their applications.

Moreover, FDM 3D printing is increasingly seen as an environmentally friendly option within the manufacturing sphere. The precision and efficiency of an FDM printer allow for lower material waste and reduced energy consumption. The reuse of materials also plays a significant part in minimizing environmental impacts.

Charting the Path for the Future

With advancements in technology and a steady drive towards innovation, the use of fused deposition modeling is set to expand further across industries. LS Hardware Tech Co., Ltd remains at the cutting edge, ready to face upcoming challenges through continual improvement of their processes and capabilities. Their mission is clear: empower clients to bring their ideas to life by leveraging state-of-the-art technology and manufacturing solutions.

For anyone interested in the innovative domain of 3D printing technology, LS Hardware Tech Co., Ltd exemplifies how a company can integrate expert knowledge, sustainability, and customer focus to remain a trusted partner across the global landscape. Embracing both the opportunities and responsibilities of being at the forefront of additive manufacturing, they truly embody the spirit of innovation.