Fused Deposition Modeling (FDM) is a groundbreaking technology in the realm of 3D printing that has transformed various industries by introducing innovative solutions and enabling rapid prototyping. As the capability to manufacture precise and high-quality components becomes increasingly vital in today's fast-paced world, *LS Hardware Tech Co., Ltd* has positioned itself at the forefront of this technological revolution. With over two decades of experience, LS provides an array of hardware and plastic parts that leverage the efficiency of FDM technology, ensuring high production efficiency and top-notch quality.

The core principle of FDM involves the process of layer-by-layer manufacturing by extruding thermoplastic material in a heated form through a nozzle. This method allows for the creation of complex geometries and detailed models, which are essential in the prototyping and manufacturing of precise parts. FDM technology stands out due to its versatility, affordability, and ability to create strong and durable products. When comparing *FDM vs SLA* (Stereolithography), many manufacturers prefer FDM for its material diversity, cost-effectiveness, and broader range of applications.

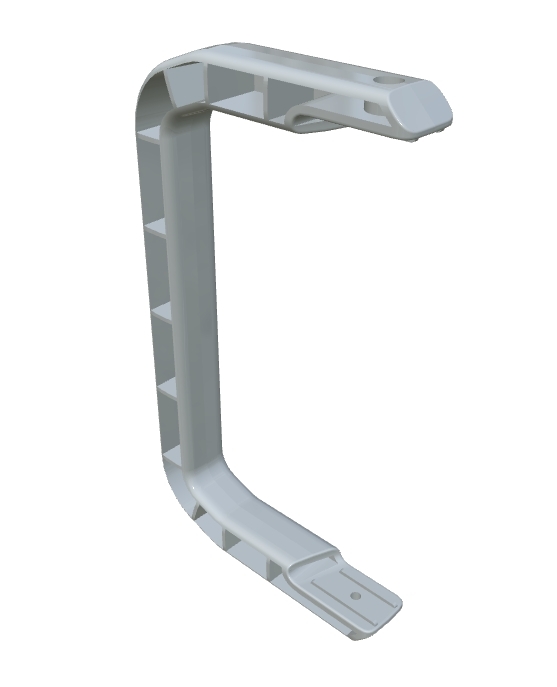

One of the standout applications of *3D printing FDM* is in the development of robust and capable handheld mounts such as those manufactured by LS Hardware Tech Co., Ltd. These mounts are designed for modern professionals—their sleek design ensures they are not only functional but also aesthetically pleasing. Crafted meticulously, they offer a robust grip and stability, crucial features for industries such as mobile computing, point-of-sale operations, and industrial applications. The combination of cutting-edge FDM technology with LS's integrity in manufacturing yields a product that is both practical and durable.

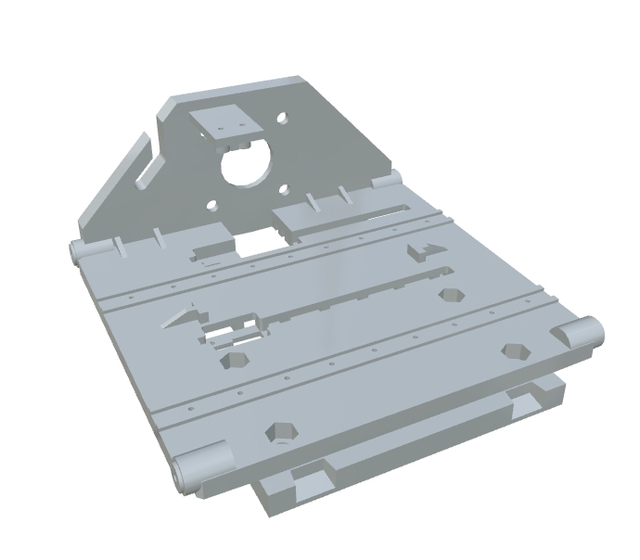

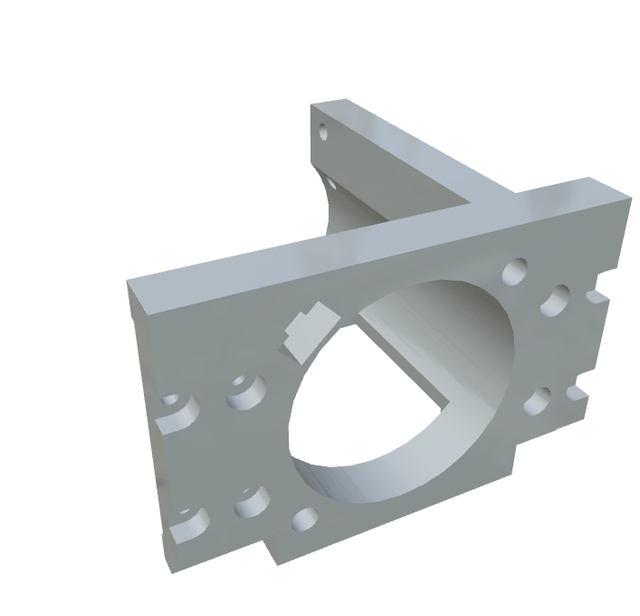

As a leader in the hardware sector, LS Hardware Tech utilizes its state-of-the-art facilities, which include over 100 high-end machining centers, to produce high-precision parts. This ensures that the intricate designs created through the *FDM process* are replicated with exactitude and reliability. The company is ISO 9001:2015 certified, evidencing its commitment to excellence and quality assurance, and highlighting its capability to meet both prototype and mass production demands effectively.

In terms of materials, *FDM materials* include a wide range of thermoplastics such as ABS, PLA, PETG, and polycarbonates, each offering distinct advantages in terms of strength, flexibility, and temperature resistance. This diversity enables manufacturers to choose the most suitable material for specific applications, further enhancing the utility and reliability of FDM printed products.

Beyond simply manufacturing, LS Hardware Tech Co., Ltd also focuses on continual improvement and adaptation to new technologies and industry trends. This dedication ensures that they not only meet but exceed the expectations of their clients, which span across numerous sectors including automotive, aerospace, medical devices, consumer electronics, and industrial equipment. By harnessing the capabilities of FDM technology, LS transforms ideas into tangible products, with services extending to over 150 countries and regions worldwide.

In conclusion, Fused Deposition Modeling is more than just a method for 3D printing. It represents a larger movement towards innovative, efficient, and precise manufacturing processes that can meet the diverse needs of modern industries. With the expertise of companies like LS Hardware Tech Co., Ltd, which excels in the *FDM process* and continues to push the boundaries of what is possible, fused deposition modeling applications are becoming an indispensable tool in the realm of high-precision parts manufacturing, demonstrating a blurred line between creativity and practicality in today’s manufacturing landscape. As the world continues to evolve, FDM ensures that industries remain agile, allowing them to adapt and advance quickly in response to market innovations and customer demands.

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.