In the fast-paced world of digital logistics, a groundbreaking advancement is on the horizon, poised to revolutionize the way data is managed and transferred. Fused Deposition Modeling (FDM) 3D printing technology has become a cornerstone of modern manufacturing methods, enabling the creation of intricate models with remarkable precision. As industries continue to push the boundaries of innovation, the role of 3D printing technology, specifically the FDM process, becomes ever more crucial in realizing designs that were once deemed impossible.

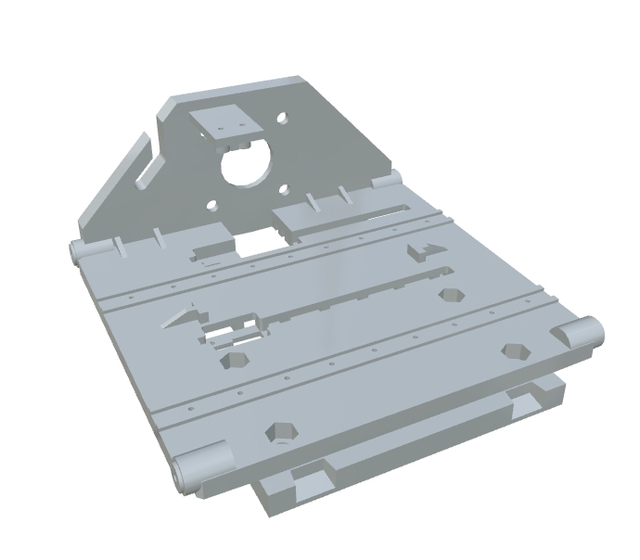

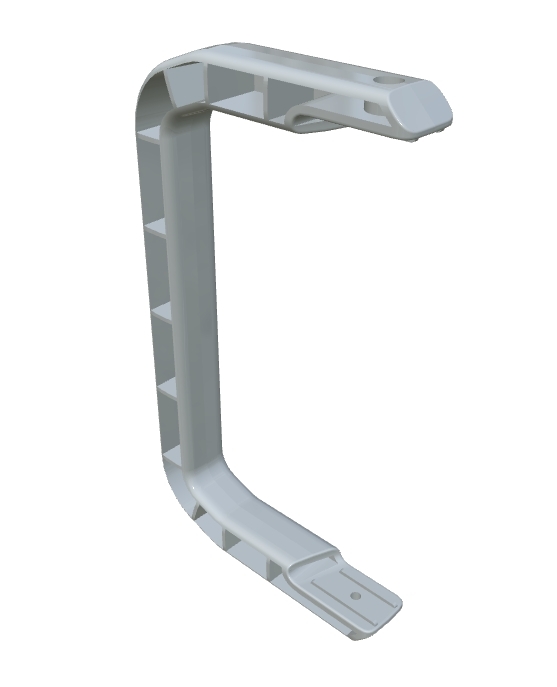

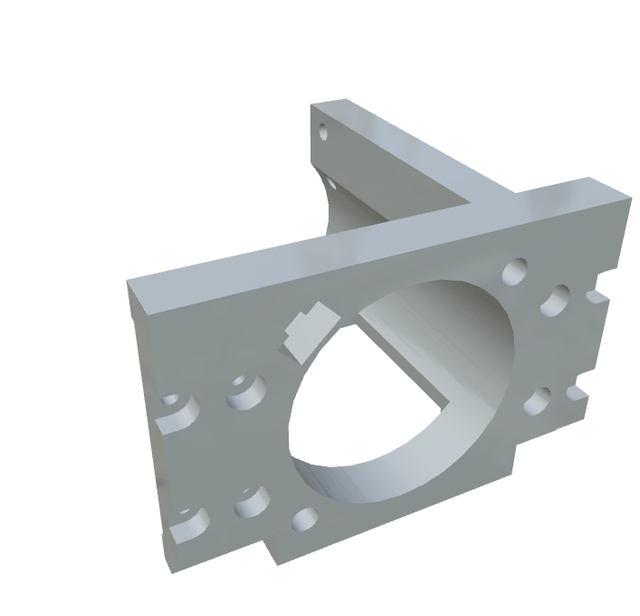

The Streamline Data Relayer, a product of LS Hardware Tech Co., Ltd, stands as a testament to the transformative power of additive manufacturing. FDM 3D printing technology utilizes thermoplastic extrusion to construct three-dimensional objects layer by layer, a method that allows for unparalleled customization and adaptability, key components of today's rapidly evolving tech environment. As we increasingly rely on digital solutions to enhance productivity, the integration of FDM materials offers both strength and flexibility, ideal attributes for cutting-edge devices like the Streamline Data Relayer.

LS Hardware Tech Co., Ltd, founded by visionary Nick Zhang, has carved a niche in the manufacturing sector, leveraging over two decades of expertise to produce high-quality, precision parts. With comprehensive services extending to over 150 countries, the company is renowned for its state-of-the-art production capabilities, underpinned by ISO 9001:2015 certification. This commitment to quality and innovation has made LS a trusted partner to major industries, including automotive, aerospace, and consumer electronics.

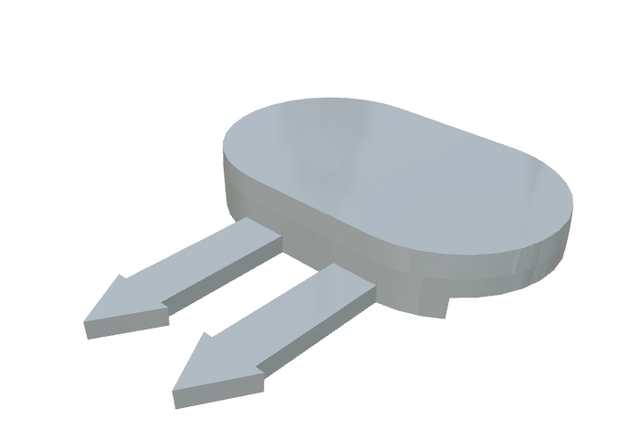

At the heart of this technological leap is the Streamline Data Relayer. Its sleek, pill-shaped design, crafted from high-grade reflective alloy, underscores a commitment to both aesthetics and functionality. The device's minimalist appearance is not just for show; it represents the pinnacle of modern design, strategically engineered for durability and performance.

The hallmark of the Streamline Data Relayer is its innovative dual-channel mechanism. This design allows simultaneous data input and output, effectively doubling data throughput and minimizing latency. In an era where efficiency and speed are paramount, such advancements are crucial in maintaining competitive edges across various sectors. The dual-directional arrows, embossed on its surface, are a subtle nod to its core functionality—ensuring seamless connectivity, a feature that tech enthusiasts will find indispensable.

Incorporating fused deposition modeling into its production, LS Hardware Tech Co., Ltd demonstrates a profound understanding of the dynamic intersections between 3D printing technology and modern product development. By employing the FDM process in the creation of the Streamline Data Relayer, the company assures each unit meets stringent standards of resilience and performance, tailored precisely to meet the demands of today's discerning tech users.

The journey from concept to creation in the world of additive manufacturing is fraught with challenges, yet LS has harnessed its extensive experience to streamline production, delivering solutions that not only meet but exceed customer expectations. By constantly refining their processes and embracing state-of-the-art innovations, LS Hardware Tech Co., Ltd is positioned at the forefront of a manufacturing renaissance, shaping the future of how products are conceived and realized.

As the world continues to embrace digital transformation, the need for robust, reliable, and high-performance data management solutions like the Streamline Data Relayer becomes ever more apparent. The convergence of FDM 3D printing and traditional manufacturing excellence as demonstrated by LS is not merely about improving existing workflows; it's about redefining them entirely, embedding flexibility and resilience at every stage of the product lifecycle.

In closing, the adoption of Fused Deposition Modeling in manufacturing processes signals a bold step forward. The Streamline Data Relayer embodies this advancement, offering a glimpse into the future of seamless connectivity where speed and reliability are harmonized through expertly engineered solutions. For LS Hardware Tech Co., Ltd, the journey is only just beginning, as they continue to harness the power of innovation to empower their clients, fostering an era where bold ideas can be swiftly and accurately brought to life.

The Future of Connectivity: Fused Deposition Modeling Transforming Streamline Data Relayer

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Exploring Fused Deposition Modeling in Modern Manufacturing

Fused Deposition Modeling: Transforming Additive Manufacturing

Fused Deposition Modeling: Pioneering 3D Printing Advances

Fused Deposition Modeling: Transforming Manufacturing with LS Hardware Tech Co., Ltd

The Future of Connectivity: Fused Deposition Modeling Transforming Streamline Data Relayer

Exploring Additive Manufacturing FDM: Innovation & Applications