Fused deposition modeling (FDM) is a groundbreaking technology that has significantly revolutionized the field of additive manufacturing and 3D printing. As a leading 3D printing technique, FDM 3D printing stands out due to its versatility and efficiency. This method is distinguished by its use of thermoplastic materials which are melted and extruded layer by layer to form geometric constructs and complex designs. Today, FDM technology continues to transform manufacturing processes across diverse industries, from automotive to aerospace.

LS Hardware Tech Co., Ltd, a pioneering company in the field of 3D printing and hardware manufacturing, is at the forefront of incorporating FDM technology into its wide array of high-precision products. Founded by Mr. Nick Zhang along with a team of seasoned engineers, LS has over two decades of experience in the manufacturing sector. With a global presence in more than 150 countries, LS specializes in the production of over 5,000 innovative solutions tailored to meet the diverse demands of industries such as medical devices, consumer electronics, and industrial equipment. Their mission is to continuously drive innovation and enhance manufacturing capabilities through state-of-the-art processes and technologies, including the widespread adoption of fused filament fabrication.

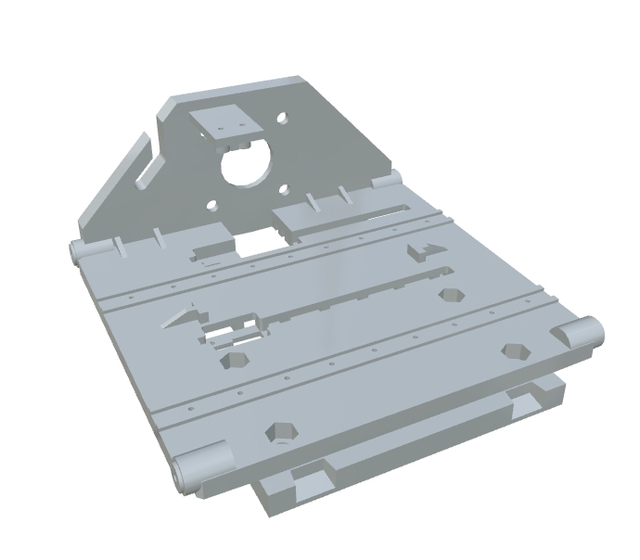

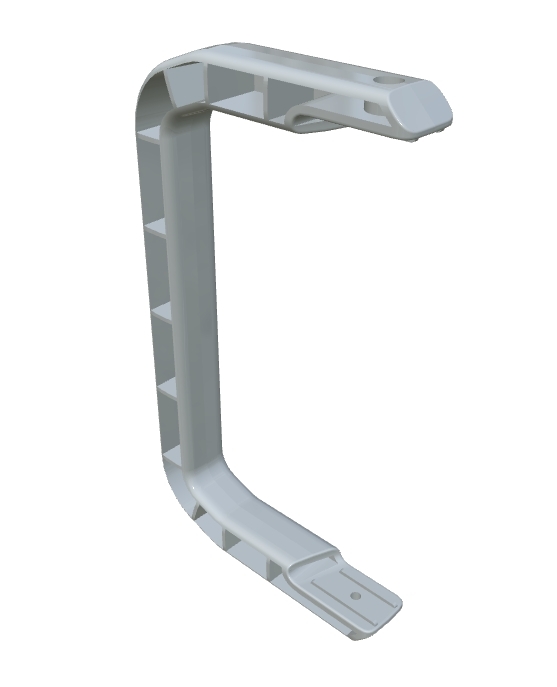

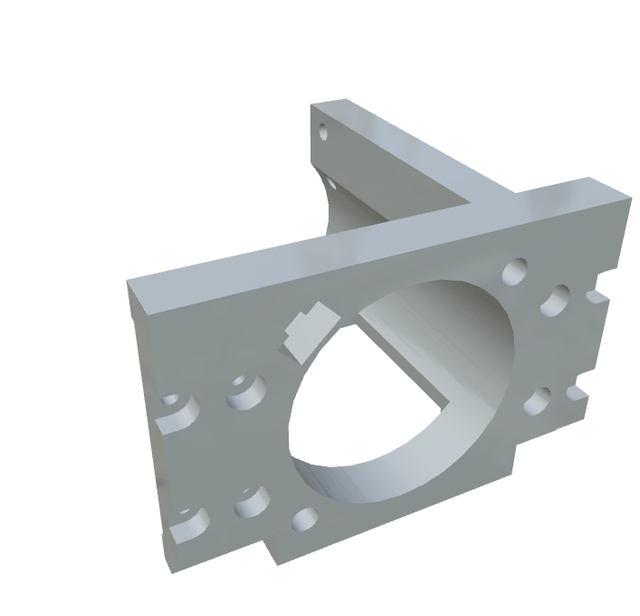

The debut of LS's new metal mounting bracket demonstrates the seamless integration of FDM printers into their production lines. This versatile bracket, crafted from high-grade aluminum, benefits from the precision and durability afforded by FDM materials. Its sleek, minimalist aesthetic does not detract from its robust functionality, making it suitable for diverse applications in automotive, industrial, and custom fabrication projects. Featuring meticulously designed circular cut-outs for tubing and multiple strategically placed mounting holes, the bracket offers unparalleled adaptability for various installation configurations.

FDM technology serves as a foundational pillar in the development of LS's innovative products. This efficient 3D printing technique offers unparalleled advantages, such as the cost-effective and flexible production of prototypes. Rapid prototyping through FDM enables engineers and designers to refine and perfect their designs, reducing time-to-market and improving product quality. As an ISO 9001:2015 certified company, LS leverages this 3D printing method to deliver consistent, high-quality results that meet stringent industry standards.

The success of FDM 3D printing lies in its ability to democratize manufacturing by providing access to cost-efficient, on-demand production. Unlike traditional manufacturing methods, FDM's layer-based approach allows for the creation of intricate and highly customized parts without the need for costly and time-consuming tooling. This makes it possible for LS Hardware Tech Co., Ltd to offer clients a nimble and patient-friendly solution, aligning perfectly with their commitment to innovation and customer satisfaction.

The introduction of fused deposition modeling as a central component in LS's manufacturing processes reflects a broader trend in the field of additive manufacturing. As industries evolve, the demand for highly detailed, bespoke parts that can be produced at speed continues to grow. FDM technology is poised to meet this demand, driven by companies like LS that are dedicated to leveraging state-of-the-art methods to enhance product offerings and client service.

In conclusion, LS Hardware Tech Co., Ltd's integration of fused deposition modeling represents not just a technological advancement but a commitment to revolutionizing the manufacturing landscape. With FDM printers, LS delivers parts that are not only functional and precise but also embody the aesthetic sophistication required in modern industrial applications. As the horizon for additive manufacturing expands, LS remains at the forefront, utilizing fused filament fabrication to exceed the ever-changing expectations of its global clientele.

Fused Deposition Modeling: Transforming Manufacturing with LS Hardware Tech Co., Ltd

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.