In today's rapidly evolving technological landscape, **3D printing technology** stands out as a revolutionary force that is transforming industries across the globe. With its roots in additive manufacturing, 3D printing services now encompass an array of techniques including FDM (Fused Deposition Modeling) and SLA (Stereolithography) 3D printing. This technology is not only accessible to industries with commercial 3D printers but is also increasingly popular for home use, utilizing a wide variety of 3D printing materials.

The remarkable versatility of 3D printing has enabled companies such as LS Hardware Tech Co., Ltd to bring innovative products to market efficiently and with precision. LS Hardware Tech Co., Ltd, founded by Mr. Nick Zhang and his team of expert engineers, is a prime example of how this technology can be leveraged to meet diverse manufacturing needs. With over 20 years of expertise, the company has cemented its reputation as a leader in manufacturing high-precision hardware and plastic parts, serving over 5,000 clients worldwide.

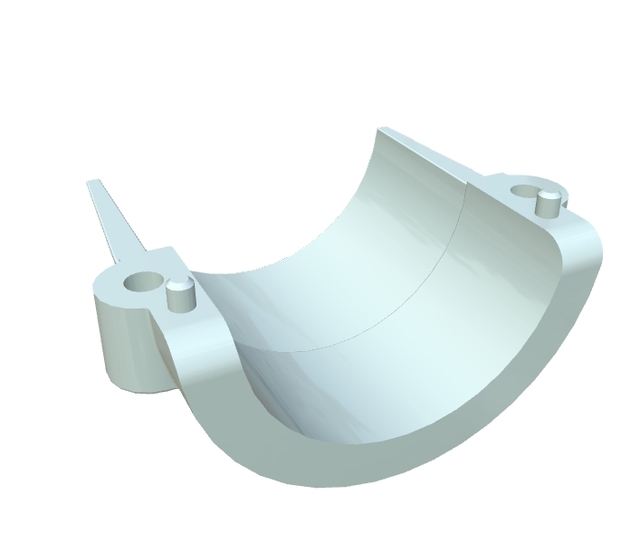

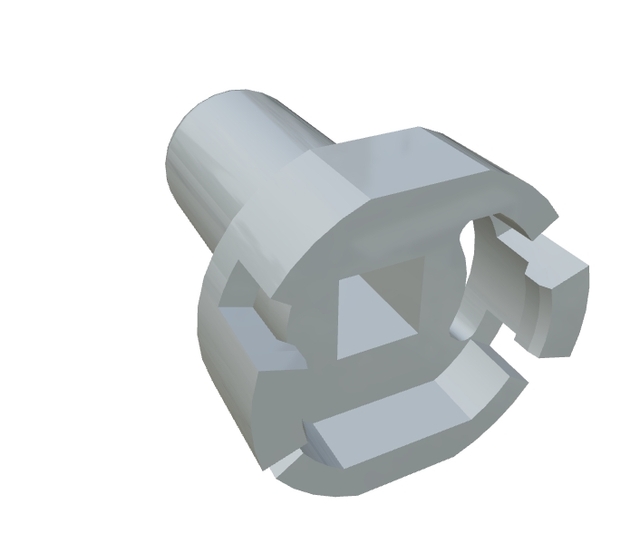

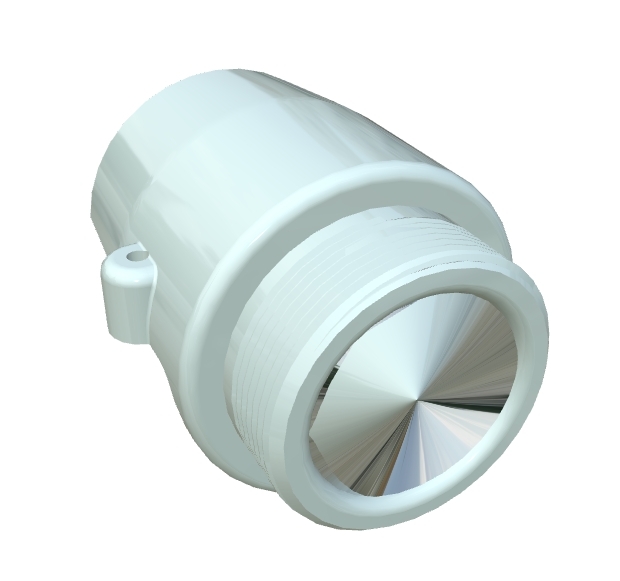

One of the latest innovations from LS Hardware Tech is a sleek and modern light fitting socket. This product perfectly exemplifies how 3D printing technology can be used to create functional yet aesthetically pleasing designs. Made from durable materials, the socket exudes a minimalist aesthetic with its glossy white finish that aligns perfectly with contemporary design trends. The 3D printing process allows for intricate features, such as the subtle ribbed pattern on the socket, which not only adds an elegant touch but also facilitates easy handling during installation.

The light fitting socket from LS Hardware Tech is designed to be versatile, making it suitable for both residential and commercial settings. Its robust threaded base ensures secure installation and broad compatibility with various light fixtures, showcasing the practicality and reliability of parts fabricated using **3D printing technology**. This aligns with the company's mission to provide innovative manufacturing solutions that help bring client ideas to life.

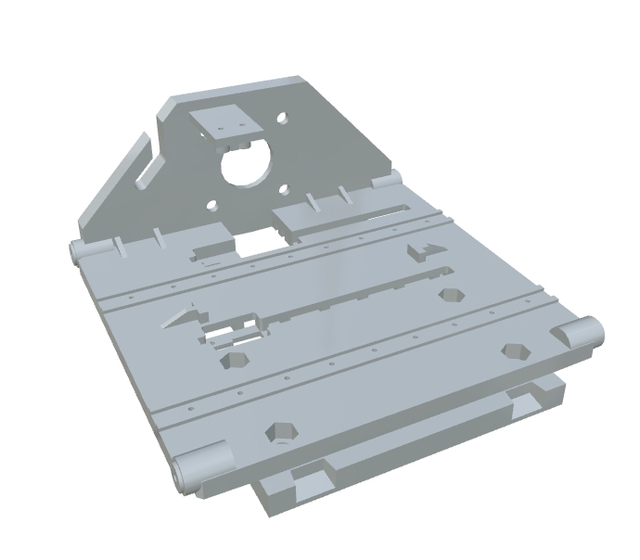

The integration of 3D printing technology in LS Hardware Tech’s product line demonstrates a commitment to staying at the forefront of technological advancements. Equipped with over 100 high-end machining centers and ISO 9001:2015 certification, LS Hardware Tech ensures high production efficiency and top-quality outputs. This technological edge facilitates their capacity to meet the full spectrum of client needs, from prototypes to full-scale mass production, across various industries including automotive, medical devices, consumer electronics, aerospace, and industrial equipment.

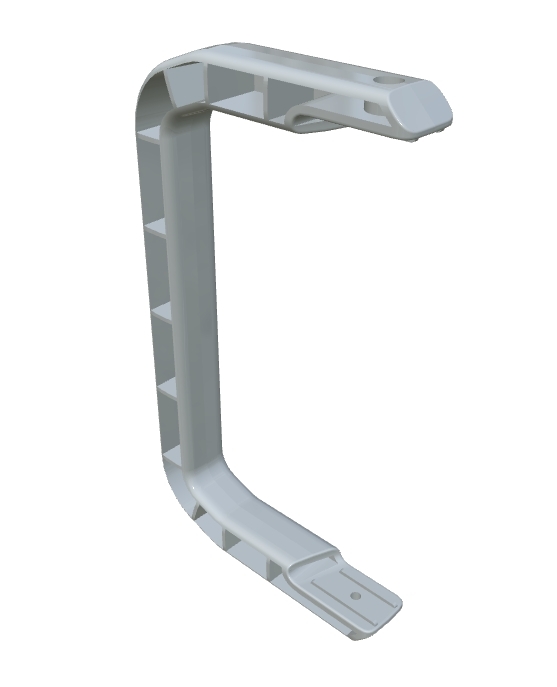

Furthermore, as 3D printing technology continues to develop, it offers new possibilities for innovation in product design and manufacturing processes. The detailed precision of 3D printers makes it possible to create complex geometries and customized solutions that were previously unfeasible with traditional manufacturing methods. This not only provides a competitive edge to manufacturers like LS Hardware Tech but also drives the broader adoption of **3D printing technology** across industries.

With the expansion of 3D printing services, more businesses and consumers are beginning to recognize the benefits of this technology. The ability to produce unique designs with faster turnaround times and reduced material waste positions 3D printing as an environmentally friendly choice as well. Companies like LS Hardware Tech are well-positioned to capitalize on these trends, offering products like their modern light fitting socket that utilize the advantages of **additive manufacturing** to enhance functionality and design.

As LS Hardware Tech Co., Ltd continues to innovate and expand its product offerings, the potential for **3D printing technology** to revolutionize manufacturing processes becomes increasingly clear. By continually improving their processes and capabilities, LS Hardware Tech not only meets the evolving needs of their customers but also sets a benchmark for excellence in the production of high-precision parts. Their dedication to quality and innovation ensures that they remain a trusted partner in delivering exceptional manufacturing solutions globally.

Revolutionizing Industries with 3D Printing Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Revolutionizing Manufacturing with Multi Jet Fusion Technology

Exploring Multi Jet Fusion Technology in Modern Manufacturing

Exploring Multi Jet Fusion Technology: Applications & Benefits

Advancements in Multi Jet Fusion Technology Transform Manufacturing

Multi Jet Fusion Technology: Advancements in 3D Printing and Its Industrial Applications

Revolutionizing Design with Multi Jet Fusion Technology

Multi Jet Fusion Technology: Revolutionizing 3D Printing Solutions

Exploring Multi Jet Fusion Technology: Applications & Advantages

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology