In the ever-evolving landscape of manufacturing, technologies like *selective laser sintering* (SLS) have carved a niche for themselves by offering unparalleled precision and versatility. This innovative method of additive manufacturing, which utilizes polymer powder printing, is transforming industries by providing efficient solutions with high durability and design flexibility. At the forefront of this revolution is LS Hardware Tech Co., Ltd, a pioneering company specialized in manufacturing high-precision hardware and plastic parts with more than 20 years of experience.

SLS technology operates by employing a laser to sinter powdered polymer materials, effectively 'printing' components layer by layer from the ground up. This process not only allows for the creation of complex geometries that would be challenging to achieve with traditional manufacturing but also offers significant benefits in terms of customization and material efficiency. The laser sintering process ensures durable and reliable parts which add great value particularly in industrial 3D printing.

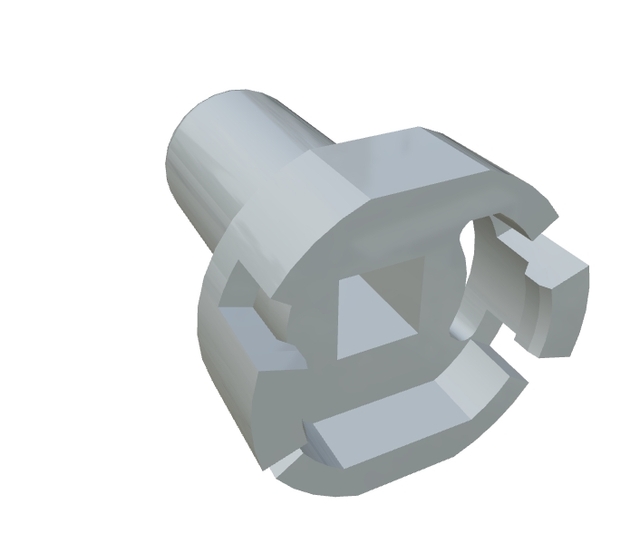

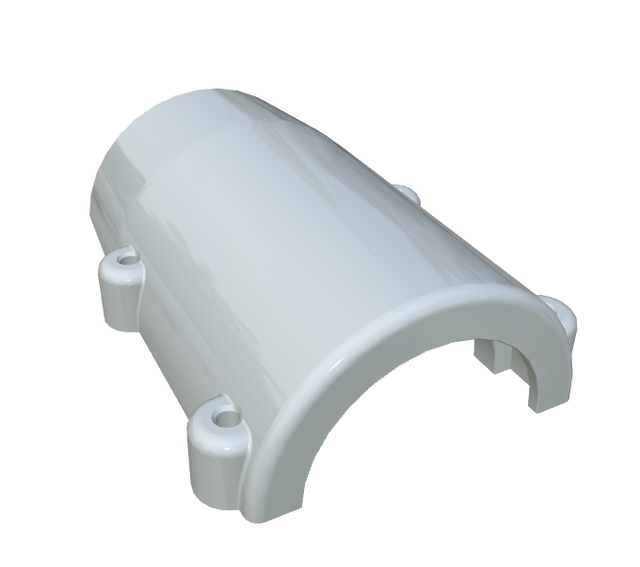

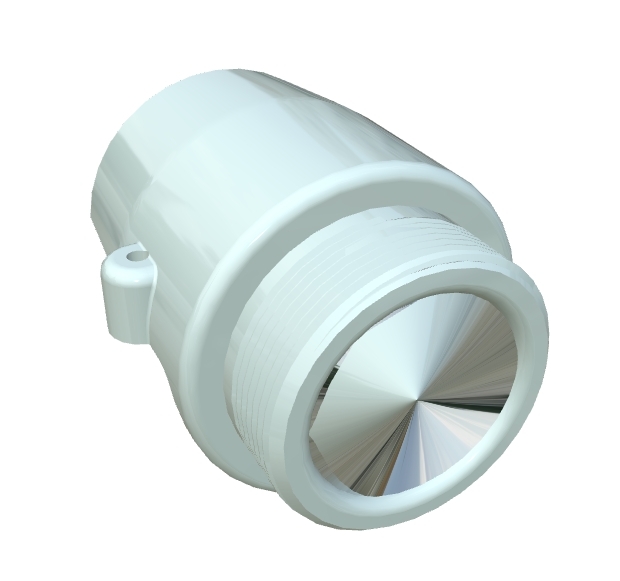

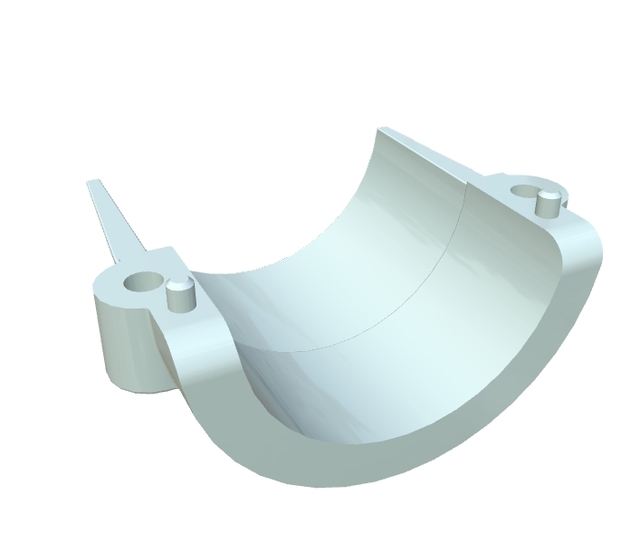

The applications of SLS are diverse, spanning industries including automotive, aerospace, medical devices, and consumer electronics. As a trusted partner to major factories around the world, LS Hardware Tech Co., Ltd leverages SLS for the production of high-quality parts, like their innovative pipe saddle. This sleek component is crafted with precision to support piping systems, designed for both aesthetic appeal and functional efficiency.

With a commitment to innovation, LS Hardware Tech Co. continues to revolutionize the manufacturing sector by pushing the boundaries of what is possible with products like the pipe saddle. Engineered from high-quality materials, it offers robustness and longevity, complete with a smooth, glossy finish that is resistant to environmental factors, making it suitable for both indoor and outdoor installations.

SLS applications manifest in the meticulous details of LS Hardware Tech Co.’s offerings. With pre-drilled mounting holes, the pipe saddle demonstrates how additively manufactured components can simplify installation processes while ensuring security and reliability. Whether applied in domestic projects or demanding industrial contexts, the integration of cutting-edge technology with sophisticated design exemplifies the forward-thinking ethos of the company.

Moreover, LS Hardware Tech Co. Ltd's dedication to quality and efficiency is supported by their ISO 9001:2015 certification, reflecting a steadfast commitment to maintaining rigorous standards across their manufacturing processes. With a global footprint extending to over 150 countries and regions, the company’s advanced machining centers—over 100 high-end units—demonstrate their capability in delivering large volumes of precision parts effectively, underscoring their position as a leader in the field of additive manufacturing.

As industries continue to evolve, embracing innovative solutions like SLS technology becomes imperative for staying ahead. LS Hardware Tech Co., Ltd exemplifies this mindset, focusing on delivering solutions that not only meet current demands but also anticipate future challenges. Their mission to empower clients by bringing creative ideas to life through innovative manufacturing solutions positions them as key players in the additive manufacturing arena.

In essence, *selective laser sintering* represents not just a technology but a gateway to smarter, more adaptable manufacturing. By embracing this approach, LS Hardware Tech Co., Ltd not only addresses current industry needs but sets the stage for what is to come, continually improving processes and broadening capabilities to meet the dynamic conditions of the modern market. Through the application of SLS technology, products like the versatile pipe saddle stand testament to the transformative potential of additive manufacturing, ensuring LS Hardware Tech Co. remains a name synonymous with excellence and innovation in the manufacturing world.

Selective Laser Sintering in Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.