In the ever-evolving world of industrial 3D printing, selective laser sintering (SLS) stands out as a groundbreaking technology offering unparalleled precision and efficiency. Utilizing high-powered lasers, SLS technology selectively fuses powdered materials, layer by layer, to create robust and complex shapes. This laser sintering process allows manufacturers to leverage the full potential of additive manufacturing, producing components that are both durable and intricately detailed. SLS technology has revolutionized industrial 3D printing, and its applications continue to expand across various industries.

One of the key advantages of selective laser sintering is its versatility in material usage. SLS materials primarily include polymers, such as nylon, which offer high strength-to-weight ratios and excellent thermal and chemical resistance. This makes them ideal for producing functional prototypes and end-use products, particularly in demanding environments where durability is paramount. The ability to create complex geometries without the need for support structures further enhances the appeal of SLS, allowing for more freedom in design and engineering.

At the forefront of harnessing the potential of SLS technology is LS Hardware Tech Co., Ltd. Founded by Mr. Nick Zhang, a seasoned expert with over 20 years of experience, LS has made a name for itself by providing innovative hardware and plastic parts solutions globally. The company's commitment to precision and quality is reflected in its state-of-the-art manufacturing facilities, which house over 100 high-end machining centers. These resources enable LS to produce high-precision parts for a wide range of industries, including automotive, medical devices, and aerospace, among others.

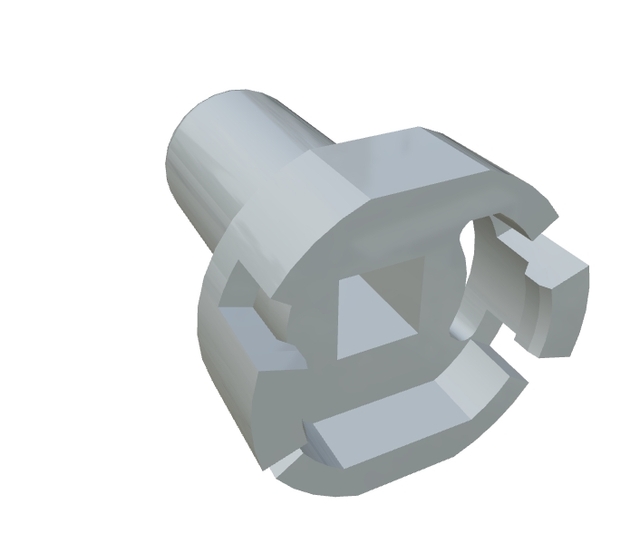

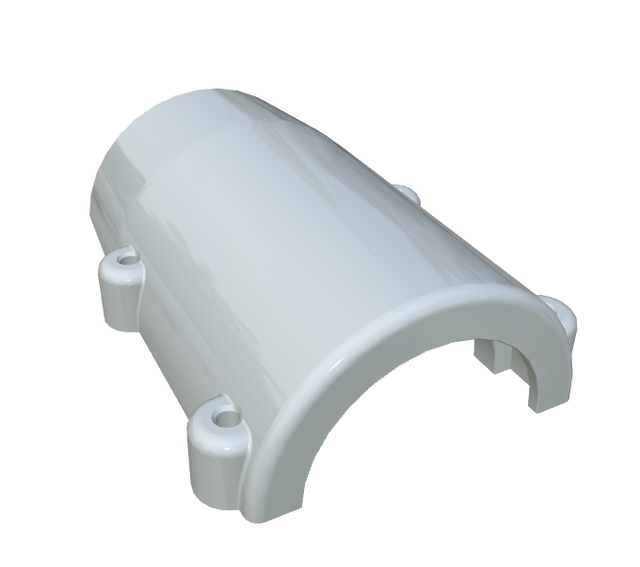

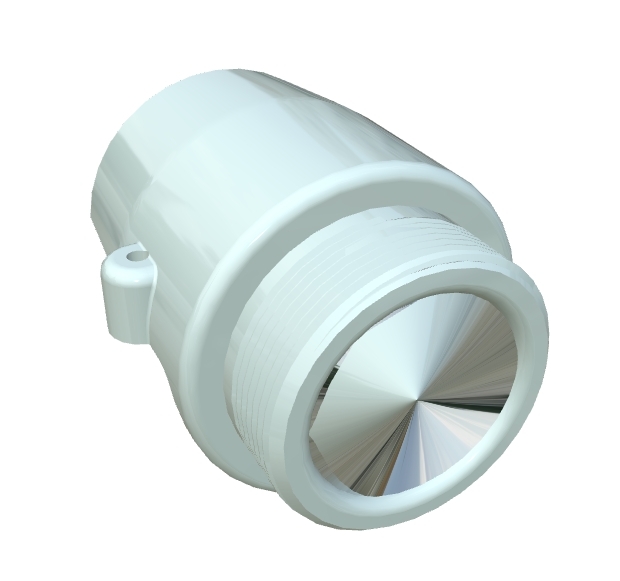

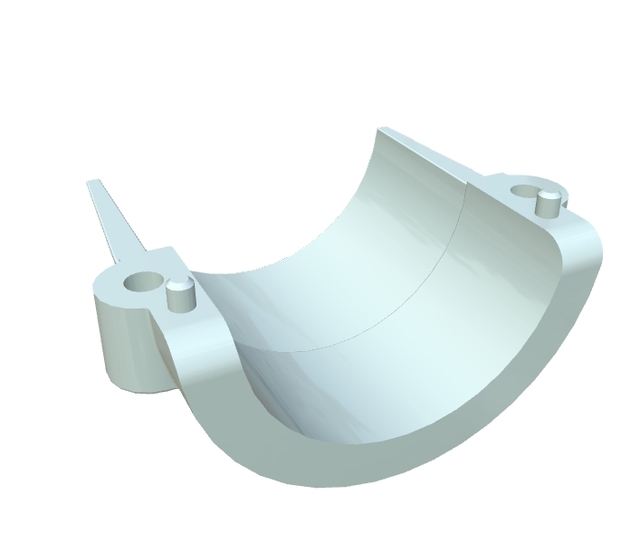

One of LS's recent innovations is a newly engineered ductwork component, meticulously crafted using selective laser sintering. Designed to revolutionize HVAC systems, this component boasts a sleek design that optimizes airflow efficiency and minimizes operational noise—critical factors in both residential and commercial settings. Constructed from high-quality, durable materials, the ductwork component guarantees long-term reliability and performance, standing testament to the robustness of SLS materials. Its precisely molded contours allow for maximum space utilization and facilitate easy installation, making it the ideal choice for modern construction projects.

Emphasizing the company's mission, LS strives to deliver innovative manufacturing solutions that bring clients' ideas to life, continuously improving processes to meet evolving customer needs. The benefits of selective laser sintering are perfectly aligned with LS's objectives, offering clients new possibilities in design that were previously unattainable with traditional manufacturing methods. As industry demands evolve, the adaptability of this laser sintering process ensures that LS remains at the cutting edge, ready to tackle the challenges of future innovations.

Selective laser sintering is transforming the landscape of industrial 3D printing by offering a unique combination of efficiency, flexibility, and quality. By enabling the creation of complex, durable parts without the typical constraints of conventional manufacturing, the laser sintering process opens up new realms of possibility for engineers and designers. Thanks to leaders like LS Hardware Tech Co., Ltd., businesses can harness this technology to create superior products that meet the exacting standards of today's markets. With LS’s steadfast commitment to quality and innovation, the future of SLS technology and additive manufacturing looks exceptionally bright. Manufacturers worldwide can look forward to a new era of creative freedom and operational excellence brought about by the continued development of polymer sintering technologies.

Selective Laser Sintering: Revolutionizing Industrial 3D Printing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

SLS Technology Advancements: Future, Safety, Applications

Selective Laser Sintering: Revolutionizing Industrial 3D Printing

Exploring the Impact of SLS Technology in Modern Manufacturing

Selective Laser Sintering: Revolutionizing Additive Manufacturing with SLS Technology

Exploring Selective Laser Sintering: Revolutionizing 3D Printing and Beyond

Selective Laser Sintering in Modern Manufacturing

Selective Laser Sintering: Revolutionizing Additive Manufacturing

The Innovations of Selective Laser Sintering Process