Selective laser sintering (SLS) has revolutionized the field of additive manufacturing, ushering in a new era of 3D printing capabilities that promise greater flexibility, speed, and quality. This advanced technology harnesses the power of laser sintering processes to create precise and durable parts for a wide range of applications. With the growing interest in SLS technology, it has become an essential part of industrial 3D printing, helping companies streamline production while maintaining the highest standards of quality.

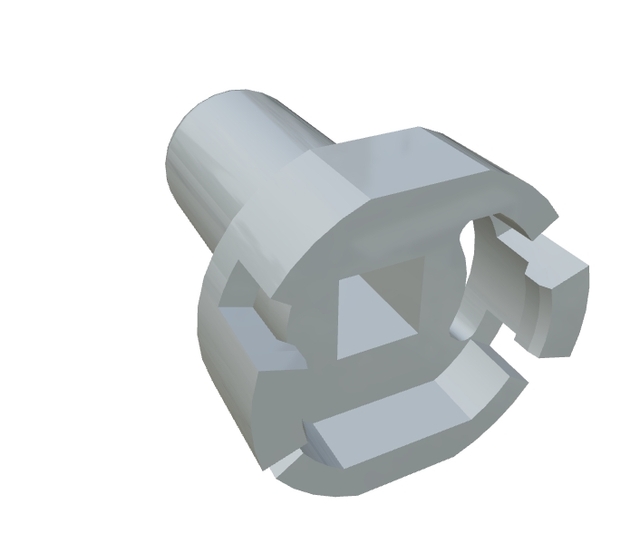

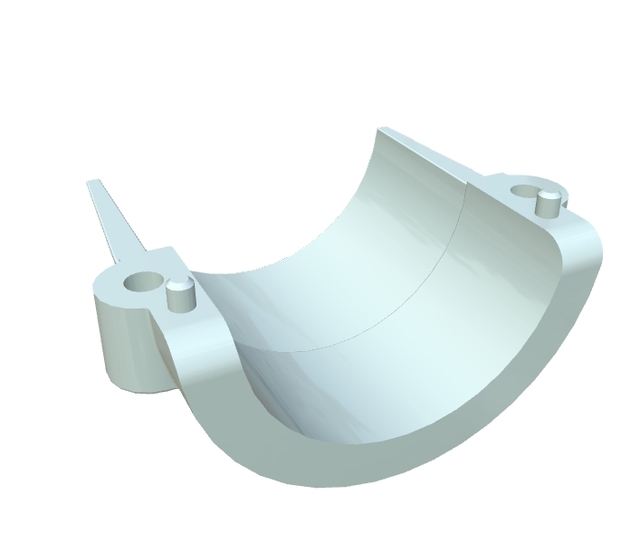

The process of selective laser sintering involves the use of a high-powered laser to sinter powdered materials, such as polymers, into solid structures. One of the critical advantages of SLS technology is its ability to create complex geometries that would be challenging or impossible with traditional manufacturing methods. The laser sintering process works by scanning a laser across a bed of powder, fusing particles together layer by layer until a complete object is formed. This method of polymer sintering is widely respected for its precision and cost-effectiveness, making it an attractive option for industries such as aerospace, automotive, medical devices, and consumer electronics.

LS Hardware Tech Co., Ltd has embraced this innovative shift towards additive manufacturing and has become a trusted provider in the field. Founded by Mr. Nick Zhang and his team of experienced engineers, the company has over 20 years of expertise in producing high-precision parts for a variety of industries. LS's factory, equipped with state-of-the-art machining centers, continually raises the bar in production efficiency and product quality. The company's ISO 9001:2015 certification speaks to its commitment to maintaining the highest standard across all facets of its operations.

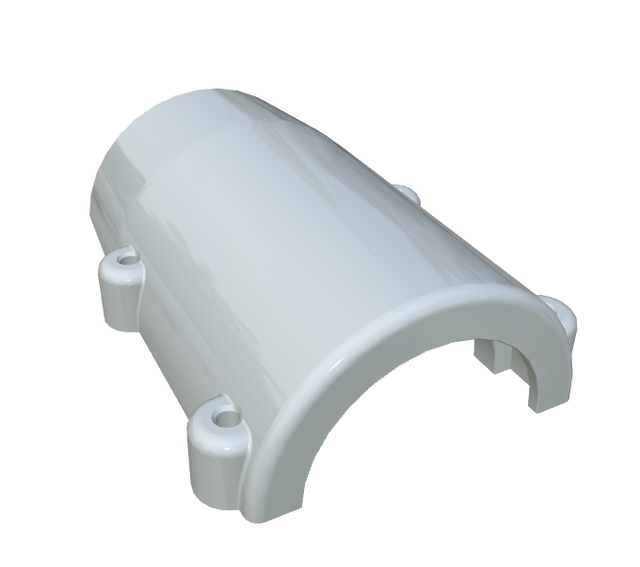

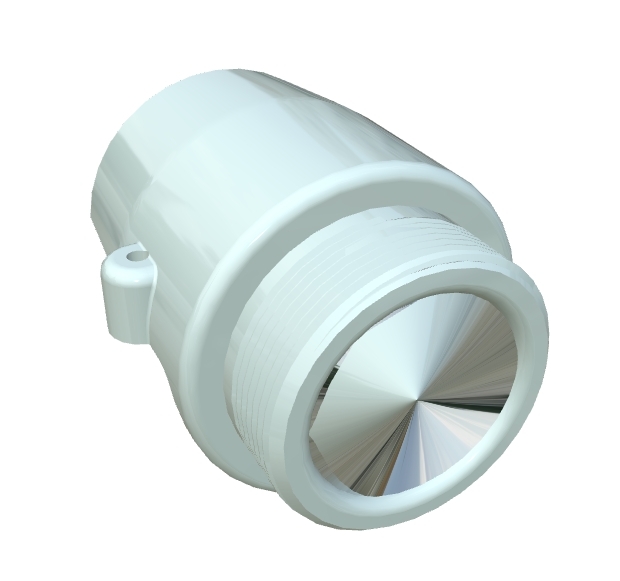

Among the groundbreaking products offered by LS Hardware Tech Co., Ltd is their new, sleek hose nozzle attachment designed to deliver optimal performance and versatility. This cylindrical-designed nozzle is crafted from durable materials, ensuring longevity and reliability for both professional and home applications. The elegant white finish enhances its aesthetic appeal, effortlessly integrating into any toolkit. The nozzle features a built-in fitting that allows secure attachment to varied hose sizes, effectively minimizing leakage and providing a reliable water flow, making it perfect for garden watering and vehicle washing.

The incorporation of SLS technology in the manufacturing processes at LS Hardware Tech Co., Ltd ensures that their products not only meet current market standards but exceed them. With refined laser sintering techniques, the company produces parts and attachments that offer unparalleled durability and functionality. This commitment to quality and innovation places LS at the forefront of technology, continually advancing its processes and capabilities to meet the evolving needs of the global market. This dedication to excellence is why LS Hardware Tech serves more than 150 countries, bringing innovative manufacturing solutions to empower clients worldwide.

Through the use of SLS technology and comprehensive manufacturing know-how, LS Hardware Tech Co., Ltd helps clients bring their unique ideas to life, supporting the production requirements from prototyping to mass production. As additive manufacturing continues to evolve, the company remains dedicated to improving the efficiency and quality of their processes, ensuring they remain a partner of choice for major industries in need of cutting-edge solutions. With selective laser sintering leading the way, LS Hardware Tech Co., Ltd not only shapes the future of manufacturing but also offers robust products like the versatile hose nozzle attachment, blending functionality with style to meet today's demands.

Selective Laser Sintering: Revolutionizing Additive Manufacturing with SLS Technology

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Selective Laser Sintering, Stereolithography, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.