The advent of the selective laser sintering process in the realm of manufacturing has ushered in a new era of innovation and efficiency. Often referred to as SLS 3D printing, this advanced technique utilizes laser sintering technology to produce parts and prototypes with unparalleled precision and detail. The process involves the use of high-powered lasers to fuse powdered materials, such as polymers or metals, layer by layer, into a cohesive and detailed structure. This technique has transformed the landscape of manufacturing, allowing for the efficient creation of complex geometries that would be difficult to achieve using traditional methods.

SLS manufacturing is at the heart of the innovations at LS Hardware Tech Co., Ltd. Founded by Mr. Nick Zhang alongside a team of seasoned engineers, LS has steadily risen to prominence in the global manufacturing sector. The company, with its deep expertise in hardware and plastic parts, leverages selective laser sintering to deliver products that meet demanding specifications for industries ranging from automotive and aerospace to medical devices and consumer electronics. Their state-of-the-art factory, equipped with over 100 high-end machining centers, is a testament to LS's commitment to pushing the boundaries in manufacturing technology.

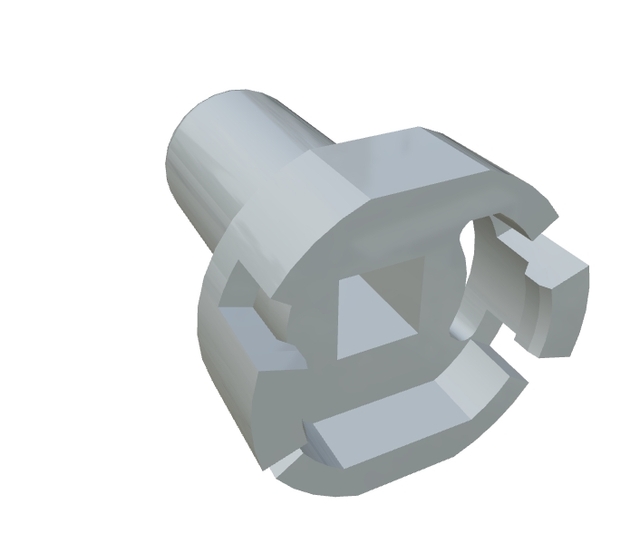

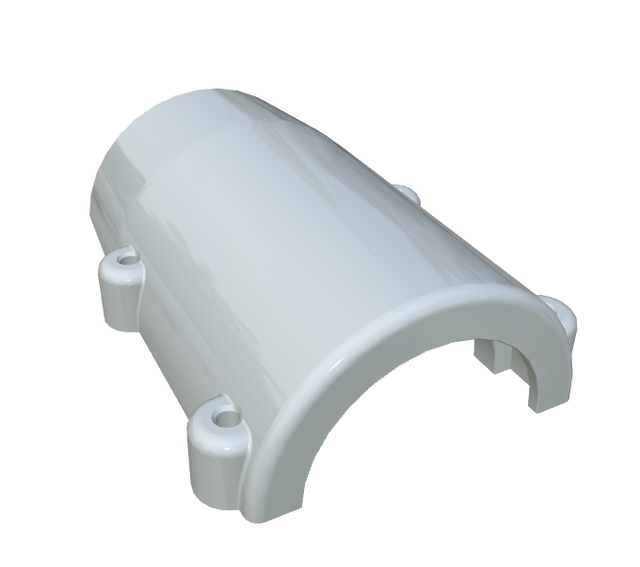

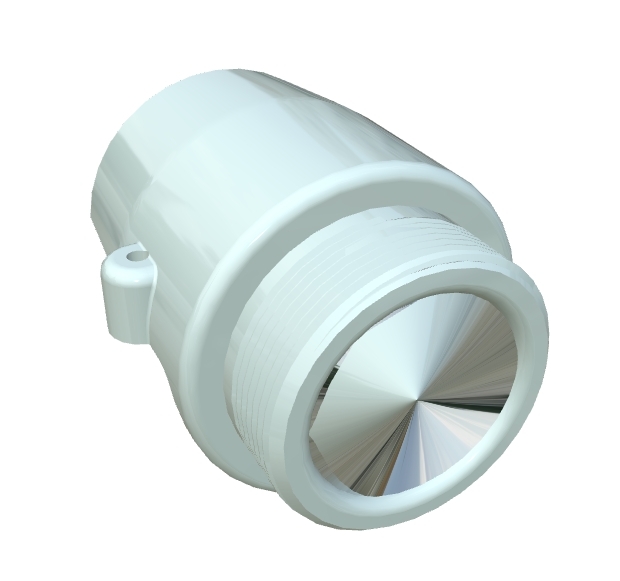

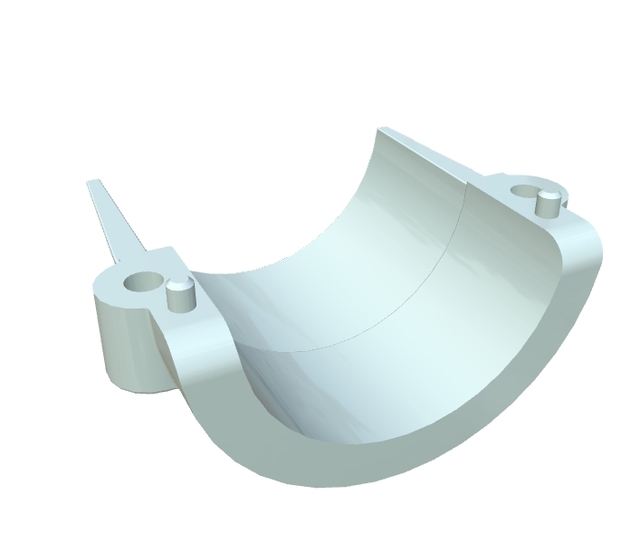

One of LS's standout offerings is their latest advancement in clamp design—a half-pipe bracket using selective laser sintering materials that reflect the sophistication and reliability inherent in laser sintering technology. The bracket is not just a piece of hardware; it's a culmination of years of innovation and expertise in SLS manufacturing. Crafted with high-strength materials, it boasts remarkable durability and support. The smooth, contoured profile of the bracket ensures minimal friction and wear, while the precision-engineered holes facilitate easy installation and secure fastening. Whether it's being utilized for industrial projects or home applications, the bracket exemplifies LS Hardware Tech's dedication to quality and innovation.

The applications of selective laser sintering are both diverse and growing. Selective laser sintering applications span across various sectors, enabling industries to rapidly prototype and produce end-use parts with minimal waste. In the field of polymer laser sintering, the flexibility of design and material customization stands out. Manufacturers can choose from a wide array of materials tailored to specific functional needs whether it's achieving high resistance to heat and chemicals or developing lightweight yet structurally sound components.

The same benefits are found in metal laser sintering, which is revolutionizing industries by offering a means to produce metal parts that are not only strong but also precisely shaped according to intricate design specifications. This versatility is invaluable, as it allows companies like LS Hardware Tech Co., Ltd, to respond adeptly to the specific needs of their diverse clientele, which include major factories across more than 150 countries.

As LS Hardware Tech steadily evolves, its mission remains clear—to empower clients worldwide with innovative manufacturing solutions. Being ISO 9001:2015 certified, LS assures its clients of the highest standards in quality and efficiency. Through the adoption and refinement of selective laser sintering processes, LS is at the forefront, transforming ideas into tangible, refined products that push boundaries and pave the way for future innovations in technology and design.

In conclusion, the selective laser sintering process is more than just a manufacturing method—it's a stepping stone to a world of possibilities. As LS Hardware Tech Co., Ltd continues to harness the power of SLS 3D printing, it sets a benchmark in the industry, ensuring that every product—like the half-pipe bracket—is not only a component but a testament to their cutting-edge approach and commitment to excellence. Through continual enhancement of their processes and capabilities, LS remains dedicated to meeting the evolving needs of their customers, establishing itself as a trusted leader on the global stage.

The Innovations of Selective Laser Sintering Process

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.