In the modern world of manufacturing, 3D printing has transformed the way we design, create, and innovate. As one of the most exciting developments within the technology and manufacturing sectors, 3D printing, also known as additive manufacturing, offers a plethora of new opportunities for precision and creativity. At the forefront of these advancements is LS Hardware Tech Co., Ltd., a company committed to pushing boundaries in the production of high-quality components.

Founded by Mr. Nick Zhang and a team of dedicated engineers, LS Hardware Tech Co., Ltd. has established itself as a leader in the field of manufacturing hardware and plastic parts. With over two decades of experience, LS Hardware Tech is renowned for providing world-class 3D printing services and innovative manufacturing solutions. Their state-of-the-art factory, equipped with more than 100 high-end machining centers, exemplifies their dedication to quality and high production efficiency. ISO 9001:2015 certification is a testament to their commitment to excellence, allowing them to serve as a trusted partner to industries across 150 countries.

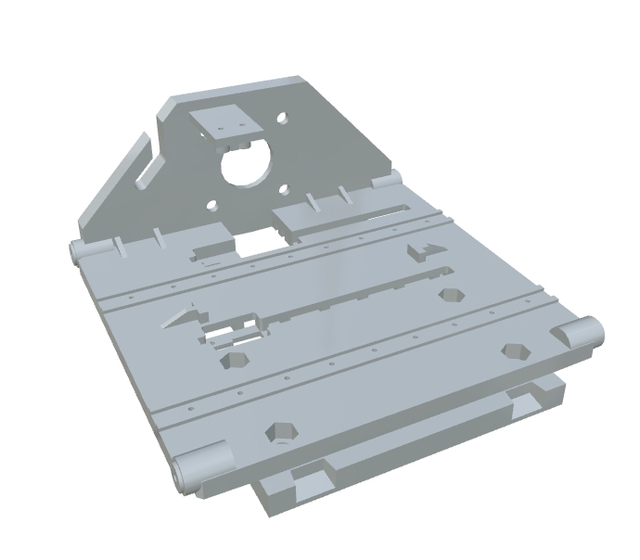

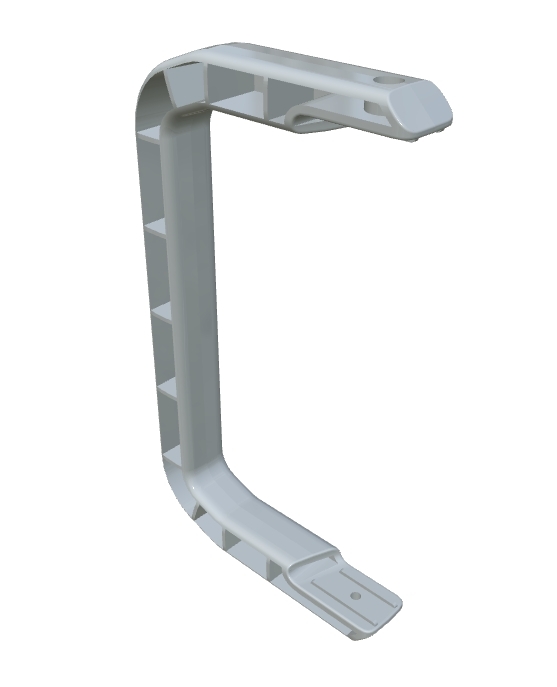

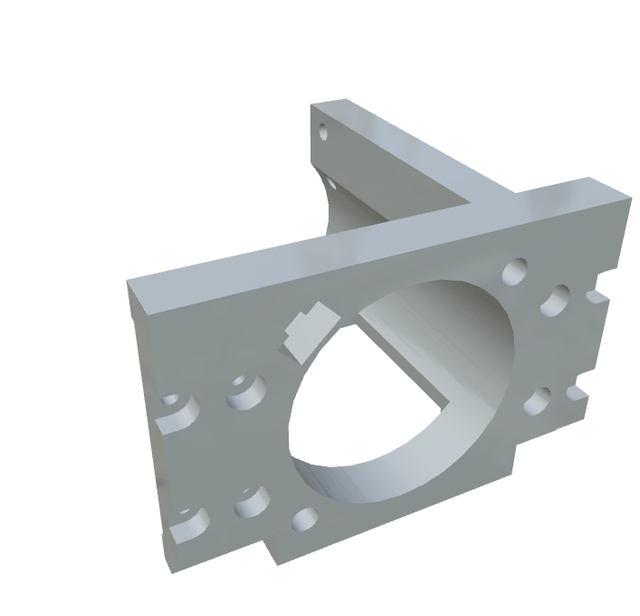

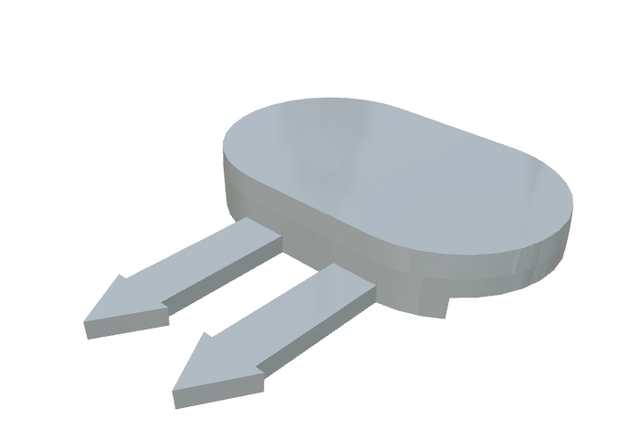

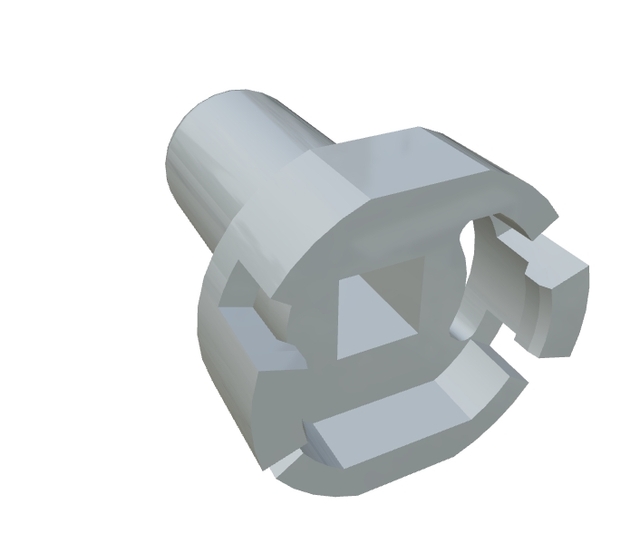

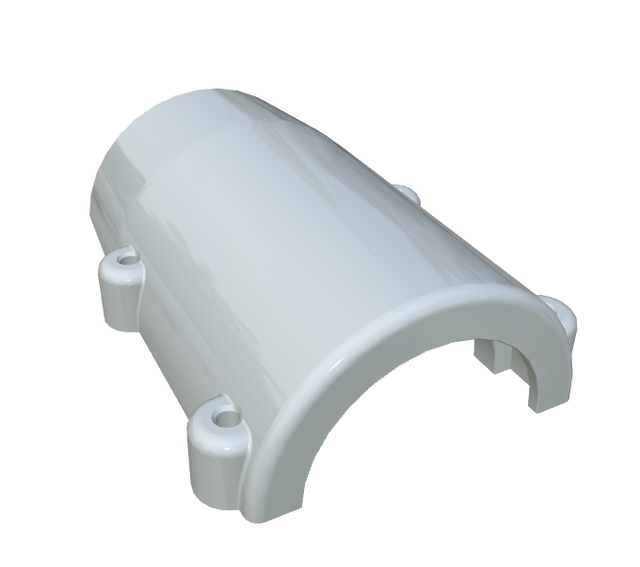

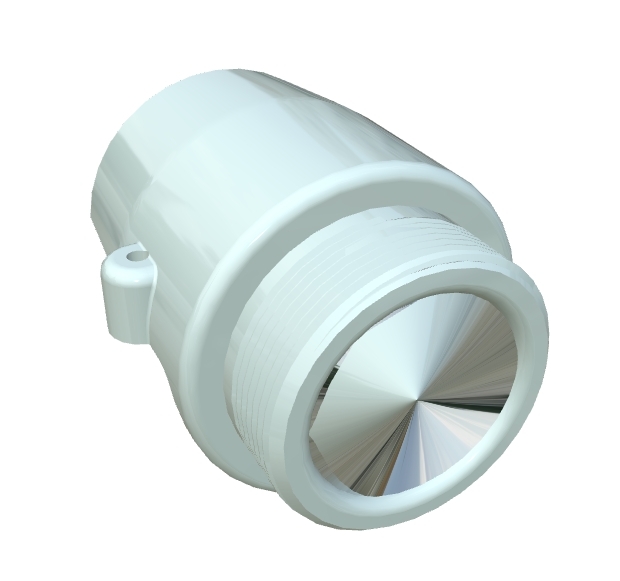

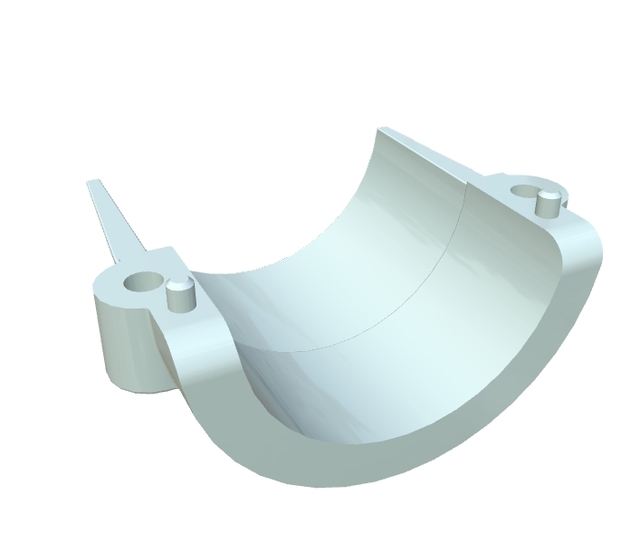

Among the groundbreaking products offered by LS Hardware Tech Co., Ltd. is the Revolutionary Locking Retainer Ring. Crafted with meticulous precision, this component redefines what is possible in mechanical assemblies. Its sleek, compact design is engineered for durability and precision, providing an innovative solution for secure fastening and alignment. The strategic placement of notches and anchoring points ensures maximum stability and ease of installation, making the Locking Retainer Ring ideal for applications in automotive, aerospace, and industrial machinery sectors.

3D printing technology has made it possible to design and produce complex geometries that were previously unimaginable. LS Hardware Tech Co., Ltd. utilizes cutting-edge 3D printing software to enhance the functionality and reduce the weight of products such as the Locking Retainer Ring. This software enables detailed 3D printing design which streamlines the production process and offers superior adaptability.

The versatility of 3D printing materials plays a crucial role in the success of products across different industries. LS Hardware Tech carefully selects high-quality materials to ensure that the Locking Retainer Ring meets the stringent requirements of advanced engineering projects. The company’s proficiency in this area is indicative of their full range of services, from prototyping to mass production, offering customers solutions tailored to their specific needs.

For industries such as aerospace and automotive, where weight and functionality are critical, 3D printing applications provide innovative ways to meet ever-evolving challenges. LS Hardware Tech Co., Ltd.'s Locking Retainer Ring is a prime example of how additive manufacturing fosters innovation by allowing for the integration of robust construction with a streamlined design. This enables engineers to optimize functionality without compromising on strength or efficiency.

Furthermore, the application of 3D printing is not confined to large-scale industries. Its adaptability makes it suitable for smaller-scale projects where customization and flexibility are required. This capability aligns perfectly with LS Hardware Tech Co., Ltd.'s mission statement - to deliver manufacturing solutions that empower clients to bring their ideas to life. Their continuous innovation and improvement in processes and capabilities ensure that they remain at the forefront of technology, meeting the diverse needs of their global clientele.

In conclusion, 3D printing stands as a revolutionary force in modern manufacturing, and companies like LS Hardware Tech Co., Ltd. are paving the way with groundbreaking solutions like the Locking Retainer Ring. By integrating additive manufacturing within their production processes, they provide high-precision, high-quality components that drive innovation across multiple industries. As the demand for advanced engineering and manufacturing solutions continues to grow, LS Hardware Tech Co., Ltd.'s dedication to quality and innovation positions them as a leader capable of meeting these challenges with finesse and expertise.

3D Printing Innovations: Transforming Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.