In today's rapidly evolving tech landscape, 3D printing technology stands at the forefront of innovation, transforming industries by offering unparalleled customization, rapid prototyping, and efficient manufacturing solutions. Entwined with the promise of revolutionizing production cycles, 3D printing technology is not merely a manufacturing tool but a beacon for creativity and entrepreneurial ingenuity.

At the heart of additive manufacturing, 3D printing technology opens a paradigm wherein traditional manufacturing constraints are surpassed. Looking at 3D printing applications, its power is evident across diverse sectors from healthcare to aerospace, each benefitting from the precision and adaptability that 3D print services provide. Companies are leveraging 3D modeling and printing to innovate product designs, reduce time to market, and offer bespoke solutions tailored to customer specifications.

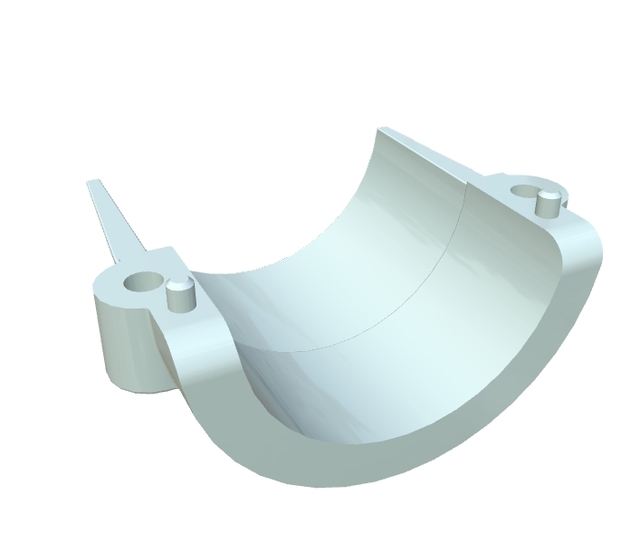

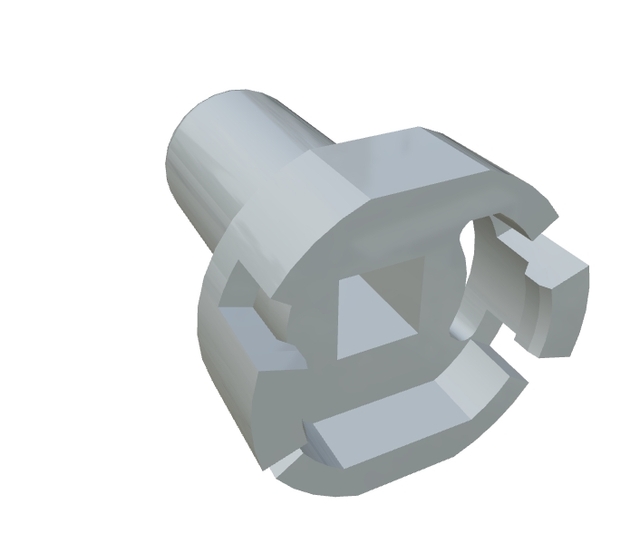

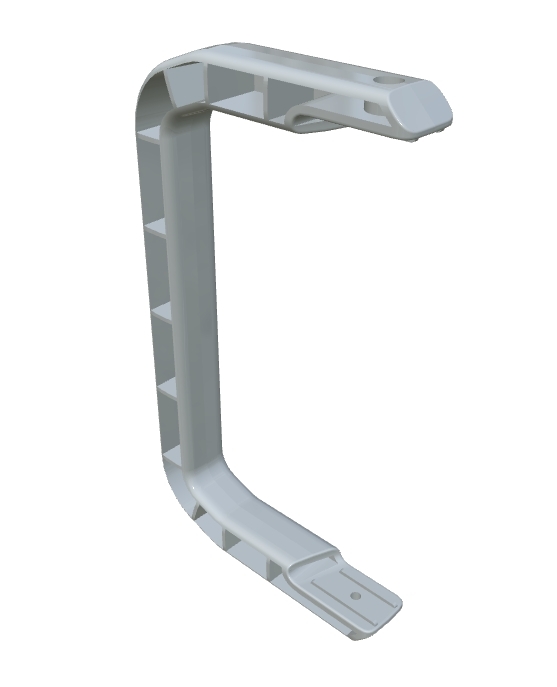

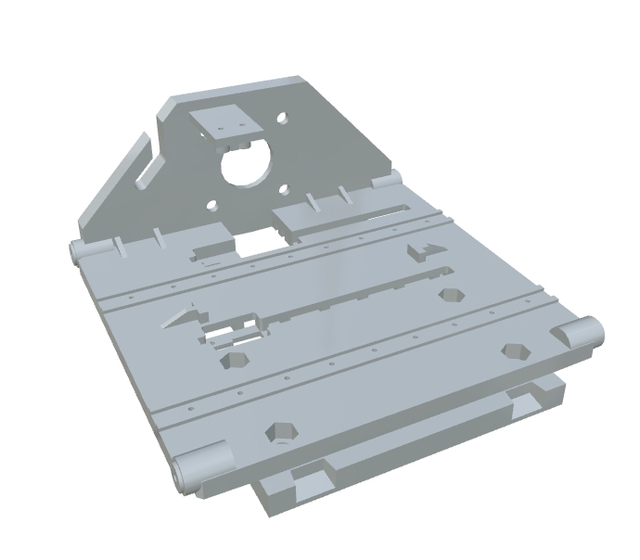

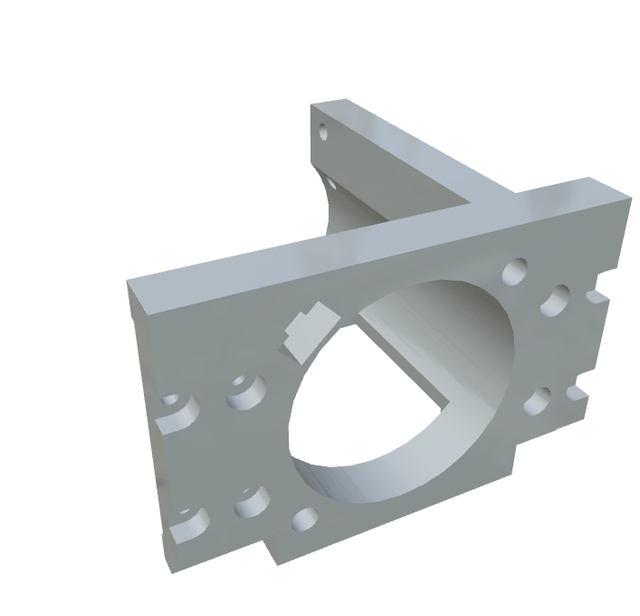

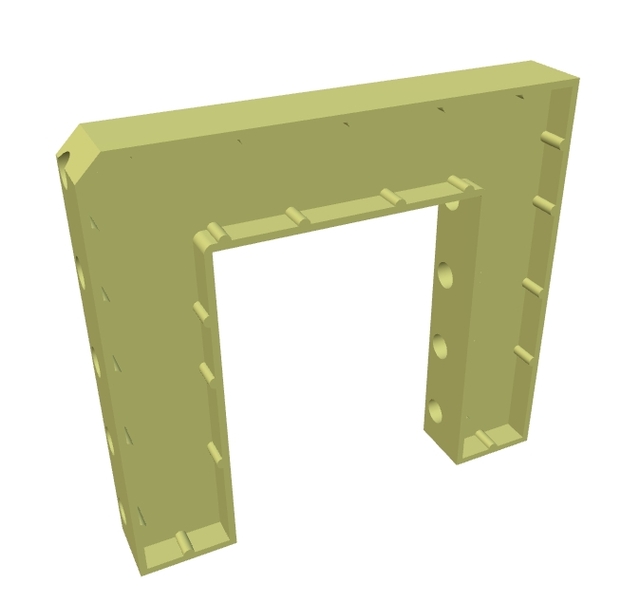

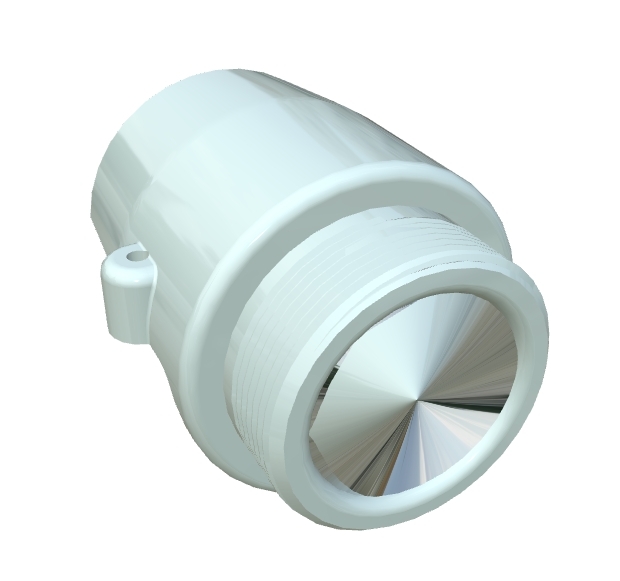

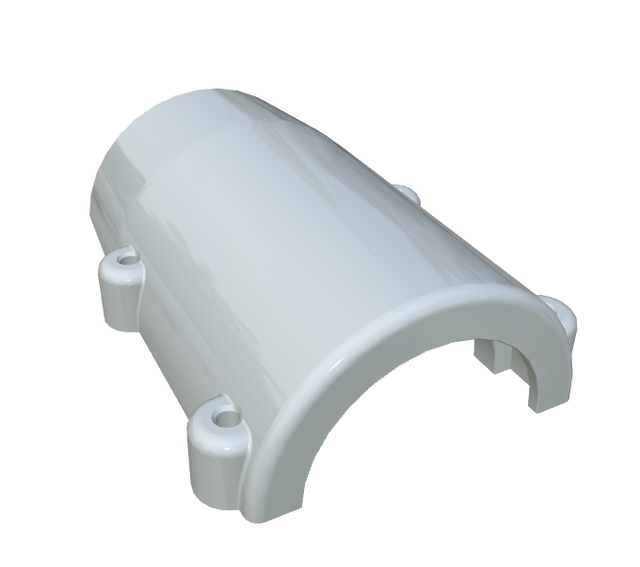

Amongst the plethora of products born from this technology, LS Hardware Tech Co., Ltd introduces its groundbreaking component: the dynamic multi-functional fastener. This exceptional product epitomizes the advantages brought by 3D printing. It is engineered for superior precision and performance, utilizing an intricate design that combines slots and recesses for optimal torque distribution. Crafted from durable materials, this fastener withstands a range of environmental stresses, making it ideal for industrial applications and consumer products alike. Its robust yet elegant design guarantees not only efficiency and practicality but also adds a modern touch to any mechanical assembly.

LS Hardware Tech Co., Ltd has emerged as a leader in the hardware manufacturing segment. Founded by Mr. Nick Zhang, whose more than 20 years of industry experience have established him as a seasoned expert, LS specializes in producing high-precision parts catered to various sectors, including automotive and medical devices. With an array of over 100 high-end machining centers, the company ensures superior production efficiency and product quality. Serving over 5,000 clients globally, the business extends its reach across more than 150 countries, evidencing the trust and reliability that their partners place in them.

The introduction of the dynamic multi-functional fastener marks a milestone in innovative manufacturing solutions. It aligns seamlessly with LS Hardware Tech Co.'s mission to empower clients, turning creative ideas into tangible realities. By sustaining a commitment to staying at the technological forefront, LS enhances its processes and capabilities to adapt to customers' evolving needs, be it for prototypes or mass production.

When delving into the versatility of 3D printing materials, it's clear they play a pivotal role in the flexibility of 3D printing for prototyping and production. From metals to plastics, each material can be fine-tuned to suit specific mechanical properties, further expanding the scope of 3D printing applications. The innovations integrated into the dynamic multi-functional fastener exemplify how these materials contribute to creating products that exceed conventional designs in terms of functionality and resilience.

In healthcare, 3D printing has emerged as a game-changer, paving the way for personalized medical solutions and customized implants. This symbiotic relationship between technology and medicine demystifies complex healthcare needs, offering efficient, patient-specific treatments and thus underscoring the potential that 3D printing in healthcare holds.

Overall, 3D printing technology is reshaping industries by fostering customizability, accelerating the innovation timeline, and reducing production waste. Its vast range of applications across various industries not only enhances operational efficiencies but also spurs creative exploration and development. LS Hardware Tech Co., Ltd, with its commitment to delivering high-quality, innovative manufacturing solutions, remains steadfastly aligned with the core values of 3D printing technology: precision, adaptability, and continuous improvement in meeting customer needs in our ever-changing global landscape.

As the world leans further into high-tech solutions, the role of robust, innovative companies like LS becomes increasingly significant in leading the charge of technological advancements. In embracing the potent capabilities of 3D printing technology, LS Hardware Tech Co. Ltd propels itself and its clientele into a transformative future defined by ingenuity and excellence.

3D Printing Technology: Transforming Industries & Innovation

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | 3D Printing Services, Stereolithography, Selective Laser Sintering, Fused Deposition Modeling, Multi Jet Fusion |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Revolutionizing Manufacturing with Multi Jet Fusion Technology

Exploring Multi Jet Fusion Technology in Modern Manufacturing

Exploring Multi Jet Fusion Technology: Applications & Benefits

Advancements in Multi Jet Fusion Technology Transform Manufacturing

Multi Jet Fusion Technology: Advancements in 3D Printing and Its Industrial Applications

Revolutionizing Design with Multi Jet Fusion Technology

Multi Jet Fusion Technology: Revolutionizing 3D Printing Solutions

Exploring Multi Jet Fusion Technology: Applications & Advantages

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology

Fused Deposition Modeling: Revolutionizing 3D Printing with FDM Technology