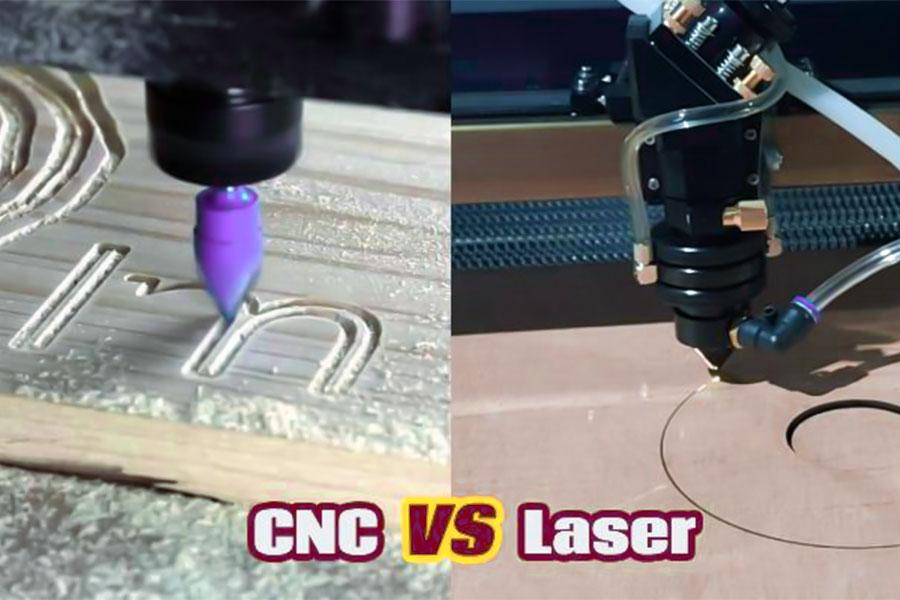

In the wood processing industry, CNC cutting and laser cutting are two mainstream cutting technologies, each of which occupies an important position with its unique characteristics. The working principles of the two are very different, and the advantages they show are also different, and the applicable scenarios are even more different. For wood processing practitioners, a clear understanding of the difference between CNC cutting and laser cutting plays a decisive role in deciding which cutting method to use, which is directly related to processing efficiency, product quality and cost control. Next, this article will unravel the specific differences between CNC cutting and laser cutting in wood processing applications, and help practitioners make more accurate technical choices.

What Fundamental Principles Separate CNC and Laser Wood Cutting?

In the field of wood cutting, CNC (computer numerical control) and laser cutting are two completely different technologies that achieve material processing based on different physical principles. The following is a detailed overview of the differences in the basic principles of CNC and laser wood cutting:

1. Differences in the principle of action

CNC cutting

Based on the principle of mechanical cutting, a carbide cutter (e.g. milling cutter) rotating at high speed (18,000 RPM) comes into contact with the wood and peels off the fibers with shear force to separate the material, with a depth of cut of 5 - 20 mm, depending on the material and the material.

Laser cutting

Using the principle of thermal gasification, the CO₂ laser beam (wavelength 10.6 μm, power 80 - 150 W) focuses on the wood, causing the local temperature to rise sharply to 300 - 800 °C, pyrolysis, gasification and even combustion of the wood components to form a cutting channel.

2. Differences in processing methods

CNC cutting

It is a contact machining, the tool relies on physical force to destroy the wood structure, resulting in chips, and it is necessary to change the tool and clean the chips regularly to ensure the continuity and accuracy of processing.

Laser cutting

Non-contact, the laser beam is applied to the wood by air or assist gas, without physical contact and chips, but with smoke and carbonization residue.

3. Material response differences

CNC cutting

The chips are in the form of bands or fragments, 0.1 - 0.3 mm thick, the processed surface is rough and sanded, there is no heat affected zone, and the wood structure is well maintained.

Laser cutting

With a 0.5 - 1mm carbonization layer on the cutting edge and a 1 - 2mm heat-affected zone around the edge, the wood may be discolored and weakened. Thin plates are cut with high precision, and thick plates are inefficient and easy to delamination.

4. Differences in applicable scenarios

CNC cutting

It is suitable for thick plate, solid wood and three-dimensional surface processing, such as furniture structural parts and carving, and has strong adaptability to material thickness and hardness, but the processing speed is limited by tool life and feed rate.

Laser cutting

It is suitable for thin plates, precision patterns, and low-deformation demand scenarios, such as veneer parquet and model making, with fast cutting, high precision, and sensitive to material thickness and moisture content.

5. Cost vs. efficiency differences

CNC cutting

The equipment cost of 10-500,000 yuan is low, the tool loss and labor cost are high, and it is suitable for small batch and multi-variety production.

Laser cutting

The equipment cost is 50 to 2 million yuan, and the processing efficiency and automation degree are high, which is suitable for large-volume and high-precision production.

How Do Cutting Tolerances Compare in Fine Woodworking?

In the field of fine woodworking, cutting tolerance is the core indicator for measuring processing accuracy, which directly affects the assembly performance and aesthetics of the product. The following systematically compares the tolerance control capabilities of CNC and laser cutting from three dimensions: positioning accuracy, edge quality, and dimensional consistency, combining the technical characteristics of CNC and laser cutting.

1. Positioning accuracy

CNC cutting

The three-dimensional positioning accuracy of CNC cutting can reach ±0.1mm, and the ideal state can reach ±0.05mm according to ISO standards, which is suitable for complex structures such as mortise and tenon joints and engraving. However, tool wear can affect the positioning and thus the cutting tolerance.

Laser cutting

Plane positioning accuracy up to ±0.08mm, beam positioning as low as ±0.03mm. Thermal deformation is easy to cause the cutting edge to shift, and optimization processes such as short focal length lenses are often used to reduce the interference of thermal effects on positioning accuracy.

2. Edge quality

CNC cutting

The cutting allowance is 0.1 - 0.3 mm, no heat affected zone, and the surface roughness is Ra 3.2 - 6.3 μm, and the material structure is stable and the utilization rate is high.

Laser cutting

The cutting edge has a 0.3 - 0.8mm carbonization layer and needs to be sanded twice. Edge verticality fluctuates between 89.5° and 90.5°, affecting assembly accuracy.

3. Dimensional consistency

CNC cutting

The dimensional deviation of batch processing ≤± 0.15mm, the moisture content of the wood (8 - 12% is preferable) and the wear of the tool affect the dimensional consistency, and the equipment needs to be calibrated regularly.

Laser cutting

The dimensional deviation ≤± 0.1mm, and the thermal deformation has a great impact on the thin plate, especially when the moisture content of the wood is higher than 12%, it is easy to destroy the dimensional consistency.

4. Applicable Scenarios

CNC Advantages

It is good at dealing with three-dimensional complex structures, with high material utilization rate and low secondary processing cost, which is suitable for furniture manufacturing, wood carving handicrafts and other fields.

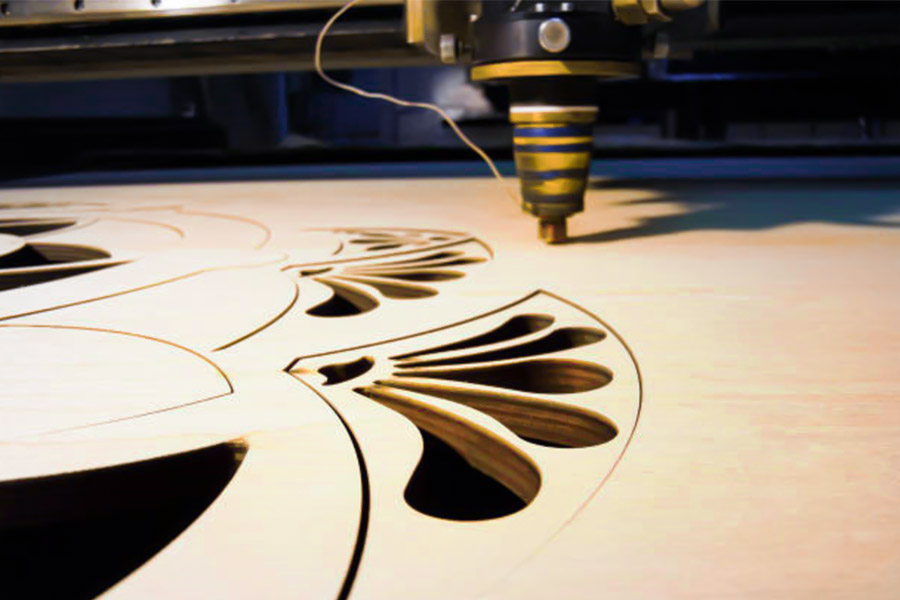

Laser advantages

It has high plane accuracy, efficient cutting of thin plates, and good edge verticality, which is suitable for scenarios such as fine veneer parquet and high-precision model making.

Which Wood Types Demand Strict Technology Selection?

In joinery, specific processing techniques are required for the different characteristics of the wood in order to achieve the desired results. Here are the key points for processing several common special woods:

Wood processing with a high resin content (e.g. pine, spruce)

This type of wood is prone to resin volatilization and knife sticking problems during processing. When laser cutting, it must be equipped with a Class IV fire protection system to prevent fires caused by resin volatiles. In the case of CNC equipment, it is necessary to continuously clean the chips with compressed air and choose a special tool with a Teflon coating to effectively prevent the resin from sticking.

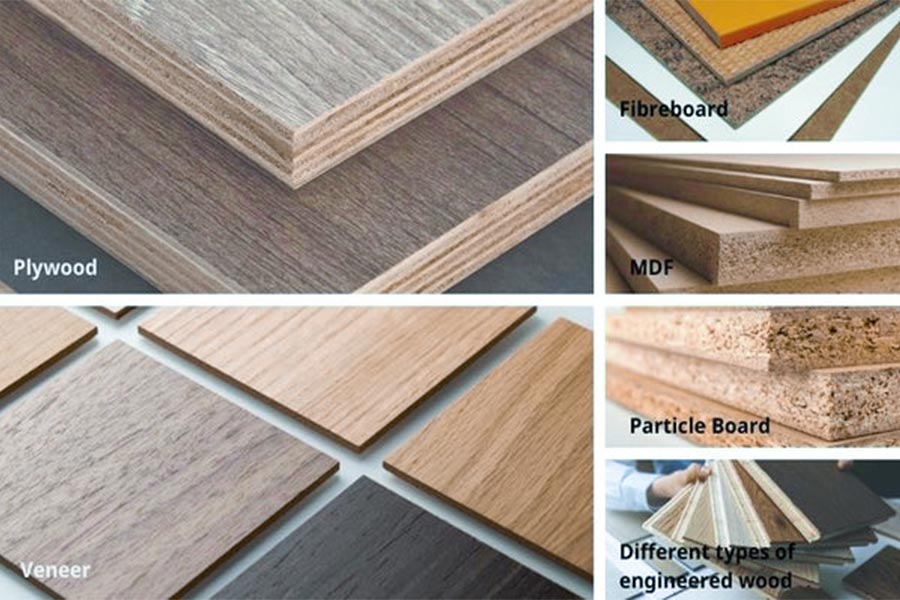

Key points of processing of man-made panels (e.g. MDF, OSB panels)

Due to the presence of formaldehyde adhesives, these materials are subject to a risk of dust explosion during processing. Laser cutting is recommended to be used in conjunction with a water-cooled cutting table and an activated carbon filtration device, which can significantly reduce formaldehyde emissions. CNC machining requires ATEX compliance and the installation of an efficient dust collection system to ensure that the dust concentration in the working area is controlled below 30 g/m³.

Techniques for processing high-density hardwoods (e.g. teak, oak)

This type of wood has high hardness and strict requirements for processing equipment. Tungsten carbide-coated special knives should be selected for CNC cutting, and the spiral knife process of "low speed and large feed" should be used to prolong the service life of the tools. Laser cutting requires more than 150 watts of high-power equipment with assist gases such as oxygen, but it should be noted that secondary treatment may be required to remove the carbide layer after cutting.

Processing of wood with special composition (e.g. mahogany, camphor)

This type of wood contains natural oils or aromatic substances and is susceptible to oxidation and discoloration during processing. Laser cutting is recommended to be carried out in a nitrogen-protected environment, which can effectively prevent oxidation of the material. CNC machining needs to be carried out in a confined space and equipped with a professional gas purification system to reduce the diffusion of irritating gases.

Core principles of technology selection

When choosing a processing technology, the following factors need to be taken into account:

- Characteristics of the wood itself (resin content, density, special composition, etc.)

- Specific requirements for machining accuracy

- Productivity and cost control

- Safety standards for the working environment

Through the scientific selection of processing technology, it can not only ensure product quality, but also ensure production safety and achieve the best processing effect. In practice, it is recommended to conduct a sample test first and confirm the process parameters before mass production.

How Does Production Speed Vary by Thickness?

Selection of processing technology for different thickness plates

Sheet processing (thickness less than 6mm)

Laser cutting process performance:

The cutting speed advantage is significant, and materials such as oak can reach up to 3 m/min

Pay attention to the follow-up processing time, as the removal of scorch marks will increase the man-hours by 10-20%.

It is suitable for large-scale standardized production

CNC machining process features:

The processing speed is relatively slow, about 0.8 m/min

The machining accuracy is higher and the surface quality is better

Suitable for small batches of high-precision products

Thick plate processing (thickness over 25 mm)

It can be molded in one step

The tool overhang ratio is 1:5 and still maintains good accuracy

The material is adaptable and suitable for a variety of materials

Multi-layer scanning is required, which reduces efficiency

The cost of high-power equipment (above 500W) has skyrocketed

Cutting depth and heat-affected zone issues affect quality

What Hidden Costs Impact Profit Margins?

Hidden costs are hidden in business operations but have a significant impact, affecting profit margins at all times:

- Equipment loss and maintenance: wear and tear of laser cutting machine lenses and CNC machine tools, regular maintenance costs of equipment, frequent occurrence, difficulty in accurate accounting, and erosion of profit margins.

- Downtime and tool change: equipment failure or tool change leads to production interruption, idle manpower, missed sales opportunities, and cuts profits even though they are not reflected in the financial statements.

- Quality loss: equipment and process problems make the product substandard, causing returns, compensation, rework, scrapping, and eating up profit margins.

- Energy consumption accessories: laser cutting nitrogen, CNC machining coolant, etc. continue to consume, the cost is small, and the long-term accumulation of the cost is high.

- Manpower training: Employee training increases costs in the short term, and employee turnover and new employee recruitment and training expenses also pose a hidden burden.

- Management and administration: Decision-making deviations, unreasonable processes, and poor communication increase operating costs, hinder efficient operations, and affect profit margins.

- Time opportunities: Equipment failures, production delays waste time, missed sales opportunities, and undermine profitability.

How Do Surface Finishes Affect Product Value?

The surface finish affects the value of the product in many ways:

- Enhance aesthetics: Smooth surfaces are visually appealing, giving products a sense of high quality, stimulating consumers' desire to buy and increasing market value.

- Optimized performance: It can reduce the coefficient of friction, prolong the product life, reduce energy consumption, and enhance the practical value and competitiveness.

- Convenient cleaning and maintenance: stains are difficult to adhere, cleaning and maintenance are easier, reducing costs and difficulty, especially suitable for products with frequent cleaning or harsh environments.

- Safety: For food contact materials, smooth surfaces reduce the growth of bacteria, meet hygiene standards, and protect health.

- Enhance the coating effect: It is conducive to the uniform adhesion of the coating, giving full play to the functions of anti-corrosion and decoration, and improving the protection and appearance texture.

- Balance cost-effectiveness: Although improving the finish will increase the cost, the high price and market recognition can compensate for it, and the benefits can be balanced.

Which Safety Standards Are Non-Negotiable?

In industrial production, these safety standards cannot be compromised:

(1) The iron law of laser system safety

- Interlocking safety door fast response: The safety gate response time is less than 50ms, which can instantly prevent personnel from accidentally coming into contact with the laser beam.

- Accurate monitoring of CO concentration: When the CO concentration in the work area exceeds 50ppm, the laser system automatically shuts down to prevent harmful gases from endangering personnel.

(2) Safety guidelines for CNC workshops

- Dust collection system with strong dust collection: Each equipment is equipped with a dust collection system with an air volume of more than 1000CFM to effectively collect dust and reduce hazards.

- Robust and reliable tool crushing protection: The test pressure of the guard is greater than 50kPa, which blocks the splashing of debris and ensures the safety of personnel.

What is the difference between CNC and laser cutting wood?

Here is a table on the differences between CNC wood cutting and laser wood cutting:

| CNC wood cutting | Laser wood cutting | |

|---|---|---|

| Cutting principle | Physical cutting with a twist cutter or similar tool | A high-power-density laser beam is used to irradiate the wood, causing the wood to partially vaporize, burn, and blow away the slag |

| Cutting accuracy | High, affected by tool wear and equipment accuracy | High, affected by laser beam focusing and positioning accuracy |

| Cutting speed | Medium to high speed, depending on the knife, wood and cutting parameters | High speeds, especially when the laser power is high |

| Cutting surface quality | The surface finish is high, but there may be knife marks | The surface finish is good, the cutting line is narrow, but there may be pigmentation or carbonization |

| Material adaptability | It is suitable for a wide range of woods, including solid wood, wood-based panels, etc | It is suitable for a variety of woods, but there are certain requirements for the moisture content and density of wood |

| Cutting thickness | Thicker timber can be cut, depending on the tool and equipment capacity | The cutting thickness is affected by the laser power and the density of the wood, and is generally slightly thinner than CNC cutting |

| cost | The cost of the equipment is higher, but the cost of tool wear is lower, which is suitable for high-volume production | The equipment cost is also higher, but it does not require tools and is suitable for small batches and customized production |

| Operation & Maintenance | Professional training and regular maintenance of knives and equipment are required | Professional training and regular maintenance of laser equipment are required, and attention to laser safety is required |

| Eco-friendliness | Wood chips are generated during the cutting process and need to be collected and disposed of | Smoke and odors may be generated during the cutting process and a smoke collection system is required |

| flexibility | Low, it takes time to change tools and set up new programs | High, the cutting path and parameters can be quickly adjusted by software |

How to Choose Based on Business Scale?

When choosing between laser cutting and CNC machining, the size of production is a critical consideration. The following are suggestions for the selection of corresponding processes based on the scale of different enterprises:

Low-volume customization (less than 100 pieces per month):

Laser cutting is often the preferred choice for low-volume customization. The advantages are significant: First, there is no need to change tools or fixtures frequently. The laser cutting machine only needs to quickly adjust the cutting path and parameters in the software, which can meet various design needs, which greatly saves the time and energy spent on changing tools and fixtures. Second, the design is extremely easy to switch. With the high flexibility and high precision of laser cutting, it can quickly switch between different designs, which is perfectly adapted to the diverse and changing design requirements of low-volume customization business. However, it should be noted that the laser cutting process is prone to thermal deformation of the workpiece due to thermal effects. Therefore, when arranging production, enterprises should reserve a certain percentage (such as 10%) of the scrap rate to make up for the possible adverse effects of thermal deformation.

High-volume production scenarios (more than 5,000 pieces per month):

Entering the high-volume production stage, CNC machining has full advantages in terms of economy. As production scales up, CNC machining can achieve significant reductions in overall costs (around 40% in practice) by finely optimizing process parameters and maximizing production efficiency. In order to further improve production efficiency and reduce labor costs, it is inevitable to invest in an automatic tool change system in the mass production mode. For CNC machining equipment, an automatic tool change system with more than 16 tool positions can greatly reduce the tool change time, keep the equipment running efficiently, and further reduce costs, helping enterprises to achieve higher profits in large-scale production.

Summary

CNC and laser cut wood each have their own unique advantages and application scenarios. CNC technology is better suited for 3D machining, thick material handling, and projects that require multiple process combinations, while laser cutting excels in fine 2D patterns, complex cut-out designs, and thin material machining. From an economic point of view, CNC operating costs are relatively low but the initial investment may be high, while laser systems are more flexible in small batch diversification.

When selecting the right technology, a combination of material properties, product design requirements, production volumes, budget constraints, and environmental factors should be considered. As technology advances, the boundaries between the two technologies are blurring, and hybrid systems offer more possibilities for the future of wood processing. For professional users, it is possible to have both systems together for maximum production flexibility; For beginners or users on a budget, the choice should be based on the main product needs.

Regardless of the technology chosen, mastering the correct operating methods and optimizing the processing parameters is the key to achieving a high-quality finished product. It is advisable to conduct a full technical evaluation and sample testing prior to actual commissioning to ensure that the selected technology meets specific production needs and quality standards.

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What is the basic principle of CNC cutting wood and laser cutting wood?

CNC cutting wood is a pre-programmed program that controls a high-speed rotating cutter to cut wood along a specific path. This cutting method is similar to traditional mechanical cutting, but with a higher degree of precision and automation. Laser cutting wood uses a high power density laser beam to irradiate the surface of the wood, so that the wood heats up and vaporizes rapidly, and at the same time, the air flow is used to blow the melted wood away to form a cutting joint.

2. What is the difference in accuracy between CNC cut wood and laser cut wood?

The precision of CNC cutting wood is usually high, depending on the precision of the equipment and the quality of the knives. Since CNC cutting uses the method of physical cutting, its accuracy is affected by various factors such as tool wear, vibration, etc. The precision of laser cutting wood is also very high, mainly depending on the focusing and positioning accuracy of the laser beam. The accuracy of laser cutting is usually not affected by factors such as material hardness and thickness, so laser cutting is more advantageous in some occasions that require extremely high precision.

3. What is the difference in cutting speed between CNC cut wood and laser cut wood?

CNC cutting wood is usually medium to high speed, depending on the tool, the type of wood, and the cutting parameters. In some cases, the cutting speed may be reduced due to the effects of knife wear or wood hardness. Laser cutting wood, on the other hand, is very fast, especially when the laser power is high, and the cutting task can be completed quickly. Therefore, laser cutting is more advantageous in situations where large quantities of wood need to be cut quickly.

4. What is the difference between CNC cut wood and laser cut wood in terms of cutting surface quality?

CNC-cut wood has a higher surface finish, but may leave knife marks or minor blemishes. These imperfections can usually be eliminated by subsequent treatments such as sanding, polishing. The surface finish of laser-cut wood is also very good, with narrow and uniform cutting lines, but there may be pigmentation or carbonization. These phenomena can often be mitigated or avoided by adjusting the laser parameters or employing special processes.

Resource