Laser cuttingis an advanced material processing technology that uses a high-power, high-energy-density laser beam to precisely cut materials. This technology is not only widely used in various industrial manufacturing fields, but has also gradually penetrated into the practical activities of education, small businesses, and individual enthusiasts. This article aims to elaborate on the operating principles, significant features, diverse application areas, and manyadvantages of laser cutting.

What Is Laser Cutting?

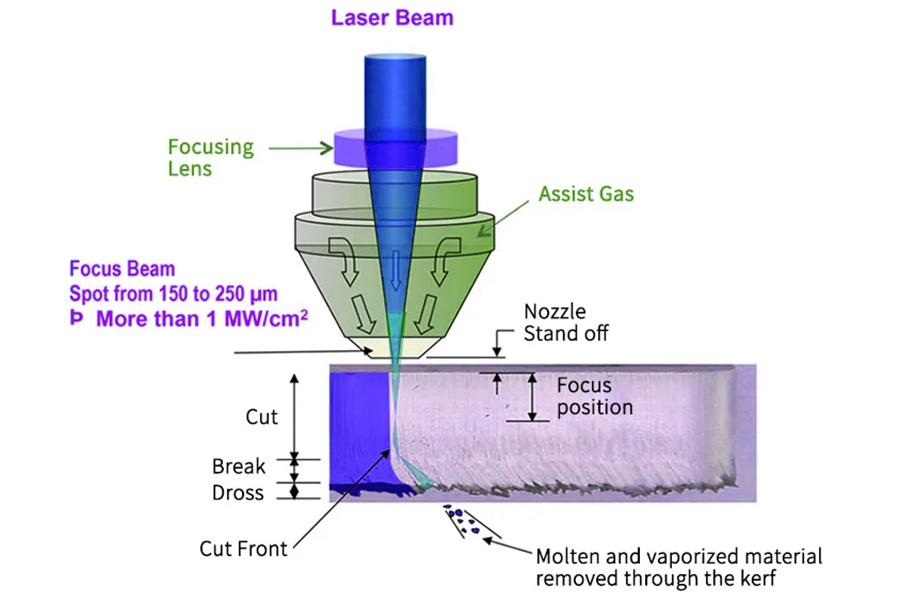

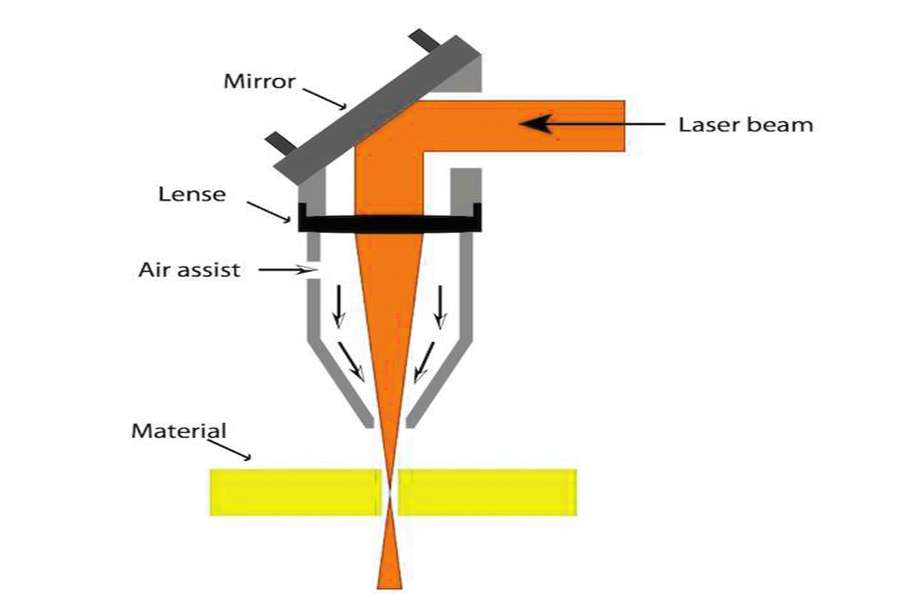

Laser cutting is a high-precision, non-contact material processing technologythat uses a high-energy-density laser beam as a "cutting tool" and accurately controls the movement path of the laser through a computer program, so that the laser beam is focused on the surface or inside of the material, generating high temperatures to quickly melt, vaporize, evaporate or reach the ignition point of the material, and at the same time, auxiliary gases (such as oxygen, nitrogen, argon, etc.) are used to blow away the melted or vaporized material, thereby achieving the purpose of cutting. This technology can process a variety of materials including metals (such as stainless steel, aluminum alloys, titanium alloys), non-metals (such as wood, plastics, glass, ceramics), etc., and has the advantages of fast speed, high precision, good edge quality, high degree of automation, and high material utilization.

How Does Laser Cutting Work?

Theprocess of a laser cutting machineusually includes a series of orderly and detailed steps. The following is its process:

| Process | Description |

| Start-up preparation | First, turn on the power supply, check and ensure that all parts of the equipment are normal, including the cooling system, gas system, etc. |

| Material preparation and parameter setting | Place the material to be cut on the cutting table, enter the corresponding cutting parameters such as laser power, speed, etc. on the operation interface according to the material type and cutting requirements, and import the cutting graphics. |

| Focus and positioning | Adjust the focal position of the laser beam to ensure that the laser can accurately focus on the material and determine the starting point of cutting. |

| Start cutting | Start the laser and machine tool, and cut according to the preset graphics and parameters. |

| Monitoring and adjustment | During the cutting process, the operator needs to pay close attention to the cutting situation and adjust the cutting parameters according to the actual situation if necessary. |

| Cutting completion and shutdown | After the cutting is completed, check the product quality and then shut down the equipment in the correct order. |

| Maintenance and care |

Clean, inspect and maintain the equipment regularly to ensure that the equipment is in good condition. Maintenance results after points redemption speech surprise tuna join hot pot but join the guild good condition Ruyi check post need him scold too much to replace as soon as possible. |

What Are the Different Types of Laser Cutting Techniques?

Thetypes of laser cuttingare mainly classified according to the material removal method and characteristics during thecutting process. The following are the main types:

CO2 laser cutting

In CO2 laser cutting, laser amplification occurs via CO2 gas discharge. CO2 lasers are one of the earliest and most popular types of lasers. The gas discharge is not exclusively CO2. It contains CO2, nitrogen, hydrogen, xenon, and helium.

There are two options for C02 laser cutting: using oxygen or nitrogen. Oxygen is preferred when laser cutting thicker materials. Nitrogen is preferred when laser cutting thin sheets. C02 laser cutting with oxygen forms an oxide layer on the cut surface. To avoid this, pre-treatment processes such as sandblasting are required on the workpiece.

Fiber laser cutting

Fiber laser cutting uses optical fibers for light amplification, rather than traditional gas discharges. Light from a laser diode travels through the fiber. The resulting beam is strong enough to melt stainless steel up to 1 cm thick.

The beam is usually accompanied by a powerful gas flow system. The gas flow pushes the molten material away, allowing for a clean cut. The fibers of these lasers utilize a variety of elements such as ytterbium, neodymium, erbium, and dysprosium.

Nd:YAG laser cutting

Nd:YAG (neodymium: yttrium aluminum garnet) laser is a solid-state laser whose active material is yttrium aluminum garnet crystal (YAG crystal) doped with a small amount of neodymium (Nd). This laser can produce pulsed or continuous lasers, emitting infrared light of a specific wavelength, usually 1064nm.

The laser source is focused by a lens in the cutting head to a spot size of a few tenths of a millimeter and melts the material, usually metal. A coaxial gas flow "blows" the melt downward, forming a cut in the process.

Excimer laser cutting

Use excimer laser to precisely cut materials. The laser beam is controlled by a computer, and the energy of laser photons is used to open the chemical bonds of tissue molecules, gasifying the tissue to achieve cutting effect.

Direct diode laser cutting

Based on the stimulated radiation effect of semiconductor materials. In semiconductor materials, when electrons jump from high energy levels to low energy levels, energy is released, which is emitted in the form of photons.

Laser diodes use specific structural design and doping processes to repeatedly amplify and enhance these photons inside the semiconductor, ultimately forming a beam of high-brightness, high-coherence laser.

What are some common laser cutting materials?

Laser cutting technologyis widely used in industrial production for processing a variety of materials due to its high precision, high speed and strong flexibility. The following are some common laser cutting materials:

1.Metal

(1)Aluminium

- Characteristics:light weight, corrosion resistance, easy processing and molding, and has good electrical and thermal conductivity.

- Application:Widely used in construction, transportation, packaging, electronics and other fields, aluminum cladding materials are often used to make doors and windows, furniture, decorative materials, etc.

(2)Steel

- Characteristics:high strength, good toughness, wear resistance, and good weldability and processability.

- Application:Widely used in automobiles, construction, machinery and other fields, steel cladding materials are often used to make structural parts, connectors, etc.

(3)Stainless steel

- Characteristics:Excellent corrosion and high temperature resistance, and easy to clean and maintain.

- Application:Widely used in medical, food, chemical and other fields, stainless steel cladding materials are often used to make medical equipment, tableware, containers, etc.

(4)Copper

- Characteristics:It has good electrical and thermal conductivity, and has certain antibacterial properties.

- Application:Widely used in electrical, construction, plumbing and other fields, copper cladding materials are often used to make wires and cables, pipes, etc.

(5)Titanium alloy

- Characteristics:high strength, low density, good corrosion resistance, and good biocompatibility.

- Application:Widely used in aerospace, medical and other fields, titanium alloy coating materials are often used in the production of aircraft engine parts, medical equipment, etc.

2. Non-metallic materials

- Plastics:Laser cutting can cut various types of plastics, such as polyester, polypropylene, polyethylene, polyurethane, polystyrene, etc. However, it is important to note that some plastics, such as polyvinyl chloride PVC, may emit toxic fumes during the cutting process, which can be harmful to the operator and the laser cutter itself, so laser cutting of such materials should be avoided.

- Wood:Laser cutting can cut various types of hardwoods and softwoods, such as oak, elm, maple, pine, etc. However, due to the flammability of wood and the average laser cutting effect, the use of laser cutting wood is relatively rare in practical applications.

- Rubber and leather:These materials absorb laser light and can be processed by laser cutting.

- Paper and cardboard:Laser cutting usually leaves no marks on these materials, so they are often used to make labels, packaging, and more.

- Ceramic:For some types of man-made or decorative ceramics, laser cutting is also feasible.

What Are the Advantages of Laser Cutting?

Compared with traditional mechanical cutting methods, laser cutting machines have the following advantages:

1. Fast cutting speed:Laser cutting machines use a high power density laser beam, which is able to cut out extremely thin thick materials in a very short time, compared to traditional mechanical cutting methods that take longer.

2. High cutting accuracy:The precision of the laser cutting machine is very high, which can achieve very precise cutting size and edge quality. Traditional mechanical cutting methods are less accurate, and cutting deviations and burrs may occur.

3. Wide range of cutting materials:Laser cutting machines can cut all kinds of metallic and non-metallic materials, including carbon steel, stainless steel, aluminum alloy, plastic, etc. Traditional mechanical cutting methods can only cut some harder materials, such as steel plates and cast iron.

4. Environmental protection and energy saving:The laser cutting machine has low energy consumption, does not produce smoke and harmful gases, and is an environmentally friendly and energy-saving cutting method. However, traditional mechanical cutting methods have high energy consumption and produce a large amount of smoke and harmful gases.

5. Can cut complex shapes:The laser cutting machine can cut all kinds of complex shapes, such as three-dimensional parts, special-shaped parts, etc. Traditional mechanical cutting methods can only cut conventionally shaped objects.

FAQs

1.What is meant by laser cutting?

Laser cutting is a technology that uses a high-powered laser beam to cut through materials. It usually directs the laser output through an optical device, and uses a laser optical system and a CNC system to guide the material or the laser beam. During the cutting process, the laser beam is focused and aimed at the material, causing the material to melt, burn, evaporate or be blown away by a gas jet, leaving an edge with a high-quality surface finish.

2.What is laser cutting metal?

Laser cutting of metal refers to the process of cutting metal materials using a laser beam. The laser cutting system uses a high-power laser beam to locally heat the metal target material to the melting point or evaporation point, thereby achieving fast and precise cutting. This cutting method has the advantages of high precision, high efficiency, non-contact and strong applicability, and is widely used in manufacturing, aerospace and other fields.

3.What are the benefits of laser cutting?

The benefits of laser cutting mainly include: ① High precision: The laser cutting machine can achieve very precise cutting, with a minimum cutting width of several millimeters, meeting the needs of high-precision and fine cutting. ② Non-contact cutting: During the laser cutting process, the laser beam is directly irradiated on the workpiece without physical contact. ③ Complex shape cutting ability: The laser cutting machine can cut various complex shapes of workpieces, including curves, circles, and sharp angles, by controlling the path and intensity of the laser beam. ④ High efficiency: The laser cutting machine has a fast cutting speed and high processing speed. The high energy density of the laser beam can quickly heat and melt the workpiece, thereby achieving rapid cutting. ⑤ Strong applicability: Laser cutting technology can be applied to a variety of materials, including metals, non-metals, etc.

4.What is laser machining used for?

Laser processing has a wide range of uses, mainly including: ① Drilling: Laser can be used to drill precise small holes in materials, such as μm-level holes on circuit boards. ② Marking and cutting: Laser can be used for a variety of processing methods such as marking and cutting, suitable for precise processing of various materials. ③ Line ablation (removal of coating): Laser can be used to accurately remove coatings without damaging or slightly damaging the base material. ④ Surface structuring: Laser can change the physical properties of the material surface, such as creating a hydrophobic or hydrophilic surface. ⑤ Engraving and molding: Laser can be used for three-dimensional processing methods such as engraving and molding, suitable for making products of various complex shapes.

Summary

As an efficient, precise, flexible and environmentally friendly material processing technology, laser cutting is constantly expanding its application areas and playing an increasingly important role in industrial production. With the continuous advancement of technology, the future of laser cutting will be broader and brighter.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.