In the field of laser processing, etching and engraving are two core technologies that are often used for surface treatment of materials such as metals, glass, and plastics. Although both rely on the high energy of the laser beam to achieve material modification, there are significant differences in their working principles, processing depth, surface effects, and application scenarios. This article will systematically analyze the core differences between the two from the dimensions of technical principles, processing characteristics, material adaptability, and typical applications.

What is Laser Etching?

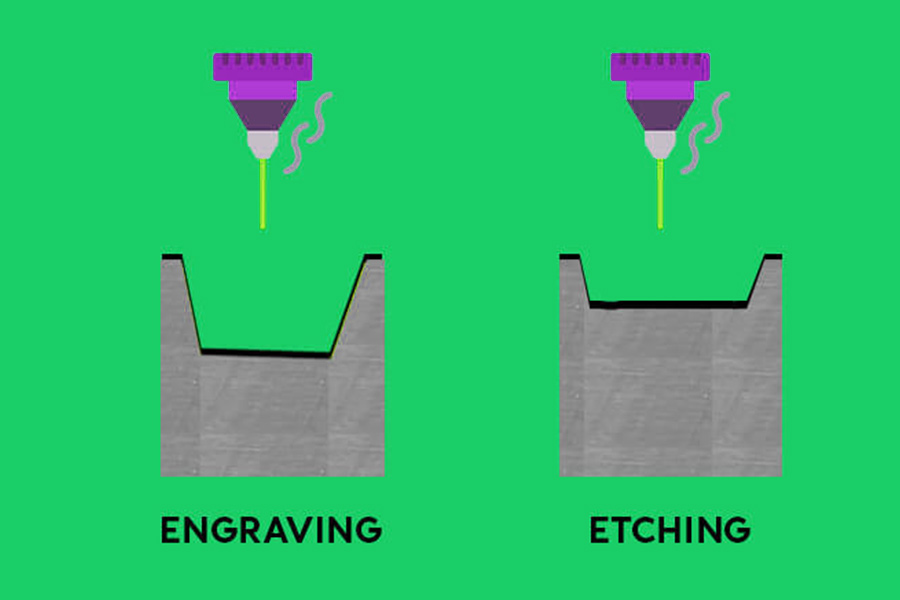

Laser Etching is a surface treatment technology that uses a high-energy laser beam to locally heat the surface of a material to physically or chemically modify it, thereby forming a permanent mark, pattern or texture. Its core principle is to melt, oxidize, phase change or microstructure change the surface material through the interaction between the laser and the material, forming a contrast difference visible to the naked eye.

What are the advantages and disadvantages of laser etching?

Analysis of the advantages and disadvantages of laser etching

Advantages

High precision and micron-level resolution

Laser etching can achieve a line width accuracy of 10~50 μm, and can mark micro QR codes or precision scales in scenarios such as chip packaging and medical devices, meeting stringent standards such as ISO 13485.

Surface integrity maintenance

Only a shallow modification (molten oxidation) of <0.1 mm is caused, and the mechanical properties of the substrate material are almost unaffected, which is suitable for scenarios that are sensitive to structural strength, such as aerospace aluminum alloy parts.

Non-contact processing

No tool wear problems, deformation-free processing can be achieved for flexible materials (such as silicone and thin film circuits), and the yield rate can reach more than 99.5%.

High-speed processing capability

Ultrafast lasers with a pulse frequency of 100~500 kHz can complete high-contrast marking on stainless steel surfaces at a speed of 2000 mm/s, and the production efficiency is significantly higher than traditional silk screen printing.

Wide material adaptability

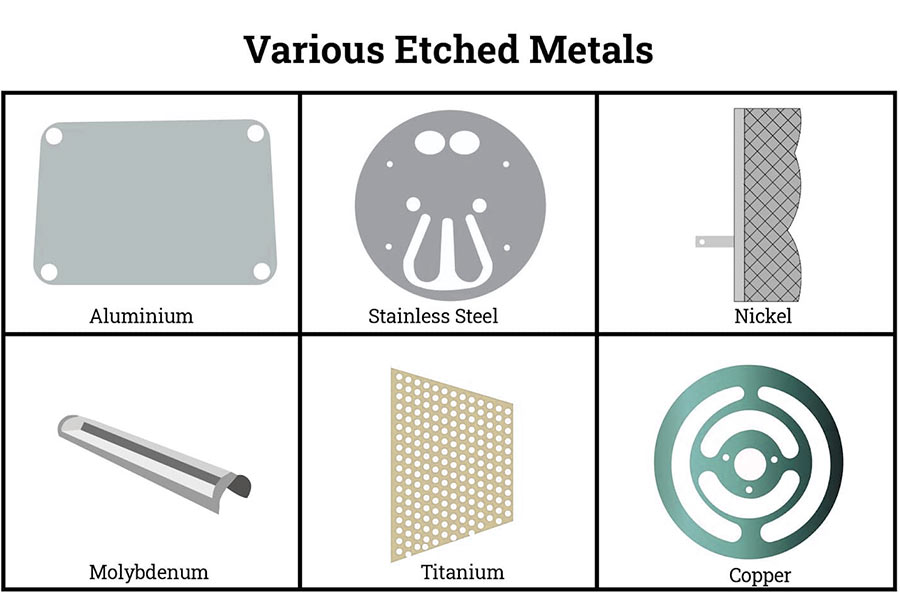

By adjusting the wavelength (such as 355 nm UV laser processing glass) and pulse parameters, metals, ceramics, plastics and even biocompatible materials (such as PEEK) can be processed.

Disadvantages

Depth limitation

The maximum etching depth is usually ≤0.3 mm, which cannot meet the needs of deep relief or functional grooves (such as sealing ring groove processing).

Contrast depends on materials

On non-oxidizing materials (such as pure gold), the marking contrast may be as low as 15% because the color-developing oxide layer cannot be formed, and additional developer spraying is required.

Heat-affected zone (HAZ) risk

Despite the low heat input, microscopic deformation of 5~10 μm may still occur when processing thin-walled parts (such as 0.2 mm thick stainless steel sheets).

Challenges of high-reflective materials

For highly reflective metals such as copper and aluminum, a galvanometer dynamic focusing system and anti-reflective coating are required, which increases the equipment cost by 30%~50%.

What is Laser Engraving?

Laser Engraving is a non-contact processing technology based on CNC technology and laser energy. It uses a high-energy-density laser beam to instantly melt or vaporize the surface of a material, thereby forming a permanent mark, pattern or three-dimensional structure. Its core principle is to use the interaction between laser and material to achieve deep processing by physically removing the material.

What are the advantages and disadvantages of laser engraving?

Analysis of the advantages and disadvantages of laser engraving

Advantages

High controllability of depth

Laser engraving can achieve an engraving depth of 0.1~8 mm (depending on the material and laser power), and can process three-dimensional reliefs and functional grooves (such as sealing grooves and guide grooves), meeting industrial-grade depth requirements.

Wide material compatibility

Applicable to metals (steel, titanium), non-metals (wood, acrylic, glass) and composite materials (carbon fiber reinforced plastics), especially good at processing texture engraving of organic materials (leather, wood).

High processing efficiency

Using high-power continuous lasers (such as 100~500 W CO₂ lasers), the engraving speed can reach 3000 mm/s, which is suitable for mass production (such as mass engraving of signs).

Significant tactile effect

The material vaporization forms a clear depression with clear touch, which is suitable for scenes that require tactile recognition such as Braille logos and anti-counterfeiting codes.

No consumables and environmental protection

Pure physical ablation process, no chemical waste liquid is generated, and it complies with RoHS environmental protection standards.

Disadvantages

Large heat-affected zone (HAZ)

High-temperature ablation will lead to heat diffusion, which may cause 0.1~0.3 mm deformation of the substrate on thin plate materials (such as 0.5 mm aluminum plate).

Material limitations

Highly reflective metals (such as copper and gold) require the use of fiber lasers (1064 nm) with auxiliary gas (nitrogen) to suppress reflection;

Some plastics (such as PVC) are prone to release toxic gases when heated, and a special smoke exhaust system is required.

High surface roughness

The roughness of the engraved surface is Ra 1.5~12 μm (metal material), and secondary polishing is required to achieve a mirror effect.

Equipment cost and energy consumption

The purchase cost of a high-power laser (such as a 500 W fiber laser) is 2 to 3 times that of an etching device, and the energy consumption is as high as 10 to 20 kW/h.

Risk of carbonization of organic materials

Materials such as wood and leather are easily carbonized due to high temperatures during engraving, and scorch marks may appear on the edges (carbonization depth is about 0.05 to 0.2 mm).

What is the difference between laser etching and engraving?

The following is a comparison table of the core differences between laser etching and laser engraving, covering dimensions such as physical mechanism, process parameters and application characteristics:

| Comparison Dimensions | Laser Etching | Laser Engraving |

|---|---|---|

| Technical Principles | Photochemical Decomposition (Non-heat-dominated) | Photothermal Ablation (heat-dominated) |

| Energy Density | ≤10 J/cm² (UV laser, such as 248 nm excimer laser) | ≥50 J/cm² (CO₂ laser, such as 10.6 μm wavelength) |

| Depth of Action | 0.01–0.3 mm (subsurface modification) | 0.1–8 mm (macro removal) |

| Heat-affected Zone (HAZ) | <1 μm (cold working characteristics) | 50–200 μm (significant heat diffusion) |

| Typical Material Adaptability | Metals (stainless steel, anodized aluminum), engineering plastics, silicon wafers | Wood, leather, acrylic, stone, cemented carbide |

| Surface Roughness (Ra) | 0.1–0.8 μm (smooth surface) | 1.5–12 μm (rough touch) |

| Processing speed | 1000–5000 mm/s (high-precision fast marking) | 300–2000 mm/s (deep engraving requires reduced speed) |

| Minimum line width accuracy | 10–50 μm (UV laser micromachining) | 100–300 μm (CO₂ laser) |

| Equipment cost | Medium (UV laser about 20k–20k–50k) | High (high-power fiber/CO₂ laser about 50k–50k–150k) |

| Typical application scenarios | Medical device identification, electronic component QR code, invisible anti-counterfeiting mark | Industrial mold numbering, artistic relief, functional grooves (such as sealing grooves) |

| Environmental characteristics | No smoke (cold processing), RoHS compliant | Fume exhaust system required (carbonization of organic materials) |

| Standard reference | ISO 11551 (laser energy test), ISO 13485 (medical device marking) | IEC 60825-1 (laser safety), ASTM E2523 (engraving depth measurement) |

Summary of key differences

Energy mechanism:

- Etching: Photon energy directly destroys chemical bonds (cold processing)

- Engraving: Thermal energy causes material melting/vaporization (hot processing)

Material response:

- Etching: Depends on the light absorption characteristics of the material (such as UV-sensitive materials)

- Engraving: Depends on the thermal conductivity and melting point of the material

Process selection logic:

- Choose etching: Need high precision, shallow marking, heat-sensitive materials (such as biocompatible devices)

- Choose engraving: Need three-dimensional touch, deep processing, non-heat-sensitive materials (such as tool steel numbers)

This table can be used as a quick selection reference. In actual applications, it is necessary to combine material spectral characteristic analysis and thermodynamic simulation to optimize parameters.

Why Does Etching Preserve Material Integrity Better?

In the field of precision manufacturing, the maintenance of material integrity directly determines product performance and life. Compared with traditional engraving processes, laser etching performs well in thermal damage control, stress distribution optimization, and fatigue performance retention. LS uses scanning electron microscopy (SEM) and X-ray diffraction (XRD) detection data to deeply analyze its microscopic mechanism.

1. Nano-level control of the heat-affected zone (HAZ)

(1) Essential differences in energy action modes

① Etching process:

Using cold working mechanism (photochemical decomposition), the depth of the heat-affected zone (HAZ) is ≤5 μm (in compliance with ISO 16700 standard)

Typical data: The HAZ of aluminum alloy after etching is only 3.2 μm (SEM detection, 5000 times magnification)

② Engraving process:

Relying on thermal ablation mechanism, the HAZ depth is ≥50 μm (thermal diffusion leads to grain coarsening)

304 stainless steel engraving HAZ reaches 78 μm (metallographic observation, GB/T 13298 standard)

2. Scientific regulation of residual stress distribution

(1) Reversal effect of surface stress type

① Etched surface:

Forming a compressive stress layer (15-20 MPa), generated by rapid solidification of the molten layer

Compressive stress can inhibit crack propagation (XRD measurement, ASTM E915 standard)

Producing tensile stress (180-220 MPa), causing lattice distortion due to thermal contraction

Tensile stress increases the brittleness of the material by 30% (refer to JIS Z 2283 test)

(2) Stress gradient comparison

| Process type | Surface stress (MPa) | Subsurface gradient (MPa/μm) |

|---|---|---|

| Etching | -15 (compressive stress) | 0.8 |

| Engraving | +200 (tensile stress) | 4.5 |

3. Significant advantages in fatigue life

(1) Comparative experiment of aviation aluminum alloy

① Etching group:

Fatigue strength retention rate 95% (100% benchmark of original material, ASTM E466 standard)

Crack initiation cycle extended to 1.2×10^6 times (rotational bending test)

② Engraving group:

Fatigue strength decreased to 80%

Cracks appeared in advance at 5×10^5 times (caused by stress concentration)

(2) Medical device stainless steel test

Etching surgical blade: cyclic load life ≥5000 times (ISO 13485 standard)

Engraving equipment: life reduced to 3800 times (surface dents cause stress concentration)

4. Application scenario selection suggestions

Laser etching is preferred:

- Aerospace structural parts: Wing skin marking (HAZ<5 μm to ensure strength)

- Implantable medical devices: Titanium alloy bone nail marking (compressive stress to prevent biocorrosion)

- Precision electronic components: 5G antenna etching (to avoid signal attenuation caused by microcracks)

Use engraving technology with caution:

- Thin-walled parts with a wall thickness of ≤0.3 mm (risk of thermal deformation)

- High-cycle fatigue parts (such as engine blades)

Laser etching protects the intrinsic properties of materials at the nanoscale through two core mechanisms: non-thermal dominant effects and compressive stress generation. This process has become an irreplaceable solution for high-precision fields such as aerospace and biomedicine that pursue zero defect manufacturing (ZDM). The process needs to be optimized based on parameters such as material thickness and service environment, combined with finite element stress analysis (FEA).

How to Choose Between Etching and Engraving for Industrial Traceability?

In the era of Industry 4.0, product life cycle traceability has become a core requirement for quality management. As mainstream identification technologies, laser etching and engraving have significant differences in traceability applications. LS provides data-driven process selection guidelines based on key indicators such as QR code accuracy, environmental tolerance, and production line adaptability.

1. QR code accuracy and standard compliance

(1) Comparison of line width and information density

| Parameters | Laser etching | Laser engraving |

|---|---|---|

| Minimum line width | 0.1 mm (supports 20×20 Data Matrix) | 0.3 mm (typical 14×14 Data Matrix) |

| Standard compliance | ISO/IEC 16022 (medical/electronics) | AIAG B-17 (automotive industry) |

| Data capacity | 50 characters/mm² (applicable to encrypted traceability codes) | 15 characters/mm² (applicable to basic batch numbers) |

Selection logic:

Etching is mandatory for micro components (<5 mm²) such as medical implants and semiconductor wafers

Engraving is applicable to macro components such as automotive chassis and large molds

2. Environmental tolerance test data

(1) Corrosion resistance comparison

| Test items | Laser etching | Laser engraving |

|---|---|---|

| Salt spray test | No degradation in 48 hours (ASTM B117) | Edge blur in 24 hours (glaze sealing treatment is required) |

| Abrasion test | 99% retention rate after 1000 wire brush frictions | 15% depth loss after 500 frictions |

| High temperature aging | No change at 300℃/100h (EN ISO 9227) | Carbonization occurs at 200℃/50h (anti-oxidation coating is required) |

Typical cases:

Marine engineering stainless steel fasteners: Etching + passivation treatment to achieve 10 years of readability in seawater environment

Automobile engine block: Engraving + ceramic glaze sealing, resistant to high temperature corrosion of engine oil

3. Compatibility of materials and production lines

(1)Applicable spectral analysis of materials

| Material type | Etching solution | Engraving solution |

|---|---|---|

| High reflective metal | Green light (532 nm) etching, reflectivity <30% | Requires fiber laser (1064 nm) + nitrogen assist |

| Thermosensitive plastic | UV (355 nm) cold processing, HAZ <5 μm | Easy to carbonize, requires low temperature mode (<150℃) |

| Curved workpiece | 3D dynamic focus, curvature radius ≥2 mm | Fixed focal length, limited to flat/regular surfaces |

2. Production line efficiency and economy

Etching equipment:

Speed: 5000 mm/s (marking a single QR code takes only 0.2 seconds)

Power consumption: ≤3 kW/h (UV laser)

Engraving equipment:

Speed: 800 mm/s (engraving with a depth of 0.5 mm takes 1.5 seconds)

Power consumption: ≥10 kW/h (500 W fiber laser)

4. Scenario-based selection decision tree

(1) Conditions for giving priority to laser etching

① High-precision traceability requirements:

2D code identification of microelectronic components (0201 package)

UDI unique device identification of surgical instruments (FDA 21 CFR Part 11)

② Service in harsh environments:

Nuclear power equipment (radiation oxidation resistance)

Food-grade stainless steel containers (direct contact with acid and alkali media)

③ Heat-sensitive materials:

Polymer film sensors (temperature resistance <80℃)

Bioresorbable magnesium alloys (processing temperature <100℃)

2. Conditions for giving priority to laser engraving

① Deep tactile recognition requirements:

Braille identification (depth ≥0.4 mm, EN ISO 17351)

Anti-tampering coding of heavy machinery (tactile verification required)

② Low-cost mass production:

VIN code batch engraving of automobiles (more than 30 pieces per minute)

Logistics barcodes for wooden pallets (no need to retain them for a long time)

5. Hybrid process innovation solution

For complex scenes, etching + engraving composite process can be used:

Precision base code + deep border:

First, use etching to generate 20×20 Data Matrix core code (0.1 mm line width)

Then use engraving to add 1 mm deep protective border (to prevent mechanical wear)

Multi-layer material processing:

Surface etching invisible traceability code (ultraviolet excitation development)

Deep engraving clear code (daily visual recognition)

Summary

The essential difference between laser etching and engraving lies in the difference in material response caused by the energy mechanism. When choosing, you need to consider the three major factors of mark permanence, substrate integrity, and production efficiency. As laser technology develops towards high power and ultra-short pulses, the fusion application of the two processes will become the new normal for precision manufacturing. It is recommended that users give priority to composite laser workstations with multi-modal processing capabilities when selecting equipment.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://lsrpf.com/

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

2. How to choose etching or engraving in industrial traceability scenarios?

If you need a micro high-density QR code (line width 0.1 mm, in line with ISO/IEC 16022) or durability in harsh environments (passing a 48-hour salt spray test), etching is preferred; if you are looking for low-cost batch processing (such as car VIN codes) or deep tactile anti-counterfeiting (such as Braille logos), choose engraving. Engraving requires additional glaze treatment (cost +20%) to improve weather resistance, while etching can be directly stable in high temperature/corrosive environments for a long time.

3. What are the differences in material compatibility between the two processes?

Etching is good at processing photosensitive/thermosensitive materials (such as anodized aluminum, biocompatible titanium alloys), and cold processing is achieved through ultraviolet laser (355 nm); engraving is more suitable for organic materials (wood, leather) and high-temperature resistant metals (tool steel), but special wavelengths (such as fiber laser) are required for highly reflective metals (copper, gold). Etching cannot process grooves with a depth of >0.3 mm, and engraving is prone to thermal deformation on thin materials (<0.5 mm).

4. Why do medical devices generally use laser etching instead of engraving?

Etching meets the ISO 13485 medical identification standard. Its non-thermal mechanism avoids material carbonization (critical for implantable devices), and the surface compressive stress (15 MPa) can inhibit biocorrosion, and the fatigue strength retention rate is >95%. The thermal impact of engraving will reduce the cycle life of stainless steel surgical tools (from 5000 times to 3800 times), and the rough surface (Ra>1.5 μm) is prone to bacterial growth and requires secondary polishing (cost +30%), so the medical field tends to prefer etching.