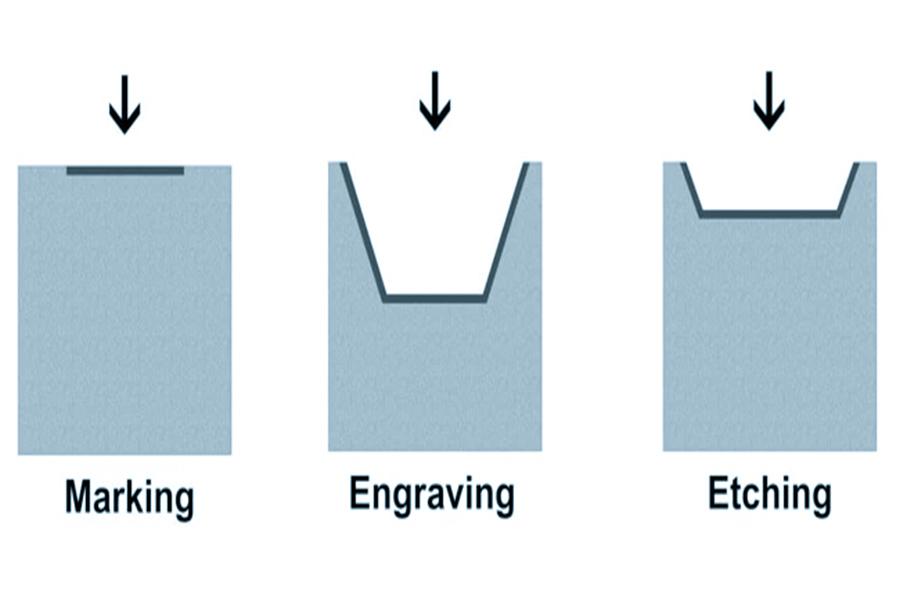

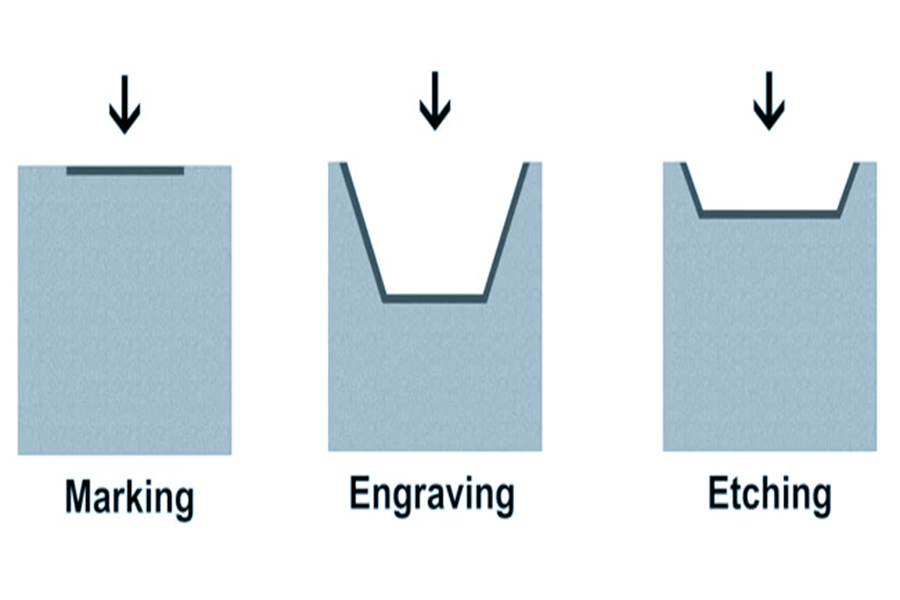

People often think oflaser etching and laser engravingas interchangeable, but there are differences between the two in terms of their processes and results. Both laser etching and laser engraving have advantages and disadvantages, depending on the desired outcome of the project. The laser marking process involves changing the appearance of the surface of a material. Laser marking technology is ideal for barcodes, QR codes, data matrices, and logos, among others.

In this blog post, we will discuss thedifferences between laser marking, laser etching, and laser engraving, and what are the application areas of each technology.

What is Laser Marking?

Laser marking, also known as laser coloring, carbonization or laser dark marking, is a high-precision marking technology. It uses alaser beamto perform non-contact operations on the surface of the material to produce logos, labels, patterns or text. The principle is to control the energy and focus of the laser beam so that the laser interacts with the surface of the material. This technology uses a low-power beam to change the surface of the material without damaging the material, such as changing the color,oxidizing the surface, leaving a permanent mark or making a deep mark.

There are four main ways of laser marking: foaming, annealing, carbon migration and coloring. By adjusting the laser parameters, it can adapt to different materials and application requirements. This technology is widely used in sign making, medical equipment, electronic components and other fields to meet the needs of high-precision identification and marking.

What is Laser Engraving?

Laser engraving is an advanced precision processing technologythat uses a focused laser beam to accurately carve text and patterns on the surface of a material. It works by focusing a high-energy-density laser beam on the material, causing it to heat up rapidly. When the temperature reaches a certain level, the material melts or evaporates, resulting in a fine and complex engraving effect of varying depths. This process is very rapid, and each laser pulse evaporates the material a little, and through multiple repetitions, deeper markings can be achieved.

More importantly, the non-contact nature of laser engraving makes it particularly suitable for processing a variety of sensitive materials, such as films, plastics, and glass, without causing physical damage or deformation to them. As a result, laser engraving has become the preferred technology for most personalized or customized projects.

What is Laser Etching?

Laser etching is a high-precision material processing technologythat uses laser energy to etch fine patterns, text or depth on the surface of a material in a non-contact manner. The principle of this process can be regarded as an extremely precise chemical or physical reaction. When the energy of the laser beam is focused on a certain point on the surface of the material, the area will quickly absorb the energy and heat locally. During the etching process, the material becomes ductile due to the heat, which may cause the surface to expand and deform, thus forming the desired texture.

In laser etching, the laser beam works in pulses, which release energy instantaneously at specific time intervals. Compared to laser engraving, laser etching of metal requires less energy per unit area, so the distance between pulses is set larger. For example, a 100-watt pulsed laser device can emit up to 100,000 pulses in one second, each pulse contains one millijoule of energy, and the peak power can be as high as 10,000 watts. For high-quality marking effects, the contrast between black and white is considered optimal. Of course, the specific process of laser etching will be adjusted according to the needs of different applications, so it will vary.

What is the difference between laser marking, engraving and etching?

Laser marking, laser engraving and laser etching are three common laser processing technologies. Although they all use laser beams to interact with the surface of materials, they have significant differences in principles, effects and application scenarios. The following are the main differences between them:

| Topic | Laser Marking | Laser Engraving | Laser Etching |

|---|---|---|---|

|

Applications

|

Laser Marking

Logos, barcodes, UID codes.

|

Laser Engraving

Logos, serial numbers, and personalization.

|

Laser Etching

Marks on polymers, metals, and ceramics.

|

|

Alteration

|

Laser Marking

Discoloration of material surface.

|

Laser Engraving

Pulse vaporization of material.

|

Laser Etching

Methods of melting and material expansion.

|

|

Core Process

|

Laser Marking

Uses the beam to alter the surface with high contrast and low (to no) damage.

|

Laser Engraving

Physically removes material from the surface of the item.

|

Laser Etching

Melts surface material with heat.

|

|

Strong suit

|

Laser Marking

A go-to option for effective and efficient part and product identification.

|

Laser Engraving

Utilized for depth requirements or customizing personal items.

|

Laser Etching

Boosts visual contrast and reflectiveness.

|

What are the applications of laser marking?

The application of laser marking is very wide, covering almost all fields from daily consumer goods to high-end manufacturing. The following are some of the main application areas of laser marking:

- Electronics and communications:marking and etching on electronic components, integrated circuits, electronic product housings, etc. to improve product traceability and brand value. For example, engraving serial numbers, production dates, brand logos and other information on the surface ofelectronic products such as mobile phone housings and batteries.

- Automobile manufacturing: used for marking and tracing automotive parts,improving production efficiency and quality control by engraving unique identification codes on parts. For example, marking on engine parts, body frames, window glass and other parts.

- Medical devices: marking product information such as surgical instruments and medical equipmentto improve product identifiability and safety. For example, coding on surgical knives and implant products, as well as batch numbers, expiration dates, and barcodes on drug packaging boxes.

- Pharmaceutical and food packaging:Printing production date, expiration date and other information on drug packaging, medicine bottles, and food packaging to improve product traceability and management efficiency.

Jewelry and luxury goods: Fine marking on gold, silver, gemstones and other materials to improve product added value and market competitiveness. For example, engraving barcodes, patterns, text and other content on precious items such as gold, diamonds, and silver jewelry. - Other industries:Also includesaerospace, military industry, industrial product packaging, building materials ceramics, plastics and rubber and other fields.

What are the applications of laser engraving?

The application areas of laser engraving are very wide, covering multiple industries and material types. The following are the mainapplication areas of laser engraving:

- Advertising decoration:making all kinds of signs, display boards, light boxes, and cutting and engraving of advertising words. For example, engraving patterns and words on materials such as acrylic and plexiglass.

- Craft gifts:engraving patterns and words on handicrafts, bamboo and wooden slips, packaging boxes, porcelain, trophies and other items.

- Home decoration:engraving and decoration on wooden floors, furniture, lighting and other household items.

- Leather clothing:engraving of words and graphics on materials such as genuine leather, synthetic leather, and cloth, as well as cutting, carving and hollowing.

- Model making: cutting and engraving in the making of architectural models, aircraft models and other models.

Other industries: also include theelectronics industry(such as circuit board engraving), the stone industry (such as tombstone engraving), etc.

What are the applications of laser etching?

The application areas of laser etching are very wide, covering multiple industries and material types. The following is a summary of the main application areas of laser etching:

- Microelectronics industry:Etching on integrated circuit boards and semiconductor components to form tiny circuit patterns.

Touch screen industry: In the process of touch screen manufacturing, ITO (indium tin oxide) thin films are accurately etched to form conductive lines. - Photovoltaic industry:In the production process of solar cells, it is used for scribing and cutting to improve the photoelectric conversion efficiency of the battery.

- Medical devices:In the manufacture of medical devices, high-precision sensors and micro components are processed.

- Other industries:Also includes automobile manufacturing (such as automobile parts marking), aerospace (such as parts serial number marking), jewelry (such as gemstone micro-carving patterns), etc.

Summary

Laser marking, engraving and etching are three common laser processing methods, each with its own characteristics in terms of process principle, processing effect and application field. They each have unique advantages and application scenarios, providing strong technical support for modern manufacturing. With the continuous advancement and innovation of technology, the application fields of laser marking, engraving and etching will continue to expand, bringing more efficient and sophisticated processing solutions tomore industries.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1. What is the difference between etching and engraving?

The main difference between etching and engraving lies in the processing method and effect: Processing method: ① Etching: Usually chemical or electrochemical methods are used to form patterns or text by corroding the surface of the material. Etching can be wet (using corrosive liquids) or dry (such as using plasma or lasers). ② Engraving: Using mechanical tools (such as knives, drills) or physical forces such as laser beams to directly remove materials from the surface of the material to form patterns or shapes. Processing effect: ① Etching: Usually produces shallow grooves or textures, the effect is delicate and uniform, and is suitable for occasions that require fine patterns. ② Engraving: It can produce deeper grooves or raised shapes, the effect is three-dimensional and vivid, and is suitable for occasions that require the removal of a large amount of material or the formation of complex three-dimensional shapes.

2.What is the difference between laser engraving and machine engraving?

The main difference between laser engraving and machine engraving lies in the processing tools and working principles: (1) Processing tools: ① Laser engraving: Using a laser beam as a processing tool, the high temperature energy of the laser causes the material to melt, evaporate or produce a chemical reaction, thereby removing the material. ② Machine engraving: Using mechanical tools (such as milling cutters, drill bits) as processing tools, removing materials through physical forces such as cutting, milling or scraping. (2) Working principle: ① Laser engraving: It is a non-contact processing that does not produce mechanical stress on the material. It is suitable for fine processing and engraving of complex patterns. ② Machine engraving: It is a contact processing that requires the workpiece to be fixed and may produce mechanical stress. It is suitable for processing large areas or simple three-dimensional shapes.

3.What is the difference between chemical etching and laser engraving?

The main difference between chemical etching and laser engraving lies in the processing method and scope of application: (1) Processing method: ① Chemical etching: Use corrosive liquid or gas to react chemically with the surface of the material to remove the material. ② Laser engraving: Use the high temperature energy of the laser beam to melt, evaporate or produce a chemical reaction to remove the material. (2) Scope of application: ① Chemical etching: Widely used in integrated circuit manufacturing, metal sign production, glass decoration and other fields, suitable for the processing of various metal and non-metal materials. ② Laser engraving: Suitable for the processing of various materials, including metals, non-metals, hard and brittle materials, etc., especially suitable for occasions requiring fine processing and complex patterns.

4. What is the difference between laser engraving and printing?

The main difference between laser engraving and printing lies in the processing method and effect: Processing method: Laser engraving: Using a laser beam as a processing tool, the high temperature energy of the laser causes the material to melt, evaporate or produce a chemical reaction, thereby removing the material or forming a pattern. Printing: Transferring patterns or text to the substrate through ink or other media. There are many printing methods, such as offset printing, gravure printing, relief printing, silk screen printing, etc. Processing effect: Laser engraving: High processing accuracy, smooth edges, patterns or text are permanent, not easy to wear or fade. Printing: The printing effect depends on the quality of the ink, printing technology and the characteristics of the substrate. The pattern or text may be temporary and easy to wear or fade.

Resource