In modern manufacturing,laser cutting technology has shown great application potentialand value in the fields of metal and paper manufacturing with its unique advantages. This article will explore in depth from multiple dimensions whylaser cutting technologyis so important for metal and paper manufacturing.

What is Metal Laser Cutting?

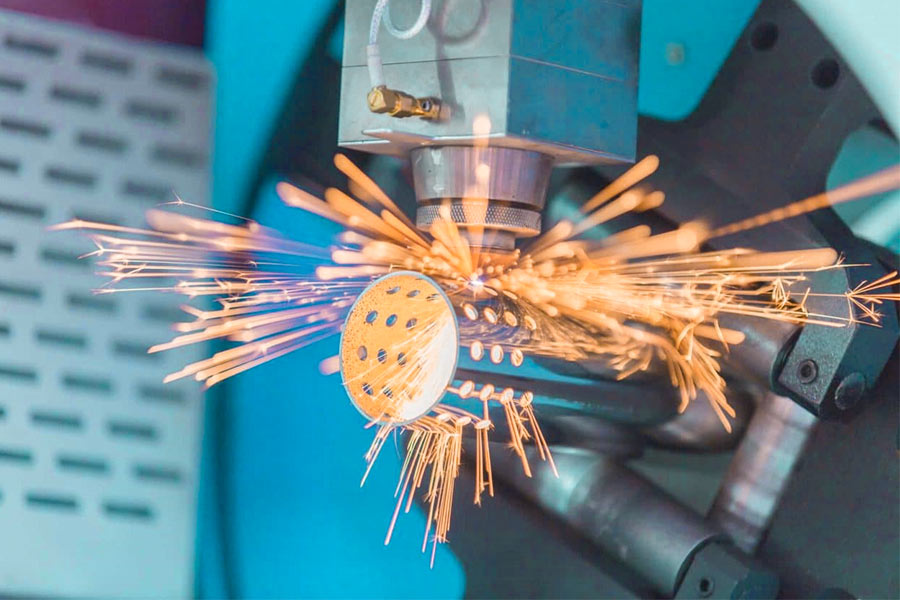

Metal laser cutting is a process that uses high-power laser output to form a cutting edge by evaporating the material.The process relies on laser optics and CNC systems to guide the laser beam and make precise cuts according to the pattern set by the CNC or G-code. After the laser beam is focused, it can melt, burn, evaporate or be driven away by gas, leaving an edge with a high-quality surface finish.

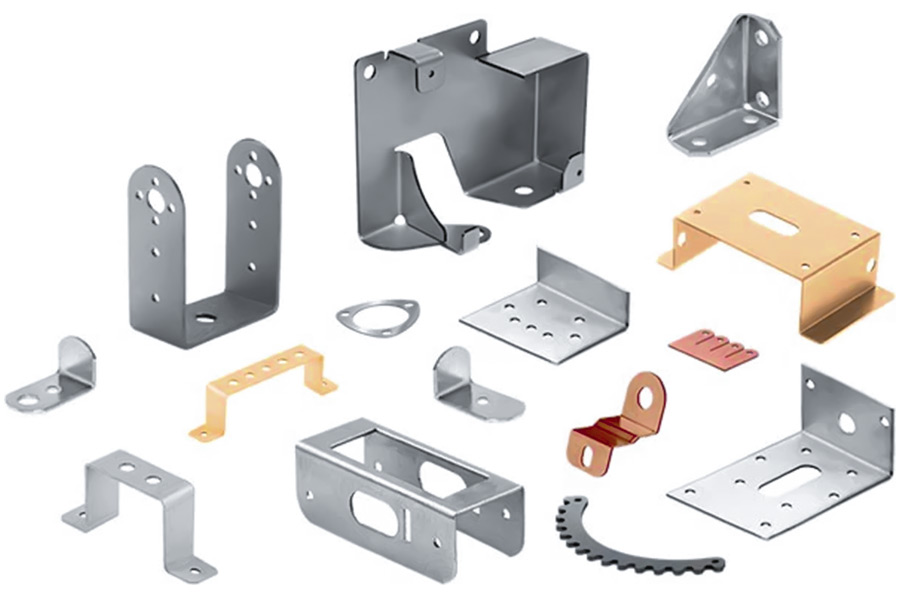

Due to the high density of metal, higher-power lasers are required for cutting.Laser cutting technology is popular in fields such as energy storage, electronics, robotics and aerospace, and is often used to make parts such as flat patterns and panels. Today, this technology is not only widely used in the industrial field, but is also gradually being adopted by schools, small businesses, etc.

What is paper laser cutting?

Paper laser cutting is a process that uses a high-energy-density laser beam to cut paper. The laser beam is concentrated into an extremely fine spot through a focusing lens. When it is irradiated onto the surface of the paper, the paper material absorbs the laser energy in a very short time and heats up rapidly, then melts, vaporizes or burns, thereby achieving precise cutting. Paper laser cutting has the characteristics of non-contact, high efficiency, and high precision. It can cut various complex shapes and patterns and is widely used in paper packaging, paper models, paper artworks, paper carvings and other fields.

Which Materials Can Be Processed Together?

Industrial-grade combinat

Ion solution: stainless steel sheet metal (1-3mm) with waterproof cardboard (300gsm)

Overview of material properties:

- Stainless steel sheet metal (1-3mm):It has excellent characteristics such as high strength, corrosion resistance and easy processing, and has been widely used in many industries such as machinery and equipment, building decoration, andautomobile manufacturing.

- Waterproof cardboard (300gsm):After special treatment, it has the characteristics of waterproof, moisture-proof and wear-resistant, which is very suitable for making paper products that need to be moisture-proof and waterproof, such as operation guides,product manuals, etc.

Combined processing feasibility analysis:

- Using laser cutting technology, it is possible to precisely cut stainless steel sheet metaland waterproof cardboard, achieving high-precision control of size and shape.

- Laser cutting ensures that the screw holes are accurately cut out in the stainless steel sheet metal, while matching slots are cut in the waterproof cardboard, allowing the two to be assembled precisely.

- Thelaser cutting processdoes not require a mold, which supports fast and flexible customized production to meet the personalized customization needs of industrial-grade products.

Application Scenarios:

This combination is particularly suitable for the production of metal housings and paper operating instructions for machines. The metal housing provides robust protection, while a paper operating guide provides detailed instructions on how to use it. The two are precisely mated with laser-cut slots and screw holes for easy installation and use.

Consumer-grade combination is preferred: aluminum alloy nameplate (0.5mm) is matched with embossed art paper

Brief description of material properties:

- Aluminum alloy nameplate (0.5mm):known for its lightweight, corrosion-resistant and easy-to-process characteristics, it is widely used in electronic product identification, home decoration and gift packaging and other fields.

- Embossed art paper:made by special printing or embossing process, the paper surface presents a relief effect, which has both a unique artistic beauty and tactile enjoyment.

Feasibility study of combined processing:

- Laser cutting technology can easily cope with the cutting needs of aluminum nameplates, accurately shaping the desired shape and size, while ensuring that the edges are flat and smooth.

- Similarly, laser cutting technology can also accurately make grooves or openings on the embossed art paper that match the nameplate, so as to achieve a perfect fit between the nameplate and the paper.

- This combination processing method not only retains the metallic texture of thealuminum alloynameplate, but also highlights the artistic charm of the embossed art paper, and the two are seamlessly integrated and complement each other.

Application Scenarios:

This combination is perfect for creating high-end gift sets. The aluminum alloy nameplate is used as the identity or brand identity of the gift, and the embossed art paper is turned into the outer packaging or inner lining of the gift, and the two are precisely docked through the laser-cut grooves or openings, which greatly improves the overall taste and ornamentality of the gift.

Analysis of LS laser cutting application examples

Example 1: High-precision stainless steel component manufacturing

A customer commissioned the processing of a batch of stainless steel parts with complex structure and strict tolerance requirements. Conventional processes are difficult to meet the expected standards, and we use high-power laser equipment for processing. Through precise laser energy control and process parameter optimization, the dimensional accuracy of ±0.02mm is realized, and thesurface roughnessis controlled within Ra0.8. Compared with the traditional method, the processing efficiency is increased by 35%, and the cost per part is reduced by 20%, which helps customers shorten the product delivery cycle.

Example 2: Processing of large aluminum alloy components

An engineering project needs to process a batch of aluminum alloy supports with complex shape and large size. We use wide-formatlaser processing equipmentand intelligent path planning system to achieve a single molding process of complex contours. The edges of the machined workpiece are flat, free of burrs and cracks, and the surface quality reaches Sa2.5 level. Through the laser processing process, the material utilization rate is increased to 92%, which is 15 percentage points higher than the traditional method.

Example 3: production of high-grade paper packaging boxes

A luxury brand commissioned the production of a batch of unique gift packaging boxes. Using laser processing technology, the fine pattern cutting with a line width of 0.3mm is realized. In the processing process, the non-contact processing method is used to avoid the deformation of the material, and the edge of the finished product is smooth and flat. Compared with the traditional die-cutting process, the processing efficiency is increased by 40%, and there is no need to make molds, especially suitable for small batch custom orders.

Example 4: Creative paper print production

An advertising agency needed to produce a batch of brochures with innovative designs.We use laser processing technology to achieve precise processing of complex hollow patterns, with a minimum hole diameter of 0.5mm. Through the intelligent nesting system, the material utilization rate reaches 95%, which is 20% higher than the traditional method. The processing speed reaches 15 m/min, which is 50% faster than the traditional process, helping customers win market opportunities in urgent orders.

These cases fully demonstrate the application advantages of laser processing technology indifferent materials and different fields. Through precise process control and intelligent production system, we help customers achieve dual improvement in product quality and production efficiency, and gain a significant advantage in market competition.

Why choose LS as a laser cutting service provider?

At LS,we focus on precision laser cutting services and specialize in providing high-quality cutting solutions for a variety of industries. WithIS0 9001:2015 certificationand advanced laser cutting technology, we ensure that complex parts are cut with high accuracy, smooth edges and excellent precision.Whether you need laser cutting metal or laser cutting paper, our experienced team can ensure minimal material waste and consistent results quickly. From prototyping to mass production, we provide cost-effective solutions tailored to your specific project needs, ensuring efficiency and excellent quality. Looking for precision laser cutting solutions for your project?Contact us now for a free quote!

Summary

In the metal and paper manufacturing industries,laser cutting technology plays an indispensable role. It not only significantly improves production efficiency and product quality, but also effectively reduces production costs and energy consumption. From its initial use in material surface treatment to its current widespread use in various processing techniques, laser cutting technology has undergone a continuous development and improvement process and has gradually formed a relatively complete system. With the continuous development of science and technology and the gradual expansion of its application scope, laser cutting technology is expected to play a more critical role in the future manufacturing industry.

As an advanced processing technology with high efficiency, high quality and low cost,laser cutting technology has been widely used in many industries such as automotive parts, home appliances, electronics, etc., providing a new way for the rapid upgrading of products. For manufacturers, mastering and applying laser cutting technology will be the core strategy to enhance their market competitiveness and expand their market share.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.Can I use laser decrement?

Yes, you can use a laser to cut paper. Laser cutting technology is a non-contact processing method that is capable of cutting a variety of materials, including paper, with precision. By adjusting the parameters of the laser, such as power, speed, frequency, etc., it is possible to achieve precise cutting of paper of different thicknesses and materials.

2.How do you laser cut paper without leaving burn marks?

The key to cutting paper with a laser without leaving burn marks is to control the power and cutting speed of the laser. Too much power or too slow can cause the paper to burn. Therefore, it is necessary to choose the appropriate laser power and ensure that the cutting speed is fast enough to reduce the contact time between the laser and the paper. In addition, the use of a high-quality laser cutting machine and suitable cutting parameters are also important factors in avoiding burn marks.

3.How much laser power do you need to cut paper?

The laser power required to cut the paper depends on factors such as the thickness of the paper, the material of the paper, and the cutting speed. In general, thinner paper, such as regular printer paper, may require a lower power laser to cut, while thicker paper, such as cardboard or cardboard, may require a higher power laser. Therefore, it is not possible to give a specific power value, but it needs to be selected and adjusted according to the actual situation.

4.What type of paper can be laser cut?

Laser cutting technology is suitable for many types of paper, including ordinary printing paper, cardboard, cardboard, art paper, etc. Different types of paper may have different thicknesses, materials, and characteristics, so it is necessary to choose the appropriate laser cutting parameters according to the specific properties of the paper. In general, as long as the paper is not too heavy or contains a special coating (such as some waterproof or fireproof coatings), you can try cutting with a laser.