Sand casting techniques have been pivotal in manufacturing, offering a versatile method for creating complex metal components. This traditional process involves making a mold with sand where molten metal is poured to form intricate shapes. The sand casting process stands out due to its ability to produce large and heavy parts with ease and cost-effectiveness. The foundry sand casting method is celebrated for its flexibility in using various metals and alloys, making it an indispensable tool in industries across the globe.

This method's practical applications extend far and wide, being integral in manufacturing castings for automotive parts, aerospace components, and even artistic sculptures. Sand casting molds are meticulously crafted using a pattern of the desired object, which allows many replicas to be made efficiently. This manufacturing technique supports a range of materials, notably metal sand casting, which includes popular metals like aluminum sand casting. The adaptability of these processes to accommodate different material properties makes them highly valuable in various sectors.

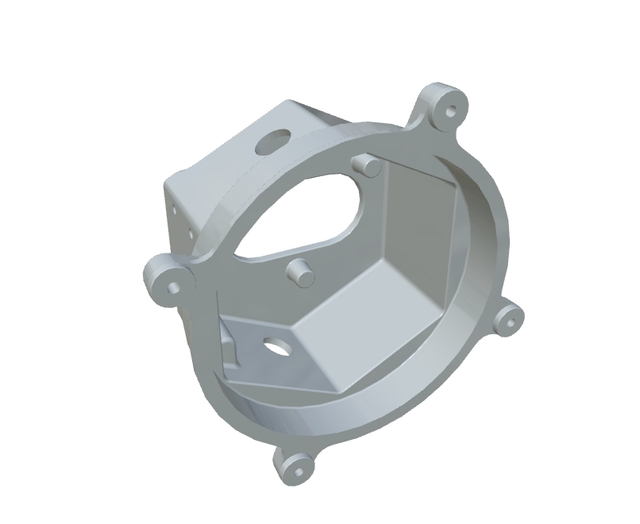

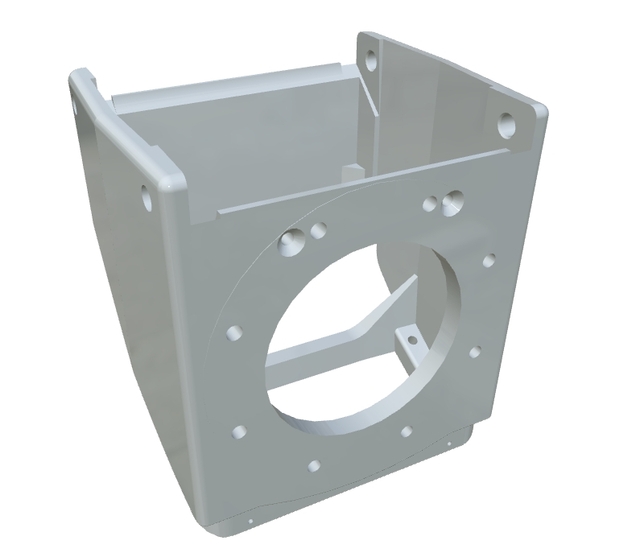

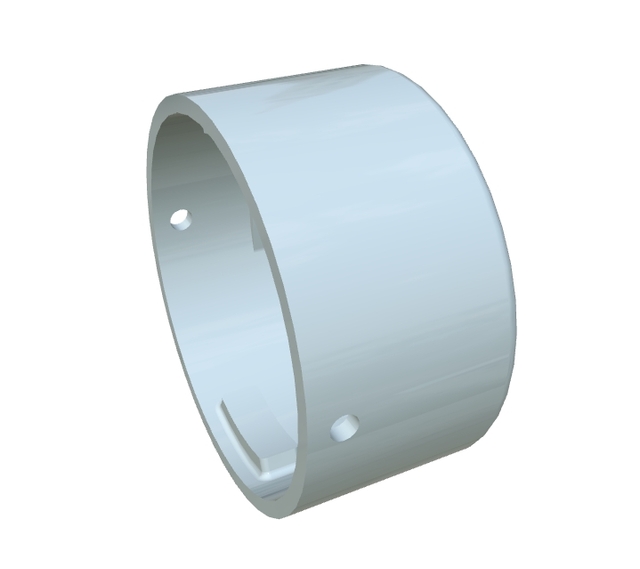

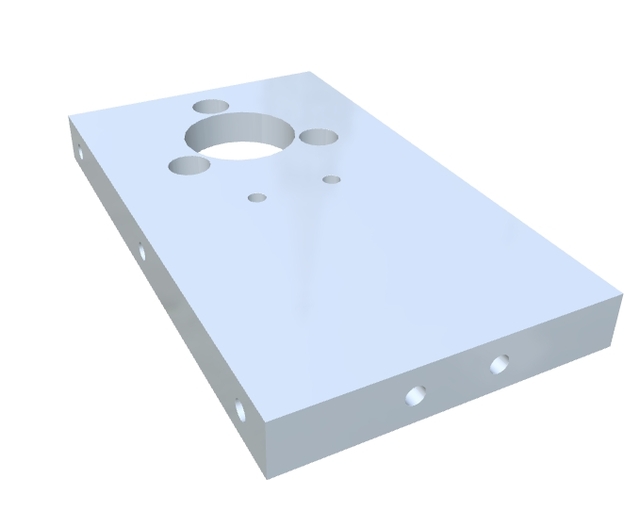

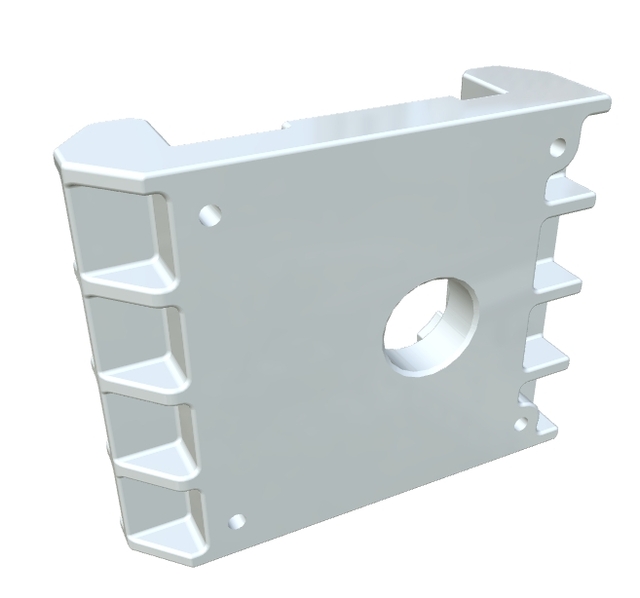

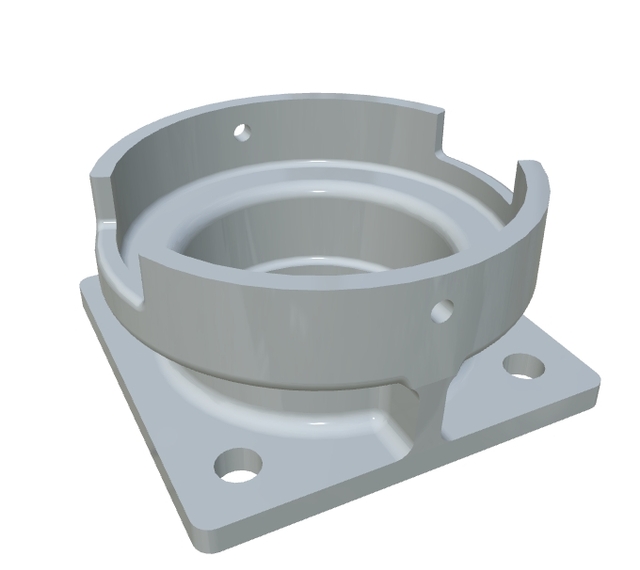

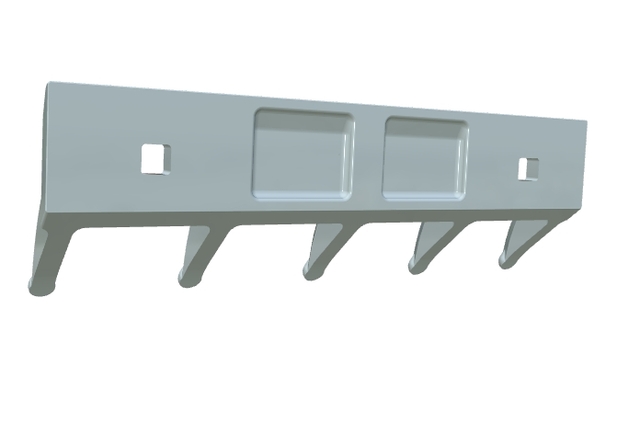

Aluminum sand casting, in particular, has gained prominence due to its lightweight nature and corrosion resistance, making it ideal for components like the Precision Mount Base. This new product is a testament to the advancements in manufacturing through sand casting techniques. It exhibits impeccable durability and strength, attributed to the high-grade materials and meticulous engineering involved in its creation. The mount's sleek design with strategic cutouts ensures optimal weight distribution, showcasing the practical application of effective sand casting techniques in reducing weight while maintaining stability.

Designed for seamless integration into diverse engineering applications, the Precision Mount Base features pre-drilled holes for quick and secure attachment to various surfaces. Its polished finish not only enhances the visual appeal but also provides essential corrosion resistance, offering reliability even in challenging environments. This makes it particularly appealing to professionals seeking efficiency and longevity in their projects. With these high standards of functionality and design driven by insights from sand casting, we continue to push the boundaries of what's possible in modern mechanical support systems.

The innovations seen in products like the Precision Mount Base are reflective of sand casting's role in redefining industry standards. As we harness these techniques, incorporating advanced engineering and practical designs, we are better equipped to meet the evolving demands of diverse industrial landscapes, ensuring that products remain at the forefront of quality and innovation.

Mastering Sand Casting Techniques for Innovative Solutions

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Manufacturing

LS ManufacturingRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.