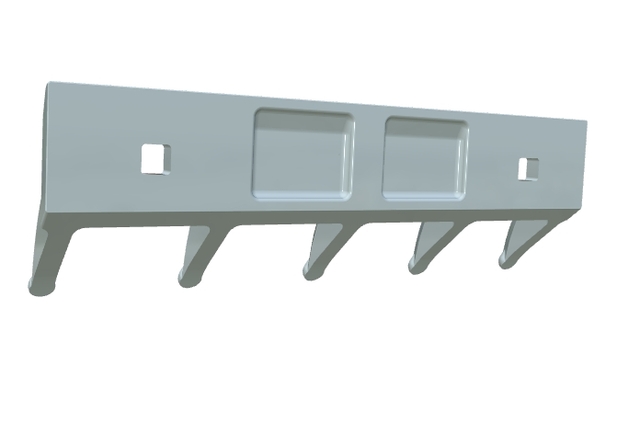

The sand casting process is a fundamental technique in the manufacturing industry, renowned for its versatility and cost-effectiveness. By utilizing a variety of sand casting techniques, manufacturers are able to create complex metal parts with high precision. This process involves the creation of a mold using sand, which provides the ability to produce intricate shapes that would be difficult to achieve through other methods.

One of the key advantages of the sand casting process is its compatibility with a wide range of materials. Sand casting materials commonly include aluminum, brass, bronze, and steel, offering manufacturers the flexibility to produce components in the desired material that best suits their application's requirements. The distinction between sand casting vs die casting surfaces, among which sand casting stands out for its ability to accommodate larger metal castings without the limitation of die size.

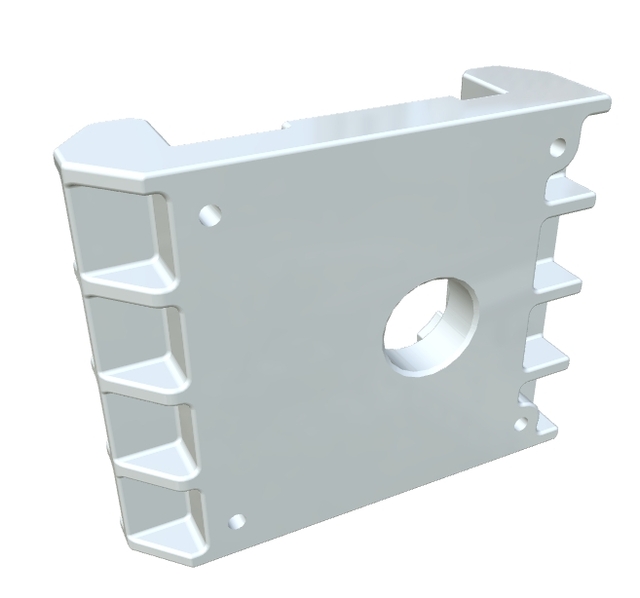

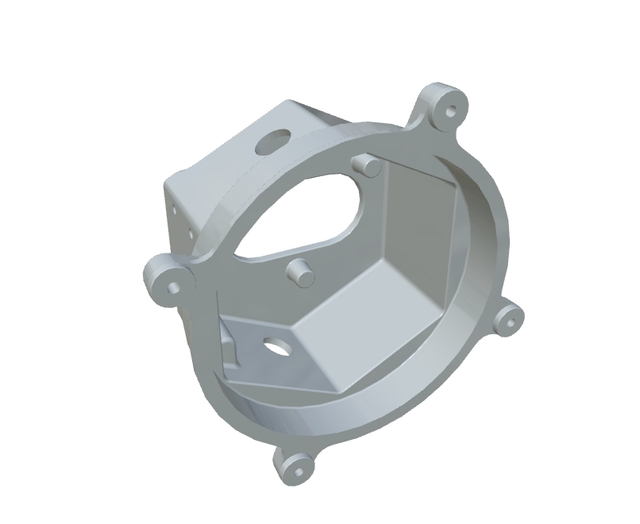

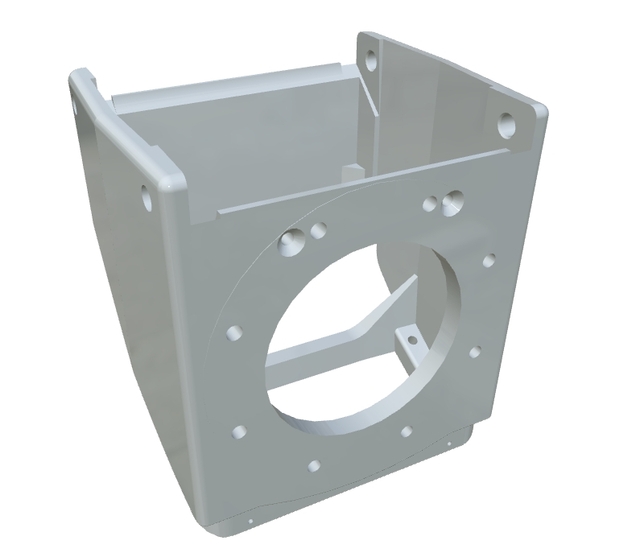

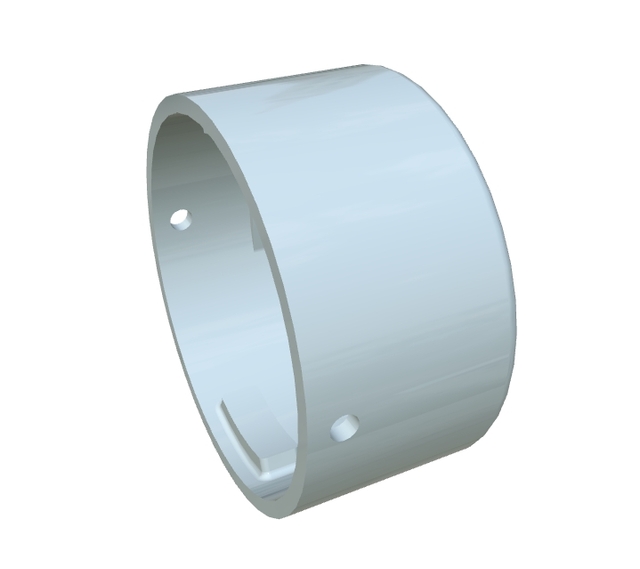

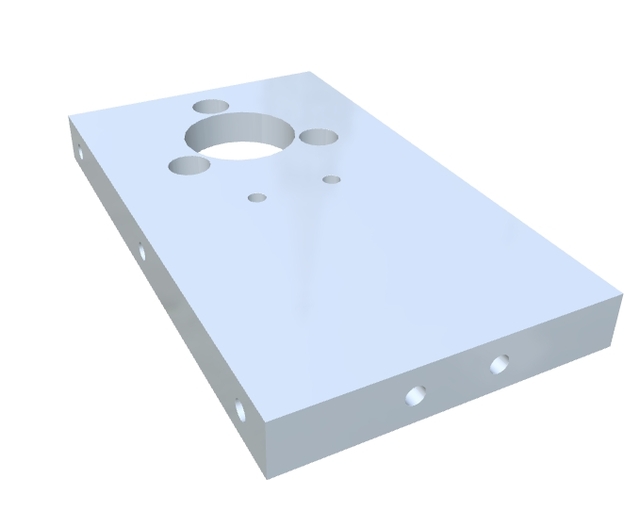

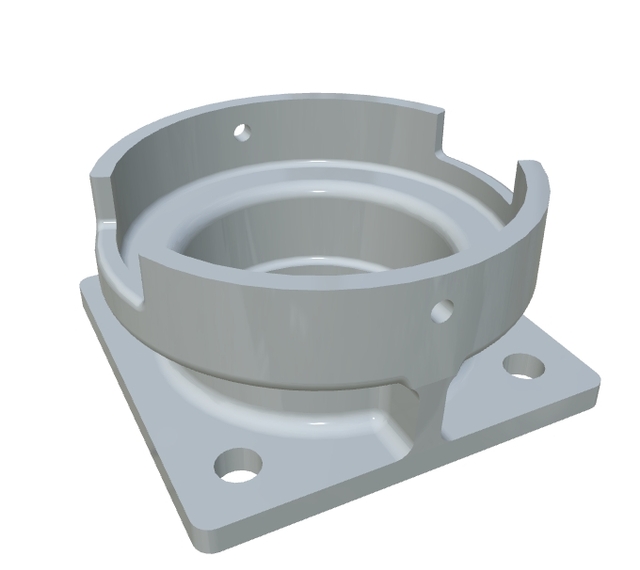

Our latest product, the Multi-Functional Mounting Plate, exemplifies the benefits of the sand casting process in action. Crafted from high-grade aluminum, it offers robust performance suitable for various industrial applications. Aluminum is a preferred choice in sand casting due to its lightweight and durable properties. The sand casting mold used in this product’s creation ensures precise dimensioning and superior finish quality, essential for meeting diverse mounting requirements.

While sand casting is often praised for its adaptability and economic edge, it is important to address common concerns like sand casting defects. With advanced techniques and quality control, such vulnerabilities can be minimized, ensuring consistent output quality. Through the use of permanent mold sand casting, our production not only mitigates potential defects but also enhances the durability and reliability of the final component.

The Multi-Functional Mounting Plate’s design, featuring a series of strategically placed holes, allows for effective utilization across various setups. This adaptability is imperative for professionals in need of a dependable and versatile setup solution. Sand casting provides the ideal solution for creating components like the Multi-Functional Mounting Plate, offering a balance between customization and efficiency that is hard to match.

In conclusion, the sand casting process continues to be a pivotal manufacturing technique due to its resource efficiency and capability to produce intricate and resilient components. By embracing this process, products like the Multi-Functional Mounting Plate can be crafted to meet the highest industry standards, proving essential in a wide range of mechanical setups.

The Sand Casting Process: Advantages & Techniques Unveiled

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Sand Casting Process: Benefits and Techniques

Sand Casting Techniques: Modern Methods for Complex Designs

Casting Agency: Essential Services for Entertainment

Expert Casting Services for Precision Components

The Sand Casting Process: Techniques, Materials, and Applications

The Sand Casting Process: Advantages & Techniques Unveiled

Mastering Sand Casting Techniques for Innovative Solutions

Exploring the Versatile Sand Casting Process in Modern Manufacturing