The investment casting process is a vital manufacturing method used to create intricate and detailed metal components. Often referred to as precision casting or lost-wax casting, this technique has transformed the industry with its ability to produce components with remarkable precision and minimal material wastage. The main keyword 'investment casting process' highlights its significance in producing high-quality products across various sectors, providing a cost-effective solution compared to other casting methods.

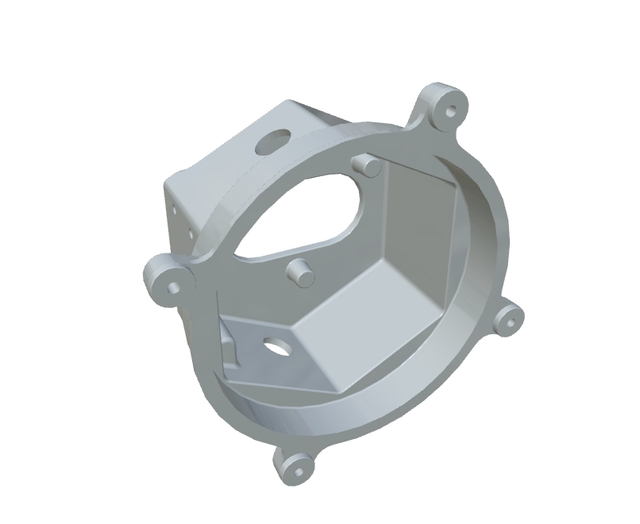

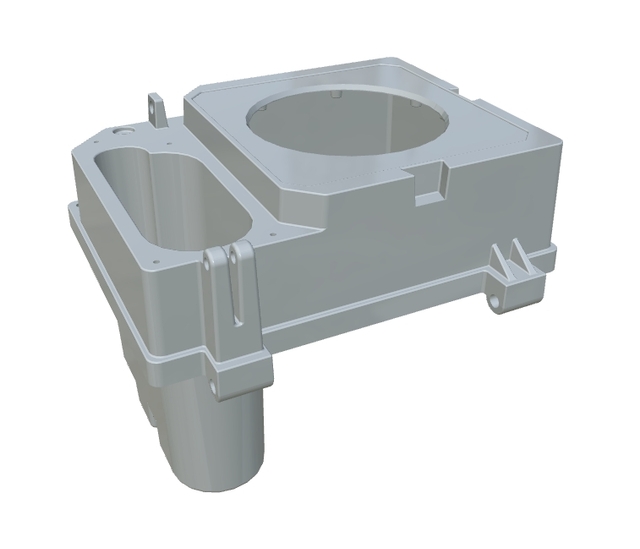

Investment casting techniques involve creating a wax pattern of the desired part, which is then coated with a ceramic material to create a mold. Once the mold hardens, the wax is melted and drained away, leaving a precise cavity into which molten metal is poured. This method stands out for its ability to produce complex geometries and tight tolerances, making it a preferred choice for producing components with intricate designs.

There are several advantages of investment casting, one of which is its ability to manufacture components with excellent dimensional accuracy and intricate details. This reduces the need for additional processing, saving both time and resources. Investment casting materials include a variety of metals, such as stainless steel, carbon steel, aluminum, and more, offering manufacturers flexibility in achieving the desired material properties for their products.

Investment casting manufacturers have embraced this process due to its efficiency and the high quality of investment casting products it yields. They've been able to meet the diverse requirements of industries ranging from aerospace to automotive, thanks to the adaptable nature of the materials. The advantages of investment casting over other methods, such as sand casting, are clear through its superior precision, smooth finishes, and reduced machining requirements.

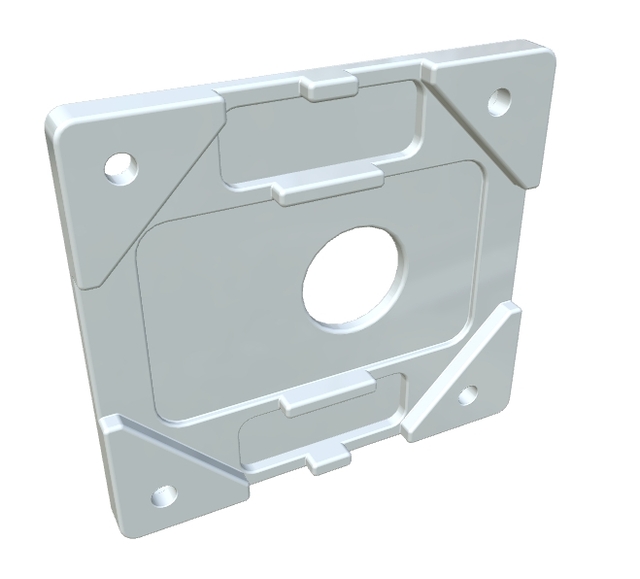

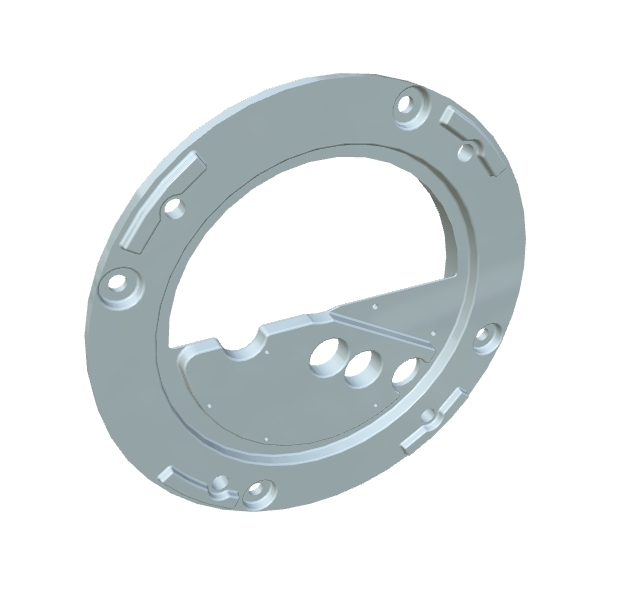

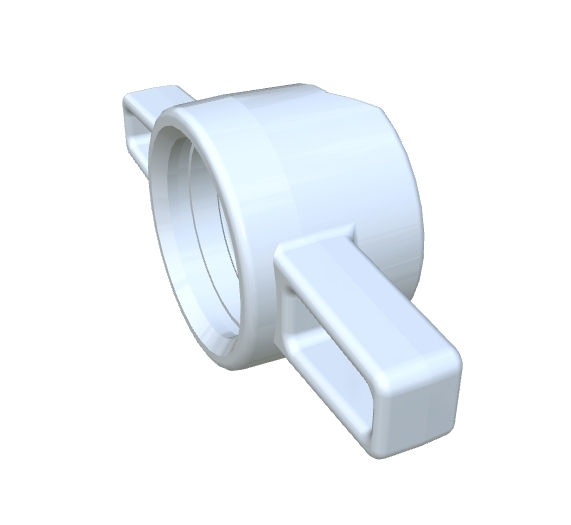

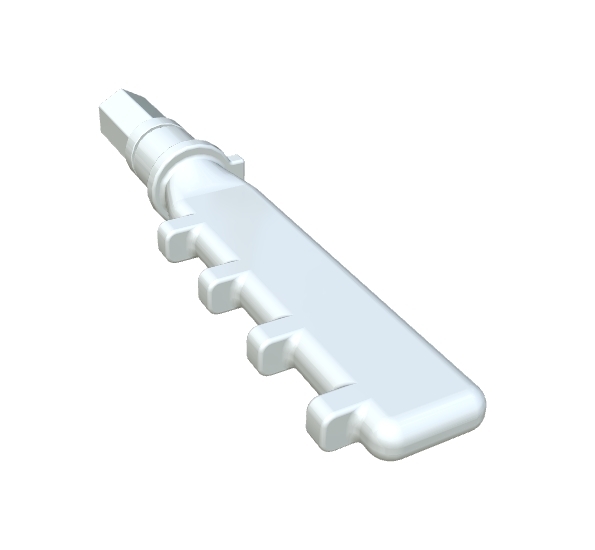

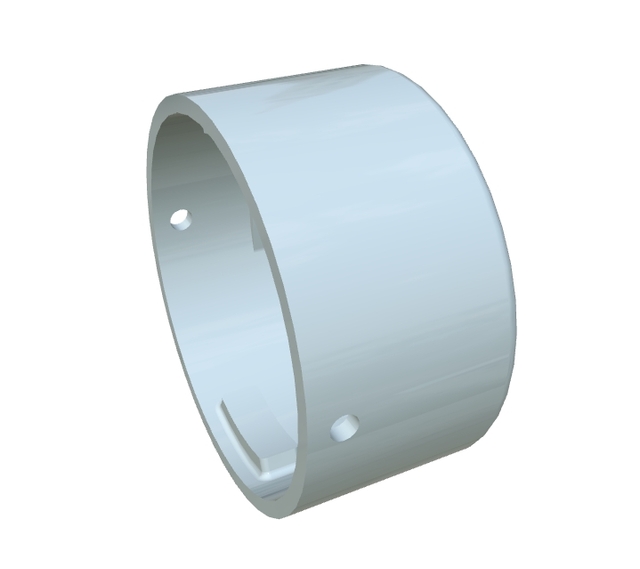

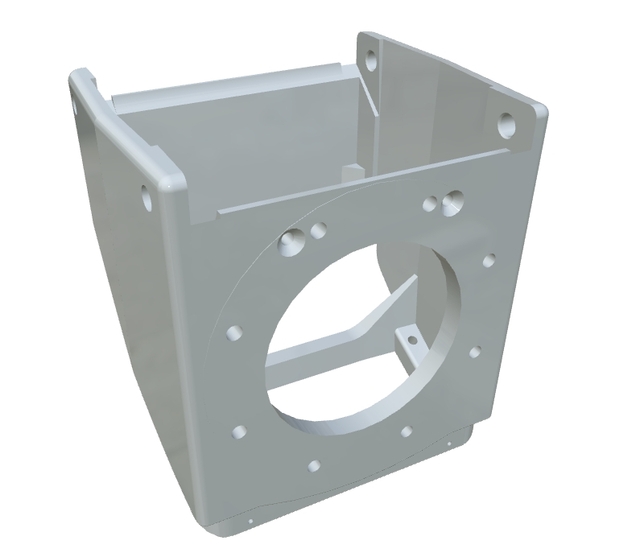

Incorporating the investment casting process in the production of a new 3D-printed clamp showcases its versatility. This sleek ergonomic clamp, crafted from durable and lightweight materials, benefits from the precision and aesthetic appeal provided by investment casting. The circular grip and extended handles ensure secure fastening, making it ideal for DIY projects and professional setups. The clamp's bold white finish and efficient design highlight the seamless merging of modern design with practical efficiency, demonstrating how investment casting continues to innovate and advance product development.

Understanding the Investment Casting Process: Techniques and Benefits

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Metal Casting, Sand Casting, Low Pressure Casting, High Pressure Casting, Investment Casting |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Find Similar Products

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.

People who viewed this also viewed

Investment Casting Benefits: Unlocking Precision & Durability

Investment Casting Process for Precision Engineering

Understanding the Investment Casting Process: Techniques and Benefits

Investment Casting: Techniques and Modern Applications

The Investment Casting Process: Precision & Advantage

Investment Casting Process: Precision & Advantages

Understanding the Investment Casting Process and Its Advantages

Investment Casting Manufacturers: Precision & Innovation