Rapid prototypingis a method of validating product concepts and user needs by quickly building and testingprototypes early in product development. This method is widely used in many fields such as software development, product design, and machinery manufacturing. Its core is to shorten the product development cycle, reduce development costs, and avoid market risks in advance. This article will elaborate onhow rapid prototyping works in terms of its definition, workflow, applications and advantages.

What is Rapid Prototyping?

Rapid prototyping, in short, refers to the use of advanced manufacturing technology or design software in the early stages of product development to produce a preliminary model or prototype of the product at a lower cost and in a shorter time. Theserapid prototypes can be functional, cosmetic, or even a combination of the two and are used for testing, validating design concepts, evaluating user experience, presenting to investors, or marketing.

Compared with the traditional product development process, rapid prototyping focuses more on speed and flexibility, allowing designers and engineers to discover and solve problems early in product development and avoid costly and time-consuming modifications later.

What is the principle of rapid prototyping?

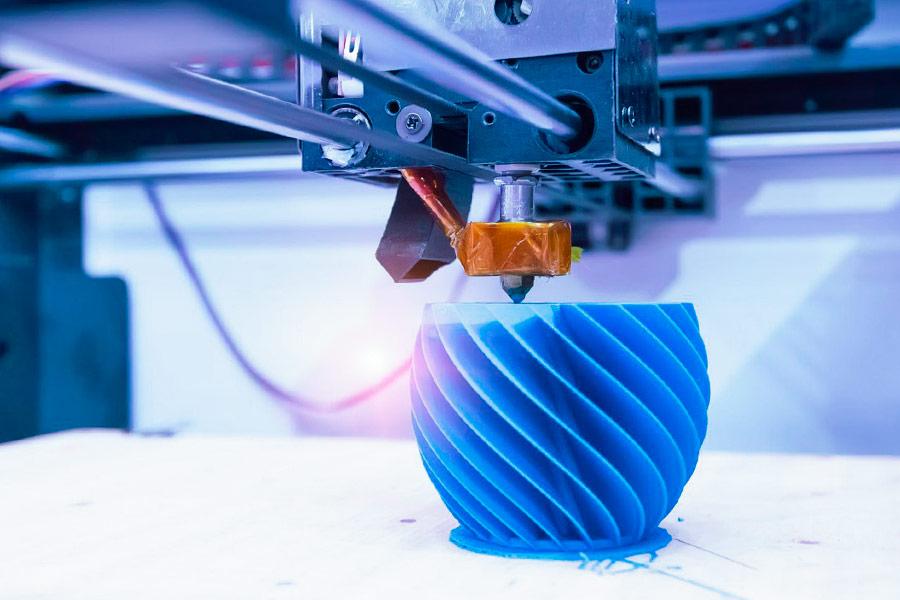

The principle of rapid prototyping is based on the discrete layered molding method, which is directly driven by the CAD model to achieve rapid manufacturing of three-dimensional entities. With the continuous advancement of technology and the expansion of application fields,rapid prototyping technologywill play an important role in more fields.

How Does Rapid Prototyping Work?

Rapid prototyping is an efficient product development method that allows teams to quickly create testable, verifiable prototypes in the early stages of product development. The following is therapid prototyping process:

Requirements analysis:Work closely with users or stakeholders to collect and clarify the basic needs and functional requirements of the product. Determine the goals and scope of prototype design by sorting out and analyzing requirements.

Preliminary design:Based on the results of demand analysis, conceptualize the product and form a preliminary design plan. Use hand-drawn sketches, design software and other tools to quickly draw preliminary design drawings of products.

Prototyping:Useprototypingtools or software, such as Axure RP, InVision, Marvel, etc., to quickly builddigitalprototyping model. If a physicalrapid mockupis required, select appropriate materials and processes and produce it through 3D printing, CNC processing, hand-making, etc.

Testing and Validation:Invite target users or potential users to test the prototype and collect their feedback. Conduct functional testing, usability testing, performance testing, etc. on prototypes to ensure that theprototypemeets design requirements and user needs.

Feedback and iteration:Make necessary modifications and optimizations to therapid prototypebased on test results and user feedback. Repeat the process of testing and iteration until theprototypeddesignachieves satisfactory results.

Delivery and Evaluation:Deliver the final prototype to the project team, client, or stakeholders for evaluation and decision-making. Summarize and evaluate the entire prototype design process to provide reference for future product development.

What are the Different Rapid Prototyping Technologies?

The main types of rapid prototyping technologies are as follows:

| SLA | LOM | SLS | FDM | |

| Principle | The liquid photosensitive resin is irradiated with a laser beam to solidify it layer by layer, eventually forming an integral part. | Thin layers of material coated with hot melt adhesive are bonded together using a hot pressure roller, and then cut into the shape of the part using a laser beam. | The laser selectively sinters the powder material layer by layer to solidify it into parts. | Hot-melt materials (such as ABS, nylon, etc.) are melted by a heater, then extruded, extruded, and stacked into a three-dimensional solid. |

| Features | It has high precision and good surface quality, and is suitable for manufacturing parts with complex shapes. | The process is simple and the processing cost is low, and it is suitable for making larger-sized prototypes. | It can manufacture parts from a variety of materials, such as plastic metals, ceramics, etc., and is suitable for prototyping that requires higher strength and durability. | Low cost, high material utilization, suitable for rapid prototyping and small batch production. |

| CNC Prototype Machining | Injection Molding | laser cutting | Binder jetting | |

| Principle | Through pre-programmed instructions, the motion trajectory and processing parameters of the machine tool are controlled to realize the cutting, milling, milling and other processing processes of materials. | Injection molding is a method of injecting molten plastic into a mold cavity, cooling and solidifying to obtain a product with a specific shape and size. | Laser cutting is a manufacturing technology that uses high-energy-density laser beams to irradiate the surface of materials to quickly melt, vaporize, or reach the ignition point to achieve cutting. | Binder jetting technology builds three-dimensional parts layer by layer by depositing a liquid binder from a print head to selectively bind powder materials together on a powder bed. |

| Features | High precision, complex shape processing, and high degree of automation are widely used in mold manufacturing, aerospace, automobile manufacturing and other fields | High precision, mass production, and flexible material selection are widely used in automobiles, medical care, consumer electronics, home appliances and other fields. | High precision, non-contact processing, wide range of applicable materials, and high efficiency are widely used in metal processing, advertising production, packaging and printing and other fields | Material diversity, high precision and detail, flexible post-processing, and environmental protection |

What are the advantages of rapid prototyping?

As an efficient product development method, rapid prototyping has many significant advantages. Here are theadvantages of rapid prototyping:

Shorten product development cycle

Rapid prototypinggreatly shortens the product cycle from concept to market by quickly converting design concepts into touchable, testable physical models. In the traditional product development process, it often takes a long time from design to manufacturing prototypes to testing feedback. Rapid prototyping technology can complete this process within days to weeks, allowing developers to verify designs earlier, discover problems, and perform iterative optimization, thereby accelerating product launch.

Improve design accuracy

Rapid prototyping technologyusually combines advanced computer-aided design (CAD) software and CNC processing equipment to achieve high-precision and high-complexity product prototypes. These technologies can ensure a high degree of consistency between prototypes and design drawings, reducing errors caused by manual production or traditional processing methods. High-precision prototypes help to more accurately evaluate the function and performance of the product, providing a reliable basis for subsequent production and manufacturing.

Reduce costs

Althoughrapid prototyping technology may require a higher investment in initial equipment, it actually helps reduce costs when viewed throughout the product development cycle. First, through rapid prototyping, developers can detect problems in the design early and avoid large-scale modifications in the later production stage, thereby reducing unnecessary waste and costs. Secondly, rapid prototyping supports small-batch, multi-variety production models, which helps companies flexibly respond to market changes and reduce inventory backlogs and capital occupation. In addition, with the popularization and cost reduction ofrapid prototyping technologiessuch as3D printing, its production costs are also gradually declining.

Enhance user experience and feedback

Rapid prototyping allows users or customers to have early access to physical products and provide feedback through first-hand experience. This kind of intuitive and instant feedback helps developers more accurately grasp user needs and market trends, so as to make targeted improvements and optimizations. At the same time, rapid prototyping also provides investors and partners with an intuitive display method, helping to enhance their confidence and recognition of the product.

What materials are used in rapid prototyping?

- Plastic:It is widely used due to its versatility and affordability. Examples include ABS, polycarbonate, nylon, and PLA for 3D printing.

- Metal:Ideal for high-strength and heat-resistant applications. Common metals include aluminum, stainless steel and titanium, often used in processes such as selective laser melting (SLM) and direct metal laser sintering (DMLS).

- Resin:Resin is used in stereolithography (SLA) and digital light processing (DLP) and is known for producing parts with high detail and smooth surfaces.

- Composite materials:These materials combine the properties of different materials, such as carbon fiber reinforced plastic, to increase strength and reduce weight.

- Ceramic: For applications requiring heat resistance and high durability.

- Wax:Often used in investment casting models during the manufacturing process.

What are the cost components of rapid prototyping?

Material cost

Rapid prototyping technology uses a wide variety of materials, including plastics, metals, ceramics, composite materials, etc. The costs of different materials vary greatly. For example, inplasticrapid prototyping, commonly used materials include ABS, PLA, nylon, etc., and their prices range from a few hundred yuan to several thousand yuan. Material cost is an important part of the total cost of rapid prototyping technology, and its price is affected by market supply and demand, raw material price fluctuations and other factors.

Equipment cost

Rapid prototyping equipment, such as 3D printers, injection molding machines, laser sintering machines, etc., have large price differences, ranging from a few thousand yuan to several million yuan. Equipment cost is affected by equipment model, performance, brand and other factors. High-performance, high-precision equipment usually costs more, but provides better printing results and productivity.

Process cost

Therapid prototyping processneeds to be carried out in multiple links such as mold making, melt injection molding, cooling and unloading, and each link requires a certain amount of time and resources. Process costs include mold manufacturing costs, energy consumption costs, equipment maintenance costs, etc. In addition, different rapid prototyping processes have different requirements for equipment, materials, environment, etc., which will also lead to differences in process costs.

Labor costs

The rapid prototyping process requires operating equipment, debugging process parameters, assembly inspection and other links, all of which require manual participation. Labor costs include wages, benefits, training and other expenses. As labor costs continue to rise, the proportion of labor costs in the totalcost of rapid prototyping technology is also gradually increasing.

What are Some Examples of Rapid Prototyping?

rapid prototyping technology has a wide range of applications in practical applications,rapid prototyping examples are as follows:

- Automotive Industry: For creating scale models, testing functional parts, and design verification of components such as instrument panels, lighting systems, and engine components.

- Aerospace Industry: Used to createrapid prototypepartswith complex geometries and lightweight components, often using high-performance materials.

- Healthcare and Medical Devices: Create anatomical models for surgical planning, custom prosthetics, and medical devices customized to individual patient needs.

- Consumer Electronics: Prototyping of cases, buttons and internal components for devices such as smartphones, laptops and wearables.

- Architecture and Construction: Used to create detailed scale models of buildings, bridges, and other structures for visualization and design verification.

- Fashion and Apparel: Design accessories, prototype footwear, and experiment with new materials. Education and Research: Used to create models and experimental instruments in various academic fields.

- Entertainment and Film: Prop making, costume design, and set models for visual and practical effects.

- Robotics and Automation: For prototyping of robots, automated mechanical parts, and testing of new designs.

- Sports equipment manufacturing: Designing and testing equipment such as helmets, rackets and protective gear.

FAQs

1.What are the most common rapid prototyping techniques?

The most prevalent rapid prototyping techniques include 3D Printing (FDM, SLA, SLS), CNC Machining, and Stereolithography. These methods are favored for their speed, accuracy, and the ability to produce complex geometries, making them versatile tools in various industries.

2.What are the 5 steps of rapid prototyping?

Step 1:The designer uses CAD (computer-aided design) software to create a three-dimensional model of the product;Step 2:Prepare the 3D printer. Before choosing a suitable 3D printer, you need to determine the printing technology and materials used;Step 3:Transfer the CAD model to Import it into a 3D printer and perform slicing processing. The slicing software converts the 3D model into a series of 2D layers, which will be printed layer by layer and stacked to form a physical prototype;Step 4:After printing is completed, the prototype needs to be post-processed and finished.Step 5:Test and evaluate the prototype to verify whether it meets the design requirements. This includes functional testing, performance testing, user testing and many other aspects.

3.What is the principle of rapid prototyping?

The principle of rapid prototyping is based on the discrete layered molding method, which is directly driven by the CAD model to achieve rapid manufacturing of three-dimensional entities. With the continuous advancement of technology and the expansion of application fields,rapid prototyping technologywill play an important role in more fields.

4.What are the Challenges in Rapid Prototyping?

Rapid prototyping has challenges mainly in terms of technical limitations, cost issues, design complexity, software tools and development environments, testing and verification, and personnel training and skill improvement. In order to overcome these challenges, continuous innovation and improvement of technology are required to adapt to market needs. and improve production efficiency.

Summary

Rapid prototyping is efficient and flexible and plays an important role in many fields.Prototyping meaning is not only the development of the entire product cycle, reducing development costs, but also improving product quality and user satisfaction. With the continuous progress and the continuous expansion of application scenarios, rapid creation will play an even more important role in the future.

Disclaimer

The content on this page is for reference only.LSmakes no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyer seeking a quote for parts to determine the specific requirements for those parts.Please contact us for more information.

Longsheng Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.