Rapid prototyping services create material choice predicaments for engineers. Conventional material databases cannot keep pace with different processes or with materials of higher technology levels. Such inconsistencies prompt errors in prototyping. There is inaccurate data in the test results. There is also project postponement as well as expensive redesigning of the product.

Issues exist because of gaps in knowledge from material science and manufacturing knowledge. Information from qualified suppliers will not be relevant when it comes to sophisticated activities like new material composites and specialty plastics. Later, a decision tool for 100+ materials will be explained based on 20 years of knowledge at LS Manufacturing.

Rapid Prototyping Services: Master Quick-Reference Guide

| Aspect | Key Points |

| Objectives | Accelerate design cycles, and perform form and function verification to quickly enter the markets and produce low volume. |

| Core Technologies | FDM: Thermoplastics, cost-effective. SLA/DLP: Resins, high detail. SLS/MJF: Nylon, functional parts. Metal PBF: Final-grade metal components. |

| Material Selection | Criteria: Mechanical properties, thermal/chemical resistance, appearance, budget. Pitfall: Prototype material properties may differ from production materials. |

| Key Advantages | Speed, design freedom, easy production of complex geometry, Rapid prototyping without the high cost of tools, and Risk reduction due to testing. |

| Limitations | Such a process is not economical for volume production. Material properties may be anisotropic. Surface finishmay be required. Not available in larger sizes. |

| Ideal Use | Cases Concept models, functional prototypes, custom jigs/fix-tures, small-batch end-use parts, and complex assemblies. |

| Workflow | 1. Determine the objective of the prototype. 2. Technology and material selection. 3. Optimizing the 3D model. 4. Manufacturing of the prototype. 5. Post-processing. |

Rapid prototyping is essentially one of the most basic steps in any agile development project, and this goes a long way in converting electronic designs to physical components in a matter of days. The advantage in the above does not only lie in the speed with which it can be done-this aspect is quite obvious and a major positive aspect in itself. In fact, it has a lot to do with its usage in validating and producing geometries that cannot be produced through machining by hand.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are many articles available related to rapid prototyping. The uniqueness in this article will be related to the fact that it will be possible for me to give my own opinions based on what is observed from the shop floor. Indeed for over 15 years now, it will remain in the tradition of the company at LS Manufacturing that it will maintain its own proving ground and environment, contrary to the environment that will be known as the clean room environment. That is where our rapid prototype undergoes the test in very harsh conditions at the shop floor.

Our method is systematic in nature. We follow the processes defined in terms of design and processes in Additive Manufacturing (AM). Moreover, the project management and design of work processes that we conduct is a systematic approach developed from American Production and Inventory Control Society (APICS). This ensures that any recommendation we make in relation to rapid prototyping will not be speculative but a result of a method developed after several builds and working.

All guidelines which we seek to impart have emerged from our personal experience - lessons learned the hard way and at a high cost when we were young. This guide embodies our learned experience in the form of guidelines that must be followed, These are the things we believe in because they have been proven true as a working model that could pass the test as well as the pleasing look when viewed in the computer simulation.

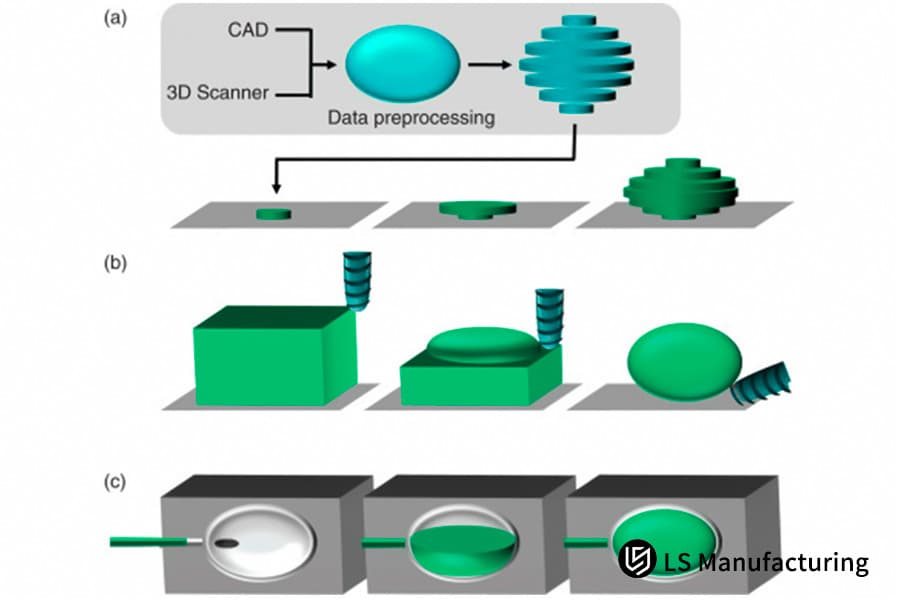

Figure 1: Visual overview of the 3-step prototyping process by LS Manufacturing

Why Is Scientific Material Selection Key To The Success Of Complex Prototype Projects?

The answer lies in the profound impact materials have on functional performance, testing validity, and ultimate project viability. A single rapid prototyping material selection guide error can cascade into failure, delay, and cost overruns, making informed choice the foundational pillar of development:

- Material Science Fundamentals Determine Functional Fidelity: Use of specific material science fundamentals, strength, heat resistance, resilience, or flexibility, automatically validates the functionality or non-functionality of the prototyping design to address real-world issues. For better understanding of this concept, it can be said that using a generic material such as ABS plastic in the context of a high temperature fluid automatically incorporates failures in terms of deformation.

- Navigating the Maze of a Complex Project Material Guide: When it comes to projects that are complex involving more than one assembly of parts, there might arise a conflict of necessities for separate materials. For instance, a gear requires wear resistance property functionality; however, the damping of the gear requires damping of the damper on the gear. Random assignment is a contradiction within the system itself. The systematic complex project material guide is of use in determining the relationships among all the materials that work in cooperation.

- The High Cost of Ignoring a Rapid Prototyping Material Selection Guide: One can only put oneself in a position of a flying aerospace drone with a failed structural component due to material fatigue carefully hidden in static analysis or a biocompatible casing with irritation properties against human skin. The sad reality is these represent not designs but selections gone wrong. Such examples bring one close to realizing that overlooking a proven rapid prototyping material selection puts one at risk of complete prototype irrelevance, a scenario in which the prototype is unable "to test its intended application.

- Data-Driven Decision Models: Beyond Intuition: Modern selection transcends catalog browsing. It involves decision models built on vast test databases. For example, LS Manufacturing’s system analyzes millions of data points on parameters like creep under load or long-term UV exposure. This transforms rapid prototyping material selection from guesswork into a predictive science, aligning candidate materials with precise lifecycle demands.

Scientific material selection serves as the bridge for the digital design to translate into a practical prototype for a feasible prototype at this stage, because scientific material selection encompasses among others the use of the basic principles of material science in project control as a rapid prototyping material selection guide because the use of a guide in a task that has a lot of data avoids the risk associated with material selection apart from accuracy in function as a means to achieve success at the expense of efficiency.

How To Select The Best Prototype Material Based On Mechanical Performance Requirements?

The final consideration in choosing the best prototype material will be ensuring that its key mechanical attributes relate well to functional requirements. The basis for material mechanics performance selection will take into consideration their tensile strength, impact resistance, and expected life in order to ensure functionality.

| Selection Criterion | Key Consideration | Material Examples |

| Tensile Strength | Highly resistant to high stresses and static loading. | PC, Nylon, PEI |

| Impact Toughness | Shock resistance/energy absorption. | ABS, PC, Toughened Nylon |

| Fatigue Life | Performance of material when subjected to repeated cyclic loading. | PEI, Nylon |

| Heat Resistance | High temp resist. | PEI, PC |

| Process Suitability | Ease of use for complex part rapid prototyping. | ABS, PLA, Nylon |

An accurate engineering plastics comparison is necessary to make an educated choice. Ultimately, empirical performance test verification is crucial. LS Manufacturing in-house lab provides this certainty through custom mechanical testing, supplying validated data that de-risks your complex part rapid prototyping and ensures the chosen material performs as required under real-world conditions.

How To Select Materials For Special Environments Such As High Temperature And Corrosion Resistance?

As a consequence, material selection in high-temperature environments or when facing corrosive environments is an extremely critical task that demands an extremely high level of judgment. Appropriate material selection would ensure performance and safety with longevity in demanding service sectors and is key to forming a strategic approach to identify particular stress factors and align them with properties of advanced materials.

- Key Considerations for High-Temperature Use: The high-temperature material selection involves a preliminary examination of the Heat Deflection Temperature values - HDT and continuous service temperature. However, it requires a clear understanding of the relative variations in the mechanical properties related to the strength and stiffness of the material with exposure to high temperatures, which is possible only if accurate temperature-performance curve data are provided.

- Navigating Chemical Compatibility: The selection of the corrosion-resistant prototype will depend on the type of chemical involved and the time factor. For the selection of the materials that are resistant to corrosion based on the chemical involved, the specifications of the chemical compatibility chart for the material RPPS/PPA or RPTFE should be consulted. This will ensure the failure-free operation of the prototype materials under fuels/solvents or sterilization agents.

- Leveraging High-Performance Polymers: Specialty engineering plastics like PEEK, PEI, and PPS dominate this sector. They give a performance that is unmatched in terms of heat stability and chemical resistance and mechanical strength simultaneously. More expensive upfront, but they can justified when used in conditions that could lead to catastrophic failures.

- From Specification to Validated Prototype: This needs custom rapid prototyping solutions to effectively use these materials. It needs to be done by machines capable of working with the high-performance materials being utilized, and more importantly, with a focus on extensive post-testing protocols. This needs to be done by subjecting prototypes to simulated environmental stress conditions before scaling up to mass production.

In summary, selecting materials for extreme environments is a meticulous, data-driven process. It progresses from defining thermal and chemical exposures to choosing appropriate specialty engineering plastics. The path from high-temperature material selection to a reliable corrosion-resistant prototype is completed through custom rapid prototyping solutions, ensuring a functionally representative and validated component.

What Are The Material Selection Ranges For Different Rapid Prototyping Processes?

The choice of the right prototyping method is directly linked to the selection list of the material because in every method of the prototyping process, there are advantages and limitations. It would be quite apt to identify the needs of prototype process material matching.

| Process | Material Range | Key Characteristics / Limits |

| 3D Printing (FDM/SLA) | Thermoplastics (ABS, PLA, Nylon, PC), Photopolymers, Composites | Excellent for complex geometries; 3D printing material selection varies by tech; layer adhesion & anisotropy considered. |

| CNC Machining | Solid Plastics: Acrylic, Nylon, PC, PEEK; Metals: Aluminum, Steel | Very strong Isotropic strength & smooth surface finish. The material chosen is restricted to stock blanks only with a high degree of precision. |

| Vacuum Casting | Urethane Resins (Silicone Molds) | Recommended for small series production when achieving a finish simulating the appearance and feel of end-produced plastics like ABS, PP, and Rubber; flexible to rigid components can be produced. |

| Injection Molding | Production-grade Thermoplastics & Elastomers | Used for high-volume prototypes; high upfront tooling cost; full production material properties. |

Sometimes, optimal routes require integration or multi-process synergy For example, since you would be seeking a comprehensive rapid prototyping supplier, LS Manufacturing can integrate processes like making a master through 3D printing for vacuum casting, and then the process consisting of machining metal inserts and printed encasements. This will be led by prototype process material matching related to your project phase.

Figure 2: Batch of complex custom prototypes on metal build plate by LS Manufacturing

How To Balance Prototype Material Costs With Project Budget?

The cost balancing of prototype materials and the total project costs play a very important role in product development and directly influence financial viability as well as technical viability. Balancing here involves more than just getting the least expensive material, but also to find one method or solution that gives the best value based on a total prototype material cost analysis as a smart budget balancing strategy, aiming at meeting all the technical specifications successfully.

Deconstructing the True Cost

The true cost considers aspects such as ease of processing, waste factor, machine time, and potentially extra post-processing steps, rather than only the material cost per kilogram in a detailed prototype material cost analysis. A good example in this regard may thus be an engineering plastic that is more expensive but has an easier ease of processing and waste factor, which would in reality be cheaper in the longer term because of the fact that a harder processing time will make a less expensive material even more expensive in comparison.

Implementing a Tiered Approach

An effective budget balancing strategy often employs a phased or gradient material selection process. Early conceptual prototypes can utilize cost-effective, general-purpose materials, while functional testing stages progressively use higher-performance grades. This staged investment aligns spending with the prototype's validation phase, ensuring funds are allocated efficiently and supporting broader cost-performance optimization across the project lifecycle.

Matching Specification to Actual Need

This is literally the meaning and point of successful cost-performance optimization - matching the characteristics of the material to the needs of the final created prototype. Over-specification - using say an expensive aerospace material grade on an initial form and fit test - is pointlessly ratcheting the cost skyward when in fact an analysis of needs would indicate a specification of material that could meet but not necessarily exceed needed specifications.

Leveraging Expert Partnership for Value

In order to minimize cost, it will be wise to consider an expert manufacturing partnership. This is where an expert in rapid prototyping quotation will be able to spot options on DFM that reduce a large number of operations in manufacturing to reduce the cost of an even greater number of operations or simply use cheaper materials within the manufacturing process of the involved product(s) in this particular case.

In the end, value engineering as a cost-performance balance methodology would mean either cost analysis of material used for the purpose of prototype material cost analysis, where cost-performance optimization would ensure the optimal use of the project cost, or partnering to get a comprehensive rapid prototyping quotation that assists in generating the required alternatives to achieve optimal economic efficiency in acquiring a valid prototype successfully.

Figure 3: Display of fast prototype fasteners in vibrant colors by LS Manufacturing

Medical Device Industry: Customized Multi-Material Prototype Of Precision Gripper For Surgical Robots

With the progression of the design of the gripper in the stages of the rapid prototype development for the surgical operation, some of the most urgent requirements for the specific organization would be that it should be rigid, strong, and biologically compatible because these requirements could not be met by a combination of materials.

Client Challenge

The problem is that until now, a material like this did not exist; therefore, until now, there did not exist a material with the ability to fulfill the property requirement because it has to provide all the properties in one side. One side of the problem: Biocompatible materials lack proper mechanical articulation wear resistance properties. The other side of the problem: There might not be proper safety standards for using engineering plastics with high strength for medical purposes.

LS Manufacturing Solution

Our company, due to the knowledge that it has accumulated all these years with rapid prototyping manufacturer, created an exclusive multi-material solution We selected the latest 3D printing technology for the manufacture of the structural part of gripper manufactured from medical device prototyping from TPU materials on the touch part.

Results and Value

The LS Manufacturing success case has successfully demonstrated effectiveness related to the acquired outcomes. The multi-material prototype, which is expected to be developed, has already performed the test of functionality and compatibility as well as the test of durability as a part of this experiment. Additionally, besides that process, it has also helped in proving the product design even before the tooling experiment. All of these processes took 60 percent less time compared to before with a cost saving of 800,000 RMB related to mold adjustment for the customer.

The importance of material innovation and process innovation in navigating challenging design issues is highlighted in the particular case study for this project. As we have facilitated the delivery of a very complex multi-material solution, a challenging topic in the medical device prototyping has been mastered by making it successful in proving the importance of having a professional in the rapid prototyping manufacturer.

Ready to Engineer Your Precision Surgical Gripper? Get Your Customized Multi-Material Prototype Solution Now!

Why Choose LS Manufacturing As Your Rapid Prototyping Service Partner?

Your decision regarding rapid prototyping services may lead to affecting product development time, quality, and costs. The most ideal rapid prototyping service may imply that you have access to or may have the most optimal form of technology, materials, and processes that can potentially lead to a speedy conversion of designs into reality. Among the most persuasive reasons that can establish that choosing to benefit from a professional and expert rapid prototyping service provider like that of LS Manufacturing may lead to a critical juncture for you in initiating your conversion from designs to a functional prototype.

Deep Material Expertise and Extensive Inventory

The key to success in the aforementioned components and parts will be the amalgamation of a comprehensive inventory of materials expert team. The materials expert in our company will take care of the fact that with regard to the selection of the material, it should be done with a focus and target on rapid prototyping materials and cost in a precise manner. With the consideration and inputs given by a materials expert in our company with regard to the selection of material, the said selection will be done in a manner that it enhances ease of manufacture, cost, and performance to a maximum extent.

Certified Quality and Precision Verification

Our intention is to ensure that we have a good quality verification, such as ISO 13485 quality certification, which is tailored for medical quality verification. All this will be covered by ensuring that we have good quality measurement tools for importing and verifying our quality at a certain precision level. This will mean that we have tested all our prototypes for their quality before we can deliver them to you.

Integrated Technical Ecosystem and Collaborative Team

A major LS Manufacturing advantage is our integrated technical ecosystem with multiple processes, made possible through our 20-person-strong expert team. Another benefit from this integrated technical ecosystem is the rapid resolution of problems with complex geometries and multiple materials, rapid iteration, and finally, rapid success with the first conceptual product solution itself.

Proven Track Record and Client-Centric Process

We deliver value based on a proven track record-a rate of success in our pursuits that is the highest in the industry and the second highest in material selection. All this while keeping at the forefront the client-centric process for each and every undertaking-a mindset that says partners. By concentrating on communication from the point of contact through to the end of each and every project we undertake, we deliver not merely the part but the whole rapid prototyping service provider experience to bring you confidence and value in your development cycle.

In summary, when you choose LS Manufacturing, you are choosing a partner that is dedicated to excellence in technology, knowledge in materials, and success in your particular project. Our strengths, in being one of the leading rapid prototyping service provider - from our materials expert team and our great resources to our certified processes and collaboration-all provide a number of LS Manufacturing advantages: quicker development, managed rapid prototyping materials and cost, and pretypical models that instill absolute certainty in final product performance.

Figure 4: Orange prototype with its industrial 3D printer and filaments by LS Manufacturing

How Can I Get Professional Advice On Material Selection And An Accurate Quote?

Nevertheless, it is the crucial initial stage of an optimal rapid prototyping process to ask for professional advice on what material should be used and get a quote on it. That is accomplished via an extensive structured discussion of your needs, allowing our experts to merge your requirements in terms of technology and business needs with optimal advice.

- Initiating the Collaboration: The process of initiating our collaboration will begin with a materials selection consultation. This will entail that you share your specifications through CAD and performance specifications. This information allows us to thoroughly understand your objectives, forming the essential basis for a precise evaluation and effective professional solution customization tailored to your specific needs.

- Technical Analysis and Feasibility Study: After you place your inquiry, a technical analysis is carried out on your design by us. This evaluation includes assessing the ability of our design to be produced and the limitations involved and how your requirements are measured against the material requirements that we will be needing. This phase of the evaluation is more about striking a balance between the pros and cons involved in your design feasibility.

- Developing a Personalized Plan and Transparent Quote: Based on this technical analysis, we craft and present a detailed, personalized proposal. This professional solution customization includes the recommended materials, manufacturing processes, projected timeline, and a complete, transparent cost breakdown. The resulting rapid prototyping quote is precise, itemized, and fully justified, providing you with complete financial clarity and a reliable plan before any commitment is made.

- Delivering Added Value Through Expert Review: One of the most important values that can be offered in a project at Howe Design Group is expert review of the materials and manufacturability of a product, which is a complimentary service of a project with us. Through this complimentary service, we can make use of expert knowledge at Howe Design Group and provide value to a particular project related to ways and means through which improvements can be made or costly errors can be averted.

In summary, the process of seeking professional advice and an accurate quote is an efficient procedure where you collaborate with us. This procedure goes from an initial materials selection consultation to a technical analysis until it reaches an accurate rapid prototyping quote. The commitment of our company to professional solution customization and collaboration will support you in achieving the attainment of a value-driven approach that is in proper alignment with your technical project and goals.

How Will New Materials And Processes Influence The Future Development Of Prototype Manufacturing?

The future of prototypes is undergoing a revolution according to the progress made in materials and processing. There is a paradigm shift in prototypes from a passive system to an active piece. The development of innovative materials, together with innovative ways of their processing, is presenting an endless number of possibilities in designs. This is the emerging revolution in the technology of rapid prototypes, destined to facilitate intelligent innovation in products.

- Rise of Advanced and Programmable Materials: The most important driver influencing the usage of advanced materials is the growing demand for high-performance composites and smart materials. It has also been observed in the new material trends like composites and smart materials enable prototype simulation with the ability to see and feel like finished goods and also behave like finished goods.

- Unlocking Unprecedented Design Freedom: Innovative prototyping technologies are breaking a paradigm in the world of manufacturing. Consequently, multi-material 3D printing platforms will soon allow an assembly in a single pass that was heretofore impossible in terms of designing that could not be prototyped in the early stage design.

- Investment in Next-Generation Capabilities: In order to ensure continued leadership, one must perform as a leader in making these efforts happen. We integrate our knowledge of what the next generation of manufacturing capabilities consists of through our work with innovators of technology as well as building our skills in these newer tools. This enabling means that validation of the inclusion of next-generation materials/procdures into our clients' projects can, in fact, be offered.

- Towards a Sustainable, Integrated Ecosystem: The last effect of these innovations is a sustainable future of manufacturing as a whole. The functioned prototypes do not waste resources during the post-production stage, whereas the biological materials help towards a circular future. The whole future manufacturing insight indicates a future of prototyping as a comprehensive activity that generates data, meaning that the whole life cycle becomes risk-free.

The combination of new material trends and innovative prototyping technologies is resulting in a revolution in prototypes, making it an essential innovation generator. By actively applying these future manufacturing insights, we can prepare our clients for embracing innovation designs and can help them enter into a new world of innovation.

FAQs

1. May I please have the performance specifications that are correct?

We also provide full third-party certified performance specification sheets for all materials that have more than 20 specifications, including mechanics, thermal, and electrical specifications, to ensure the correctness and accuracy of the information provided.

2. What measures do you take to ensure that your medical materials are biocompatible?

The biocompatibility reports are also supplied for all of the materials that have a relation to medicine and that have a USP Class VI biocompatibility certification. This means they are in compliance with a standard for a medical device.

3. Does your company provide content creation services?

The fact that ours is able to take advantage of the availability of materials laboratory for research and development activities means that material processing for modifications is also viable. In addition to this, the creation of novel material formulation for our clientele has been successful.

4. What may happen if I select the wrong material?

We follow the procedure called dual confirmation for the selection of materials. And if there was some problem with the material. Suppose there was some issue that may arise through our selection of the material. Then we will reproduce the item for free in case of that material.

5. What does a person need to do in order to determine that the given material possesses environment resistance?

The company is also involved in the simulation of accelerated aging tests for long-term running in a certain environment condition of materials in order to provide a scientific basis for related material selections.

6. What does the MOQ and MOC of the material mean?

There may be orders such as an order of a sample and an order of a batch of materials. It is clear that the minimum order quantity of special material must be 100 grams to ensure that the customers could check the feasibility of the material at the least cost.

7. Could you give details about material processing?

First of all, we would like to highlight the fact that we make specific recommendations in relation to the parameters of processing in regard to each type of material, such as highly important parameters like temperature or speed.

8. Can you give some tips on techniques that could ensure consistency between lots?

We continue to repeat the process of implementation for the supplier management and incoming inspection system. Every batch of material has to be tested using a heavy index test.

Summary

From the above comprehensive analysis carried out with the assistance of this guide, it is evident with emphasis that the science of material selection is the prime reason behind fully succeeding at complex prototyping projects. With the assistance of the highly qualified material database, testing facilities, and joint efforts at the process of material, the company referred to as LS Manufacturing can make perfect material choices for any and every kind of complex project with utmost ease alone.

As being the best in being the prototyping service provider company, we also engage at providing solutions for material science solutions exclusively for our beloved clients alone. Just click below for instant quotes, tech support, and much more! This project will get an analysis report concerning material selection, process, project quote, and tech support.

Validate quickly before mass production. Click to get your customized prototyping solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.