Rapid prototyping services are the most difficult services in product development, though the challenges involved in these services are slow cycles, quotation given at the end of the cycles, and the level of services provided. The conventional manufacturing sector is unaware of the time involved in the services associated with prototyping, thereby contributing to the high cost of communication in R&D services.

The traditional issue of the suppliers not being able to leverage the benefits of the processing capacities that are optimized for large volumes in a way that could be applied for the creation of prototypes, almost similar to manufacturing, has been tackled by the LS Manufacturing with the use of the end-to-end solution. At LS Manufacturing, we provide you with quoting, DFM analysis, and ordering so that you can access your prototypes.

Rapid Prototyping Services Quick-Reference Guide

| Section | Key Focus | Core Offerings / Solutions |

| The Pain (What) | Common Challenges | Slow turn-around time, slow quotes, quality variability, high communication expenses, slow R&D. |

| The Root Cause (Why) | Core Problem | Suppliers do not have processes optimized for prototypes; they regard prototypes as production units. |

| The LS Manufacturing Solution (How) | End-to-End Service | Standardized quoting, professional DFM analysis, flexible production scheduling, transparent pricing. |

| Key Benefits | Value Delivered | Faster time-to-market, reduced risk, better design validation, informed decision-making, cost predictability. |

| Supported Methods | Available Technologies | CNC Machining, 3D Printing (SLA, SLS, FDM), Vacuum Casting, Sheet Metal Prototyping. |

| Industries Served | Application Areas | Consumer Electronics, Automotive, Medical Devices, Aerospace, Industrial Equipment, Robotics. |

Rapid prototyping has to play the part of an intermediating factor for design and its execution. The structured approach that serves the purpose of the LS manufacturing solves the problems in the sector by focusing on speed, knowledge, and communication. In this way, various individuals involved can easily create reliable prototypes in the shortest period of time.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are thousands of articles available online about the rapid prototyping services; so, what is the point in wasting your precious time with us? This is mainly because we are not theorists; in fact, we are doers. The workshops of our company are actual places where we work with the difficult-to-work-with high-tech polymers on a daily basis in order to manufacture prototypes. Again, the expertise of our company is not based on theory or research; in fact, it is based on how-to ensure reliability with every project.

This manual leverages all of the best practices that have been derived from all of our experience in prototyping due to the fact that, in our field of work, having been practitioners of precise component manufacturing used in the validation of aerospace projects and also biocompatible models used in the testing of biomedical equipment, among others. Our field of expertise qualifies according to the standards of bodies such as Society of Manufacturing Engineers (SME) and therefore qualify our expertise to be practical and not theoretical.

What 3D printing technique is best at ensuring CNC machining is optimized for turnaround, and what must be weighed when speed versus quality is a consideration within a time constraint. We share this hard-earned, shop-floor-validated expertise to help you navigate your prototyping journey efficiently, following protocols that meet guidelines from organizations like the Environmental Protection Agency (EPA) for sustainable practices.

Figure 1: Precision prototype manufacturing via automated processes by LS Manufacturing

Why Are Professional Rapid Prototyping Services So Crucial To Product Success?

The process itself, from the moment of conceptualization until the actual product launch in the market, is full of unknowns in this saturated market scenario. An efficient rapid prototyping services requires more than a one-step process of risk mitigation since the crux of the issue is the acceleration of the verification process of the product made in order to cater to their intentions as well as aspirations—basically the professional prototype value.

Design Validation and Risk Management

This highly accurate prototype is validating in the real operating environment, form, fit, function, before committing significant capital expenditure to production tooling, where the providers are producing highly accurate parts, very similar to the end products, which point out the design flaws at the beginning of the design process. Design validation at this level of designs, which sees the models come to life, validates the importance of LS Manufacturing prototypes in risk management.

Time to Market

This is perhaps the most defining criterion. The successfully delivered services of companies offering rapid prototyping services use the best practice and leverage advanced technology as well as effective project management. Fast execution within design services enables a larger number of design cycles in a shorter period of time. The increased design cycles stemming from collaboration with companies that advocate faster execution but within set quality parameters exert a direct influence on product and entry to market.

High Quality & Technical Services

The gap that is present between professionals and common work shops is very wide. Professionals are in a position to provide technical feedback regarding DFM, material, and precision that common work shop s are not in a position to provide. Technical partnership promotes perfection in value for money being provided by professional prototype value and ensures that developments made by them are prototype models, which are aesthetically pleasing but technical pioneers of high-quality production.

Long-Term Cost Efficiency

Although professional services could charge a higher starting price, their long-term savings are huge. Professional services help avoid expensive production mistakes, eliminate rework, and facilitate a smooth transition to mass production. The importance of LS Manufacturing prototypes is well captured by the long-term value they add, because it is much more expensive to produce a product than a prototype.

The expertise of rapid prototyping services is an investment rather than an expense in the long run. Rapid prototyping services can reduce risk throughout a product's development lifecycle, help with timelines, and provide an effective cost structure relative to the successful launch of your product. The professional prototype value, such as the importance of LS Manufacturing prototypes in translating an innovation into reality dependably.

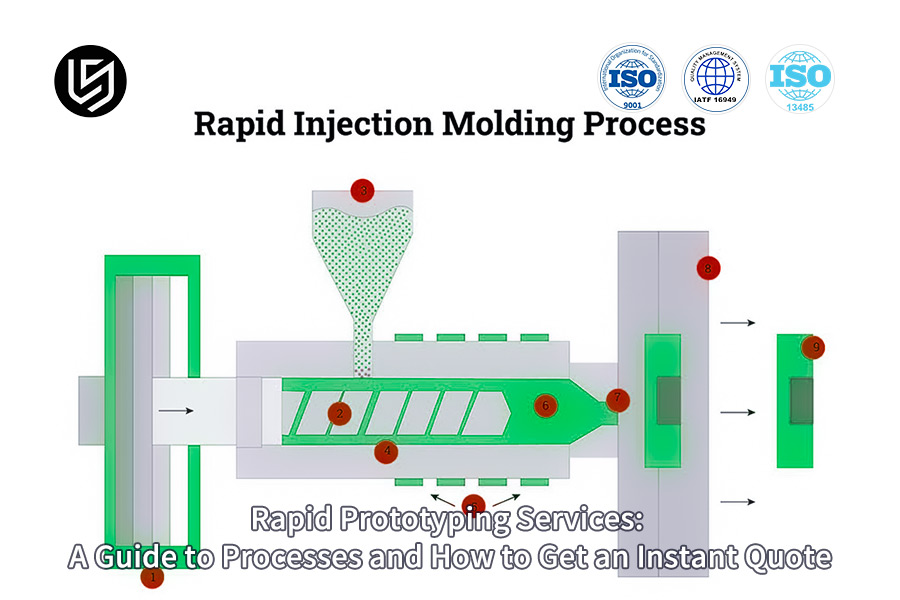

3D Printing, CNC Machining, Vacuum Molding: How To Choose The Best Process For Your Project?

Choosing the best prototyping process can make all the difference in the success or failure of a project. A good prototyping methods guide can help you to effectively utilize prototyping in advancing your goals. It may be an incredibly empowering experience when technology lets you further exactly what you need to accomplish through prototyping, whether that be prototype modeling, prototype testing, or prototype production.

| Process | What is best suited | Common Materials | Typical accuracy | Typical lead tim |

| 3D Printing (Additive) | Rapid prototyping, complex geometries, design iteration. | Photopolymer resins, nylon, ABS-like. | ± 0.1% - 0.5% (layer-dependent) | 1-3 days |

| CNC Machining (Subtractive) | Functional prototypes, high strength, tight tolerances. | ABS, PC, aluminum, stainless steel. | ± 0.025 - 0.125 mm | 2-5 days |

| Vacuum Casting (Urethane Casting) | Production in small series, model making, elastomers, parts with multiple materials. | Polyurethane resins-mimicking PP, ABS and silicone among others. | ± 0.2 mm per 100mm (mold-dependent) | 5-10 days (incl. mold) |

A certain amount of awareness regarding the state of 3D printing vs CNC machining, as well as awareness regarding other relevant key technologies, marks the beginning of smart prototyping. Perhaps the single most significant variance regarding the differences comparison of rapid prototyping processes has little to do with determining the best approach as a whole, and even more to do with a whole different agenda, such as determining the value to your particular project.

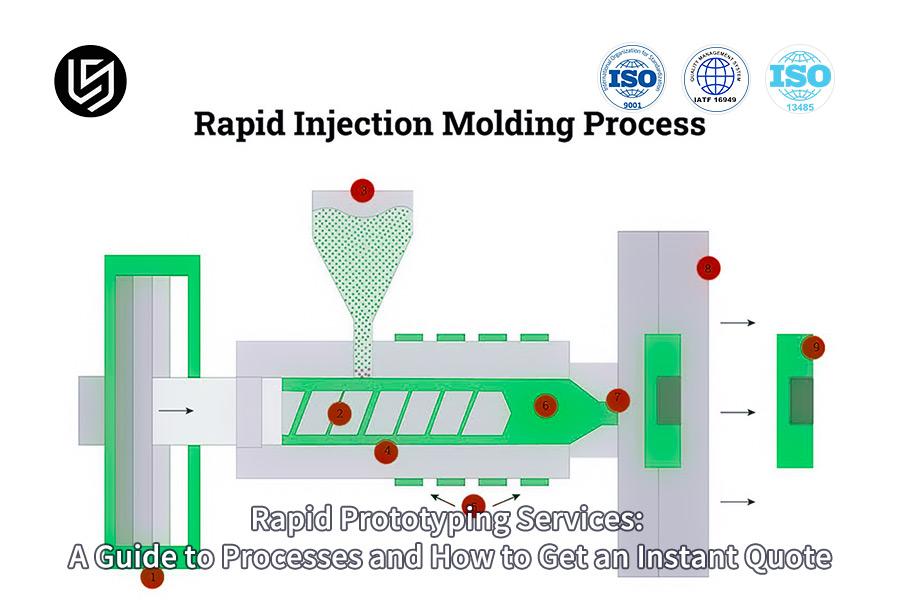

What Are The Key Steps In LS Manufacturing's Rapid Prototyping Process?

Having an efficient workflow process, which will be understandable and transparent, will provide good grounding for all prototyping. The rapid prototyping process at LS Manufacturing will include fast prototyping, where the uncertainty and delay will be minimized. Then there are specific procedures to be followed for all inquiries concerning the delivery of your prototypes, which will be devised for all communications, extensive engineering assistance, and complete observation for the purpose of having quality prototyping arrive at your location on schedule.

| Step | Key Action | LS Manufacturing's Value & Output |

| Instant Quote | Upload of 3D files and requirements described in detail. | Quote available instantly. |

| DFM Analysis | Peer review for your project. | Manufacturing-related aspects with active feedback. Optimization suggestions. |

| Order & Scheduling | Confirm the order and production schedule slotting. | Verify the position within the production line and timeline. |

| Production & Updates | Manufacturing of parts, post-processing. | Receive critical notifications for updates such as, the start of manufacturing and post-processing. |

| QC & Delivery | Final inspection and shipping. | Parts undergo strict QC against your specs and are shipped promptly. |

With an optimal process in place, LS Manufacturing can ensure that the benefit of optimal professional rapid prototyping process is actually ensured in every project. The process followed by an LS Manufacturing service steps, followed below, can therefore ensure the optimisation of complex prototyping projects by making the task simpler and more collective for all parties involved in the task. The three key aspects of prototyping, which are given emphasis by LS Manufacturing, are embedded in every stage, ranging from DFM review to inspection.

Figure 2: From digital model to 3D printed prototype workflow by LS Manufacturing

What Are The Main Factors Affecting Rapid Prototyping Quotes? How Should We Understand "Instant Quotes"?

The element of cost transparency is a crucial aspect of project planning. This is a dissection of prototype cost pricing, and it explains the key factors that determine the cost and how an instant and rapid prototyping quotes system functions. Once you understand the factors and concepts that govern them, you will be equipped with sufficient information that will guide you throughout your projects.

- Primary Cost Drivers: Several factors influencing prototyping quotes directly impact the final price. The choice of processing, such as 3D printing or CNC machining, material description, material grade, scale of the model, and level of complication, meaning the list of finishing tasks such as painting, plating, and assembly, have been important considerations in arriving at a quotation.

- How Instant Quote Systems Work: Development of an online prototype quote using smart algorithms. When uploading your file in 3D format, the system automatically checks the geometry of your file based on the material selected, as well as the volume of the build, and instantly provides a quote which only takes minutes, unlike the current system in place.

- Role of Engineering Review: The example at hand is good enough to start with. Going by accuracy, in this case, first of all, what should happen is the reviewing of a professional manual by a professional engineer. They review DFM, determine the correct process, and even determine what could potentially be complex issues, beyond what the algorithm has taken into account, to ensure that what has been determined, is in fact to be paid.

- Price Principles: The principles behind online prototyping quotes are rooted in standardization and digital workflow integration.The direct impact of the automation process enables immediate transparency and fast feedback regarding the initial assessment of the standard factors. The initial process is designed to provide fast feedback to all parties, along with the second assessment by humans for detail, if required for complicated projects.

In brief, instant and rapid prototyping quotes make up a perfect amalgamation of automation as well as human intellect. Once you understand what all is involved in the factors influencing prototyping quotes, as well as what all is involved in online prototyping quotes, you will find it much easier to make use of all these technological advances. All this will allow you to take proper advantage of the online prototype quote process with your prototyping partner.

Figure 3: Rapid-turnaround, end-to-end custom manufacturing by LS Manufacturing

Medical Device Industry: Customized Multifunctional Prototype For Handheld Diagnostic Device Housing

This LS Manufacturing success case shows that our company has the capability to handle the most difficult difficulties related to the development of timesaving products. The difficulties faced by us include designing the function prototypes of the clinical demonstration.

Client Challenge

A med-tech startup needed 5 sets of custom medical device prototypes for a handheld diagnostic tool within one week. The medical device involved in the project is the handheld diagnosis device. The prototype developed has been highly important, and there has been an important requirement for it to consist of snaps and posts, which can be considered quite complex. Various companies had refused to work on this project owing to an incredibly tight deadline, and the outcome for them would entail an inability to release their products.

LS Manufacturing Solution

We immediately analyzed the design, recommending high-temperature SLA 3D printing for its accuracy and smooth surface finish. Our engineer provided a DFM report with optimization suggestions within an hour. Leveraging our fast prototyping services, we prioritized the order, managing the entire rapid prototyping of multifunctional housings—from printing to post-processing (sanding, painting)—within 48 hours.

Results and Value

The five high-fidelity prototypes took just 4 working days to complete. This has enabled the client to develop a successful one which finally got them the required funds to undertake the implementation of the projects. This collaboration has ensured that the two firms currently enjoy an incredibly excellent relationship as preferred partners in developing prototypes and manufacturing.

This case is a unique example that demonstrates the feasibility of the entire rapid prototyping of multifunctional housings. The successful implementation of the consultation process throughout, along with the fast prototyping services that we follow, enabled us to achieve a successful outcome for our client, changing what could have been a very strict deadline into a successful event. The case is a truly successful example of what a typical LS Manufacturing success case could look like.

Ready to begin accelerating your prototyping process? Simply upload your 3D file and get a free quote.

How Can We Reduce Prototyping Costs And Shorten The Cycle Time Through Design Optimization (DFM)?

Designing efficiently is the very first step, as designing efficiently has the most leverage in designing prototypes that result in minimal costs. If designing with help of manufacturing is being done from the initial phases of a project, then it might be likely that some problems associated with manufacturing complexities and waste might already be eliminated. This section shares practical, expert-backed strategies for prototype design optimization that can directly accelerate your development cycle and lower overall expenses.

Optimize Wall Thickness

Maintaining uniform and appropriate wall thickness is a cornerstone of prototype design optimization. Walls that are too thin may be fragile or warp, while excessively thick walls waste material, increase weight, and extend print or machining time. Adhering to the recommended thickness for your chosen material and process ensures structural integrity while optimizing both the production speed and material usage, which directly contributes to DFM reduces prototyping costs.

Simplify Geometry & Minimize Supports

High overhangs, together with the complex paths involved in the additive process in scenarios, lead to high support values. Optimization of designs using self-supporting angles or reducing design parameters responsible for the high support values of overhangs remove high overhangs. Optimized designs influence lead times.Reducers are used in designs to ensure designs are optimal.

Select the Right Material and Process

The material and technology for development of prototypes is the aspect that can never be considered separately for the purposes of DFM. Though there has been some design for an aluminum CNC machining material, owing to the overall complementarity between the technology used in the process of CNC machining, this does not guarantee efficiency in the determination of the respective technology for the development of prototypes, which may be graphical, functional, or pre-production prototypes.

Leverage Expert Analysis

Although all of this advice is great to follow, it is much more effective to know all of this and use it in conjunction with manufacturing expertise. That is exactly what an LS Manufacturing free prototype DFM analysis can help you do. Our engineers review your design to identify potential manufacturing hurdles, suggest specific optimizations, and recommend the most cost-effective process—all before production begins, ensuring you receive the most accurate and competitive get prototype quote.

In summary, proactive prototype design optimization is a powerful lever for controlling both timeline and budget. Uniform walls, straight geometry, and process alignment-all of which you emphasize-are the keys to efficiency. The most important part of this contract agreement for you in relation to having an effective and error-free production process is working together on the free prototype DFM analysis, as this ensures that the quote for the end prototype has the most economic and effective way of get prototype quote.

Figure 4: Get an instant quote for precision SLA-printed parts by LS Manufacturing

What Capabilities Should Be The Focus When Selecting A Rapid Prototyping Service Provider?

Choosing the right partner is crucial for project success. Selecting a rapid prototyping supplier requires a clear evaluation framework. Focus on capabilities that ensure not just a delivered part, but a seamless, reliable, and collaborative development experience for your custom rapid prototyping needs.

- Technical Versatility: It has to involve various processes, and this has to be beyond CNC and 3D printed solutions, amongst others. The reason being that every single detail is aimed at enabling you to identify the best process suited for your use of the product, look, and cost. Such is fundamental in evaluating prototyping service providers.

- Expert DFM & Engineering Support: It is an unfindable reality that, in order for the message of added value, supportive services are required. The expertise of the supplier must be judged in view of manufacturability analysis in order to make the utmost use of designs in relation to cost, functionality, and rapidity. This collaborative engineering is a key aspect of the LS Manufacturing capability assessment.

- Quality Control & Reliability: Quality of parts and reliability of delivery times are key. The quality of the services, besides being prudently judged, also has to be examined when part deliveries come in. Delivery times should be of utmost importance when considering different partners.

- Responsive and Transparent Communication: Communication has become the backbone driving all the activities taking place in the team projects. The overkill that has occurred concerning this aspect as regards the response and transparency needed by the project communication for the projects taking place in teams is quite high. Having a contact within each team project partner and his or her role concerning the leading role in project communication would eliminate project risks.

A wise judgment, based on the factors of technical scope, alliance for engineers, reliability, and communications, would help you to identify the correct person who would further help you to identify the correct partner that you would be linked to. The judgment criteria checklist would also help you selecting a rapid prototyping supplier, which would further help to satisfy the needed criteria regarding the custom rapid prototyping carried out by the successful product.

How Do I Start Your Prototyping Project And Get An Instant Quote Online?

An accurate and quick quote is where things start, helping launch your creation. Our system, at our side, is optimized for both speed and simplicity such that you will get an instant prototype quote without much of a wait, and you can begin without any commitment. Complete quotes can be generated in mere minutes on our website.

- Upload Your 3D File: To start your prototype project involves creating and uploading the CAD file, STEP file, or STL file to the site. As soon as you upload it, analysis of the geometry starts so that it can be ready to undertake the next task. No complicated RFQs and emails to answer.

- Define Your Needs: The next step is to define your needs regarding the manufacturing process, material, and finally your type of finishing, like smoothening and/or painting, and so on. The last step regarding the aforementioned process would then be the completion of your quote, and thus, your instant rapid prototyping quote shall appear.

- Receive and Review Your Quote: The transparent instant rapid prototyping quote will be with you in no time. The transparent instant rapid prototyping quote will be divided into various sections. This will help you review your quote with the application engineer from our company so that you can check whether all is well with your quote with a possibility of changing your quote in a particular way such that your requirements can be met.

Your design is quite simplistic in nature. With our three-step online quote process—upload, setup, view, there are no bumps in the road ahead for you. Consequently, it will prove to be the fastest available alternative to you to get an instant quote prototype in order to give you vital input concerning working on your own prototype project.

FAQs

1. Is your “instant quote” correct? Would this tend to differ?

“Our instant quote” accuracy level, which has automatically been processed by intelligent systems, has remained above 90% regarding basic quotes. The same will be checked by our engineers. In case you find any inequality regarding quotes allocated to you, direct communication will take place between us and you to prevent any kind of confusion regarding any of your quotes.

2. How many days are there from the date of receiving the quote to the date of receiving the prototype?

Generally, the cycle time needed in the project delivery process to our company takes 3 to 7 business days depending on the process and the creation complexity of the parts. Sometimes, 24-hour manufacturing is required.

3. Are limited production prototype manufacturing facilities (50 to 100 units) available?

Of course. Further, we can also help you in small-batch prototyping down to units of hundreds to enable you to find out which economically optimal alternatives in terms of numbers that your product is made of are appropriate.

4. I have trade secrets in my design documents. Who is the duty of care owed to?

What all this means, of course, is that in 100% clear speak, all of our clients are completely bound to us EX OFFICIO by and under our Inked and Iron-Clad Confidential Agreements to ensure that they gain the full benefit of the State of the Art Encryption Transmission and Storage of all of their design work done on our servers.

5. Does the price for post-processing jobs such as painting, sand-blasting, and so on include in the quote?

After obtaining the quote, the system shall highlight the list of post-services, for example, painting and sandblasting, amongst others, in relation to their charges. You shall be able to pick the services you want, which should be in the quote free of charge.

6. What if I'm unhappy with the prototype that I will receive?

In the scenario when you may not be satisfied with your prototype because of any deficiency, possibly existing in our process, then you would be offered a remake of your prototype. The first reason for this is to make sure that you, as a client, would be satisfied with your prototype, which would be designed as per your requirements.

7. Which 3D file types can be converted?

We support common formats such as STEP, IGES, STL, and X_T. We recommend uploading parametric formats such as STEP for more accurate DFM analysis.

8. Additionally, may reports of material certifications, as well as test reports, be required?

Yes, we could provide you with your certification reports of the materials that go into functional prototypes, inspection reports of critical dimensions. Thus, your device would be meeting specifications.

Summary

Rapid prototyping assistance and effective and reliable rapid prototyping help present an accelerative factor in the successful entry of products into the market. LS Manufacturing can help you to efficiently and properly, through the aid of standardized online help services, accomplish your ideas with the establishment of prototypes of your product with the assistance of our qualified engineering staff and our instant quote system.

Your product development project should not wait at all. Just send us your 3D designs and learn how effortless it is to have an instant quote from us at LS Manufacturing. A prototyping expert will give you a quote in just 15 minutes.

Let us help you, starting with getting a personalized manufacturing quote.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.