Rapid prototyping services can also be included within the challenge for development. Even today, many technologies are available, but they are likely to have certain variability in accuracy, material, and cost, and the companies tend to exaggerate this information, leading to disappointment in prototypes.

Briefly, it is a problem of structured knowledge absence related to prototyping processes, which is further exacerbated by a lack of adequate, objective criteria for evaluating suppliers. In prototyping, decisions of this type basically have to do only with considerations like price, without accompanying assessments regarding actual technology appropriateness and supplier expertise.

Rapid Prototyping Services Quick-Reference Guide

| Category | Key Technologies | Materials | Lead Time | Best For | Key Considerations |

| 3D Printing | FDM/SLA/SLS/MJF | Plastics/Resins/Metals (indirect) | Hours-Days | Form & Fit/Models/Complex Geometry | Surface Finish, Strength vs. Speed, Cost per Part |

| CNC Machining | CNC Milling, CNC Turning | Plastics, Metals, Composites | Days | Functional Components, High Strength & Tight Tolerance | Material Waste, Setup Cost, Excellent Finish |

| Vacuum Casting | Silicone Molding | from Master Pattern Urethanes, Silicones, and Similar to Plastics | Days - Weeks | Small Batches (10-100), Pre-production, Multi-material | Upfront Master Pattern Needed, Good for Aesthetics |

| Sheet Metal | Laser Cutting/Bending/Stamping | Aluminum, Steel, Brass | Days - Weeks | Enclosures, Brackets, Housings | Tooling for Complex Forms, Design for Manufacturability (DFM) |

| Rapid Tooling | Soft Tooling, Aluminum | Molds Production-grade Plastics | Weeks | Bridge Production, 100-10,000 parts | Higher upfront cost than vacuum casting, faster than production tooling |

Rapid prototyping services allow one to take advantage of rapid testing and validation of designs. The primary technology employed in this process is 3D printing, which may be preferred in rapid prototyping or complexity, CNC machining, which may be preferred in case of high strength or accuracy, or Vacuum Casting, which may be preferred in case of producing a small series.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

This handbook is created as a result of our experience in the field of rapid prototyping in the last several decades. All the findings provided in this handbook have been obtained from actual work where speed and precision cannot be compromised. We apply models which have been benchmarked against models by Deloitte Insights and Gardner Business Media to ensure our prototypes conform to all norms related to shape, function, and reliability.

Our multi-material capabilities and digital manufacturing process allow you to iterate quickly. Whether you require prototypes made of metals and/or complex assemblies involving polymers, industry-standard techniques are employed to provide dimensional accuracy and enhance strength and therefore help with rapid developments.

It starts with material selection and continues with post-processing procedures that include the implementation of the quality system following the best practices and benchmarking guidelines provided by Deloitte Insights and Gardner Business Media. This approach will make sure that your prototype works not only as meant by the design but also as a completed product.

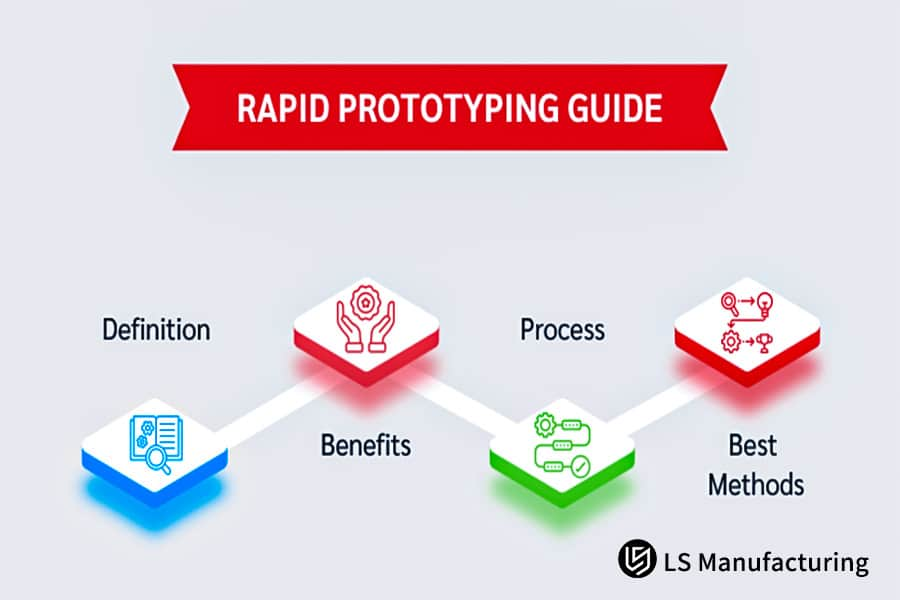

Figure 1: Guide to rapid prototyping methods and selection criteria by LS Manufacturing

How To Choose The Most Suitable Rapid Prototyping Technology Based On Project Requirements?

Selection of rapid prototyping methods should be done through a systematic evaluation against project requirements. The following analysis compares mainstream rapid prototyping service types across four dimensions to guide effective prototyping technology selection.

- Dimensional Accuracy and Surface Finish: CNC machining can provide the highest accuracy, ±0.025mm, with the best surface quality, which will be ideal for functional testing on engine parts. 3D printing, on the other hand, such as SLA, has good detail, and post-processing may be required to meet tight-tolerance project requirement matching.

- Material Properties and Application: CNC works with production-grade metals and plastics for prototypes that must have special mechanical or thermal characteristics. The vacuum casting process uses polyurethane resins to achieve appearance models, with great accuracy in reproduction of minute details. This constitutes the core criteria in prototyping technology selection with regard to performance validation.

- Cost Structure and Lead Time: 3D printing has the least initial cost and is the fastest in the case of single, complex geometries, which are best for early concept models. In medium batches, that is, in the range of 10 to 50 units, vacuum casting becomes economic. The choice directly impacts the budget in consideration with rapid prototyping service types.

- Production Speed and Flexibility: 3D printing has the advantage in speed for design iterations in days. CNC takes longer to set up but produces resilient parts. For a small batch of housings that is needed in two weeks, vacuum casting balances speed with quality, showing strategic project requirement matching.

Prototyping technology selection should be done with key issues related to the accuracy, material, cost, and speed of production. Each one must be carefully project requirement matching to ensure a proper selection that will comply well with certain goals by optimally leveraging the spectrum of rapid prototyping service types to quickly develop concepts at minimal risk.

What Are The Advantages And Disadvantages Of 3D Printing, CNC Machining, And Vacuum Molding?

The best outcomes for any given project arise from a fundamental understanding of the core differences between the methods. Three main types of rapid prototyping are compared next to explore the strengths and weaknesses inherent in each, thus setting the stage for a more effective prototype process advantages and disadvantages analysis.

| Feature | 3D Printing (e.g., SLA, SLS) | CNC Machining | Vacuum Molding Technology |

| Key Principle | Additive: Component stacking in layers. | Subtractive: Extraction of the components from what is called block material. | Casting: Manufactured in Silicone molds. |

| Typical Materials | Photopolymers, Nylon, Resins | Wide range: Metals, Engineering Plastics | Polyurethane Resins (simulating various plastics) |

| Key Advantages | Complex geometries, Fast design iteration, Low setup cost | High precision/strength, Excellent surface finish, True material properties | Cost-effective for 10-50 units, Good detail replication, Multiple material simulations |

| Chief Disadvantages | Anisotropic strength, Poor material properties, Post-processing required. | Loss of material cost, Increased processing complexity, Design constraints (ease of access of molds) | Mold longevity restricts production volume (to about 30), Poor low-temperature and chemical resistance, Secondary processing |

A direct comparison of 3D printing and CNC machining reveals a classic trade-off: 3D printing excels in complexity and speed for early-stage prototypes, while CNC is unmatched for precision and functionality. Meanwhile, vacuum molding technology occupies a unique niche, efficiently bridging the gap for small-batch appearance prototypes. This prototype process advantages and disadvantages analysis shows that no single method is superior; the best choice depends on specific requirements among the available types of rapid prototyping.

Figure 2: Expert prototyping for precision complex components by LS Manufacturing

What Special Processes Are Required For Rapid Prototyping Of Complex Parts?

In cases where complex part rapid prototyping with complex geometries and tight specifications is required, conventional rapid prototyping methodologies may not be sufficient. In such scenarios, it would be required to fall back on special process solutions with a view to making appropriate rapid prototyping supplier selection.

- Multi-material and Dissolvable Supports: Multi-material rapid prototyping, can be done for the material jetting process due to its ability to create components with varied colors or shore hardness values within one process. More importantly, it allows for dissolvable support structures, essential for creating complex internal channels that are impossible to clean otherwise, representing a vital special process solution.

- Metal Additive Manufacturing (DMLS/SLM): It has special application value in complex part rapid prototyping, aviation, and in particular, the medical area, for example. Furthermore, in direct production of high-strength metal parts with lattice structures, cooling channels, for example, know-how of rapid prototyping processes may be needed.

- 5-Axis CNC Machining: It provides a highly efficient special process solution, particularly for the machining of complex components which require a high accuracy level on multiple surfaces. This also includes the benefit of minimizing the setup time, thereby contributing towards the machining process for deep undercuts or contour surfaces in a single piece, which is a highly required criterion in the case of the functional prototype such as impellers/blade components.

- Hybrid and Combined Approaches: In certain situations, the final process chosen may involve an amalgamation of more than one process. One of the most commonly employed techniques involves 3D printing of the complex core and then producing the high-quality surface finish via the vacuum molding technology. This highlights why thorough rapid prototyping supplier selection is key, as suppliers with a broad capability portfolio can best execute these integrated solutions.

For successful complex part rapid prototyping, it is necessary that rapid prototyping systems incorporate innovative pecial process solutions for multi-material rapid prototyping. It would be of great advantage to have a rapid prototyping supplier.

What Are The 8 Key Metrics For Evaluating Rapid Prototyping Vendors?

Choosing an appropriate partner company after understanding that there would be an identified requirement for having an effective process of prototyping may be very significant. Rational thinking requires being exercised while making proper rapid prototyping supplier selection. This involves evaluating key supplier evaluation indicators to ensure quality and reliability.

| Evaluation Indicator | Key Questions to Ask (What to Look For) | Relative Weight |

| Technical & Equipment Capability | What strength is there in your technology requirement being met by the rapid prototyping manufacturer? | 20% |

| Material Portfolio | Are they a player in various types of materials, or are they just a provider of a fundamental grade? Do they purchase special materials? | 15% |

| Quality Control & Certification | Supplier capability certification, for example, ISO 9001, and analysis results of supplier performance (CMM). | 20% |

| Engineering Support Expertise | Do engineers proactively offer DFM feedback? This is critical in how to choose a rapid prototyping supplier. | 15% |

| Portfolio & Case Studies | Think of similar projects that you have done before with similar levels of complexity and industry. | 10% |

| Lead Time & Reliability | Are the timescales realistic? Do a check on lead times while reviewing. | 10% |

| Pricing Transparency | Are the prices informative (substantive, Labor post-processing)? A lack of transparency could be viewed as a problem, for instance, during the supplier evaluation. | 5% |

| Post-Sales & Communication | Responsibility for change or defect after sales? Although an essential criterion, at times, it can rank last. | 5% |

The primary aim of successful rapid prototyping supplier selection is to strike a suitable balance, within the context of the eight supplier evaluation indicators. Prioritizing technical capability, proven supplier capability certification, and engineering support is central to understanding how to choose a rapid prototyping supplier that will become a true development partner.

Why Are There Such Large Differences In Rapid Prototyping Quotes?

While requiring a price quote on a custom rapid prototyping, the variation in price could be rather surprising. A close rapid prototyping quote analysis that reasons for price differences are responsible for this, and an cost structure analysis forms the critical part.

Technology and Equipment Investment

The core reasons for price differences often stem from the prototyping process itself. Industrial-grade metal 3D printers or 5-axis CNC machines represent a high capital cost, reflected in machine hour rates. A quote for SLS nylon will differ significantly from one for DMLS titanium, making technology choice a primary driver in rapid prototyping quote analysis.

Material Cost and Selection

The cost of the material would be considered a direct variable input cost. The cost of generic ABS or resin would not be high, but other high-end engineering thermoplastics/metal materials would be more expensive. This variability is a fundamental part of the cost structure analysis for any custom rapid prototyping project.

Labor and Post-Processing Complexity

Labor would be one of the major hidden high costs of 3D printing. While for simply printed or raw models of 3D structures very little labor would be involved, for models that have complex support structure removal, painting, assembly for functional testing, and so on, numerous man-hours would be involved, and that would contribute largely to the final costs of the final product.

Part Design, Geometry, and Order Volume

Cost is dictated by design. Complexity of design leads to higher times for manufacturing and processing. Further, economies of scale vary for varying levels of volume. It will prove to be very costly for a unit if it has to be CNC machined. But economies of scale will vary on the basis of volume. It may be cheaper even at a lower volume of vacuum casting.

In essence, price variations in custom rapid prototyping are justifiable and can be explained, primarily by the differing technologies applied in each solution, such as 3D printing, CNC machining, or injection molding. Conducting a detailed rapid prototyping quote analysis is highly enlightening, as it reveals how material choices, production speed, and finishing requirements directly influence the final cost, making the value proposition clear.

LS Manufacturing Medical Device Industry: Customized Multi-Material Prototypes for Wearable Medical Devices

This LS Manufacturing success case is examined with respect to the challenging medical technology problems of high-level functionality. The development activity pertaining to highly functional medical device prototypes and health-related monitoring was carried out in the success story. This had been an important attribute.

Client Challenge

In a medical technologies firm, there was a problem of design. While working on a health device to be worn by a person, there had been a demand for a continuous case where there is a hard component and soft components touching the skin. Assembling or overmolding, and so on, would not be very efficient for multi-material rapid prototyping.

LS Manufacturing Solution

They have managed to integrate a form of multi-material rapid prototyping, which is quite futuristic through the use of PolyJet. They were therefore able to print different kinds of photopolymer resins with differing shore hardness in one process. They were, of course, able to create a digital form of the prototype with the smooth transition of the hard inner portion of the object towards its soft outer boundary, which marked the completion of the perfect/functional integrated prototype.

Results and Value

They got the medical device prototypes, and these prototypes functioned precisely as expected. The rapid prototyping impacted the time for the customer by 50%, considering that they expected the changes owing to the costing for RMB600,000. The understanding of the rapid prototyping quote was that the final costing would be considerably higher than expected.

The LS Manufacturing success case establishes the immense importance of applying multi-material rapid prototyping skills successfully in overcoming the tough material challenges that are in existence when creating medical device prototypes. We have also been successful in innovating at a faster pace with cost savings with a defined plan and rapid prototyping quote to our valued customers.

Looking for customized prototyping solutions and accurate, transparent pricing for your creative ideas? Contact our experts today!

How To Reduce The Cost Of Rapid Prototyping Through Design Optimization?

In fact, the most important parameter while aiming for the rapid prototyping cost optimization with regard to quick prototyping is the design change activities pursued by the early design. Pro-activeness in taking design change recommendation activities regarding DFM optimization solutions will have a pivotal role in ensuring the optimization of both time and cost.

Optimize Wall Thickness and Uniformity

Maintaining consistent, recommended wall thickness for the chosen process (e.g., 1-2mm for 3D printing) is a primary design improvement suggestion. Avoiding excessively thick sections prevents sink marks and long cooling times, while walls that are too thin may fail, directly contributing to rapid prototyping cost optimization by minimizing material use and print failures.

Minimize Support Structures and Overhangs

There can be improvement in the additive process by the usage of self-supporting angles, meaning the angles will be steeper than 45 degrees, where the intention is to maximize the usage of chamfers rather than overhangs, resulting in the maximum reduction in the usage of support structures. DFM optimization solution is optimal to the extent where waste, time, and human effort can be reduced, meaning that this parameter represents a considerable cost of the time of build.

Design for Consolidation and Smart Nesting

This is a type of design in which small models/components can be consolidated/combined into a complex model prototype. The procedure for model consolidation for the CNC machining processes can be obtained through models designed in such a manner that models are nested on a production surface. This consolidation strategy is a powerful method for rapid prototyping cost optimization.

Choose Appropriate Tolerances and Surface Finish

If precision surface finishes or operations are carried out on non-critical surfaces, then it adds unnecessary extra production cost. Among all the most important aspects covered in the solution offered by DFM optimization solution is making the best use of commercially available options regarding bead blast wherever it is viable because machining and polishing operations take a much longer time.

In summary, significant rapid prototyping cost optimization is achievable by integrating these design improvement suggestions from the outset. In cases where you are getting assistance from your supplier to help you figure out ways to make improvements to your DFM, you will require realistic designs. In addition to that, you will need to make sure that your designs are cost-effective concerning prototyping. This will help you complete the whole development process more quickly.

Why Choose LS Manufacturing As Your Rapid Prototyping Partner?

It is linked to having which helps in identification of the right partners to work together regarding the development of innovations and ideas on an efficient scale. As one of the most key factors to choose LS Manufacturing as your rapid prototyping partner who will put you into a better situation to benefit all rapid prototyping service advantages.

End-to-End Service and Technology Offered

Being a professional prototype manufacturer, it was only natural for us to offer our end-to-end service to our customers right from the stage of consultancy to all the post-manufacturing tasks. The service offer which would be catered to in-house based on the knowledge of production technology existing in-house in our company, and which differed from the process described in 3D printing, multi-axis CNC machines, and then through vacuum casting, would surely be a unique service offer in our sector.

Expert Engineering Support and Design Collaboration

We offer Design for Manufacturability (DFM) concepts and notions creatively with specialized application engineers. This would most surely be considered one of the most critical factors of rapid prototyping services. In all honesty and truthfully speaking, our team of designers would assist and co-operate with yours within this rapid prototyping service advantage for an upgrade of your current design based on factors and elements of functionality, and then ‘look and feel’, and then ultimately economic factors.

Rigorous Quality Control and Consistent Results

We implement a stringent quality management system, supported by precision measuring equipment like CMMs. This commitment to consistency ensures every prototype, from a first-article model to a small functional batch, meets exact specifications, making LS Manufacturing partner you can trust for critical project milestones.

Proven Track Record and Client-Centric Focus

The success ratio in projects related to health, autos, electronics, and similar items has been quite satisfactory. It all relies on the pace of communication. The rapid prototyping quote analysis has been altered in order to ensure completion of projects within the required timeframe. The satisfaction ratio of above 98 percent has been achieved.

In summary, LS Manufacturing stands out as a professional prototype manufacturer by combining technical breadth with deep collaborative expertise. Our core rapid prototyping service advantages—comprehensive capabilities, engineering partnership, and rigorous quality—directly translate to reduced risk, lower total cost, and faster innovation for our clients.

Figure 4: Next-generation technologies powering complex prototypes by LS Manufacturing

What Information Is Needed To Obtain An Accurate And Rapid Prototype Quote?

Efficient communication of project requirements is required for ensuring that you receive an immediate and correct estimate of the cost. To satisfy the rapid prototyping quote requirements, the required information needed for comprehensive information in a technical sense is the foundation of the accurate quotation guide.

- Complete 3D Model and Critical Dimensions: The start of every quote should be founded on a correct 3D model in STEP or IGES format. The critical dimensions of every product should include the two-dimensional view in a drawing. This prevents assumptions and is the first step in technical data preparation for an accurate quotation guide.

- Material Specifications and Performance Needs: This will require material of a type that will be used in developing a prototype, for example, ABS Similar Resin or Aluminum 6061, and so on. Sometimes, based on the requirement that has to be inputted into it, for example, visual prototype development, test prototype development, or master prototype development, it will directly impact on material requirements.

- Quantity, Lead Time, and Post-Processing Details: Specify the exact number required. The difference between 1 piece and 50 is pretty huge. Turn-around time required by you-whether standard or rush turn-around time needs to be specified. Surface finish requirement whether a standard surface finish or painting, texturing, or plating-all need to be specified; reason being, post-processing too is a substantial part of a rapid prototyping quote requirements.

- Assembly and Secondary Operations: In case your project has a good number of components, you have to examine if the components require any form of assembling and in what manner, then proceed with the rest of the secondary operations, which will involve actions like entering of metal threads or labels, among other tasks. These operations are not typically factored into the technical data preparation, but they may heavily influence the accurate quotation guide.

It essentially boils down to this: an accurate quote will never come until it satisfies what it takes to provide a rapid prototyping quote requirements. Spending time on preparation in a manner that relates to technical data preparation of a model, material, quantity, and finish will give a clear project scope. This effort has been effective in providing an accurate quotation guide, or for that matter, an accurate price, which will provide you fair quotes from your suppliers.

FAQs

1. What are the minimum order quantity and maximum processing size?

For prototype development and small-batch production, services are provided with the maximum processed size of 800x600x500mm. Everything will be done from sample verification for a single piece to proof-making for several hundred pieces when placing a small-batch production order. The biggest capability of our machines is such that in both CNC services and 3D printing, prototypes measuring 800mm x 600mm x 500mm can be handled. This would be ample for housing prototypes for electronic devices.

2. How much difference is there in the accuracy between different prototyping technologies?

The accuracy level varies from ±0.1mm for FDM to ±0.02mm for SLA. In light of the processes you may need to carry out, we shall suggest an appropriate alternative. It should be considered that the differences in the level of accuracy for different processes may vary greatly. For example, differences in accuracy among such processes as FDM, which is characterized by the low accuracy level ranging from ±0.1mm-0.3mm, while highly accurate SLA/CNC Machining procedure can produce an accuracy of ±0.02mm-0.05mm. Depending on your level of precision, we shall offer you appropriate technology

3. Do you provide material performance test reports?

We provide material certification and KPT reports for all our prototypes. We could provide you batch material certification and mechanical property testing results for key mechanical properties including strength and impact resistance so that you could test and verify their acceptability when we hand over our prototypes to you for their performance criteria.

4. How would the changes in design be addressed?

Based on the need to satisfy the criteria in order to fulfill them, a procedure for the reaction towards the change of variables has been made in which the evaluation of the impact would be only carried out in a time span of 2 hours, and the solutions/quotes would be changed. Moreover, on the basis of the scenarios in which the change in the design would be made when the emphasis is on a specific project at a time, it has been concluded on the stage in which the evaluation of the impact would be made only after the receipt of the request for the change in a time span of 2 hours.

5. What surface treatment options are available?

There are more than 10 surface finishing methods, such as sandblasting, electroplating, anodization, and many others. For post-processing, several methods are used, such as sandblasting for matte or fine finishing, painting any desired Pantone color, screen printing, electroplating, and anodization for aluminum alloys, depending on the functionality required from the surface treatment finish.

6. What steps do you take to protect intellectual property?

A very tight process is followed in context to an NDA for the security of your design data. However, much before you start with your project, something can be planned regarding your Confidentiality Agreement. As underlined in the above explanations, your Confidentiality Agreement process is considered to be a standard process. Your design detail will be kept secure via an encrypted site. The limited handling of your design detail is made through our team. Deletion is made after the completion of your project.

7. Do you expedite shipments?

We also introduce an expedited production channel to meet your urgent needs for projects. In order to meet your urgent needs for projects, we have created an expedited green channel for urgent projects. By effective scheduling and application of concurrent engineering, there are projects like SLA 3D Printing that can be done and shipped within 24 hours to meet your R&D schedules.

8. How are quality issues resolved?

We also do end-to-end quality verification. Known defect in manufacturing of quality, we will do free rework to ensure the interests of our valuable clients. We also do responsibility of quality verification at every stage of processing. Right from storing of raw material to finally delivering the product, known defect at quality level through our processing, we will unconditionally start the process of immediate rework at a cost of which this product should finally qualify.

Summary

With technical analysis and scientific selection criteria, you can obtain the best solution of rapid prototyping, which would satisfy your demands. Along with technical experience and projects accomplished in the company, LS Manufacturing assures that it could provide high-quality services with every customer.

Contact our prototyping experts now for your customized response to your needs. This is your invitation to contact us now for your free DFM analysis report. In any case, we promise to safeguard your development.

Skip the bottlenecks. Get precise, functional prototypes delivered with speed and reliability. Click to see how our prototyping solutions work for you.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.