As3D printing technologybecomes more popular, designers, engineers and enthusiasts use it to turn their ideas into applications. Three-dimensional modeling is an important link, helping designers to quickly design products or parts, shorten the cycle and reduce costs. However, the size limit of3D printersoften becomes a bottleneck. Before large-scale modeling, the printed object needs to be reduced to reduce the complexity, which is time-consuming and uneconomical. When manufacturing architectural models, sculptures or functional components, the model size exceeds the maximum volume of the printer, and how to print effectively becomes an urgent problem to be solved. In order to quickly and accurately construct complex and large three-dimensional objects, various tools are needed.

What: Core Challenges of Large-Scale 3D Printing

Large-scale 3D printing faces the following core challenges:

1.Technical challenges:

Printing efficiency and speed:Large-scale production requires a fast and efficient printing process. The current 3D printing technology still has speed limitations and needs to be improved to adapt to large-scale production.

Precision and quality control:Maintaining high-precision and consistent printing quality is crucial for large-scale 3D printing. Any small deviation will cause the product to fail or reduce performance.

2.Cost challenges:

Equipment investment:High-performance 3D printing equipment is expensive, and equipment cost becomes an important consideration for large-scale production.

Material cost:Compared with traditional production materials, 3D printing materials are usually more expensive, especially those special or high-performance materials, which undoubtedly increases the total cost of manufacturing.

3.Challenges of large-scale production:

Standardization of production process:To carry out large-scale production, a standardized production process must be developed, includingprinting, post-processing and quality inspection.

Automation and integration:Improving the automation of the production process, reducing dependence on manual operations, and achieving seamless integration with other production systems constitute a major challenge faced bylarge-scale 3D printing.

4.Market demand and challenges:

Market acceptance:Although3D printing technology has many advantages,the market's acceptance of it needs to be improved, especially in some traditional manufacturing fields.

Customization and diversification:Large-scale 3D printing requires adapting to market customization requirements while coping with the production and management of diversified products.

4.Challenges in post-processing and surface treatment

Post-processing process:Products that have been 3D printed usually undergo post-processing, such as removing support structures, grinding and painting, etc., which require high efficiency and high degree of automation.

Surface quality and appearance:Ensuring that the surface quality and appearance of printed products meet market requirements is a difficult problem to be solved in large-scale 3D printing.

What materials are available for large-scale 3D printing?

1.Plastic material

| Material | Description |

| PLA (polylactic acid) | A biodegradable plastic derived from renewable plant resources such as corn starch. It is non-toxic and odorless and does not produce a pungent smell when printing, making it ideal for home use. PLA printed parts have a smooth surface and bright colors, but have a low melting point and poor high temperature resistance. |

| ABS (Acrylonitrile-Butadiene-Styrene) | A common engineering plastic with good mechanical properties and chemical resistance. It has a higher melting point and can print parts with a certain degree of toughness and strength. However, ABS may produce a pungent odor during the printing process, so it needs to be used in a well-ventilated environment. |

| PA (Polyamide) | Also known as nylon, it is a high-strength, high-toughness material widely used in industrial fields. Parts printed from nylon materials have high strength and toughness, making them suitable for manufacturing parts that need to withstand high stress and wear. However, the price of nylon materials is relatively high, and high temperature and humidity control are also required during the printing process. |

| TPU (thermoplastic polyurethane) | A special soft material whose printed products have a certain degree of elasticity. TPU printing effect is excellent, the molding is smooth, no bubbles, the surface is smooth and delicate, and the color is accurate. In addition, TPU is an environmentally friendly product, non-toxic and has no irritating smell. |

| PETG (polyethylene terephthalate) | A composite material that combines the advantages of PLA and ABS. Compared with ABS, PETG has higher toughness, is easy to print, and does not warp, smell, or bubble. The finished products printed by PETG are clear and transparent, so it has become one of the favorite 3D printing materials in the advertising letter industry. |

2.Photosensitive resin

Apolymer materialthat solidifies when exposed to light of a specific wavelength. It is usually used in SLA (stereolithography) or DLP (digital light processing) 3D printing technology. Parts printed with photosensitive resin have smooth surfaces and high precision, and are suitable for manufacturing parts that require high precision and surface quality. However, the price of photosensitive resin is relatively high, and the lighting conditions need to be strictly controlled during theprinting service.

3.Metal materials

such astitanium alloys, stainless steel, etc. These materials are usually used in SLM (selective laser melting) or SLS (selective laser sintering) technology and are suitable for manufacturing industrial parts and complex metal components. Parts printed from metal materials have metallic strength and conductivity, butmetal 3D printing equipment is expensive, has slow printing speed, and requires special post-processing processes to improve the accuracy and surface quality of the parts.

4.Ceramic material

It has excellent high temperature resistance, wear resistance and corrosion resistance.Ceramic 3D printing technologyusually uses methods such as powder metallurgy or laser melting. Ceramic printing parts can be used in high temperature, high pressure and corrosive environments in aerospace, medical equipment and other fields. However, ceramic materials are relatively brittle, and parameters such as temperature and pressure need to be strictly controlled during the printing process.

Model splitting method

1.Software splitting:

UseCAD software(such as SolidWorks, Fusion 360, Blender, etc.) to split the model into multiple smaller parts, ensuring that each part can be placed in the printer's build platform.

When splitting, you can consider adding some features to the design, such as slots, pins, tenons, etc., so that the parts can be easily assembled together after printing.

2.Manual splitting:

For some simple models, you can mark the cutting lines directly on the model, and then split it into multiple parts manually or using tools (such as saws, knives, etc.).

When splitting, make sure that the interfaces of each part can be tightly connected to ensure the integrity of the assembled model structure.

3.Printing and assembly

3D print each of the parts after they are split.

After printing, use glue, screws or other connection methods to assemble the parts together to form a complete model.

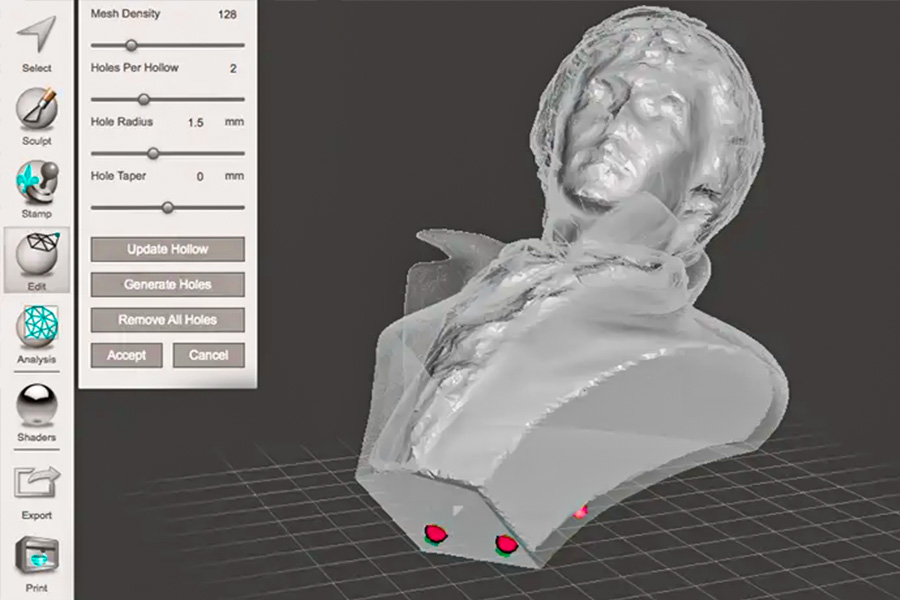

Printing shell method

1.Hollow design:

If the model does not need to be completely solid, you can consider designing it as a hollow structure. In this way, the printer only needs to print the shell of the model, saving materials and time.

When designing a hollow structure, make sure that the structural strength of the model meets the requirements of use and add support structures in appropriate locations.

2.Printing shell:

Use a 3D printer to print the shell of the model.

After printing, post-process the model as needed, such as removing support structures, polishing the surface, etc.

3.Internal filling (if necessary):

If the model needs to have a certain weight or strength, you can add other materials (such as resin, foam, etc.) inside the model by pouring, filling, etc. after printing.

Distributed printing method

1.Multiple printers collaborate:

If conditions permit,multiple 3D printerscan be used to print parts of the model at the same time.

After printing, the parts are assembled together to form a complete model.

2.Printing service:

The model is split into multiple parts and sent to different3D printing service providers for printing.

After printing, the parts are collected and assembled together.

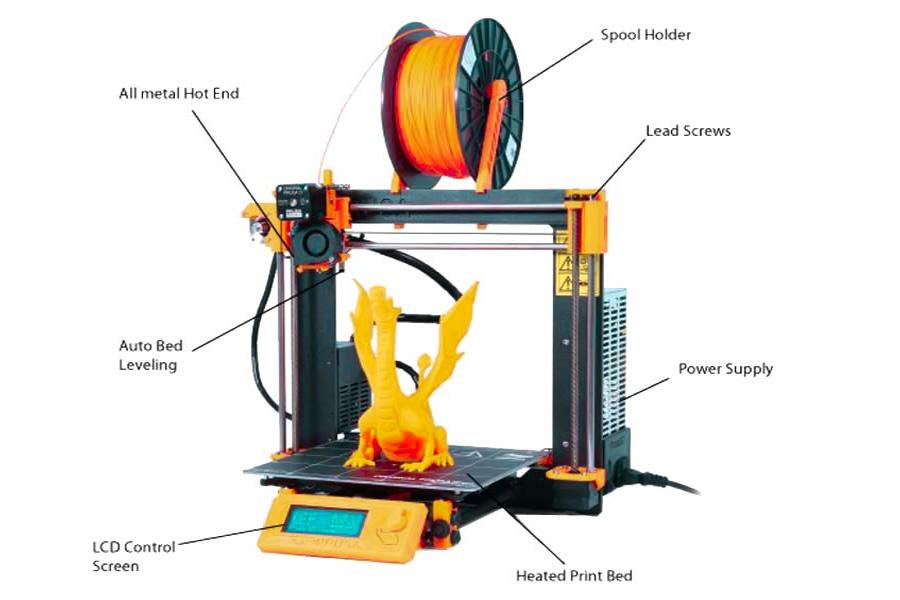

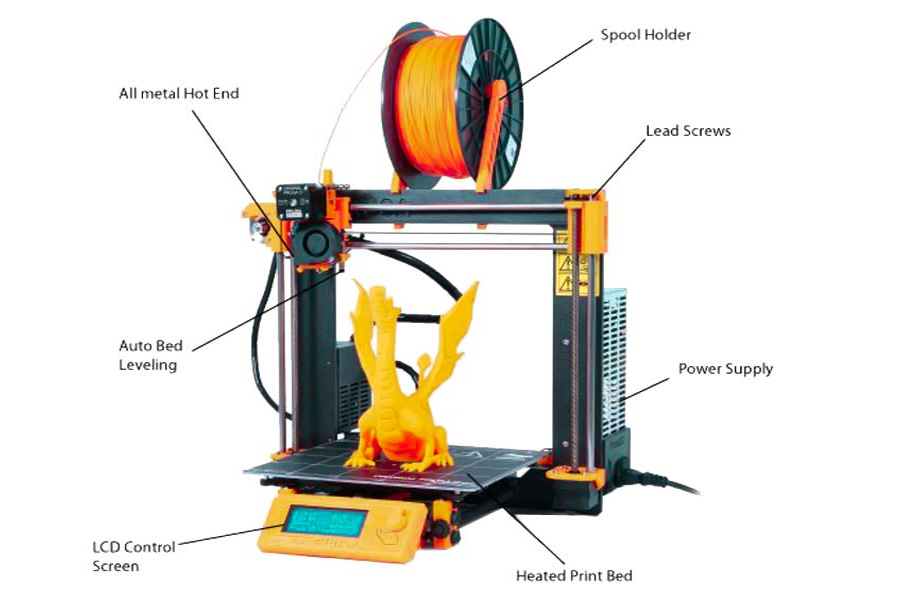

Upgrade to a large 3D printer

Purchase or lease: If you often need to print large-scale models and your financial conditions allow, you can consider purchasing or leasing a large 3D printer. This allows you to directly print large-scale models without having to disassemble or assemble them.

Summary

By disassembling the model, optimizing the printing strategy, and using sophisticated post-processing steps, we can successfully achieve 3D printing of models that are larger than the printer's build volume. This technology not only broadens the application scope of 3D printing, but also brings us more creative freedom and imagination. With the continuous development andprogress of 3D printing technology, I believe that more innovative methods and tools will appear in the future, allowing us to navigate the world of 3D printing unimpeded.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.I want to print a model that is larger than my 3D printer's build volume, what should I do?

When you want to print a model that is larger than the build volume of your 3D printer, there are several approaches to consider. First, you can try to split the model into multiple parts, then print and assemble them separately. This requires using CAD software to accurately split the model and ensure that each part fits perfectly. Alternatively, you can also consider using hollow structures or lightweight designs to reduce material usage, which may make the overall size of the model fit into the printer's build volume.

2.Is there anything special to pay attention to when splitting a model?

When splitting a model, the most important thing is to ensure the accuracy and assemblability of the split parts. You need to use CAD software to carefully plan the split lines, and consider adding some docking structures such as slots, pins or tenons to the split parts so that the parts can be easily and firmly assembled together after printing. At the same time, make sure that each split part does not exceed the printer's build volume.

3.How to assemble the disassembled parts of the model?

When assembling the disassembled parts of the model, you can use glue, screws or other connectors. The choice of connection method depends on the material, structure and purpose of the model. For example, for plastic models, you can use special plastic glue; for models that need to withstand greater forces, you can use screws to fix them. Before assembling, it is recommended to simulate the assembly process on paper or a digital model to ensure that everything goes smoothly.

4.Is there anything special to pay attention to when printing large-scale models?

Post-processing is also very important when printing large-scale models. You may need to remove more support structures and perform more detailed sanding and painting. Due to the large size of the model, the post-processing process may be more time-consuming and laborious. Therefore, it is recommended to plan the post-processing process before printing and prepare the necessary tools and materials.

5.Is it possible to use multiple printers to print different parts of a model at the same time?

Yes, it is completely possible to use multiple printers to print different parts of a model at the same time. This method can greatly improve printing efficiency, especially when you need to print large-size models quickly. However, this requires that you have enough printer resources and need to ensure that each printer can print parts of the model with consistent quality.

Resources

3.List of 3D printing software