In recent years, with the development of science and technology, environmental problems have become more and more prominent, and the production and application of environmentally friendly materials have received more and more attention.TPR material belongs to thermoplastic rubber. Because of its excellent mechanical and thermal properties, it is an environmentally friendly material widely used in industrial production, automobiles, home appliances and other industries.

Next, we will analyze in detail the definition,characteristics and application of thermoplastic rubber TPR in various fields, hoping to give readers a more comprehensive and in-depth understanding.

What Is Thermoplastic Rubber (TPR)?

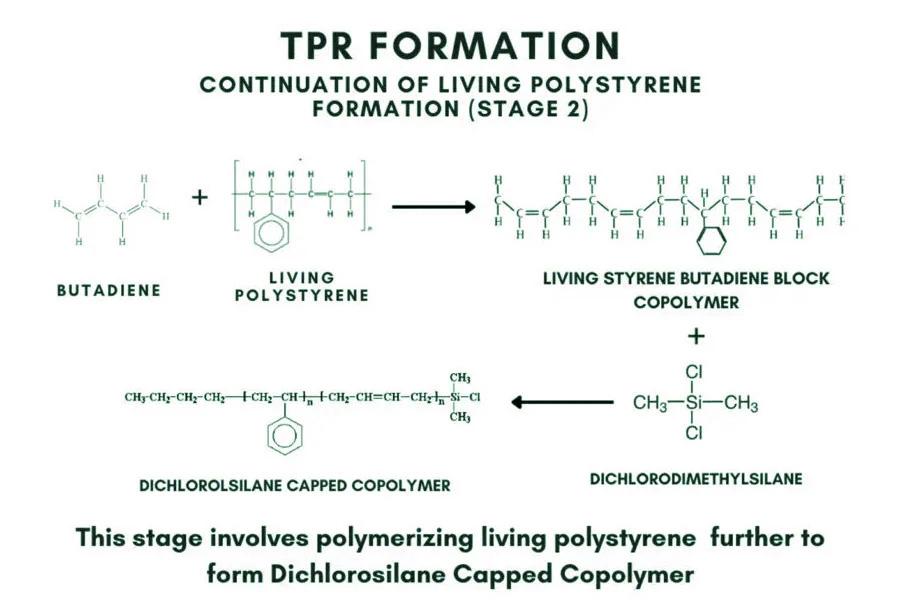

TPR (Thermo-Plastic-Rubber material) is a thermoplastic rubber material. It is a thermoplastic soft rubber material with rubber elasticity that can be directly processed and molded (e.g., injection molding, extrusion, blow molding, etc.) without vulcanization.

TPR materials are based on thermoplastic styrene-butadiene rubber (e.g., SBS, SEBS), modified by adding resins (e.g., PP, PS), fillers, plasticizers, and other functional additives. In short, it is a recoverable, elastic, and malleable composite material. One of the main characteristics of TPR materials is their high fatigue strength, which allows them to withstand high bending stresses and long service life.

TPR, the term most users use for thermoplastic elastomers, refers to materials modified with styrene elastomers such as SBS and SEBS. TPR material suppliers refer to SBS-modified materials elastomer materials as TPR and SEBS-modified materials as TPE for ease of differentiation. But in fact, TPE is a broad concept that includes styrene elastomers, SEBS, SBS modified materials, but also TPU, TPV, TPEE, TPO, and other elastomeric materials.

Key Physical & Chemical Properties of TPR

TPR (thermoplastic rubber) is a thermoplastic soft rubber materialthat combines the high elasticity, high strength and high resilience of rubber. The following is a detailed introduction to the main physical and chemical properties, performance parameters and industry standards of TPR:

Mechanical properties

- Tensile strength:The tensile strength of TPR materials is generally between 1 and 20 MPa. The specific value depends on the material formula and processing technology. By adding reinforcing materials such as glass fiber, the tensile strength can be increased to 25 MPa.

- Resilience:TPR material has excellent resilience, usually greater than 85%, which is better than PVC material and close to the level of natural rubber. This gives TPR materials significant advantages in shock absorption and anti-skid.

Thermal properties

- Melting point:The melting point of TPR materials has a wide range, generally between 130 and 200°C. The specific value depends on the ratio of SEBS (styrene-ethylene/butylene-styrene block copolymer) and SBS (styrene-butadiene-styrene block copolymer) in the material.

Short-term temperature resistance upper limit: The short-term temperature resistance upper limit of TPR materials is generally 120°C. Exceeding this temperature may cause the material performance to decrease. - Low-temperature embrittlement point:Thelow-temperature embrittlement point of TPR materialsis generally around -40°C, or even up to -55°C, and is suitable for use in extremely cold areas.

Chemical stability

- Water resistance:The water absorption rate of TPR materials is low, usually less than 0.5%, which is better than materials such as EVA (ethylene-vinyl acetate copolymer).

- Oil resistance:TPR materials have relatively poor oil resistance and may swell when exposed to mineral oil. Its oil resistance can be improved through methods such as fluorination modification.

Security certification

- Phthalate-free:TPR material does not contain harmful substances such as phthalates and meets environmental protection and safety requirements.

- Latex-free:TPR material does not contain latex ingredients and is suitable for people who are allergic to latex.

TPR materials have obtained multiple international safety certificationssuch as REACH, RoHS, LFGB, etc., such as REACH (EU Registration, Evaluation, Authorization and Restriction of Chemicals), RoHS (Restriction of the use of certain hazardous substances in electrical and electronic equipment) and LFGB (German Food and Daily Necessities Act), which prove that the material meets international safety standards.

Performance indicators and industry standard requirements

Performance parameters:The performance parameters of TPR materials will show different characteristics due to differences in material formulation and manufacturing process. Such as tensile strength, elongation, elongation at break, etc. Under normal circumstances, the hardness range of this material is very wide (Shore 0-100A), its shrinkage rate is between 1.5% and 3%, and the elongation can be as high as 300% 1500%.

Industry standard:In China, the industry standard followed by TPR products is GB/T 32447-2015 "Thermoplastic Rubber" (TPR). The standard was proposed and organized by the China Plastics Processing Industry Association. This standard describes in detail all aspects of TPR, including its definition, types, standards, test methods, inspection criteria, as well as labeling, packaging, handling and storage. There are many factors to consider when conducting quality control on rubber products for food contact, including the selection of raw materials, processing technology, and whether the product has been strictly tested before use. In addition, in terms of TPR of food contact materials, China follows the test standard of GB4806.1, which is similar to the practice of the US FDA, and both require dissolution tests in distilled water and n-hexane. At present, the EU standard is based on EU1935/2004, which is mainly used for the detection of dissolution in distilled water, 3% acetic acid and 50% alcohol.

What are the advantages of TPR materials?

Thermoplastic rubber materials provide the following advantages:

- It can be recycled and effectively save energy. It is an ideal material to replace rubber and silica gel.

- Energy saving. Most thermoplastic elastomers do not need vulcanization or the vulcanization time is very short, the production efficiency is greatly improved and the forming cycle is short.

- Environmental protection, non-toxic and safe, with excellent coloring and soft touch. TPE materials do not introduce heavy metals and toxic phthalate plasticizers in the production process, which comply with ROHS, reach, EN71, PAHs and FDA environmental protection tests.It is a good material to replace PVC.

- The properties are relatively stable, with good temperature resistance (service temperature range – 50-100 ℃), aging resistance, chemical resistance and solvent resistance. Superior processing performance.

- It can be secondary injection molding, coated and bonded with PP, PE, PC, PS, ABS and other matrix materials, or formed separately.

- It has the characteristics of high elasticity of rubber andinjection molding.

What are the disadvantages of TPR materials?

Although TPR materials offer many advantages, they also come with some disadvantages:

- Materials may become brittle or lose their flexibility outside the temperature range in which they are used.

- Has poorer elasticity and resilience properties than natural or synthetic rubber.

- Under fixed load conditions, there is a risk of creep or deformation over time, which may cause changes in the dimensions of the object.

- Ultraviolet (UV) protection is relatively weak, which poses a hidden danger in outdoor application scenarios.

- This can make overmolding or product assembly using adhesives more complicated due to poor adhesion to other materials.

Which Industries Use TPR Material?

1.Automobile industry

- CVJ dust cover, steering gear cover, shock absorber cover, dust cover, etc.

- Automotive door and window seals, mechanical seals, wheels, etc.

- Car satellite antenna cable buckle, trunk lock assembly, door lock assembly, etc.

- Airbag cover, shock-absorbing chassis, chassis stone-resistant coating, etc.

2.Daily necessities industry

- Hand grips, toothbrush handles, bellows, telescopes, etc.

- Highly transparent replacement for silicone nipples, spoons, shower elastic parts, sanitary ware series, etc.

- Soft tablecloths, curtains, gift boxes, refrigerator boxes, anti-slip mats, etc.

3.Light industrial supplies and cultural and sports supplies

- Hand tools, power tools, gas masks, casters, etc.

- Various racket grips, bicycle, motorcycle grips, luggage and suitcase grips, etc.

- Pen cover rubber parts, diving equipment, mouse balls, chest protectors, mouthguards, etc.

- Sports equipment such as (golf, ski poles) rubber clubs, (tensioners) hoses, knee pads, etc.

4.Medical instruments

- Medical saline bottle stoppers, disposable syringe stoppers, ear cleaning balls, plasma bags, etc.

- Surgical gloves, medical protective clothing, medical sanitary rubber materials, etc.

5.Industrial manufacturing and construction industry

- Seals, conveyor belts, elevator slides, high-pressure washers, etc.

- Decorative membranes, decorative strips, bridge expansion joints, alternative PVC materials, etc.

6.Electronic product

- Cases, buttons, etc. for headphones, chargers, power banks, monitors, etc.

TPR materials are widely used in various industries due to their good elasticity and wear resistance, as well as environmental protection and processability. At the same time, the application of TPR materials is still expanding and deepening, meeting the needs of more fields.

TPR vs. Silicone/Rubber: What’s the Difference?

1.Property comparison

| Property | TPR | Silicone |

| Heat Resistance | Moderate, suitable for up to moderate temperatures | Excellent, can withstand high temperatures |

| Abrasion Resistance | Superior abrasion resistance | Less abrasion resistant |

| Load-Bearing Capacity | High, suitable for dynamic loads | Moderate, better for static loads |

TPR’s superior abrasion resistance and load-bearing capacity make it particularly valuable in industries where mechanical stress is prevalent.

2.Applications and Uses

TPR is advantageous in applications requiring durability under physical stress:

- Automotive belts and hoses subject to dynamic stress

- Vibration dampening components in machinery

- High-wear floor mats and industrial flooring

Silicone is indispensable in heat-critical applications:

- High-temperature gaskets and seals in automotive and aerospace

- Protective cooking gloves and silicone bakeware

- Medical implants and prosthetics that require biocompatibility and temperature resilience

3.Cost

TPR often provides a more cost-effective solution for applications requiring durability and versatility, especially when considering long-term usage and performance needs. Silicone, though ideal for specialized applications, typically incurs higher costs due to its unique properties and manufacturing processes.

Summary

TPR material is a versatile and cost-effective plastic materialthat has been used in various industries for decades. As technology advances and new materials are developed,TPR materials will continue to be a viable option for many productsand applications in the future.

Soon, TPR materials will continue to be used in many current applications, such as kitchenware, automotive parts, and medical devices. As research continues to push the boundaries of materials science, new TPR formulations may be developed that are stronger, more durable, and more cost-effective than current formulations. In addition to new formulations, new processes and production techniques can be developed to produce TPR materials faster and more efficiently. This results in cost savings and faster turnaround times for customers.

Finally,TPR materials may have new and innovative uses.For example, TPR materials can be used in3D printing applicationsor as a replacement for metal parts in industrial equipment. As technology develops, TPR materials may become more versatile and cost-effective in many industries.

If you have additional questions or would like to learn more about this topic, please feel free to contact our team. LS specializes in prototype part manufacturing and offers comprehensive services to meet your prototyping and production needs.Please feel free to contact us for a free quote!

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1.What are the properties of TPR rubber?

TPR (thermoplastic rubber) combines high elasticity, high strength and high resilience of rubber. Its properties include: high elasticity and rebound, excellent processing performance (no need for vulcanization, injection molding, extrusion, blow molding), environmentally friendly and non-toxic, wide hardness range (5-100 Shore hardness), good coloring performance, wear resistance and anti-skid, temperature resistance and weather resistance (relative to vulcanized rubber, it has weak temperature resistance, but is stable and has strong weather resistance), and recyclable.

2.What is the difference between TPR and rubber?

The main differences between TPR and rubber are processing performance (TPR does not need vulcanization, while rubber does), composition and structure (TPR is a blended and modified thermoplastic styrene-butadiene rubber, while rubber is a polymer compound), and certain specific properties (such as temperature resistance and wear resistance may vary depending on the material).

3.What are the different types of TPR materials?

TPR materials include many types, such as polyurethane thermoplastic elastomer (TPU), polyolefin thermoplastic elastomer (such as SBS, SEBS base TPR), polyvinyl chloride thermoplastic elastomer (TPVC), polyester thermoplastic elastomer, and polyamide thermoplastic elastomer (TPAE), etc.

4.What are the properties and characteristics of thermoplastics?

It becomes soft when heated and hardened when cooled, and can be formed repeatedly; it is easy to process and can be injection molded, extruded and blown, and has high production efficiency; it has stable performance, linear polymer structure, and is not subject to thermal cross-linking; it is recyclable, saving resources and reducing pollution; it has many types to meet various needs; it has certain physical and mechanical properties, but poor heat resistance and rigidity.

Resource