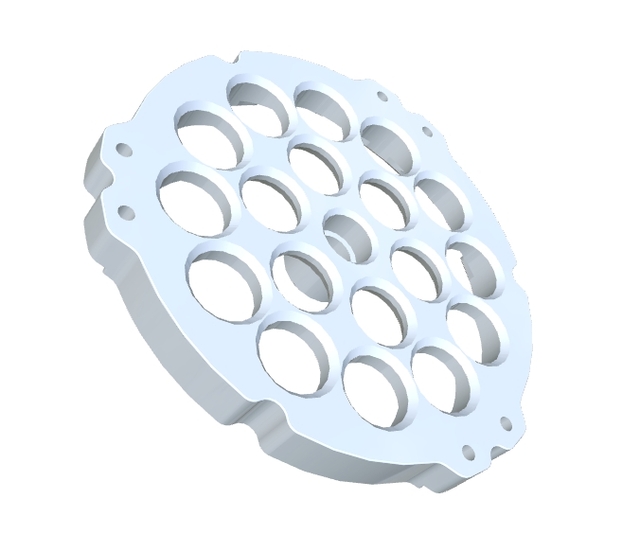

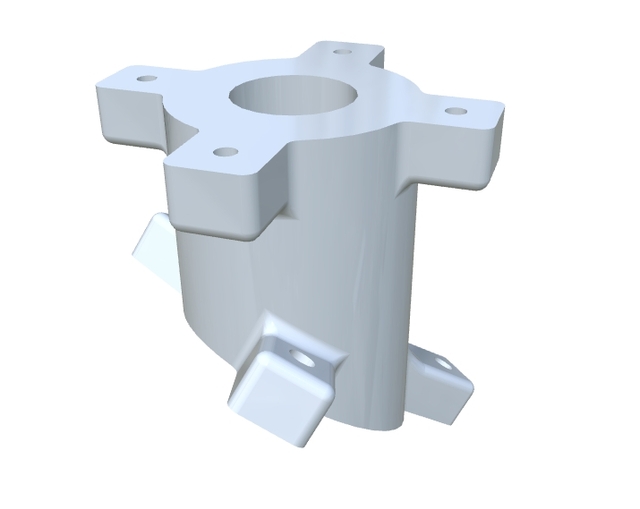

In today's fast-paced world of manufacturing and technology, **5 axis CNC machining** stands out as a game-changer. This advanced process allows for the production of complex and intricate parts with unprecedented precision, opening doors to innovative possibilities across various industries. Whether you're in aerospace, automotive, or even consumer electronics, the benefits of 5 axis CNC machining are hard to ignore.

5 axis CNC machining services offer unparalleled flexibility and efficacy, making them indispensable for those seeking high precision CNC machining. Unlike traditional 3 axis machines, the 5 axis machining centers allow for the creation of parts without having to reposition the workpiece between operations. This leads to greater accuracy and faster production times, minimizing errors and reducing costs. As a result, these machines are perfect for a range of applications, from crafting bespoke aerospace components to producing complex medical devices.

The materials used in 5 axis CNC machining are as varied as the applications themselves. With the capability to machine through a range of materials, including metals like titanium and aluminum as well as certain plastics, the possibilities are virtually limitless. This versatility makes it the preferred choice for producing durable and robust 5 axis CNC machining parts that can withstand stringent operational demands. Furthermore, the use of advanced 5 axis CNC tooling enhances the machine's ability to handle these materials effectively, ensuring each product meets its high-quality standards.

One such notable product benefiting from the advancements in CNC machining is the dual-toggle switch module. This cutting-edge component is designed for those who demand both aesthetics and functionality. Its sleek, glossy finish complements any technological environment while the dual toggles provide an intuitive means of controlling multiple circuits or devices simultaneously. Ideal for both tech enthusiasts and professional engineers, this module underscores the innovative spirit of modern machining, achieving reliability and ease of use in harmony with a futuristic design.

In conclusion, 5 axis CNC machining is transforming the landscape of manufacturing. By providing services that cater to the demands of high precision and complex designs, industries everywhere are taking advantage of this revolutionary technology. Whether exploring new materials, engaging in ambitious DIY projects, or striving for perfection in professional applications, the impact of 5 axis CNC machining is undeniable, offering a glimpse into the future of engineering and production.

5 Axis CNC Machining: Precision Parts & Innovative Applications

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | CNC Machining, CNC Milling, CNC Turning, 5-Axis CNC Machining, Gear Machining |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.