In the modern age of advanced manufacturing, precision and efficiency are paramount, especially in industries that require intricate and complex components. Enter 5 axis CNC machining, an innovative manufacturing process that has revolutionized the way we approach precision engineering. Utilizing a main keyword like 5 axis CNC machining in the first paragraph sets the stage for exploring the intricate details and advantages of this cutting-edge technology.

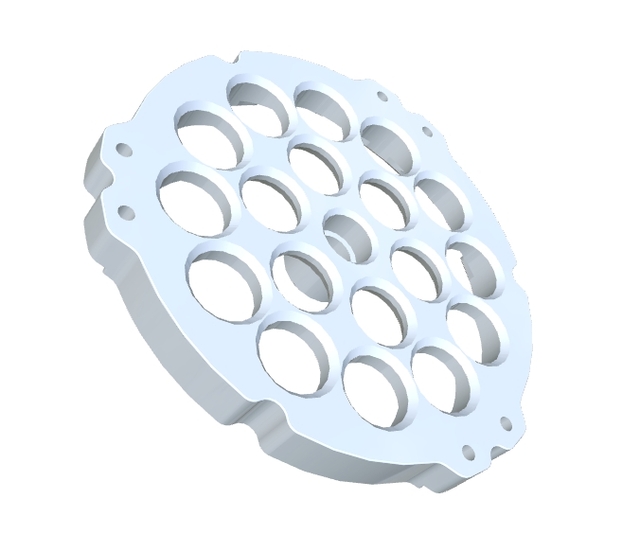

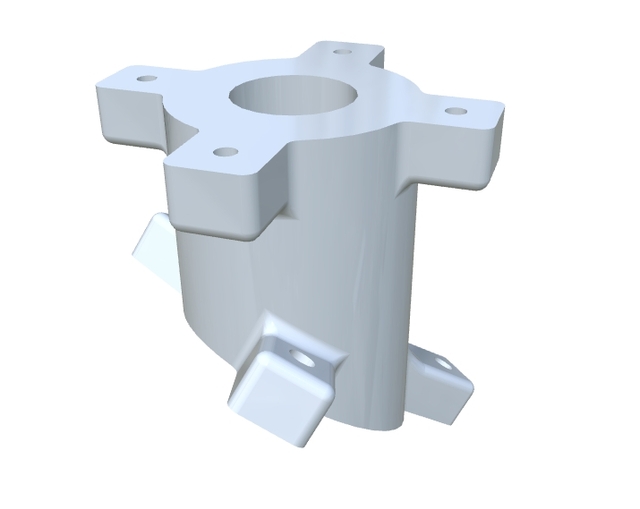

One of the most significant advantages of 5 axis CNC machining is its ability to create complex and highly detailed parts without the need for multiple setups, which is often required with traditional machining processes. This technology allows for simultaneous movement along five different axes, providing manufacturers with unparalleled flexibility and accuracy. As a result, it is particularly beneficial for creating components with intricate geometries, such as the sleek and robust mounting bracket described. This bracket not only benefits from the precision of the machining process but also from the enhanced stability and secure fastening offered by its uniquely designed cross-like top extension.

Moreover, 5 axis CNC machining services have become increasingly accessible to businesses worldwide. Whether you're looking for a 5 axis CNC machining center in your local area or comprehensive services in the UK, the industry has seen a surge in available options. Manufacturers can now find a 5 axis CNC machining center that suits their specific needs, from mini 5 axis CNC machining centers for smaller-scale projects to full-scale solutions for major industrial operations. This widespread availability ensures that businesses can leverage the benefits of precision manufacturing close to their base of operations, thus reducing costs and lead times.

The importance of high-quality materials cannot be overstated, especially when considering products like the mounting bracket mentioned. Crafted from durable and exceptionally smooth materials, the bracket demonstrates both resilience and aesthetic elegance. This aligns seamlessly with the demands of 5 axis CNC machining, which requires superior materials to match its precision capabilities. Furthermore, the additional angular supports on the bracket enhance reinforcement, showcasing how modern engineering can merge functionality with contemporary design. Thus, 5 axis CNC machining not only enhances part quality but also extends the durability and performance of the components produced.

In conclusion, the influence of 5 axis CNC machining on today's manufacturing landscape is undeniable. From automotive to aerospace, medical devices to consumer electronics, its applications are vast and varied. With its ability to boost productivity, reduce waste, and ensure the highest levels of precision, 5 axis CNC machining continues to push the boundaries of what is possible in manufacturing. As more businesses recognize its potential, we can expect this technology to become an integral component of advanced engineering solutions worldwide.

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.