In the evolving world of manufacturing, overmolding techniques have emerged as a game-changer. Overmolding is a sophisticated process that involves combining different materials to produce a single product with enhanced properties. This is achieved by molding a secondary material over a previously molded part, resulting in products that are not only durable but also aesthetically pleasing.

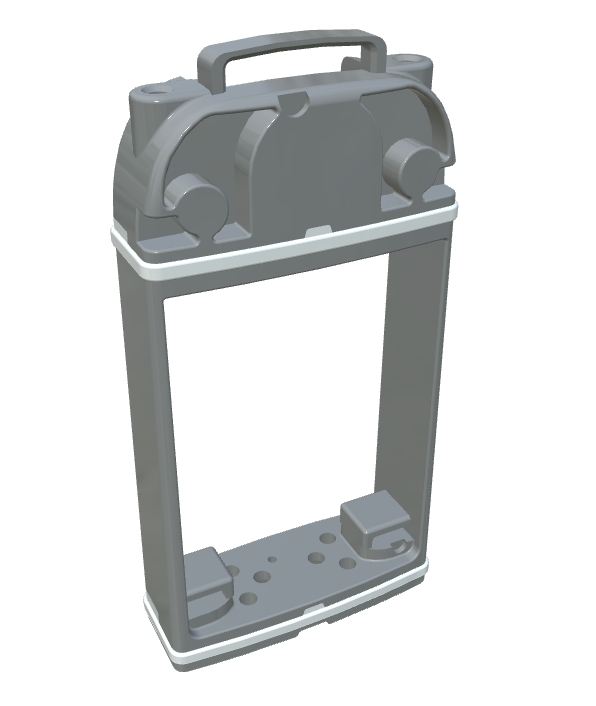

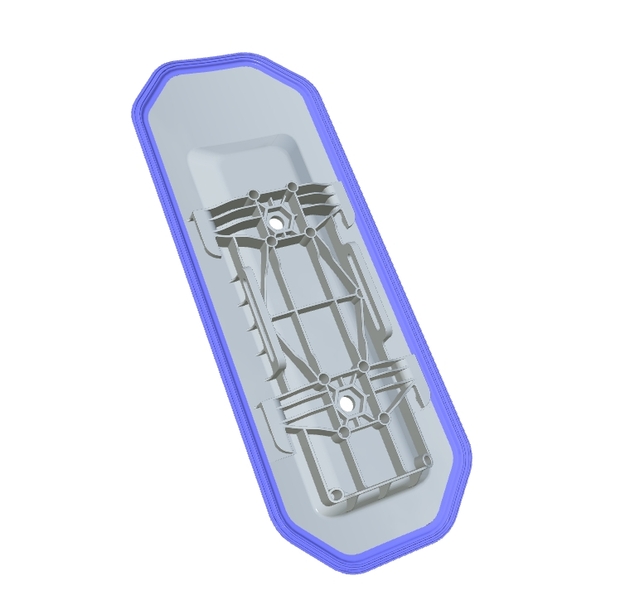

Overmolding materials, such as thermoplastics and elastomers, play a crucial role in this process. These materials are chosen for their ability to bond seamlessly, ensuring the product's longevity and functionality. Understanding the overmolding process is key to unlocking the potential of this technology. It involves several stages, starting from designing, material selection, tooling, and finally, the molding process itself. Custom overmolding allows for tailored designs, making it a preferred choice for industries seeking innovative solutions.

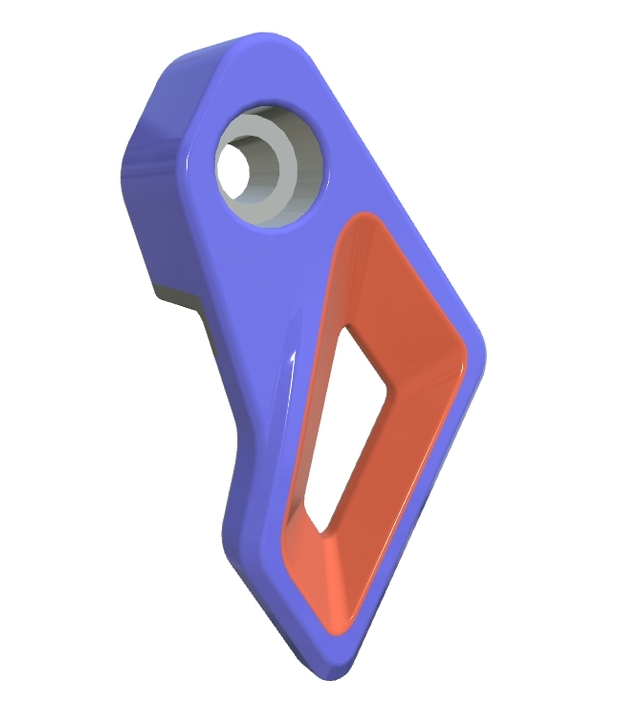

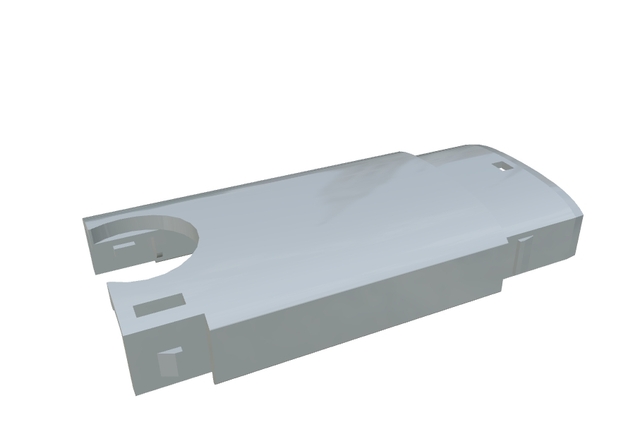

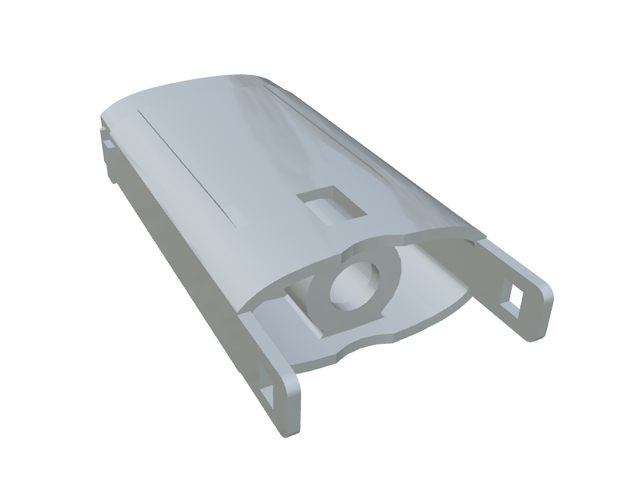

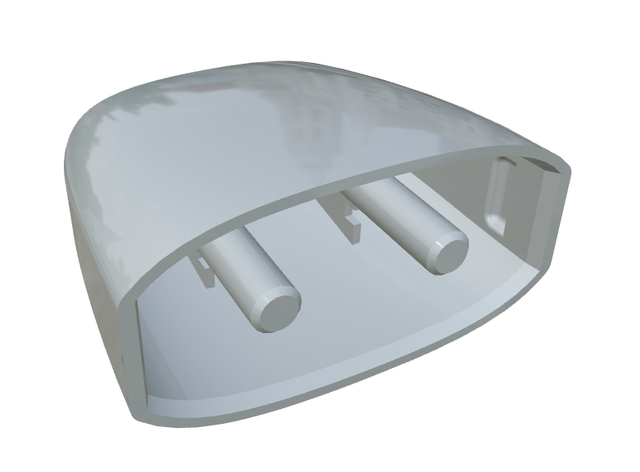

One of the most notable overmolding applications is seen in the creation of bottle openers. By utilizing advanced overmolding design principles, manufacturers can produce sleek and modern bottle openers that are both stylish and functional. The use of overmolding benefits such products by adding ergonomic enhancements, improved grip, and a modern touch, forged through a metallic finish that is not only sleek but also ensures longevity.

As seen in our innovative bottle opener design, the use of overmolding technologies has resulted in a tool that boasts minimalist aesthetics coupled with practical utility. The seamless integration of the opening mechanism, achieved through meticulous overmolding, makes it an essential accessory in any modern kitchen, bar, or picnic setup. The chic and elongated form of the bottle opener not only provides a comfortable grip but also enhances the user experience through effortless operation.

In conclusion, the advancements in overmolding technology are revolutionizing product development across industries. From enhancing durability to improving the user experience, the benefits of overmolding are countless, making it an indispensable technique in modern manufacturing. As companies continue to explore the potential of custom overmolding, we can look forward to even more innovative products hitting the market.

Exploring Advanced Overmolding Techniques in Modern Manufacturing

Get Latest Price >

| Label | Value |

|---|---|

| Brand | LS Custom Parts Manufacturers |

| Customization Service | Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Insert Molding, Overmolding |

| Drawing format | 2D/(PDF/CAD)、3D(IGES/STEP/GLB) |

| Material Capabilities | Aluminum、Brass、Bronze、Copper、Hardened Metals、Precious Metals、Stainless Steel、Alloys、TPR |

| Sample | Free |

| Supply Ability | 100000 Pieces Per Day |

| Surface Finish | Customized Finishing |

| Thickness | Customized Thickness |

| Type | Broaching/Drilling/Etching / Chemical Machining/Laser Machining/Milling/Turning/Wire EDM/Rapid Prototyping/Other Machining Services |

| Services | CNC Machining,Metal Casting,Injection Molding,Sheet Metal Fabrication,Rapid Prototyping,3D Printing |

Contact

Ready to start your next project with LS Manufacturing?

Contact us today to learn more about our services and how we can help you achieve your goals.

LS Hardware Tech Co., Ltd

LS Hardware Tech Co., LtdRapid lead times starting from just 1 business day.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification.

Over 100 materials available, with 50+ surface finish options.

Cost-effective mass production.

Order as low as 1 piece.