Casting is one of the oldest manufacturing methods, with early processes dating back thousands of years and modern processes dating back to around 1893. While casting methods and techniques have improved greatly since then, the basic principles remain the same. Essentially, molten material is poured into a preformed cavity or mold, where it is then cooled and solidified into the desired shape.LS uses different casting methodsdepending on the part and manufacturing specifications. One of the most common casting processes used in modern operations is investment casting. This article will delve into theprecision casting processof investment casting. From its basic principles, process flow, significant advantages to wide range of applications, we will unveil its mysteries one by one and lead everyone into the wonderful fusion of this ancient skill and modern technology. world.

What is Investment Casting?

Investment casting, also known as lost wax casting or precision casting, is an advanced casting process mainly used to produce metal parts with complex shapes, precise dimensions and smooth surfaces. The core principle is to use fusible materials (such as wax, plastic, etc.) to first make a prototype model consistent with the shape of the final casting, and then coat the surface of the model with refractory materials multiple times to form a strong shell. When the mold shell is strong enough, the prototype model inside is melted and expelled by heating, leaving a hollow refractory cavity. Finally, molten metal is poured into the cavity. After the metal cools and solidifies, the shell can be broken to take out metal castings with complex shapes and high precision.

Investment casting is widely used in aerospace, medical equipment, automotive industry, precision instruments and other fields because of its ability to produce high-precision, high-quality and complex-structured castings. It allows designers to create complex geometric shapes that are difficult to achieve with traditional casting methods, while ensuring the dimensional accuracy and surface quality of castings. It is an indispensable precision manufacturing technology in modern industry.

What are the advantages investment casting?

Investment casting is favored for its capability to provide parts with excessive dimensional accuracy, intricate particulars, and superb floor finishes. The process permits for the creation of advanced shapes, inside cavities, and skinny partitions which can be tough to realize with different casting strategies. It additionally gives good dimensional accuracy and repeatability, distinctive floor high quality, and the flexibility to consolidate advanced assemblies right into a single solid half. Tooling prices are comparatively low in comparison withThe Casting, and there may be much less materials wastage as feed and sprue parts will be reused. Investment casting may also produce parts with the identical properties because the uncooked materials used.

What are the disadvantages investment casting?

Regardless of its many benefits,investment casting has some limitations. It’s typically extra pricey than different casting strategies, particularly for short-run productions. The process will be difficult because of the many steps concerned, which leaves a large scope for error. There are additionally measurement and weight limitations for the solid parts, and the per-component value is increased than for sand casting on the one-off degree. Materials limitations have to be thought-about, though they don’t seem to be vital.

How Does Investment Casting Differ From Other Methods?

There are significantdifferences between investment casting, sand casting and die casting. These differences are mainly reflected in the casting process, casting characteristics, applicable fields, etc. Here is a comparison table about investment casting, sand casting and die casting:

| Casting method | Investment casting | Sand casting | The casting |

|---|---|---|---|

| Model Material | Fusible materials (e.g. wax, plastic) | sand | Metal molds |

| Shell/mold making | Coated with refractory material to form a shell, the prototype model melts and discharges | Sand is used to compact to form a mold | Precision metal molds |

| Casting size and shape | It is suitable for small and medium-sized castings, with complex shapes and high precision | Castings of various sizes and shapes can be produced | It is usually limited to small and medium-sized parts with complex shapes |

| Surface | High, up to Ra25-6.3μm | lower, additional processing may be required | High, the surface roughness Ra value is 0.8~3.2μm |

| Dimensional accuracy | High, generally up to 5~7 grades | Lower | High, dimensional tolerance level is IT10~IT12 |

| Alloy type | Virtually unlimited, including alloy steels, carbon steels, and heat-resistant alloys | Including steel, iron, and most non-ferrous alloys | Mainly aluminum, zinc, magnesium and copper alloys |

| Productivity | Relatively low, complex process | Taller, suitable for mass production | High, semi-automatic and automated production can be realized |

| Manufacturing costs | Usually high, mold manufacturing is complex and time-consuming | Lower, relatively low equipment and material costs | Mold manufacturing is expensive, but mass production reduces costs |

| Fields of application | Aerospace, medical equipment, precision instruments, etc | Automotive, construction, machinery, and a wide range of fields | Automotive, instrumentation, electronics, defense, etc |

What Are the Steps in the Investment Casting Process?

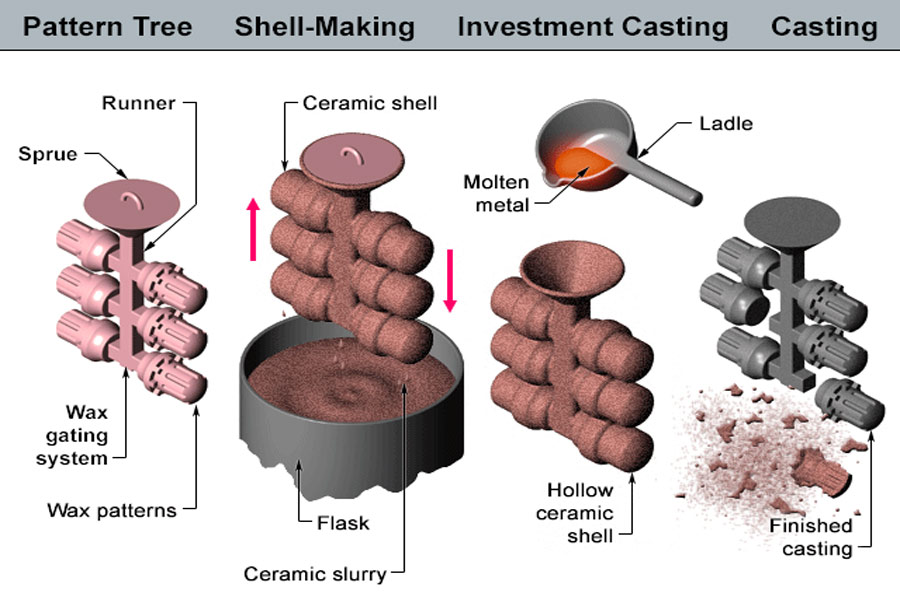

Theinvestment casting processis known for its high precision, high complexity and good surface quality, and is particularly suitable for producing small, complex-shaped metal parts. However, the process is also relatively complex and costly, so it is usually used in applications that have strict requirements on casting quality. Below we focus on learning and understanding the investment casting process, which mainly includes the following steps:

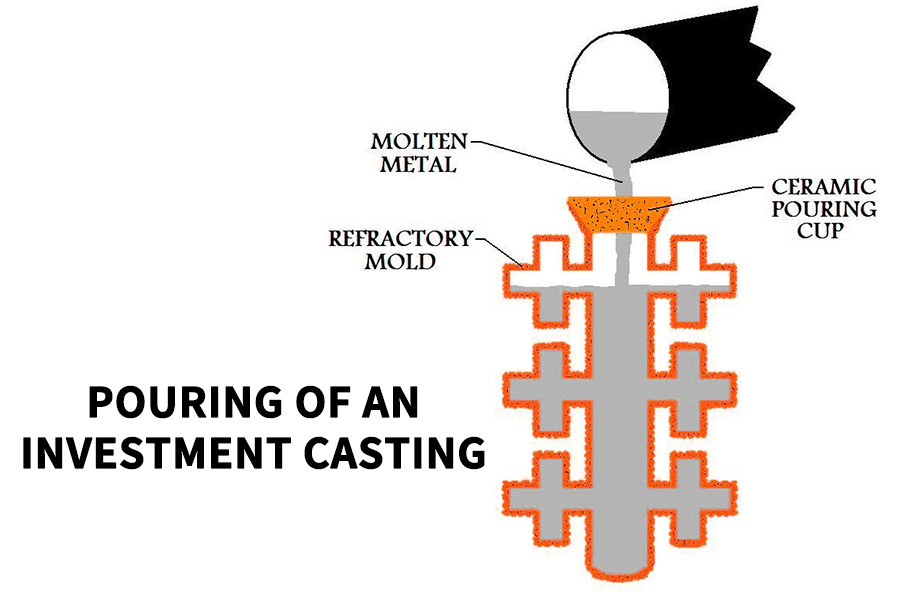

- Wax pattern making:Use specific wax materials to create a wax pattern consistent with the shape of the required casting throughinjection molding, pressing or other molding methods. The dimensional accuracy and surface finish of the wax pattern have a direct impact on the quality of the final casting.

- Tree assembly and hanging:multiple wax moldsare combined into a tree-like structure (called a wax tree) to improve production efficiency. The wax tree is then dipped into a refractory slurry to create a thin, refractory coating. This process may need to be repeated several times to create a fire-resistant enclosure of sufficient thickness.

- Sanding and Hardening:While the refractory coating is still wet, sprinkle fine refractory sand to increase the strength of the shell. Then, let the coating dry and harden. This process may also need to be repeated multiple times until the shell reaches the desired thickness and strength.

- Dewaxing:A wax tree with a refractory outer shell is heated so that the wax pattern melts and flows out of the outer shell. This process is usually done in a steam room or hot water bath to ensure that the wax is completely melted and drained.

- Firing:The dewaxed refractory shell is fired at high temperatures to solidify its structure and remove any remaining wax or moisture. Firing temperature and time depend on the type of refractory material and the size of the casting.

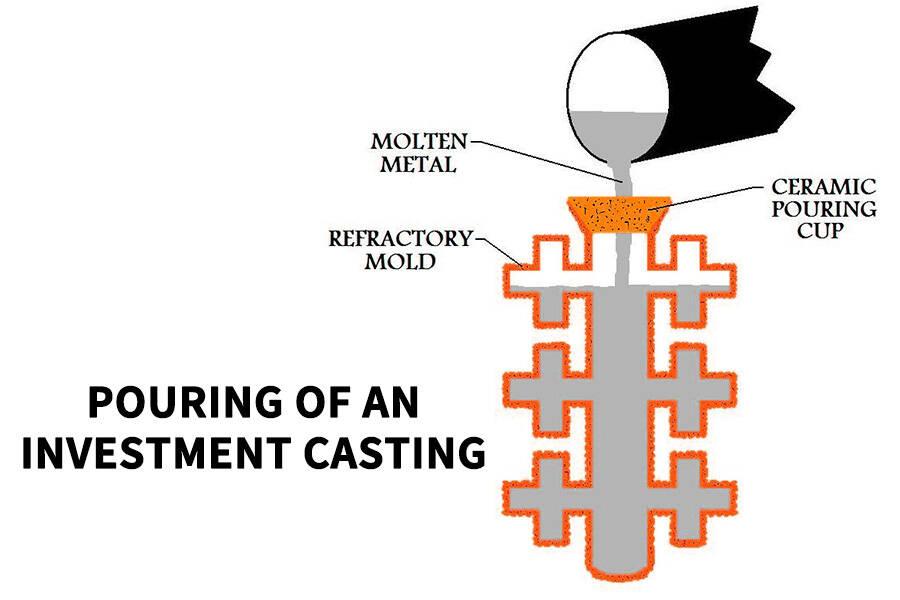

- Pouring: For molten metal(such as steel, aluminum, copper, etc.) into the fired refractory shell. The metal cools and solidifies within the mold, forming a metal casting that conforms to the shape of the wax pattern.

- Shell clearing and removal:After themetal casting has cooled, crush or cut off the refractory shell and remove the casting. This process requires care to avoid damaging the casting.

- Post-processing:Necessary cleaning and finishing of theremoved castings, such as removing burrs, oxide scale, mechanical processing, heat treatment, etc., to meet the requirements of the final product.

What Materials Are Used in Investment Casting?

A variety of supplies can be utilized in investment casting, together with numerous metals and alloys resembling stainless-steel, brass, aluminum, carbon metal, and even glass. Every materials gives totally different properties:

1.Stainless steel

Compared to many other materials,stainless steel stands out for its exceptional durability, a quality that has prompted designers and engineers to increasingly turn to investment casting technology. Stainless steel is used in a wide range of applications, including transmission components and various gears in the automotive field, as well as camping equipment and golf club heads.

2.Low alloy steel

Low alloy steeloccupies a pivotal position in the machinery manufacturing industry due to its affordable price and excellent mechanical properties. Through specific heat treatment processes, engineers can engineer different areas of the same workpiece to achieve differentiated performance, for example, making one surface tough and impact-resistant while another surface offers excellent wear resistance.

3.Aluminum alloy

Aluminum alloy is the favorite in the field of investment casting, especially in aerospace, avionics, electronic equipment and military industries. With the continuous improvement of material strength and the popularity of high-quality aluminum-silicon-magnesium alloy castings, aluminum alloy castings can now meet the needs of demanding applications such as fuselage components.

4.Carbon steel

As a low-cost and common material,carbon steel comes in various types, mainly classified according to carbon content. Through heat treatment, the strength, ductility and overall performance of carbon steel can be significantly improved. The ferromagnetic properties of carbon steel make it suitable for motor and electrical appliance manufacturing. Carbon steel has become one of the most commonly used alloys worldwide due to its safety, durability and excellent structural integrity.

5.Super alloy

Nickel-and cobalt-based superalloys play an integral role in the aerospace, energy, medical, chemical and marine industries. Nickel-based alloys perform well in high-temperature environments, while cobalt-based alloys are superior in corrosion, oxidation and wear resistance. As superalloys gradually replace sheet metal, their high stiffness, excellent service characteristics and cost-effectiveness are becoming increasingly popular.

6.Copper alloy

Copper-based alloys are known for their excellent corrosion resistance and low wear rate, and are widely used in ship propellers, pump propellers, electrical components, and pipeline components. As a versatile material, copper alloys come in more than 400 different varieties, each with its own characteristics.Investment casting technologycan be used to manufacture a variety of copper-based alloy parts, among which bronze and brass are the most common. Beryllium copper is one of the strongest copper alloys, its performance is comparable to high-strength alloy steel, and it also has stronger corrosion resistance and longer service life.

7.Cast iron

Cast iron, especially gray iron and ductile iron, is known for its high precision and affordable price. Ductile iron not only has high strength, heat resistance and toughness, but its production process is also relatively complex, resulting in production costs that are slightly higher than cast steel.

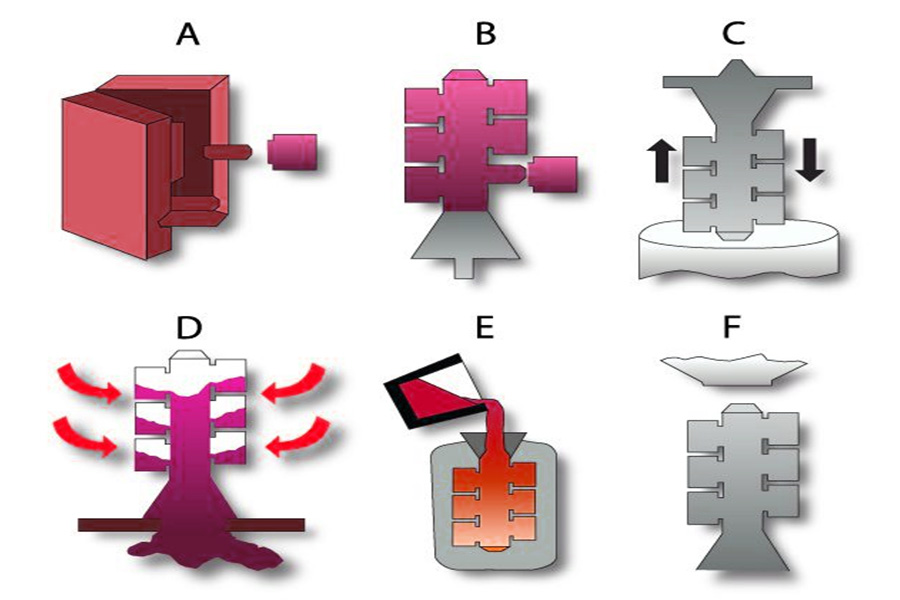

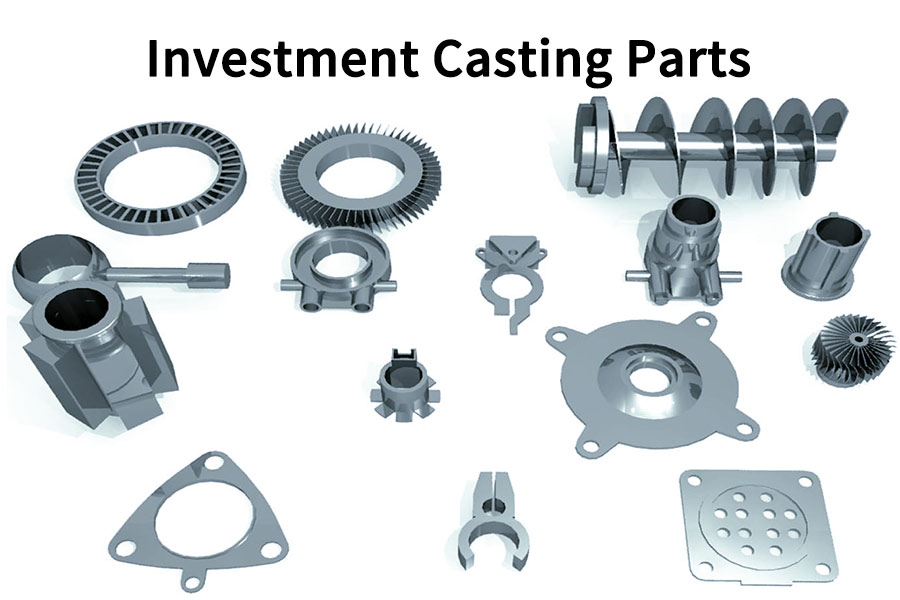

What Are the Applications of Investment Casting?

Investment casting plays a vital role in numerous industriesdue to its high flexibility and unparalleled precision. Here are some examples of particularly prominent application areas:

| Application | Functions |

|---|---|

| Aerospace | Turbine blades,airplane partsthat want to resist excessive temperatures |

| Energy Era | Parts for energytechnology tools |

| Firearm | Components with advanced geometry |

| Automotive | Excessive-temperature parts |

| Army | Numerousparts for navy functions |

| Business | Numerous business functions |

| Meals Service | Numerousparts for meals servicetools |

| Gasoline and Oil | Parts for gasoline and oil business |

| Power | Parts for vitality business |

| Medical | Surgical devices, implantable gadgets |

Find an Investment Casting Company

For those looking touse investment casting in their projects, choosing the right partner is crucial. Whether you need aluminum, stainless steel, or titanium investment casting, it’s important to choose a company that meets your specific needs.

At LS we are a top provider ofinvestment casting services. With years of industry experience and state-of-the-art manufacturing equipment, we have the knowledge, skills and tools to deliver quality rugged parts and products for the most critical industrial uses. To learn more about the differences between investment casting and die casting or our services and capabilities,contact us today.

FAQs

1.What is investment casting?

Investment casting, also known as precision casting or lost wax casting, is an advanced casting process. It works by using a fusible material (such as wax or plastic) to create an accurate fusible model, and then coating the model with multiple layers of refractory paint that dries and hardens to form an integral shell. The mold is then heated so that the wax pattern inside melts and drains away, leaving a hollow refractory mold. Finally, liquid metal is poured into the mold shell, and after cooling and solidification, a casting with the same shape as the wax model can be obtained.

2.What is the significance of investment casting?

Thesignificance of investment castingis mainly reflected in the fact that investment casting can produce castings with very high dimensional accuracy and surface quality, which is crucial for industries that require high-precision parts such as aerospace and automobile manufacturing. This technology is suitable for a variety of cast metal materials, and because of the flexibility of the wax pattern making process, it shows strong customization capabilities and can be applied to the manufacturing of complex structures, large-sized and thin-walled products. Although the investment casting process is relatively complex, once the mold is made, a large number of high-quality castings can be quickly copied, thereby improving production efficiency.Investment casting can significantly reduce the processing volumeof the product's forming surface and mating surface, saving processing time and cutting tool material consumption.

3.What are the differences between ordinary casting and investment casting?

Conventional casting (such as sand casting) and investment casting differ significantlyin several ways: sand casting uses sand and a binder to create the mold, while investment casting uses a fusible material such as wax to create the pattern. Sand casting is to pour molten metal into a sand mold, and then take out the casting after the metal cools and solidifies; while investment casting is to first cover the surface of the wax mold with refractory material to form a mold shell, then melt the wax mold and discharge it, and finally fill it with sand and pour it. Get the casting. The dimensional accuracy and surface quality of investment castings are generally higher than those of sand casting, and castings with more complex shapes and thinner wall thicknesses can be cast. Sand casting is relatively low-cost and suitable for mass production; investment casting is more expensive, but due to its high precision and customization capabilities, it is widely used in industries that require high-quality, complex-shaped parts.

4.What is investment casting powder made of?

Powders used in investment casting(especially refractory powders used in shell making) are usually mixed with a variety of inorganic materials that have high melting points, good chemical stability and thermal stability. The exact composition may vary depending on factors such as the type of casting alloy and the shape and size of the casting. Common refractory materials include silica sand, zircon sand, corundum sand, etc. After these powders undergo mixing, grinding and other process steps, they form refractory powder suitable for investment casting.

Summary

Investment casting is an advanced casting processwith a long history and wide range of applications. It can produce castings with high dimensional accuracy and good surface quality through precise investment mold making, multi-layer refractory coating and high-temperature baking. At the same time, investment casting is suitable for various alloy materials and has the characteristics of high production flexibility and strong adaptability. In future industrial manufacturing, investment casting will continue to play an important role in providing high-quality casting products for different industries.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

LS is an industry-leading companyspecializing in custom manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precisionCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 advanced 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries worldwide. Whether it’s low-volume production or large-scale customization, we can meet your needs with delivery as fast as 24 hours. ChoosingLS Technologymeans choosing efficiency, quality, and professionalism.

To learn more, please visit our website:www.lsrpf.com