It’s no accident that metal casting is one of the most efficient and versatile manufacturing processes available today. This technique involves pouring molten metal into a mold and is actually thousands of years old. Over the past 6,000 years, metal casting has been used to create everything from swords and wedding rings to sprockets and screws. Today, metal casting is used to efficiently manufacture metal parts for a variety of industries. Castings, pieces of metal formed during the metal casting process, can range in size from a few grams to thousands of pounds.

In this article, we’ll detail everything you need to know about metal casting, including what it is,how metal casting works,the varioustypes of metal casting, the materials and molds used in metal casting, and more.

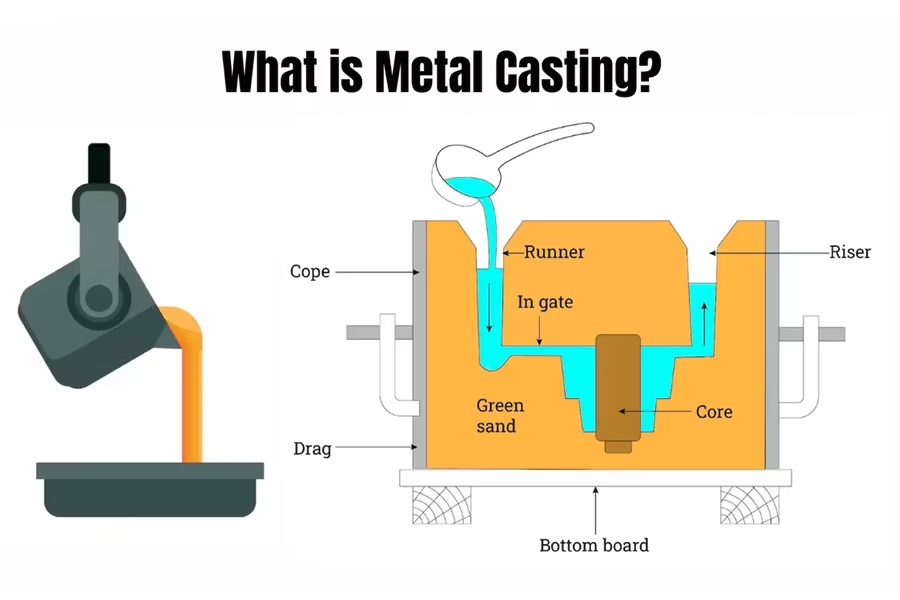

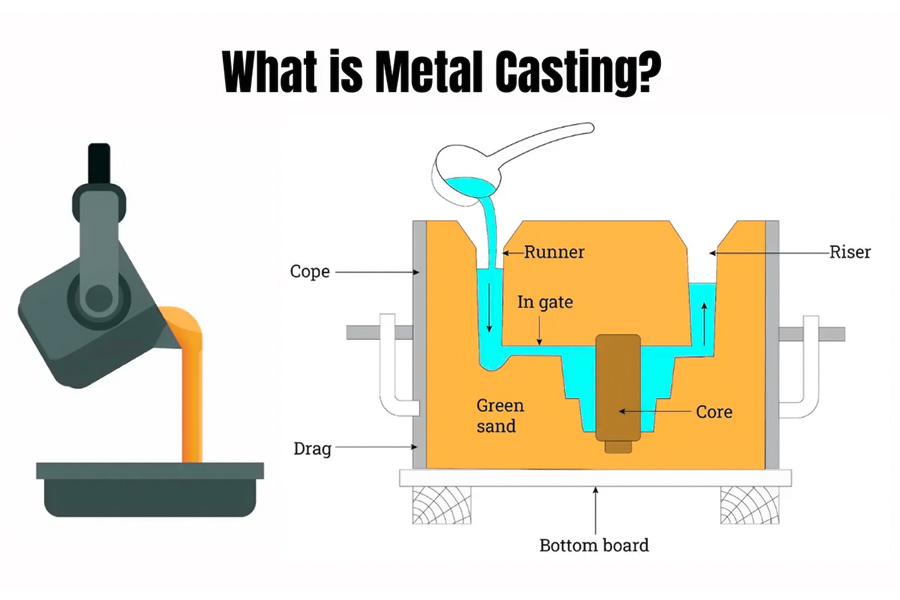

What is Metal Casting?

Metal casting is a manufacturing processthat involves pouring molten metal into molds to create 3D metal parts. The mold contains cavities of the desired geometry, and the molten metal cools to form the solidified part.

The word "cast" also refers to parts made through a casting process, which dates back 6,000 years. Historically, casting processes have been used to create complex and large parts that would be difficult or costly to create using other manufacturing processes.

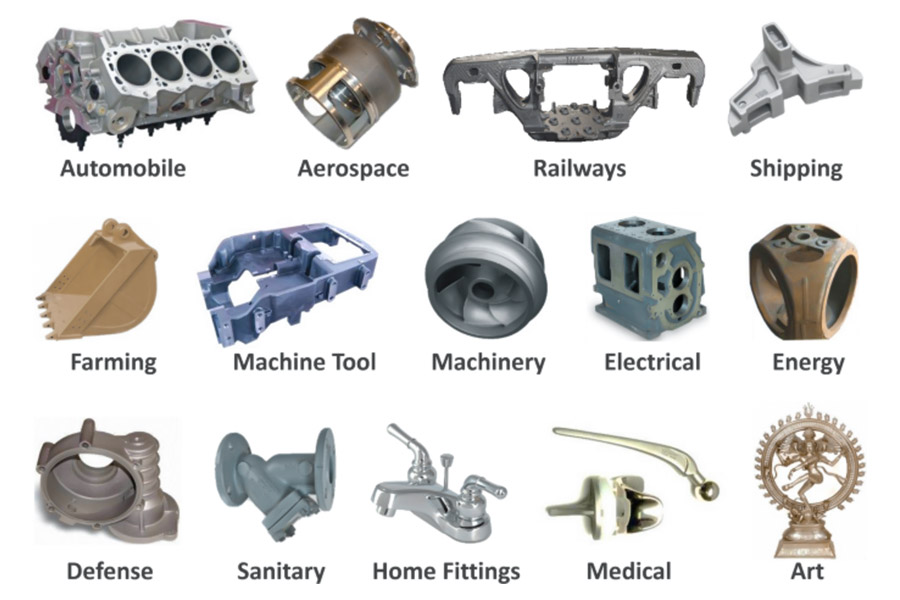

Casting is the first choice for complex geometriesbecause it is more cost-effective and the process is simpler compared to, for example,CNC machining.But casting is also widely used for the simplest shapes because of its fast turnaround time and large production capabilities. Today, the use of cast products is so widespread that no matter what environment you are in, you cannot avoid using cast products. Some examples of cast metal products include engine blocks, fire hydrants, electric motors, tools, traffic lights, manholes, pipes, valves, and various fittings.

How does metal casting work?

Metal casting is a manufacturing process that involves pouring molten metal into molds to create 3D metal pieces. Once the metal and mold have cooled down, the metal object is removed, deburred, machined and finished. Because the process involves custom molds, metal casting can be used to create metal objects in a variety of shapes and sizes.

1.Mold making

The metal casting process begins with a pattern, a model of the part that will ultimately be manufactured. Typically, models are made from wood, metal or plastic, but can also be produced by machining or3D printing.

2.Forming

Next, the mold is designed and made using the model. Molds can be reusable, meaning they can be used over and over again to cast the same parts, or they can be consumable, meaning they can only be used once and are destroyed during the casting process.

3.Melt and pour metal

The metal is heated until molten and poured into the mold cavity. Steel, stainless steel, aluminum, copper, magnesium, and zinc are the most common types of metals used in metal casting.

4.Finishing

After the metal cools and solidifies, the final casting is removed from the mold. The final step is finishing, which involves filing, cleaning and polishing the metal parts. Final steps can also include machining and drilling.

What Are the Types of Metal Casting Processes?

There are different types of casting processes, and each process has its own advantages and disadvantages as per the user requirement.

1.Sand Casting

Sand casting is a universal casting process that can be used to cast any metal alloy, whether ferrous or non-ferrous. It is widely used in mass production in industrial units such as automotive metal casting parts such as engine blocks, cylinder heads, crankshafts, etc.

The process uses molds made of silicon-based materials, such as naturally bonded sand or synthetic sand, to create a smooth mold surface. The mold surface has two parts, the upper mold (upper part) and the lower mold (lower part). A pouring cup is used to pour molten metal into the mold, where it solidifies to form the final shape. Finally, excess metal is trimmed off to complete the final metal cast product.

Pros & Cons of Sand Casting:

| Pros | Cons |

| Cost Effective for Small Batches: It is ideal for low-to-medium volume production as it is relatively cheap compared to the other casting types. | Lower Dimensional Precision: Parts have lower dimensional precision and a rougher surface finish than other casting types. This often requires additional machining. |

| Flexible Design Option:Can produce a variety of shapes and sizes, from very small parts to large components. | Greater Material Waste:Because sand molds can’t be reused, they result in a higher waste of material compared to other casting methods. |

| Material Versatility: Casts nearly any metal alloy. | Porosity Risks: Castings are at higher risk for porosity, which can impact the mechanical properties. |

| Easy Setup and Equipment: Does not require as much equipment and is less expensive than other casting techniques, making it more accessible to small-scale operations. | Post Processing Requirements: May require extensive finishing, such as grinding and machining to achieve the desired finish. |

| Ideal Castings for Large Parts: Especially suited to create large parts which would be difficult or costly to produce with other casting methods. | Lengthening of Cycle Time:The production cycle can be extended if the process is slower, particularly in the preparation and drying of molds. |

2.The Casting

While sand casting can melt alloys with higher melting points, you can use die casting to shape metals with lower melting points. After changing the material from a solid to a hot molten liquid, you can inject it into a long-life die-cast mold made of hardened steel. These tools consist of a cavity, a core, and sometimes an insert. Unlike plastic injection molding, machining side features after casting is sometimes more feasible than using side actions. Die casting dates back to the 19th century.

Since its emergence in the manufacturing world, two types of programs have been developed for your use. The first is a hot chamber, which features a built-in furnace within the machine to melt the material. If you use the cold chamber process, the second procedure, you melt the material in a separate furnace and then move the molten material into the injection chamber. You can implement die casting for high-volume production of aerospace and automotive parts, as well as toys, furniture, and electronics. Die casting is provided through Longsheng's core services, and quotes can be created through the instant quote engine.

Pros & Cons of Die Casting:

| Pros | Cons |

|---|---|

| High Productivity:Ideal for large-scale productions with short cycle times. | High Initial Cost:Die casting machines and molds are expensive, so they are not economical for small production runs. |

| High Dimensional AccuracyProduces high-precision and consistent parts, often reducing or eliminating the need for extra machining. | Limited Material Options:Mainly for non-ferrous materials like aluminum, magnesium, and zinc. Due to their high melting points, ferrous metals are used less often. |

| Good Surface Finish:Most parts have a smooth, rounded surface that may only require minor finishing. | Air Pockets and Structural Integrity:Parts can have small air pockets (porosity) which can impact surface finish. |

| Complex Parts Design:allows for the creation and manufacture of intricate shapes, complex shapes, and complex details. | Die Casting is Limited to Parts with Thinner WallsAlthough capable of producing parts with complex shapes, it is not generally suitable for parts that have very thick walls. |

| Automated Process:Can reduce labor costs, increase consistency and repeatability and can be highly automated. | Thermal Fatigue on Dies:The repeated heating and cooling can cause thermal fatigue. This could reduce the life of the dies. |

| Minimal Waste:Effective use of materials, with the possibility to recycle excess or scrap material. | Size Restrictions:Is best suited to smaller and medium-sized components. Larger parts are more difficult to manufacture, as well as more expensive. |

3.Investment Casting

Investment casting, also known as lost wax casting, uses a disposable wax pattern coated with ceramic material that solidifies into the shape of the casting. The first step in this casting process is to create a wax pattern, usually made of wax or plastic. Because the process requires precise measurements, multiple trials and errors make investment casting an expensive manufacturing process. The wax is poured into the mold, carefully removed, and then coated with adhesive or refractory material to form a thick shell. Additionally, multiple models are assembled onto the main gate. Once the shell has hardened, the model is turned over and heated in the oven to remove the wax. The molten metal is poured into the remaining shell and solidifies into the shape of the wax mold. Additionally, the refractory shell is broken off to reveal the finished casting. This casting process is commonly used to make power generation, automotive and aerospace components.

Pros and Cons of Investment Casting:

| Pros | Cons |

| High Precision and Accuracy:Producing parts with excellent surface finish quality and dimensional accuracy, reduces the need for secondary machining operations | Higher Cost: Due to materials and labor costs involved in creating wax patterns and ceramic molds, investment casting costs more than other casting types. |

| Complex Geometry: Enables creation of parts with intricate details and complex geometries which may otherwise be challenging or impossible using other casting methods. | Longer Lead Time: As this process involves multiple steps, its lead time may extend more significantly compared to other casting processes. |

| Versatile Material Options: Ideal for producing various metals and high-performance alloys, such as stainless steel casting, other steel casting, and nickel based alloy casting. | Size Limitations: This technique tends to work best with smaller parts; larger components can prove challenging and costly when made using this method. |

| Smooth Surface Finish: Smooth finishes require minimal surface finishing, saving both time and costs in post-processing. | Wax Pattern Creation: Each casting requires its own wax pattern which adds time and cost. |

| Reduced Material Waste: Due to its precision, this process ensures minimal material wastage, making it more eco-friendly. | Limited Capacity: More suitable for small to medium production runs. |

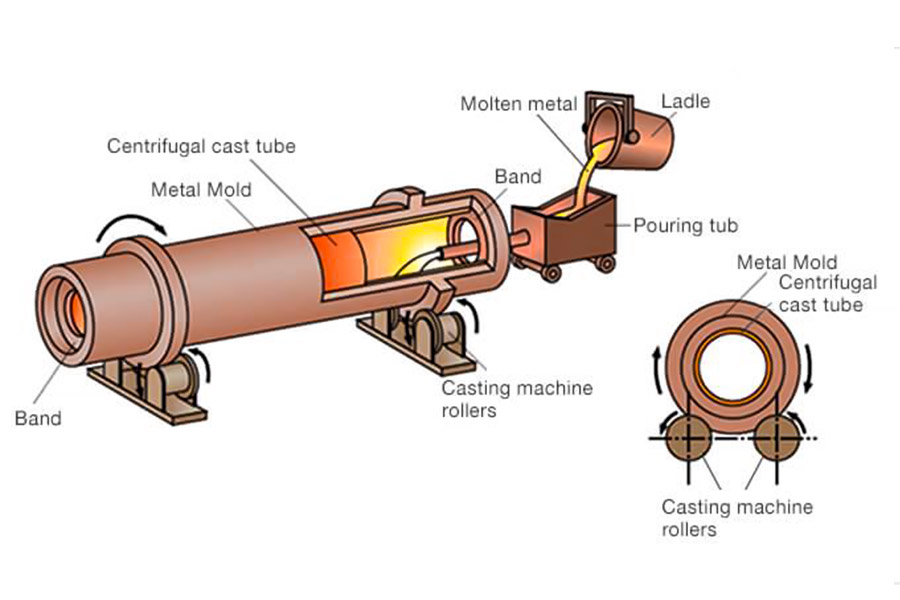

4.Centrifugal Casting

Centrifugal casting, also known as spin casting, is a process that uses centrifugal force to manufacture cylindrical parts industrially. This type of metal casting uses a preheated rotating mold into which molten metal is poured. Centrifugal force helps disperse the molten metal within the mold at high pressure.

There are three types of centrifugal casting: true centrifugal casting process, semi-centrifugal casting process and vertical centrifugal casting process. Semi-centrifugal casting differs from true centrifugal casting in that it uses a gate to completely fill the mold. However, in true centrifugal casting, the molten metal sticks to the sides due to the continuous rotation. In contrast, vertical centrifugal casting, as the name suggests, uses directional molding, following the same process as true centrifugal casting.

Typically, centrifugal casting produces a rotating shape that resembles a cylinder. Especially parts such as bearings, clutch plates, piston rings and cylinder liners. Additionally, pouring metal in the center of the mold helps reduce defects such as porosity, shrinkage, and air pockets. However, it does not work with all types of metal alloys.

Pros & Cons of Centrifugal Casting:

| Pros | Cons |

|---|---|

| High Material Pureness:Centrifugal forces drive impurities towards the inner surface of castings, resulting in higher-purity castings that have fewer defects. | Shape Complexity Limited:Best for cylindrical shapes. Comparatively, complex geometries can be difficult to achieve with other casting methods. |

| Good Mechanical Properties:High-density cast parts have superior mechanical properties. | Size Limitations:More efficient for small and medium-sized parts. Large castings are more difficult and costlier. |

| Reduced Secondary operations:Requires less machining and finishing than other methods because the surface finish and dimension accuracy are generally good. | Equipment Cost:Need for centrifugal cast machinery that is specialized can result in higher initial investment costs. |

| Material-efficient Use:This method is material-efficient because it allows precise control of the thickness of the casting. | Operational Skills Required:This requires skilled operators to control speed and temperature precisely, which adds operational complexity. |

| Material Versatility:Can work with a variety of metals and alloys. This allows for greater material flexibility. | Safety Concerns:High-speed rotating molds present safety risks and require stringent safety equipment. |

5.Continuous Casting

Continuous casting is an advanced casting method. Its principle is to continuously pour molten metal into a special metal mold called a crystallizer. The solidified (crusted) castings are continuously poured from the other end of the crystallizer. out, and then pull it out from one end to obtain a casting of any length or a specific length.

6.Lost Foam Casting

Lost foam casting is similar to investment casting, except that it uses foam instead of wax as the model. Once the model is formed, it is coated with refractory ceramic by dipping, coating, spraying or brushing. The molten metal is then poured into molds to form the desired product.

How to choose the appropriate casting process?

Choosing the ideal casting process depends on many factors, including the casting material, the size and complexity of the cast parts, the accuracy required, the quantities required, and cost considerations.

| Factor | Description |

| Material | Different casting processes are best suited for different materials. For example, die casting is typically used to process low melting point metals such as aluminum and zinc, while sand casting offers a versatile casting process suitable for casting iron and steel alloys. |

| Size and Complexity | For large parts with relatively straightforward shapes, sand casting might be the right solution due to its scaleability and versatility. But for intricate forms with intricate details such as investment casting or die casting may provide better solutions. |

| Precision and Quality | For those in search of high precision and quality casting processes, investment casting offers superior surface finish quality as well as accurate dimensions. Die casting also delivers good dimensional accuracy with smooth surfaces finishes. |

| Production Volume | If your part production requirements require large-volume parts, die casting is often the most economical choice due to its rapid production cycle. For lower to medium volumes, other methods like sand or investment casting might prove more cost effective. |

| Tooling Costs and Lead Times | Die casting has higher tooling costs and longer lead times, yet lower per-unit costs for large volumes. Sand casting offers lower tooling costs with greater design flexibility. |

| Mechanical Properties | Take into consideration the mechanical properties needed in the final part. Certain casting processes can increase strength, ductility or other desired qualities in castings. |

| Economic Considerations | Budget also needs to be considered. While the higher upfront cost of molds and setup is justified for high-volume production, for smaller batches or prototypes, a cheaper process like sand casting may be more appropriate. |

What Materials and Molds Are Used in Metal Casting?

It all depends on the type of casting you're doing, but these are the most common materials you'll use when using these casting methods:

- Metals: Certain casting methods can be adapted to the metal you want to melt, such as iron, aluminum, copper, and zinc.

- Alloys: A variety of alloys, such as bronze and brass, can be melted and cast whether using sand casting or metal molds.

- Ceramics: These materials are commonly used in pottery applications and include clay or porcelain.

- Plastics: These bendable materials can also be shaped by casting.

- Composites: Resin and fiber blends and other composite materials are another suitable option that you can use in your casting process.

- Rubber: For parts that are elastic and flexible, rubber can be used in casting.

- Glass: If you need art or thin-walled items, glass can be incorporated into certain casting processes.

- Concrete: This is a common choice when manufacturing building products and decorative castings.

What Equipment is Required for Metal Casting?

Metal casting is a complex and delicate processthat requires a variety of equipment to work together to ensure the quality and efficiency of the casting.

Melting Furnace

The smelting furnace is a key equipment in the metal casting process. It is responsible for heating the metal raw materials to a molten state for subsequent pouring and shaping. The performance of the melting furnace directly affects the melting efficiency of the metal, the uniformity of the composition and the quality of the casting. Common smelting equipment include:

- Dome:Used for melting metals, especially cast iron etc.

- Electric arc furnace:uses the high temperature of the arc to melt metal.

- Induction furnace:heats and melts metal through the principle of electromagnetic induction.

- Resistance Furnace:Uses the heat generated by the passage of electric current through a resistor to melt metal.

- Reverberatory Furnace:Heats and melts metal by reflecting heat.

Pouring and Cooling Equipment

The pouring equipment is responsible for pouring the molten metal into the mold, while the cooling equipment is responsible for accelerating the cooling and solidification process of the casting.

Pouring equipment:including pouring bags, pouring pipes, etc. The pouring bag is used to contain the molten metal and control the pouring speed and flow rate; the pouring pipe is responsible for introducing the molten metal from the pouring bag into the mold.

Cooling equipment:including cooling fans, cooling water systems, etc. They accelerate the cooling process of castings by reducing the temperature around the casting mold, thereby improving the production efficiency and quality of castings.

Finishing and Cleaning Tools

Finishing and cleaning tools are indispensable post-processing equipment in the metal casting process. They are used to improve the surface quality and dimensional accuracy of castings.

- Deburring tools:such as burr grinder, magnetic polisher, etc. These devices remove burrs and impurities from the surface of castings through physical or chemical methods to improve the surface finish of castings.

- Polishing equipment:such as abrasive belt polishing machine, surface polishing machine, etc. They polish the surface of the casting by rotation or friction to achieve the required surface quality and gloss.

- Other cleaning tools:such as cleaning agents, sandblasting machines, etc. These tools are used to remove oil, oxides and other impurities on the surface of castings to ensure the cleanliness and quality of castings.

FAQs

1.What is metal casting used for in manufacturing?

Metal casting is an indispensable and important link in the development of the equipment manufacturing industry. It is a commonly used manufacturing method with low manufacturing cost and high process flexibility. It can obtain complex shapes and large-scale castings, and it occupies a large proportion in machinery manufacturing. It is widely used in high-end manufacturing fields such as machine tools, automobiles, instrumentation, engineering machinery, shipbuilding, and aerospace.

2.What are the basic principles of metal casting?

Metal casting is a process in which molten metal or alloy is poured into a pre-made mold and then cooled and solidified to obtain the desired shape. The basic principle is to heat the metal or alloy to the melting point, then pour it into the mold, and then take it out after cooling and solidification to obtain the desired product.

3.How do I choose the right metal for casting?

When choosing a cast metal, you need to consider the physical properties of the cast metal (such as density, thermal expansion coefficient, thermal conductivity, etc.), mechanical properties (such as strength, toughness, hardness, etc.), corrosion resistance (different metals will There are different corrosion resistance performance), processing performance (such as cutting performance, casting performance, weldability, etc.), use environment (such as temperature, pressure, vibration, etc., different environments have different requirements for metal performance), etc.

4.What equipment is needed for a beginner in metal casting?

Beginners to metal casting need a series of equipment to support the casting process, mainly including a smelting furnace for melting metal raw materials into a liquid state for subsequent pouring operations. The sand mold machine is a special equipment for making sand molds. The sand mold is the mold used to fix the molten metal during the casting process. The main function of the sand molding machine is to compact the sand grains into a sand mold of the required shape to ensure that the molten metal forms the required casting shape during the cooling process. Pouring equipment is used to pour molten metal into sand molds, including pouring bags, pouring pipes, sprue cups, etc. The selection of pouring equipment needs to take into account factors such as the fluidity of the molten metal, pouring temperature and pouring speed to ensure that the molten metal can flow into the sand mold smoothly and evenly to form a complete casting. In addition, some auxiliary equipment is also needed, such as cleaning equipment, measuring equipment, etc. Although these equipment are not directly involved in the casting process, they are equally important in ensuring the quality of castings and improving casting efficiency.

Summary

Metal casting, in short, is a process in which molten metal is injected into a pre-designed mold (cavity). After the metal cools and solidifies, the mold is removed to obtain a metal product of the desired shape and size. This process involves three main stages: melting, shaping and solidification of metal materials. It is a key technology to achieve the transformation of metal from liquid to solid and give it specific shape and function. As one of the basic processes of manufacturing, metal casting not only carries the memory of history, but is also an indispensable part of modern industry. With its unique molding capabilities and wide range of applications, it continues to promote social and economic development and create a more colorful material world for mankind.

Disclaimer

The content on this page is for reference only.Longshengdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

Longsheng Team

This article was written by multiple Longsheng contributors. Longsheng is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.