CNC machining services can confuse engineers and procurement managers greatly, because comparison quotes for various suppliers may vary several times. Normally, only a 3D model is provided with unspecified process parameters, and thus unreliable, unmatching, and even wrong process choices can be encountered.

This is because of the lack of understanding of various CNC processes. Turning, 3-axis milling, 5-axis milling and mill-turning are some processes widely differing in respect of machine cost, complexity of programming, efficiency of processing, and cost of pricing. These are direct factors in respect of pricing. An unclear question does not trigger a particular response from the supplier.

CNC Machining Services Quick-Reference Guide

| Aspect | Key Points |

| Primary Processes | Turning: Rotating part, fixed tool; 3-Axis Milling: There are three linear axes that are quite versatile and are considered to be the most popular and less expensive in case of simple milling operations; 5-Axis Milling: Complex surfaces in one setup, minimized Fixturing; Mill-turning: Lathe & milling in one operation; complex rotary components in one operation. |

| Major Cost Drivers | Equipment: 5-axis/complex > basic 3-axis/turning; Setup & Programming: Complexity increases time/cost; Cycle Time: Longer runs = higher machine time; Material: Type, grade, raw stock size/cost; Quantity & Post-Processing: Volumes affect unit price; finishing (e.g., anodizing) adds cost. |

| Quotation Essentials | Provide clear: Part Drawings (with tolerances/GD&T), 3D Model (STEP, IGES), Material Spec, Quantity, Surface Finish/Special Treatment Requirements, and Application Context. |

| Process Selection Guide | UseTurning: For rotation symmetry parts (Bushings, Flanges); Use 3-Axis:_ For prismatic parts, pockets, holes; Use 5-Axis: For complicated sculpted surfaces. impellers, molds; Use Mill-Turn: When there are milling operations to perform in combination with turning operations. |

To obtain accurate and comparable quotes for CNC machining, clearly define your part's geometry, critical tolerances, material, and quantity. Understand that the choice of process—turning, 3-axis, 5-axis, or mill-turning—is the primary driver of cost. Providing comprehensive technical information enables suppliers like LS Manufacturing to recommend the most efficient and cost-effective production method.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

In CNC machining services, experience is what trust is based on. Members of our team have experience in dealing with problematic situations in various types of companies in this industry. It may range from the aerospace product category, in which case precision is always required, or from high-performance automobiles. In the CNC machining services that we offer, what has been done is always tested in the laboratory, and not in theories. These are all measured in accordance with International Aerospace Quality Group (IAQG) requirements.

Until now, every single piece of advice that you will see below has resulted from actual experience that we gathered from dealing with thousands of precision CNC machined parts over the years. What we have learned from our experience in our early years as a new company is from doing and learning from previous mistakes. In the course of optimizing an optimized milling path for a titanium material or in checking out the strength of a key thread in a particular product that needed key thread production, what has worked for us is experience.

In the course of going through rigorous steps in making sure that every single piece of advice that will be provided for you in this guide is precise, as required by the requirements of the National Institute of Standards and Technology (NIST) to ensure that every single piece of advice provided by all of us has been precise for our purposes in delivering CNC machining services.

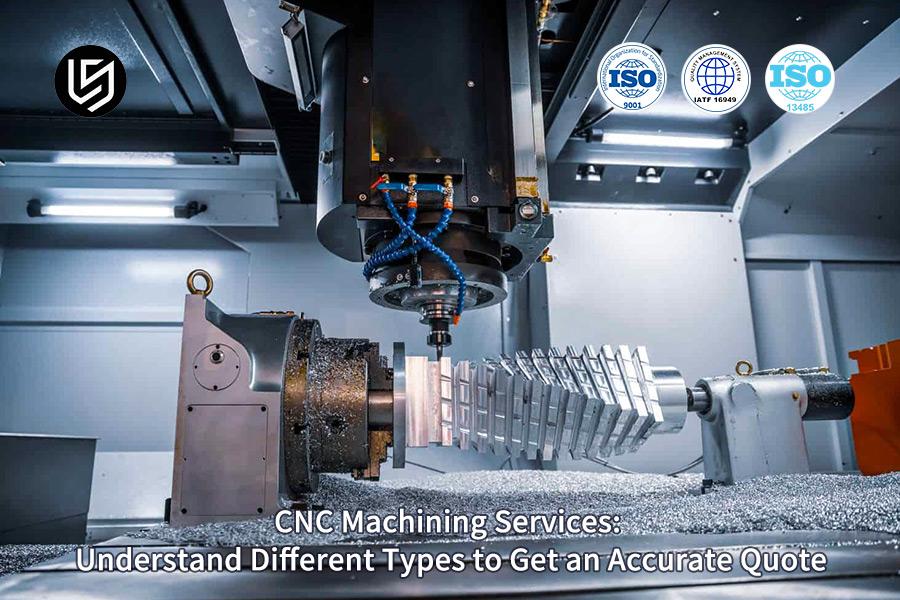

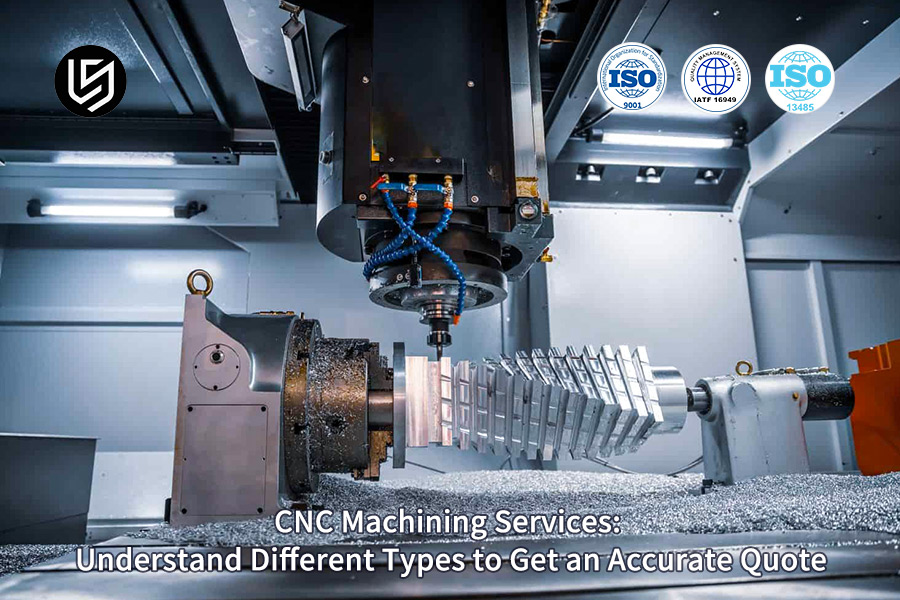

Figure 1: The process of precision CNC machining and quality inspection by LS Manufacturing

Why Is Understanding The Type Of CNC Machining The First Step To Getting An Accurate Quote?

Where accuracy of quote is concerned, it requires an accurate specification. Most engineers would focus on the 3D spec solely, and without taking into account the CNC machining types in the spec, it automatically affects the cost. The equipment, programming effort, and cycle time for turning a shaft versus 5-axis milling a complex housing are fundamentally different, impacting the final price substantially. Therefore, clarifying the process is essential to establish an accurate pricing basis.

- Core driver intrinsic process cost variation: The cost for each CNC machining types will vary. The 3-axis processing for milling will very rarely cost less. In turn, with more complex parts, 5-axis processing or mill-turn processing, which will be more expensive per hour, is likely to require much less setup and secondary processing and ultimately be less costly, and this is what should be realized during the calculation for estimating the cost.

- The Path to Clarity: Defining Your Production Intent: Instead of hoping that the supplier will receive your product model and understand what you are looking for, you can define your production requirements, specification requirements, and material requirements. For instance, we require CNC machining for production of custom parts, material titanium, for the production unit 50, and also for Specifications of ±0,05mm, will enable the suppliers to understand what you are actually trying to convey. This is where the role of the LS Manufacturing process consulting becomes extremely valuable.

- The Supplier's Role: The Translation of Requirements for a Feasible Process: The Supplier’s Role. It is important that a good supplier not only provide a price but also provide consultation. Based on your drawings and your goal, they need to identify for you in your piece what are likely the most efficient ways of CNC machining types: perhaps turning, 3-axis, or perhaps even more advanced. It is through your joint analysis that it will be determined that your method of choice is one that optimizes performance, time, and cost.

- The Tangible Outcome: Comparable and Actionable Quotes: Now you are on equal ground. Now you can compare the quotes mentioned above, which come from an equal 'ground' level. Now you are not trying to compare apples with oranges just by looking at the total cost of quotes. Now you are trying to compare the efficiency, viability, as well as processes of adding value in implementing the LS Manufacturing process consulting, tasks, et cetera, relative to your suppliers.

Awareness regarding the CNC machining types will not be needed for one to machinate, as this will be no more than the task of delivering the available information. On this matter, there is no doubt that it will help formulate the criterion based on the requirements of the manufacturing sector, as well as ensure the accurate pricing basis from the LS Manufacturing. This will definitely not have an iota of a doubt, as long as they require a quote regarding the CNC machining for custom parts.

CNC Turning VS CNC Milling: What Are The Core Differences And Cost Variations?

With regards to the budget consideration in such CNC machining systems, there are factors that constitute the point of differences between CNC turning and milling systems. Although both machining systems are associated with subtraction in machining, there are mechanical, shape, and cost variations in both machining systems. These factors introduce different considerations in selecting appropriate machining systems according to the initial process thus resulting in feasibilities and cost differences in both machining systems.

| Aspect | CNC Turning | CNC Milling |

| Principle | Rotation of workpiece, cutting tool stationery. | Workpiece stationery, rotation of cutting tool. |

| Best For Actually | Works well axis-symmetric components such as shafts, bushings, and flanges. | Prismatic parts with complex shapes and holes. |

| Typical Precision | High concentricity and diametrical accuracy. | High precision in complex dimensions and surfaces. |

| Efficiency | High efficiency in machines of an equal size; large material removal rates. | Variable; 3-axis machining of parts made of composites is slower compared to 5-axis CNC machining. |

| Cost Driver | Relative cost driver for appropriate geometry. | Relative cost for programming and setup based on dimensional complexity. |

Ultimately, how to choose the machining type hinges on part geometry: use turning for rotational symmetry and milling for complex, multi-faceted shapes. It is turning for rotational symmetry and milling for a complex part that has many sides. Even if there is a cheaper application of the former in the case of turning, it is flexibility that adds to the programming complexities of milling. It is a good understanding of the differences between CNC turning and milling that leads to differences in machining costs.

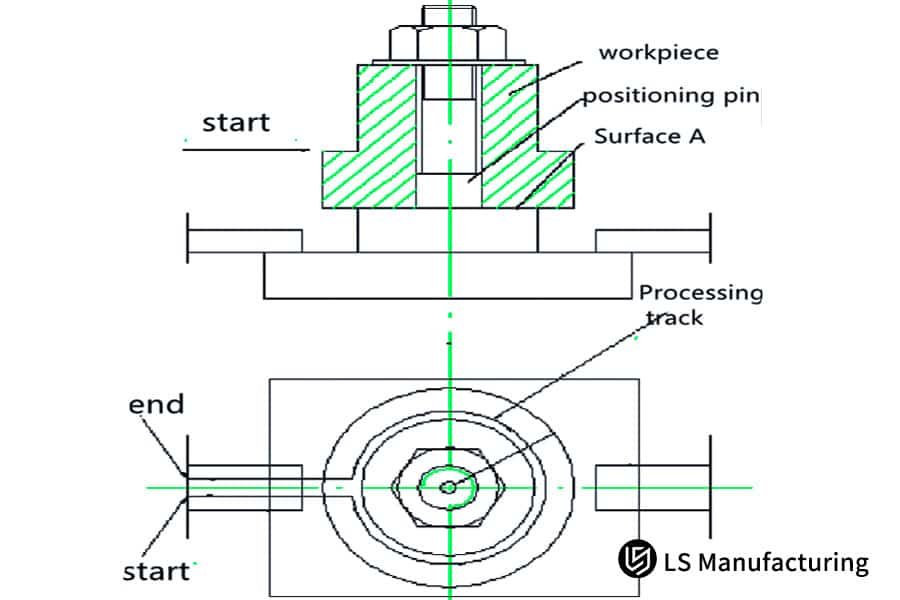

Figure 2: Diagram illustrating workpiece positioning and tool path for CNC machining by LS Manufacturing

3-Axis, 5-Axis And Mill-Turn Machining: How To Choose Based On Part Complexity?

Process selection is an important criterion for determining the functionality, accuracy, and cost of machining. With the rising complexities of parts, sometimes the need for conventional 3-axis machining has been observed to be inadequate. It is the knowledge of the limitations and advantages of 5-axis and turning composite machining, which brings forth significant insights for choosing the most suitable method for converting a complex design into an effective complex part machining solutions.

| Aspect | 3-Axis Milling | 5-Axis Milling | Mill-Turn (Turning Composite) |

| Ideal Complexity | Prismatic parts and 2.5D surfaces, holes, and pockets. | Complex surfaces and deep cavities and undercuts. | Parts with complex rotary. |

| Key Advantage | Widely available, inexpensive machines, and programming. | Complex geometry in one machine setup, good surface finish. | Entire job can be performed in single machine setup, good concentricity. |

| Principal Cost Driver | Per hour cost is reduced; multiple set-ups and/or fixtures may be required. | High machine cost; complex programming required. | High cost machine/integration. |

| Core Value | Cost effective in simpler geometries. | Removes fixtures/errors, enables unreachable geometries. | Accuracies unattained elsewhere. |

Finally, it will rely on geometric complexities along with accuracy requirements. Taking up moderately complex 'block' shaped parts, 3-axis machining machining would remain an economical process. But when it comes to complex parts, the advantage of single-setup machining on the 5-axis and turning composite machining would find that the expense associated with the equipment to be justified in order to avoid mistakes. The most advanced version of compound high-precision multi-axis machining of rotary parts would be decisive for complex part machining solutions on the special mill turn machine.

What Are The Five key Factors That Influence The Pricing Of CNC Machining Services?

Indeed, there is actually a need to cost breakdown in detail in being able to interpret a quotation properly. Thus, in this respect, the total cost of the custom parts, as a result, is not just given by one factor, but by many, as shall be clarified in the following points in being able to perform a price analysis of custom parts in relation to CNC machining:

Part Design Complexity

This is the first main factor. If the design involves simple shapes and typical design features, then the part can easily be programmed and machined. However, complex shapes, deep cavities, thin walls, or complex details involve highly sophisticated techniques that are longer to program, high-cost tools, and even higher-cost CNC machines sometimes, in CNC machining process comparison. Sometimes, even DFM analysis can simplify the complexities in the part without compromising on its design.

Material Selection

It contributes to the cost in two significant manners, through the cost of material and through machinability. In general, the selection of aluminum alloys is generally relatively inexpensive with regard to cost and easily machinable, hence the tendency to keep costs lower. Other materials, such as titanium alloys, stainless steel, or special plastics, are more expensive on a per-pound basis, and in addition, machines at slower speeds, thereby directly contributing to the price analysis of custom parts.

Tolerances and Finishes

The use of standard tolerances is ideal. However, when very tight tolerances - for instance ±0.025mm - or high polish - for example, Ra value of 0.4μm, the cost starts to increase exponentially. This involves the requirement for lower speeds during machining, special machining techniques, keen inspection, and a high risk of parts being scrap. Critical tolerances should be considered only where necessary.

Post-processing and Secondary Operations

The initial quote of machining can have a "as-machined" piece. Any further requirement, whether it be anodizing, plating, heat treating, or painting, will be an additive process with extra processes, labor involved, and time consumed. Each requirement has its own cost breakdown and needs consideration with respect to the overall project analysis.

Production Volume and Quantity

Order quantity dramatically affects the unit price through the amortization of fixed costs. For prototypes or low volumes, the cost is dominated by one-time setup, programming, and first-article inspection. For higher volumes, these fixed costs are spread across many units, making the per-part cost drop significantly, which is a key consideration in the overall factors influencing CNC machining pricing.

To sum up, an honest quote relies on an understanding of these interrelated factors influencing CNC machining pricing. In order for an price analysis of custom parts, one must take into account not only the cost per unit but also the cost detail involved in it-from designing, materials, to tolerances. Simply put, a productive CNC machining process comparison in the initial steps of an inquiry secures a competent mixture of these considerations.

Figure 3: A decision framework for CNC machining and supplier sourcing by LS Manufacturing

Optical Equipment Industry: Precision Machining Of Aluminum Alloy Lens Barrels Using Multiple Processes

A LS Manufacturing success case illustratively underlines the importance of expertise in process strategy. We worked recently with an optical equipment maker on a common and very important problem: to make an aluminum bracket of high precision, exemplifying the need for optical equipment component machining equipment components.

Client Challenge

The client had asked for a complicatedly designed aluminum lens barrel bracket with several mounting points, while the flatness criterion was to be precisely met. The first inquiries had provided foggy pricing starting from hundreds up to well over one thousand dollars, with diverse lead times, too. Pricing that is not associated with any process plan was difficult to evaluate against the project requirement, which further showed the various problems linked with vague requests for optical equipment component machining.

LS Manufacturing Solution

Our engineering staff reviewed this part and proposed the adoption of the integrated multi-process combination machining solutions approach. The suggestion here was that a mill turn machine should provide machining for the precise cylindrical datum and end face of the part. Additionally, it was suggested that the irregular holes and threads should be machined in one setup to avoid errors caused by multiple fixturing.

Results and Value

Although the hourly cost of the mill turn was higher, the efficiency factor prevailed. The integrated multi-process combination machining solutions reduced the handling and setup times greatly. Overall production cost reduced by 25%, lead time by 40%, and the critical 0.02mm flatness tolerance was ensured, which was of highest value for the optical equipment component CNC machining process due to its sensitive nature.

This LS Manufacturing success case just goes to demonstrate that this collaboration in the project, even before manufacturing, is what will make achieving such a goal critical. This is in the sense that by going from a quote request to a multi-process combination CNC machining solutions devised collaboratively, uncertainty regarding cost and delivery is converted into a predictable and highly performing result that provides exactly what the customer needs: precision, delivery times, and cost.

Looking for high-accuracy CNC machining? Contact us today to get a quote and process improvement plan tailored to your needs.

How To Effectively Control CNC Machining Costs Through Design Optimization (DFM)?

Proactive design optimization is a powerful but often underestimated tool for managing costs. Well-applied design for manufacturability addresses a big source of any CNC machining cost comparison directly before actual manufacturing, in such a way that a product is not only functional but also cost-effective. The goal of DFM optimizes and controls costs from the earliest stage.

Simplify Geometry and Standardize Features

Contours in 3D come complicated with deep pockets, sharp internal radii, and custom radius transitions. Special tooling and machining time are required, thus making special machining necessarily blind. Design optimization to machine parts using standardized endmill diameters, and minimizing the curves while maximizing straight sides, and minimizing total parts in a setup, has potential for dramatic cost reductions in programming and machining time in defining the CNC machining cost comparison.

Rationalize Tolerances and Surface Finishes

The use of highly precise values related to rationalization of justifications & surface finishes, while necessary, raises the price of the product significantly instead. Therefore, there is almost an exponential rise regarding machining, inspect, & scrap times. Thus, optimal rationalization about justifications & surface finishes of non-critical factors, a prime tenet of DFM optimizes and controls costs.

Design for Efficient Machining Access

As it may become difficult for the cutting tool so that it can machine the hole to be machined, like deep hole machining and small hole machining and inside machined areas which become difficult to machine. This automatically affects it with lower speeds and longer and finer tools and also with fixtures. The difficulties can be overcome by standard tool access design. Design for manufacturability recommendations is regularly provided to optimize part orientation and positioning by our team.

Leverage Expert Analysis Early

It also helps that changes that can save costs can and should be made early in the design phase. A review by an expert in manufacturing will also point to costly design features that the designer has not noticed. Precisely because it is that we can give free DFM analysis services, this would give an extensive report about any problems and recommendations that can be made to improve manufacturability and costs before any quoting takes place.

Ultimately, DFM optimizes and controls costs management through the correct positioning of the feasibility of production. This would realize immense cost savings in the simplification of geometry in reducing complexities as well as designing for accessing tools. It is recommended that our free DFM analysis services be taken advantage of so that a favorable CNC machining cost comparison be guaranteed.

How To Choose A CNC Machining Supplier That Can Provide Transparent And Reasonable Quotes?

A transparent pricing agreement is also a reflection of a high level of professionalism and credibility of the supplier. When it comes to a supply base with a high level of complexity, such as CNC machining supplier selection, it may well be that the quality of the quote is a better reflection of credibility than the pricing itself. A detailed and logical CNC machining services quote may be the key to a credible supplier.

Evaluate active communication and technical curiosity

A good supplier should not only accept your file and then offer a quote. A good supplier will have many questions related to your application, key tolerancing, your material of choice, and your post-processing requests. A supplier who acts in an active manner demonstrates they are concerned enough about your project to ask questions in order to show their understanding-that is the beginning of offering good prices.

Request for a Detailed and Itemized Cost Breakdown

Only when you see the transparency of the cost breakdown can you enjoy the benefits of transparent pricing. A good supplier will give you a quote with an itemized list of the major cost of the pieces, including the cost of the raw materials, the programming of the machines, the cost of the time element of the work involved in the CNC machining service. You may be assured that you will get the best price from the supplier.

Assess Their Value-Added Engineering Support

The best partners aim to be a solution provider, not just an order taker. Look for a supplier that offers constructive DFM feedback and process optimization suggestions without being asked. Their willingness to invest engineering time to improve your design for manufacturability and cost-efficiency is a strong sign they are focused on delivering long-term value and LS Manufacturing reasonable quotes.

Verify Quality Systems and Process Guarantees

Transparent pricing must be accompanied by transparencies in quality assurance levels when it comes to pricing services transparence. Indeed, it is but fitting that you would want to inquire regarding the quality control processes that they applied in relation to your industry scale concerning the kind of inspection device that they own pertaining to your industry scale before considering them to be potential CNC machining supplier selection.

In summary, the process of CNC machining supplier selection should focus on partnership potential. The ideal partner proactively communicates, provides a transparent pricing breakdown, offers expert DFM advice, and has robust quality systems. At LS Manufacturing, we believe this approach naturally leads to LS Manufacturing reasonable quotes and successful outcomes. We encourage you to use these criteria to evaluate any CNC machining services quote, and we are confident in how our process measures up.

Figure 4: Designated CNC parts storage area with posted work instructions by LS Manufacturing

When Requesting A Quote From LS Manufacturing, What Information Should Be Provided To Obtain An Accurate Quote As Quickly As Possible?

- Submit Complete Technical Data Packages: To provide the most accurate quote, we require comprehensive technical files. Please include a 3D model (STEP or IGES preferred) for the overall geometry, accompanied by a detailed 2D drawing. The drawing should clearly specify all critical dimensions, geometric tolerances (GD&T), surface finish callouts, and any specific inspection notes. This complete package is the foundation for all our precision CNC machining services analysis.

- Material Specifications and Post-processing Requirements: Specifically list the type of material required - e.g., 6061-T6 aluminum or 316L stainless steel. But it is equally important to specifically list all of the specifications required for the secondary processing - e.g., anodizing type, plating, heat treat, and painting specifications. It is critical to specifically list all of the specifications up-front in order to be able to address all of the necessary steps required in an LS Manufacturing inquiry process.

- Define Target Quantities and Timeline Requirements: The volumes and timeline requirements for your project have important implications in project costings and project timeline requirements. Kindly provide your target volumes for procurement, whether it is for prototype, low volume, and/or production volumes for your projects. Also, please provide your project timeline requirements or deadline for projects so that we can effectively utilize our resources for providing you quick CNC machining quotes.

- Share Relevant Application Context (Optional but Helpful): The requirement to provide the relevant application context for the submission may be considered optional; however, the application of this requirement definitely counts as an improvement that should always be sought after. This includes understanding the type offunction the respective component will need to fulfill.

By providing a complete technical package, clear material and finish specs, and your volume and timeline goals, you enable our most efficient evaluation. This optimized LS Manufacturing inquiry process allows us to promptly analyze your project and deliver quick CNC machining quotes that are both accurate quotes and actionable, setting the stage for a successful partnership in precision CNC machining services.

FAQs

1. Are your prices competitive with those offered by other manufacturers?

The calculation of the prices will be done by transparent cost accounting. Optimization of our processes as well as advice regarding DFM will at all times ensure that we provide you with the best possible price, as well as the quality that you deserve. Feel free to send us your designs.

2. Is the quote complete as far as cost is concerned, and if it is, is there any hidden cost?

Everything that we have quoted will be considered in the report, from the goods to the final stage of the execution of the heat treatment and the surface treatment process. There will be nothing extra from our end regarding that. Should there be any, we will discuss it before that.

3. By how many dollars does prototyping and small-batch manufacturing cost more than large-batch manufacturing and/or mass manufacturing?

This would ensure that its cost for small batches would depend on programming, rather than the cost that would be incurred by a large batch producer. The best costs, which would be incurred for each size of the batch, have been identified by us.

4. What is the most economical aid to processing?

Of course. They will provide you the best processing solutions free of charge as per your drawings and specifications. This is standard.

5. What is the Minimum Order Quantity?

In particular, our services encompass the design of prototypes using components without having to meet the minimum ordering threshold of the MOQ.

6. Are there any modifications of my design that may affect either the cost or schedule of my project?

Yes. This has to be reassessed depending on the nature of the changes in the design and the cost involved. Nevertheless, your quote and the date for the delivery shall also be reassessed in light of your response regarding the changes in design.

7. What types of quality inspection reports are offered?

These may include documents such as the report concerning the First Article Inspection, the report concerning the Full Dimension Inspection, and so on. The list of documents required may be required if the documents are required in response to something because it is known that the components comply.

8. What of those that receive but lack corresponding sizes?

Now, if in reality it truly is our responsibility, then an immediate copy will follow, and we will pay the fees in order for you to exercise your right.

Summary

A fair as well as accurate price quote in this case depends on your interpretation of the various needs & cost ratio as mentioned in the process above. It is evident that your task has been made easier through the help of this guide. Now you are free to pursue an accurate price quote as per the guide which has been presented before you.

All that you need to do is simply click on the “Get My Transparent Quote” so as to make it possible for you to upload your designs as well as the needs linked with the required part. A personnel of LS Manufacturing will deliver an accurate price quote within 24 hours.

Let's work together to optimize manufacturing. Click to get your personalized planning solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.