The following article systematically analyzes the principles and whole processes of CNC machining technology, covering how to accurately turn complex digital models into high-quality physical parts through "design for manufacturability analysis" and advanced 5-axis integrated machining technologies. We are going to begin now, from the basic definitions of the concept of CNC machining, so as to reveal its efficient and precise mode of operation.

CNC Machining Full Text Quick Reference Table

| Module | Core Theme | Content |

| Technical Fundamentals-Concepts and Basic | Benefits The method of instructive methodology in a digital way is explained | how the Computer Numerical Control-CNC directly controls the movement of machine tools, and how automation, precision, and reliability go further than conventional ones in machining. |

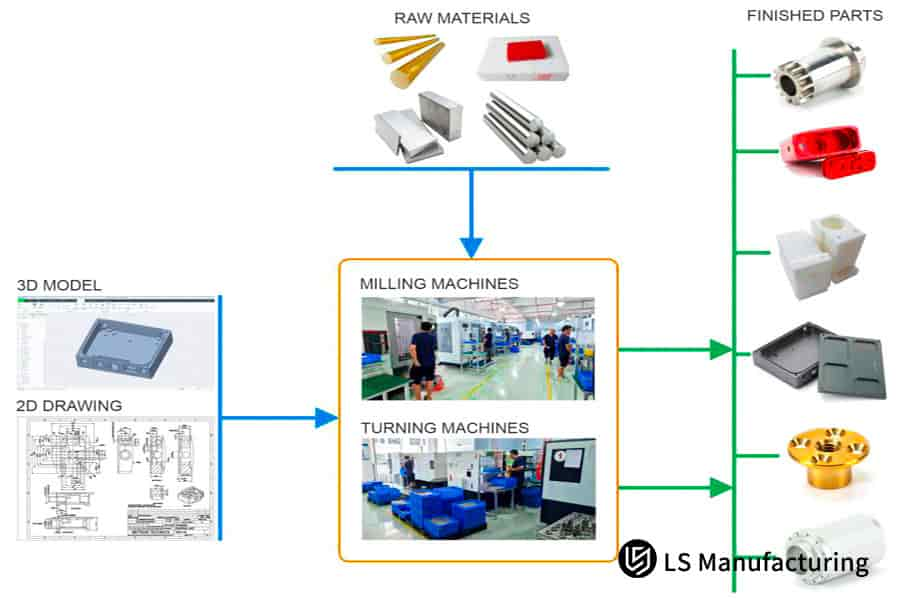

| Major steps to complete the work flow | Key Steps from Drawings to Parts | The standardized chain has been broken down, starting from 3D model designing and programming, then setting up, machining, post-processing, and quality inspection, through which one can see a birth of high-quality parts. |

| Key to Success | Pre-design collaboration | The focus is on how DFM (Design for Manufacturability) analysis can optimize part features in advance to significantly reduce manufacturing difficulty and cost while increasing success rate. |

| Advanced Processes | Revolutionary Solutions for Complex Parts |

The next section debates the analysis of how 5-axis simultaneous machining manages to process complex geometries with a number of facets in just one setup, reducing errors and saving costs while outperforming design limitations. |

| Selection and Service | How to Match High-Quality Partners |

The section below shall provide a critical rundown of assessing the technical capabilities, the list of equipment the machining providers have, their quality systems, and the lines of communication so that seamless project delivery is guaranteed. |

It systematically analyzes how modern CNC machining is transformed from a passive "drawing-based processing" service to the front-end collaborative partner in driving product success. The core value consists of guaranteeing the baseline production by process standardization, seeking leaps in quality and efficiency and freedom in design due to technological advancement: the very idea of "Design for Manufacturability" and 5-axis machining.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Actually, our workshop is a battlefield fighting against those tough-to-machine titanium alloys and high-temperature alloys for the manufacturing of parts in key fields: aerospace, , medical treatment, and automotive powertrains. Every single thread and each surface tolerance will relate directly to flight safety, patient health, or ultimate performance. What we share with you is practical experience distilled from the successful delivery of tens of thousands of complex parts.

Material properties and process parameters discussed in this guide are based on hard evidence; most of the content closely refers to and follows the authoritative industrial standard from Metal Powder Industry Federation (MPIF). Advanced standards and best practices in areas like Additive Manufacturing (AM) are extended to integrated advanced manufacturing technologies that have been drawn upon. To this extent, this guide ensures its recommendations not only come tested by oil and chips from our workshop but also withstand technical scrutiny.

What you are reading here, therefore, is anything but superficial theory. Every insight, from tap selection strategies down to clamping solutions for complex thin-walled parts, comes from costs paid and successes finally obtained. We have written down these experiences in such a form as to give you a sure map from the front lines when one faces precision manufacturing challenges-one that will get it right the first time.

What Is CNC Machining?

Workmanship by CNC machining is a method that uses computer numerical control technology for the precise guidance of machine tools and realization of workpiece automation. To the question "How does CNC Machining work?", the answer would lie in the fact that it takes a completely digital design and converts it into precisely the real physical part through a series of programmed commands. On a very basic level, "what is CNC machining?" It is automatic, accurate, repetitive manufacturing of parts by converting a digital blueprint into machine-driven motions that eliminate potential human error inherent in manual processes.

The emergence of this technology has fundamentally addressed the shortcomings of traditional manual machining, which struggled to ensure consistent accuracy, thereby making the machining process more standardized and precise. From three-dimensional complex part processing to precision mold processing, the excellence of the CNC machining will meet many industrial needs for high quality and high efficiency production.

Figure 1: Integration of automatic robotic arm in modern CNC turning by LS Manufacturing

How Do CNC Machining Work Step By Step?

Here's how it works:

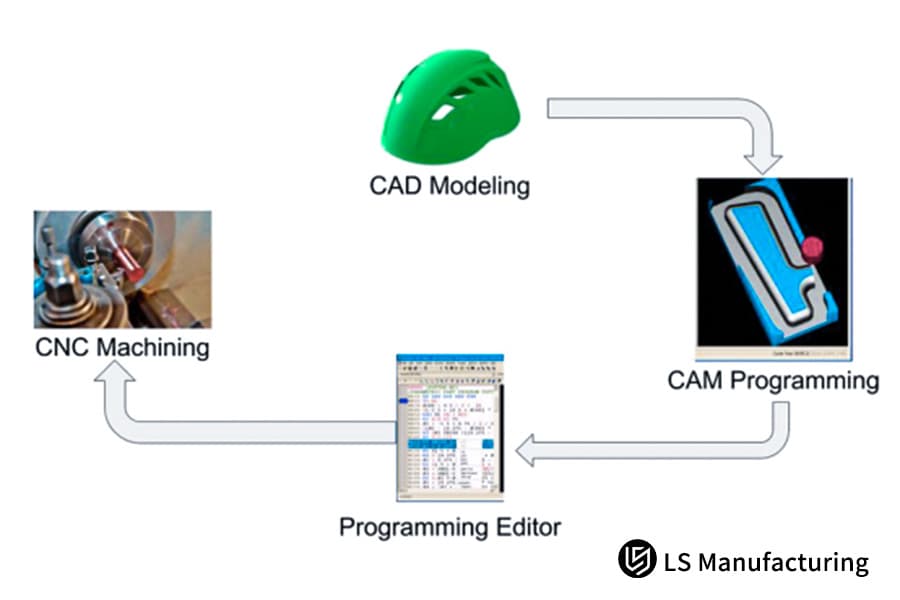

Step 1: Create a CAD drawing

The chain of CNC machining technology process starts with designing on paper, regarding the machined part. For our case, we are going to use precision machining CAD software that is meant for use in both 2D and 3D modeling. We are going to do a drawing in CAD to scale; this will avail information on inherent parameters such as thickness, depth, and other dimensions.

Step 2: Convert from CAD to CAM model

Generate CNC code using software from CAD models. As a matter of fact, it specifies the moving and cutting directives of the machine.

Step 3: CNC machine configuration

This includes setting up the given precision machine to carry out the programmed G-code and M-code. This includes preliminary checking of the input parameters for machining along with properly clamping the workpiece on the CNC machine.

Step 4: CNC machinist executes program

What Are The Types Of CNC Machining?

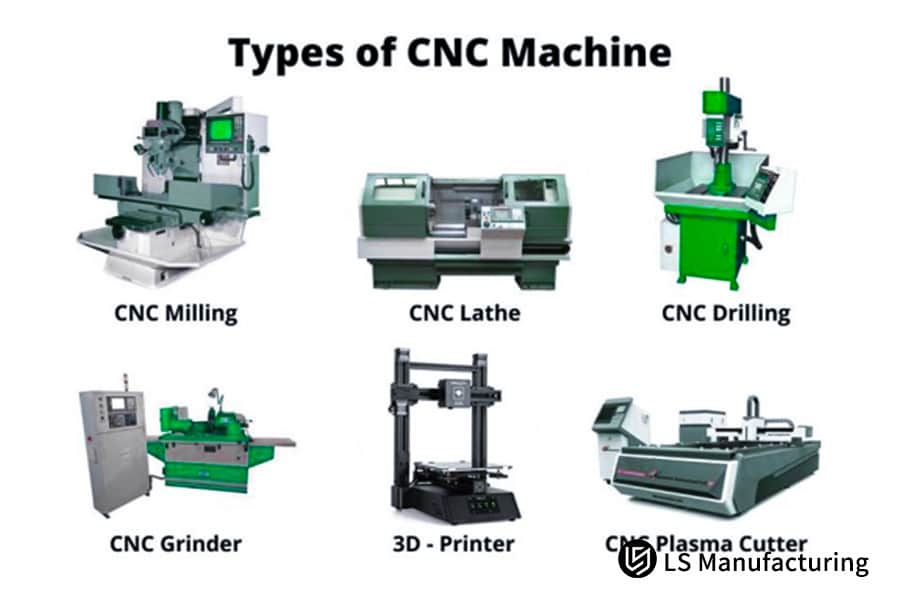

Grinding Machining

Grinding machining is widely used in machinery manufacturing, especially where high precision and high surface quality are required. It can process internal and external cylindrical surfaces, conical surfaces and flat surfaces of various workpieces, as well as special and complex forming surfaces such as threads, gears and splines. In addition, grinding can also process materials that are difficult to process with other machine tools, such as hardened steel, carbide, glass, ceramics, etc.

Lathe Machining

The basic principle of lathe machining is to use lathe equipment to remove excess material from the workpiece by rotating the workpiece and making it move relative to a fixed or moving cutting tool (such as a turning tool) to obtain the required shape, size and surface quality, parts or workpieces. Lathe machining can complete a variety of processing tasks, including but not limited to outer circle processing, inner circle processing (such as boring), end face processing, grooving, cutting off, forming surface processing, etc.

Milling Machining

Milling is the process of cutting material from a workpiece using a rotating tool to create the desired shape and size. The selection of cutting tools and the setting of processing parameters have a significant impact on the processing effect. Generally speaking, high-speed steel tools are suitable for milling most metallic materials, while carbide tools are suitable for harder materials. In addition, the settings of parameters such as cutting speed, feed amount and cutting depth also need to be reasonably selected based on specific materials and processing requirements.

Milling machining is suitable for workpieces of various materials and shapes, including flat surfaces, grooves, spiral surfaces, tooth surfaces, formed surfaces and outer circles, etc. In mass production, in addition to processing long and narrow planes,mill machiningcan almost replace planing and become a common method for processing planes, grooves and formed surfaces.

Figure 3: Key CNC equipment enabling high-precision manufacturing by LS Manufacturing

What Is The Principle Of CNC Machining?

The principle of CNC machining is to control and operate the movement of the machine tool through a computer control system to achieve precise processing of the workpiece. First, CAD (computer-aided design) software is used on the computer to mathematically describe and geometrically model the workpiece to generate a geometric model of the workpiece. In this step, mathematical expressions such as curves and surface equations are used to describe the shape and dimensions of the workpiece. Then, the designed model is converted into G code that can be recognized by the machine tool. The G code describes in detail the tool's movement trajectory, processing speed, tool selection and other information during the processing process.

How Does LS Manufacturing Help Medical Device Customers Overcome Technological Bottlenecks?

Client Challenge

The workpiece, which is a core structure made of titanium alloy, is a very important part for a leading developer of minimally invasive surgical robots. Not only was the structure of the workpiece very complicated-deep holes and thin walls-but the surface treatment also required very high biocompatibility, and the tolerances had to be strictly controlled within ±0.01mm. Previously, they were unable to reach those requirements with their current supplier, and the project would be delayed, thus directly affecting the product time-to-market.

LS Manufacturing Solution

Results and Value

We passed all acceptance criteria the first time, reduced the delivery cycle by 40%, and helped the client complete prototype verification ahead of schedule, accelerating product launch. Based on the success of this cooperation, LS Manufacturing has become the client's strategic partner in the field of precision structural component R&D and manufacturing.

LS Manufacturing intervenes from the design stage, mitigating risks through DFM analysis and advanced planning. We integrate 5-axis machining, online inspection, and compliant surface treatment to achieve stable, precision manufacturing that meets strict industry standards, serving as a technical extension to drive innovation with our clients.

Does your project have similar precision manufacturing challenges? Book a 15-minute free technical consultation with an LS Manufacturing expert to get an initial solution for your specific needs.

What Are The Advantages Of CNC Machining?

- Capabilities: CNC machining can produce a wide variety of parts, shapes, features and highly complex geometries. The technology allows manufacturers to create both self-contained end-use parts and fully functional assemblies, providing tremendous design freedom and flexibility. In addition, it can manufacture large and micro parts.

- Accuracy and Precision: As long as the CNC design is optimized, CNC machining can replicate the design with extremely high accuracy. CNC machines are highly precise and can produce parts with extremely tight tolerances. Most aspects of the CNC machining process are computer controlled, minimizing errors and ensuring consistency.

- Speed: CNC machining can deliver complex geometries quickly. This feature is especially beneficial for prototyping applications. CNC machining reduces turnaround time from design to finished product compared to traditional manufacturing methods that involve numerous time-consuming processes.

- Versatility and scalability: CNC machining is versatile, suitable for both one-off prototypes and medium-volume production. This technology enables the consistent production of multiple units of consistent quality. The range of processes and technologies within CNC machining means there is a suitable method for almost any application requirement.

- Material Compatibility: CNC machining is compatible with a variety of materials, including metal, glass, plastic, stone, and wood. If the material can be sourced in chunks, it is likely suitable for CNC machining. This compatibility is not limited to standard engineering materials, but also includes more specialized options, providing flexibility for a variety of industrial applications.

What Are The Disadvantages Of CNC Machining?

- High setup costs: Initial setup of CNC machining usually is associated with very high costs. Barely a few of the available CNC machines are cheap, while more advanced forms of industrial models come so expensive that they become useful only in large-scale industrial production.

-

High-volume production speed: This is extremely high in production speed, considering that they make a high volume within a very short time. Batch production will take much time since most of the CNC machines can make only one at a time.

-

Cost of complex geometries: With complication comes a cost directly related to a part. On the other side of the scale, complicated designs make the production highly expensive because operation hours required are long and high-range CNC machines get engaged in the process

-

Material waste: CNC machining is naturally a subtractive process; hence, material wastes emanate out, huge and big in amount. Comprehensive guide to CNC machining may include the factor of material waste. It can be defined as one of the processes whereby materials are sculpted into finished parts through some sort of subtractive process. Compared to additive and molding technologies, there usually is more material waste during such processes. Resource management and efficient design are very essential in the process.

-

Design Limitations: Other than the capability in CNC machining, there is bound to be some natural design limitation. Geometries not limited to curved holes, extremely thin walls, and straight interior edges can just not be effectively machined. Such limitations need to result in design adjustments and optimizations, which may often compromise the original design intent.

Figure 3: An overview of the fundamentals of CNC and automation by LS Manufacturing

What Are The Factors That Affect CNC Machining Costs?

|

Factor |

Description |

|

Material cost |

Different materials, including aluminum, steel, stainless steel, brass and plastic, titanium alloy cost largely differently. Each material has its cost and application. |

|

Equipment cost |

The equipment cost usually is that high-class machine tools possess more accuracy and efficiency, with multiple functions. The price is higher, too. To the processing cost should be added the regular expense of amortization and the maintenance of the equipment. |

|

Labor costs |

Experienced technicians may write more efficient programs and, therefore, make better use of machine tools because the errors and hence downtimes are reduced. |

|

Tool and fixture costs |

some tools need tailoring or special treatment; besides, wear and replacement of a tool can be more expensive. A fixture is to fix a workpiece to ensure its machining accuracy, designed and manufactured at a certain cost. |

|

Post-processing costs |

It continues to add up at every stage of post-processing, heat treatment, surface treatment, cleaning, and inspection. |

|

Logistics and transportation costs |

For the part itself, it is impossible to ignore large or heavyweight parts in terms of logistics and transportation cost. |

|

Energy and auxiliary material costs |

The energy and auxiliary material costs include a number of consumables such as electricity, coolant, lubricants, and many others which in the course of CNC machining must be comprehensively included in the overall CNC machining cost for an accurate and transparent pricing assessment. |

|

Management and administrative costs |

Including management and administrative expenses related to project management, quality control, equipment maintenance records, etc. |

Are your projects also facing challenges in terms of accuracy and delivery time? Contact our experts today for a free DFM analysis and a quick quote!

Choose LS Manufacturing To Provide You With One-Stop Service

Success is what rapid production entails, which is achieved by obtaining quality machining services. From initial roughing to finishing at the end, LS Manufacturing provides full-service CNC machining services.

Having manufactured for over 15 years, we can handle CNC parts in tolerances up to 0.005mm. Quotes are given on the same day, and delivery is within 72 hours. Quantities of parts we make are in excess of 80.00 pcs. To this end, we desire to provide high-quality, efficient metal parts processing services for our customers in prototyping and volume production. From raw material control to product inspection, we have always pursued excellence in quality and aimed at impeccable results for you.

At LS Manufacturing, we understand that each little detail in production is vital; thus, we work to ensure products not only meet but exceed your expectations in quality and aesthetic appeal. Any time you need a reliable and professional roughing service, consider LS Manufacturing-your trusted partner in efficiency and excellence in your machining process.

Figure 4: End-to-end flowchart of the CNC precision machining journey by LS Manufacturing

FAQs

1.What is the MOQ of CNC machining?

LS Manufacturing provides highly flexible services that support production, from a single prototype up to tens of thousands of pieces. We understand the needs of every customer in different stages and do not have minimum order quantities to worry about.

2. How do I make sure that my design drawings are safeguarded in addition to my IP?

We enter into strict confidentiality agreements through NDAs with all our clients. Our internal data management system, following ISO 27001 information security standards, ensures absolute security about your design and business information. That is our solemn commitment to all our clients, be it a startup or a Fortune 500 company.

3. Besides price, what are the core capabilities to focus on when selecting the supplier for CNC machining?

While price is important, comprehensive capability is what will guarantee project success. Pay more attention to: ① DFM analysis ability: Can they optimize designs and reduce costs? ② Quality control system: Is there ISO 9001 certification? CMM testing? ③ Project experience: Do they have successful case studies in your industry? As illustrated by our aerospace case study, expertise is worth much more than the minor differences in quoted prices.

4. What is the regular lead time of LS Manufacturing?

We offer a 3-day expedited prototyping service for parts of standard complexity. The mass production lead time depends on quantity, but by using concurrent engineering and lean manufacturing management, we usually reduce the lead time by more than 30% from the industry average.

5. What is the level of precision achievable through CNC machining?

The standard machining precision is up to ±0.005mm. We have 5-axis machine tools and advanced measuring equipment prepared for applications whose tolerance requirement is defined more rigidly, with precision up to ±0.002mm or higher.

6. What materials do you support? Can you provide material selection advice?

We process over 100 types of metal and engineering plastics. You can have a look at the detailed list in our [CNC Machining Materials Library]. Our engineers offer professional selection advice according to the application scenarios you require, including strength, temperature resistance, biocompatibility, and cost.

7. Do you support me in case I need something during the design phase?

Of course, Free DFM analysis is part of our service. When uploading your drawings for quotation, suggestions by our professional engineers will be proposed to optimize your design, annotate tolerances, select proper processes, etc., which can help you improve design quality from the source.

8. How to inquire and order? What is the procedure?

The whole process is very straightforward and smooth: ① Upload your CAD drawings online, such as in STEP and IGES format; ② Automatic/manual review, issuance of detailed quote including free DFM feedback; ③ Confirmation of quote, signature of contract and NDA; ④ Arrangements for production, online tracking of progress by customers; ⑤ Shipment after quality inspection. You can get your instant quote and DFM analysis here!

Still have questions? Or are you ready to start your project? Upload your 3D drawings now and get a personalized quote and DFM feedback within 3 hours!

Summary

With the core advantages of high precision, high efficiency, and high flexibility, CNC machining technology is playing a key role in the manufacturing innovation expected in 2025 CNC machining trends. Through close collaboration, the entire process—from blueprint design, process planning, and programming to machining and precision testing—ensures that high-quality, complex parts are produced efficiently. This makes CNC machining a driving force in the intelligent upgrading and high-quality development of advanced industries.

This is the moment to transform opportunity into precise outcomes. We have built a reliable bridge from concept to finished product, designed to streamline your manufacturing journey. You’re invited to upload your part drawings—our expert team will swiftly review them, assess manufacturability, and provide a customized CNC machining solution tailored to your specific needs. Let us help you bring your design to reality with confidence and efficiency.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.