Precision CNC machining services are critical, yet many engineers and procurement managers face consistent challenges. They struggle with tight tolerances, supplier limitations leading to poor yield and delays, high communication costs, and a lack of transparent, fair quotes. These pain points directly threaten project timelines, budgets, and final product performance.

The problems which come up have their root in the fact that the majority of the suppliers have little knowledge or expertise beyond the process. This creates a problem in that there is little efficient problem-solving. Knowledge and expertise created throughout the scope of the guide, the knowledge of LS Manufacturing, and the knowledge of the application of the essential process, in addition to the awareness of value and capability of partners.

Precision CNC Machining Services Full Quick Reference Table

| Section | Key Content Summary |

| Introduction | Possible Problems: tight tolerance, low yield, delays, cost. Root Cause: Lack of experience in that area, Lack of expertise in that area, Lack of experience in quality control. |

| Core Processes | Advanced Machining, Metrology, Material Science, Process Optimization. |

| Quality Systems | In-Process Inspection, Final quality assurance, Certifications-ISO 9001, AS9100, etc. |

| Industry Cases | Examples from the aerospace, medical, automotive, and electronics industries demonstrate precision solutions. |

| Supplier Evaluation | Capability, equipment, quality certification, lead time, communication, cost. |

| Cost Factors | The materials involved, the level of complexity, the amount to be produced. |

| Success Factors | Early involvement of suppliers, clearly specified criteria, prototype tests, and long-term partnership. |

This guidebook offers a short reference guide that shows what should, if possible, be included in pursuing a precision CNC machining partners. These factors range from basic processes and standards of quality, cost considerations, and assessment criteria. Emphasis is given to experience and reliability and transparency in pointing out not-so-common issues faced by consumers. Achieving high quality, full compliance, and an effective means at a strategic level of procurement is attainable in considering suppliers with a high degree of technical competency and extensive overall experience.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

That is, micron tolerances, complicated internal cavities, and high-strength material, day in and day out at the workshop from LS Manufacturing. Everything manufactured here-from an aerospace structural component upon which depends the safety of flight to a medical implant-relies upon a base of informal real-world optimization together with exhaustive reliability verification.

Having provided service for more than a decade, this team has successfully offered tens of thousands of high-precision CNC machined parts; thus, it provides extensive expertise over material properties, tool dynamics, and process parameters. Normally, this is very hard-won. It comes from the very early trial-and-error costs and is further enhanced by the sustained successful deliveries. Each strategy and technique shared within this guide is being distilled through repeated testing in cutting, coolant, and rigorous quality control.

Our practices are always based on systematic thinking. All staff strictly follows the ISO 9001 quality management system and thinks of implementing the ISO 13485 standard in medical device manufacturing, giving priority to the controllable, reliable, and traceable whole process from design to production. It is just such a reliable methodology which integrates practical experience with standardization that we share to help you transform innovative designs with speed and reliability into high-quality products.

Figure 1: Several types of industrial machinery parts manufactured by LS Manufacturing

What Is True Precision CNC Machining Service? What Is The Fundamental Difference Between It And Ordinary Machining?

At LS Manufacturing, we understand that our definition of precision is more refined. Precision implies excellence in relation to the outcome or result. Precision CNC machining services involves more than cutting. This, in fact, involves a whole system where tiny tolerances, superior surfaces, and unshakable accuracy in relation to the outcome or result in translating complex designs into perfect units are achieved.

| Aspect | General Machining | Details of Precise |

| Core Objective | Meet basic shape and size needs. | Achieve exact specifications with high consistency. |

| Tolerance & Finish | Standard tolerances (> ±0.05mm), visible tool marks. | Tight tolerances (often ≤ ±0.01mm), specific surface finishes. |

| Equipment & Control | Conventional or older CNC machines. | High-end, calibrated multi-axis CNC, temperature controls. |

| Quality Assurance | Normally done only in the final inspection. | In-process CMM/Advanced Metrology. |

| Material Expertise | Common materials like mild steel or basic aluminum. | High technology metal alloys or plastic-based materials. |

| Service Scope | Manufacturing of components according to design. | Technical consultation and analysis for technology and DFM. |

The solution is in the integrated approach. That is what a real CNC machining supplier like LS Manufacturing brings to the table. Partnership means access to the brightest and best machining tools available, the tightest machining tolerance possible, and the most forward-thinking engineers. However, the solution does more than solve a problem for you. It will bring a reliable high performance solution that is specifically designed for heavy-duty applications.

How To Ensure The Machining Accuracy And Consistency Of Parts Through Five Core Process Flows?

Attaining the right results calls for a very refined approach, which calls for more than technology on its own part to derive optimum efficiency. At LS Manufacturing, we have the right approach because the meticulous attention focused on the entire CNC machining process right down to the packing step has our own exact specifications detailed below:

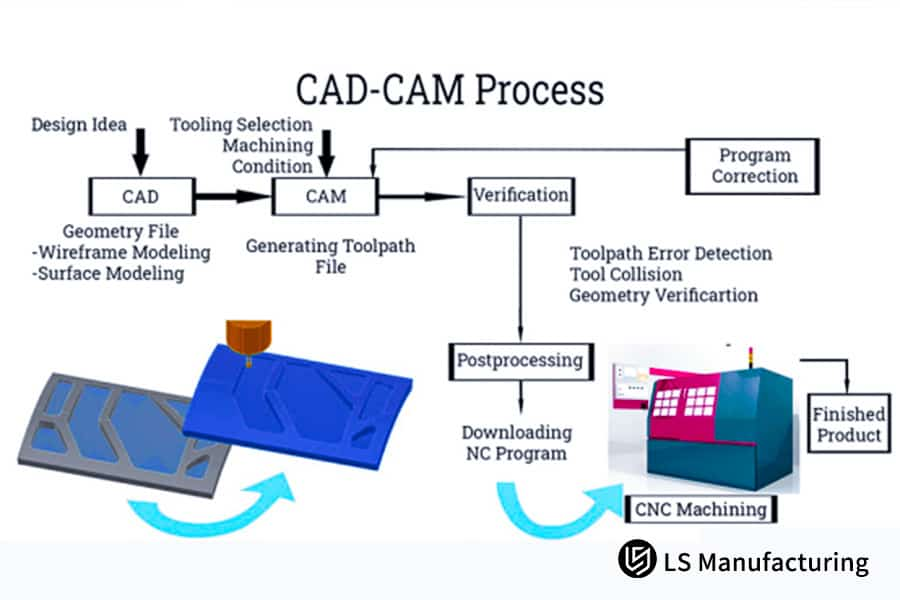

Digitized Design and Programming

All productive precision CNC machining occurs well before the first cut is made on the CNC machining center. At Hubbard-Hall, our experienced programmers interpret your CAD engineering design for optimal manufacturability. This includes interpretation even prior to machining being performed to simulate the machining process to avoid collisions or to meet the required engineering specification of the component being manufactured.

Machine Selection & Setup

Selecting a machine to do a task of high precision is not a process involving random selection of the machine. We ensure that during selection, it is done considering the best-suited machine available for a particular part, according to how old, how precise, and reliable that machine is. This is done by ensuring that the machine is set up in a manner that involves the level of accuracy comprising the fixtures, cutters, and work-origin, ensuring an error-free start of the cutting process.

Tool Strategy and Optimum Machining Factors

Essentially, the effectiveness of the tools is of utmost priority. Consequently, we use better tools suited to our operation, and subsequently, we optimize the machining factors, which include speed, rate of feeding, and quantities of cut based on the nature of the machined object. This systematic approach, as detailed in our comprehensive CNC machining services guide, ensures that our process involves positive machining factors. These factors enhance the longevity of the tools, unaccompanied by machine oscillations, with the objective of avoiding deformations on the machined object.

In Process Inspection and Quality Control

The data collected is what measures variability. As a measure to ensure this, we have incorporated inspection within our process. The installation of touch probes within our machine and also using the CMM machine offline enables us to gather data. Through this, it enables us to correct any issues along the way as we ensure that the part is within tolerance.

Post-processing & Controlled Packaging

The status of the final part is protected. This is where the post-processing phase begins. Here, the processed parts undergo processing according to a predefined procedure for carrying out part processing. Finally, the inspection on the parts is done. The parts are cleaned using the relevant solvents in the clean room, if necessary. The packs are packed using anti-static packaging.

In fact, for the best precision CNC machining, a systematic approach is needed. As LS Manufacturing begins with CNC machining process of foresight, action, verification, and security through distribution, raw materials can be developed into pieces with the best precision, quality, and reliability.

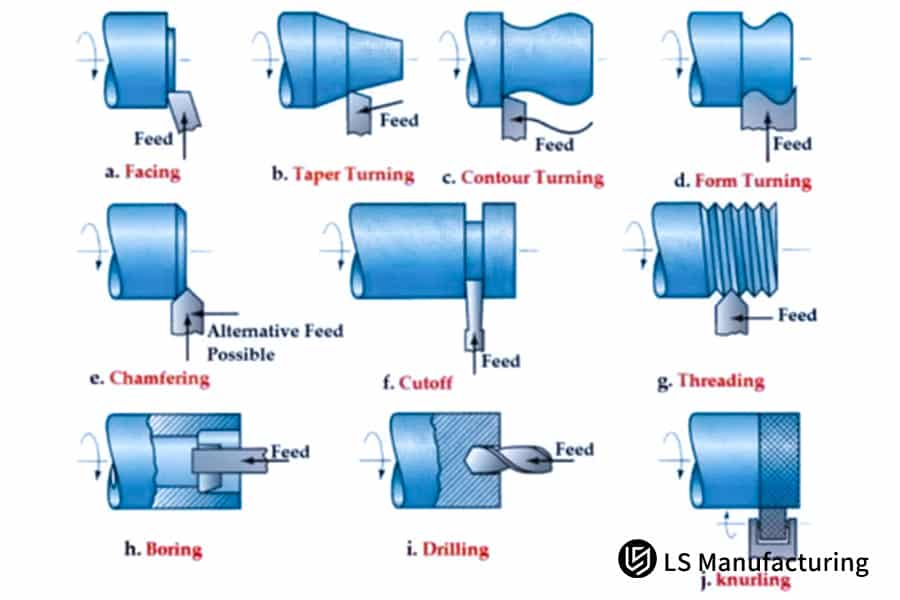

Figure 2: Visual guide contrasting CNC machining operations by LS Manufacturing

What Are The Most Critical Evaluation Criteria When Selecting A CNC Machining Supplier?

Selecting the right partner is critical for project success, as the cheapest quote often carries hidden costs. Knowing how to choose a CNC machining manufacturer requires looking beyond price to assess capability, reliability, and the total cost of partnership. This evaluation focuses on tangible standards and proven experience, not just promises, ensuring your project is in capable hands.

Technical Abilities and Equipment

A top-tier CNC machining manufacturer must have a modern, well-maintained equipment portfolio suitable for your parts. You can request that they provide you with a list of equipment that they have and then explain them to you based on age, technical skills such as multi-axis machines, and quality. The current level of technology that is capable of performing technical work such as thermal comp, precision spindles, and other technology is also important in enabling your product to achieve a tight tolerance level.

Certified Quality Management Systems

Certain aspects of a quality management system are inalienable. It is important that you look for the services of a CNC machining supplier who is going to make sure that you have a quality management system established. These include certifications such as ISO 9001:2015. It is important that your type of industry is going to be certified just like AS9100 and ISO 13485 in the aerospace industry and healthcare industry, respectively.

Metrology, Process Control

It has to be accurate, and the level of accuracy has to be verifiable. Now, quality labs—okay, is a quality lab more effective, effective in their research in process, compared to CMMs for one-piece research? This is where the best-of-breed player has to have their metrology game in order to establish prima facie proof that they are concerned about the issue.

Engineering Knowledge and Teamwork

There are some people that you would have to collaborate with in regards to each machine. It is a good thing that you would have a good team of engineers at your fingertips if possible, and some would be at your fingertips directly, all ready with the information for DFM analysis if it has been done. Just take a look at this team of people and think about how they could be used for so many case studies. A reliable CNC machining supplier is at all times the partner of your business in your design.

Communication & Project Management

There should be a seamless process flowing in the process flow for the implementation phase itself. Evaluation for their project management process, if possible, must be completed. Response of management for the RFQ response, Engineering change order, and update is the most critical phase. Communication, Single point contact, & NPI Process are the most required ones.

In summary, how to choose a CNC machining manufacturer involves a holistic audit of technical prowess, certified systems, and collaborative culture. A qualified supplier is that with cutting-edge technology equipment and quality experience that is LS Manufacturing. One is assured, therefore, not only of the product but of the entire strand of supply chain quality with the selection of a supplier that has cutting-edge equipment capabilities and qualified quality systems.

How Is The Price Of Customized CNC Machining Services Calculated? What Factors AffectThe Final Price?

The custom CNC machining price can also be determined quite easily with the help of the inputs that have been required for the project. The proper CNC machining quote has the capability to determine the cost that is required for the whole project with respect to the conversion of your design idea, reality, or physical product. There are several factors that are directly involved in determining the cost for the whole project.

| Factor | Description | Effect on Custom CNC Machining Price |

| Material | The alloys are categorized according to material, quality, as well as size. | High-quality alloys include titanium, gold, silver, and some others. |

| Part Complexity | This is essentially including all the characteristics of the geometry of the part, all the specifications included. | It has complex surfaces and small tolerance values will result in long programming times for this part. |

| Production Volume | Number of parts ordered. | High production volumes result in lower unit costs since the average cost is subdivided by a larger number. |

| Machining Time | Total time spent. | The longer the cycle, the more expensive it will become due to energy consumption. |

| Secondary Operations | Additional processes post-machining. | Anodizing, plating, heat treatment, or specialized finishing add cost. |

| Quality Requirements | Secondary operations performed subsequent to machining operations. | First-article reports, full CMM inspection, or special certifications incur added cost. |

The first article report for the CMM inspection report or any specialty certification requires an additional cost. Overall, the best and most accurate cost for any CNC machining quote and pricing relates to the overall analysis process tailored to your own specific needs. Most directly, the best and most accurate way to get the best machining quote and pricing is to download files for a free DFM analysis and quote provided by a professional OEM parts CNC manufacturer.

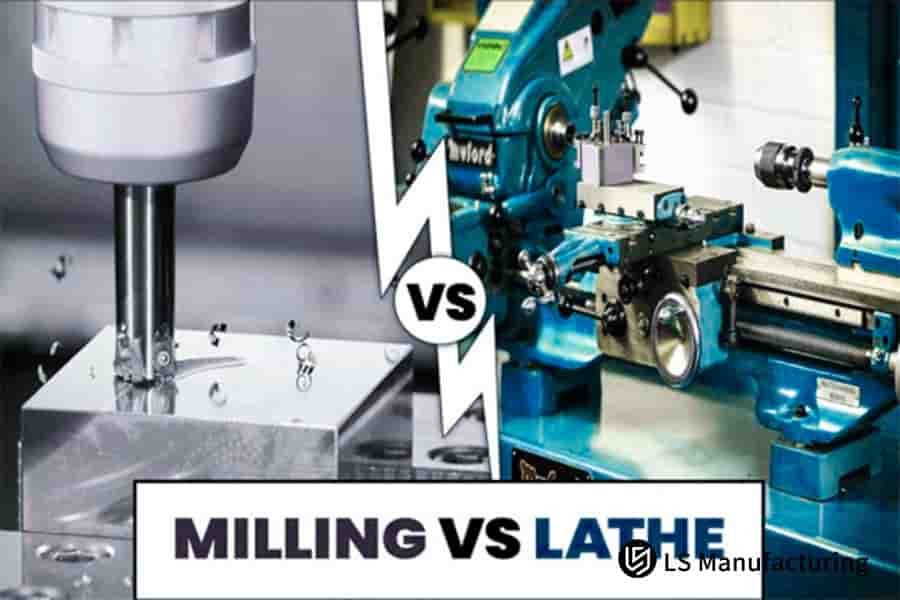

Figure 3: Comparing the capabilities of CNC turning and milling centers by LS Manufacturing

LS Manufacturing Success Story: Customized Manufacturing Of Titanium Alloy Engine Mounts For The Aerospace Industry

The LS Manufacturing case is only an example of many that demonstrate our desire to aid with matters within the industry. They came to us with a challenge of great significance with a problem of their aerospace equipment that has been produced with their high-performance components. Their situation exemplified the extreme difficulties in manufacturing advanced customized aerospace parts, particularly from demanding materials.

Client Challenge

The challenge that existed at the client level related to their need for a light and stiff bracing bracket, which had a practical goal of being used inside of their engine assembly. Their actual amount of scrap could not be controlled at a level below 30 percent. This issue was particularly evident in their attempts at custom CNC machining of the complex part, as the process they employed led to uncontrolled scrap rates and instances of problematic vibration during operation.

LS Manufacturing Solution

Our engineering group did a comprehensive study on this. This was quite an elaborate process given the various considerations. The manufacturing process for assembling required a special fixture with multiple points in line, design and production. The titanium alloy processing strategy was entirely remade. This included custom tools and a pressurized coolant system operating at high pressure to deal with the material stresses.

Results and Value

These improvements have been nothing short of revolutionary. Scrap level was reduced from 30% down to almost 1%, and that alone ensured delivery. There was also a 15% reduction in the end weight of this particular part and a 20% reduction in lead times. This LS Manufacturing case helped the client receive a better part that was also reliable and significantly cheaper.

In summary, this project underscores that successful customized aerospace parts manufacturing requires deep material expertise and innovative process engineering. For challenging titanium alloy processing and beyond, partnering with a specialized manufacturer like LS Manufacturing ensures not just a part, but a reliable, high-performance solution that delivers tangible value and project success.

Ready to go from design to precision component? Get a quote for CNC machining instantly.

How Is CNC Machining Technology Applied To Industries Such As Medical Devices, Automobiles, And Communications?

Multi-industry CNC machining applications demand not just technical skill, but a deep understanding of diverse material properties, regulatory standards, and functional requirements. Being one of the leading OEM parts CNC manufacturer which use CNC machining, LS Manufacturing uses the technical knowledge of high-precision CNC machining to deliver the urgent needs of a number of demanding fields with the flexible nature of advanced CNC machining.

- Medical Devices: In the medical industry, where businesses are regulated, precision is the synonym for success. We machine biologically safe metals such as titanium and PEEK for the fabrication of complex surgical tools, diagnostic devices, and prototypes for implants. Our machinery is set to keep a clean room with traceability, which demands micro-tolerances on the surface finish for the components, imperative in medical devices.

- Automotive: The automotive industry, from prototyping to the production of high-performance parts, requires reliable and complicated parts. We produce parts ranging from light aluminum sensor housing to complicated fuel parts and heavy transmission parts as well as engine test parts. An understanding of materials from aluminum to cast iron allows us to deliver parts with excellent performance characteristics for strength, high-temperature properties, and fit in complicated parts.

- Communications: Components in communications depend on waveguides and RF filters to achieve sufficient signal integrity and stability. The specialty of our company is machining waveguide cavity parts, antenna parts, and RF filters using brass/aluminum materials for use in communications with specific geometry and surface finishes to ensure low loss and effectiveness in shielding for use in 5G communications and radar.

- Aerospace and Beyond: We also have experience in the aerospace field. We machine structural parts and engine parts out of high-strength alloys like titanium and Inconel. This has enabled customers in the robotics, semiconductor, and related high tech markets, where reliable high-performance OEM parts are required, to benefit from our capabilities.

In other words, the success for multi-industry CNC machining applications that the industry be able to modify or adapt their precision engineering capabilities. As an experienced OEM parts CNC manufacturer, one can ensure that their parts or equipment produced for the health or car industry, as well as telecommunication, among others, meet maximum quality standards.

Why Can LS Manufacturing Be Your Reliable Long-Term Manufacturing Partner?

Supplier selection may make a huge difference on account of the effects it may create on the properties, timelines, and innovation of the finished products. Supplier selection will certainly move beyond the boundaries of a transaction because the transaction is nowhere nearing completion, and the basic ground that must be laid down is the ground of trust, capability, and common objectives. The role and importance of a contract manufacturer have been defined by its pledge to become the long-term partners.

- Deep Engineering Expertise and Collaboration: First of all, we are a group of engineers. We believe that a lot is achieved if one works with each other. First of all, we start off working with you as engineers, and at the same time do a design for manufacturability analysis, which enables us to optimize your design.

- Advanced, Scalable Capacity Investments: In order to show our commitment to never-ending investment, we have made sure that all of the equipment at hand includes a broad range of state-of-the-art multi-axis CNC machinery. Because of scalable capacity, we can assure that any equipment necessary to complete your project, whether production or prototyping, will easily support success.y.

- Systematic Quality and Intellectual Property Assurance: Your trust will be maintained at our ends. At our company, we follow a very rigid testing process for quality assurance in which checks are conducted at multiple points in the completion process in order to ensure that all parts are processed in accordance with our specifications. Even more importante, probably, we at our company follow very rigid processes regarding the retention of your intellectual property rights in order that all of your designs and developments are kept confidential with us.

- Partnership in the True Partnership Model: We at Rittal are of the belief that we are an extension of your company. Right from the stage of your prototype development process, through the stage of bridge manufacturing and all the way through mass production, we have been associating with you. Let us build a communication channel that is free and honest.

LS Manufacturing was set up to offer far, far more than a supplier. It is this outstanding combination of partnership and skill at LS Manufacturing which makes them among the most reliable CNC machining manufacturers. But we are passionate about your long-term success at LS Manufacturing, and committed to making your dreams come true.

Figure 4: Streamlined CAD/CAM process for computerized numerical control manufacturing by LS Manufacturing

FAQs

1. What is your Minimum Order Quantity (MOQ)?

It could be trial production or small production; we shall, therefore, provide you with highly flexible production support services to ensure that you validate and iterate your products as soon as possible.

2. How do you ensure the security of my design drawings and IP information?

Our design confidentiality information, as well as other technology information, is protected via nondisclosure agreements and an encrypted file transfer process. The safeguarding of intellectual property rights constitutes the very basis for our agreement.

3. What is the average delivery time?

Where there are frequently intricate parts, the time required to finalize a prototype may result in a turn-around time of 5-10 working days. In large orders, the deadline for the supply completion will be agreed on, taking into consideration the process and quantity in the order. The customer's project deadlines are accorded more significance when scheduled for production.

4. What material certifications and quality inspection reports can you provide?

Our turn-around time within the after-sales process is very quick. However, within no time, we do the root cause analysis, if there is any defect within our manufacturing process. Moreover, we respond back to you with the proposed solutions within the process, which in no way affects the time of your projects’ execution.

5. What happens if there are problems with the processed parts?

We have a rapid response after-sales process. In the event of a product anomaly, we will immediately initiate root cause analysis and prioritize rework or remanufacturing. We will also proactively communicate solutions to ensure your project timeline is not affected.

6. Do you provide Design for Manufacturability (DFM) recommendations?

At Engineering WorldWide, we provide a Free Design for Manufacturability Analysis report within our quote suggestions, which optimize your focus on enhancing the Design for Manufacturability process. It also enables you to understand the structure tolerance and manufacturing process that allow you to extract the best out of design performance and cost factors.

7. Does your quotation include VAT and shipping?

The cost within the quote clearly portrays the unit cost, taxes, and the cost of packing. However, we also keep Logistics cost separated, as we understood that we need to consider the mode of shipping that is required by you. But we can also make use of yours; we, in fact, can help with regards to packaging and shipping as well.

8. How to start your first collaborative project?

Indeed, this is much easier, and all we need from you is that we get access to the “3D Drawings/Specifications of Your Products.” And we shall provide you with your very own project managers that would look into all the above-mentioned analysis, quotes, and production of Your Project themselves.

Summary

Precision CNC machining is an engineering service that integrates advanced technology, extensive experience, and rigorous systematic processes. Choosing a partner like LS Manufacturing means gaining not just manufacturing capability, but also the technical support and quality assurance essential for your project’s success. This comprehensive approach ensures every component meets the highest standards of accuracy, reliability, and performance.

Your project deserves the most dependable manufacturing solution available. Contact the expert team at LS Manufacturing today, upload your part drawings, and receive a complimentary DFM analysis along with a precise, transparent quote. Let’s transform your design into a flawlessly executed reality, together.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.