Stainless steel CNC machining services are essential for manufacturing precision components, yet selecting the right material grade poses significant challenges. The choice to use the appropriate type of machining service which has the capability to undertake the machining process, due to the consideration that the manufacturers lack knowledge regarding the variation of various kinds of stainless steel varieties, including 18/8, 18/10, and 18/0 stainless steel , could end up being a big challenge.

All the above problems occur due to a lack of knowledge regarding the type of material as well as the behavior of the material when machined. However, all the above problems are taken care of in a very effective manner by LS Manufacturing due to their good knowledge about the type of material, as mentioned above, along with the advanced machining of this material using CNC machining. The raw materials, in fact, play a significant role in rendering quality to the machined parts as well as to offer machined parts in a cheaper manner made out of quality stainless steel.

Stainless Steel Selection & CNC Machining Quick-Reference Guide

|

Characteristic |

18/8 (304 Stainless Steel) |

18/10 (316 Stainless Steel) |

18/0 (430 Stainless Steel) |

LS Manufacturing Insights |

|

Cr/Ni Content |

18% Cr, 8% Ni |

18% Cr, 10% Ni |

18% Cr, 0% Ni |

Nickel content directly impacts material cost, corrosion resistance, and machinability. |

|

Metallurgy |

Austenitic |

Austenitic |

Ferritic |

Austenitic steels offer better toughness and are easier for complex CNC milling and turning. |

|

Corrosion Resistance |

Good (resists weak acids/bases) |

Excellent (resists chlorides, acids) |

Poor (prone to rust) |

Key Advice: Choose 316 for medical/marine environments; 304 is suitable for dry, indoor applications. |

|

Mechanical Properties |

Balanced strength & toughness |

Higher strength and hardness |

Lower strength, significant cost advantage |

For high-strength structural components, 18/10 (316) is the more reliable choice. |

|

Typical Applications |

Daily utensils, food equipment, general parts |

High-end kitchenware, medical devices, chemical piping |

Architectural decoration, appliance parts, auto exhausts |

Our Expertise: We provide precision CNC machining, 3D printing, and low-volume production for all these applications. |

|

CNC Machinability |

★★★★★ (Excellent) |

★★★★☆ (Good) |

★★★☆☆ (Medium) |

We provide optimized machining parameters to ensure superior surface finish and dimensional accuracy. |

The service being offered by the LS Manufacturing is actually incorporating the following important factors and elements that are present within the machined parts produced by utilizing the stainless steel materials: the type of materials being used, the quality products being produced, and the costs being incurred by the manufacturing of the machined parts. The consultancy service is being used to take into consideration the most feasible costs being associated.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

I am Gloria, with over 15 years of hands-on experience at LS Manufacturing. This guide originates from the real battlefield of our shop floor, embodying the culmination of our experience solving practical problems in countless projects. Everything we do strictly adheres to the framework of the ISO 9001 quality management system and has absolute respect for the ASME Y14.5 dimensional and tolerance standards.

I once helped a client solve a long-standing assembly yield problem stemming from a misunderstanding of the tolerance stack. After we recalibrated and optimized the process according to the ASME Y14.5 standard, their product yield improved by nearly 30%. This sense of accomplishment in creating real value for clients through expertise and rigorous standards is what I love about this job.

Therefore, I can assure you that every word here has been refined through practical experience. I hope to transform our accumulated experience into practical knowledge that can help you avoid pitfalls and improve efficiency. By choosing LS Manufacturing, you are not just choosing a supplier, but a trustworthy partner deeply involved in the success of your projects.

Figure 1: LS Manufacturing's stainless steel raw material inventory, showcasing various sizes of stainless steel pipes

What Are The Essential Differences In Chemical Composition And Properties Between Different Grades Of Stainless Steel?

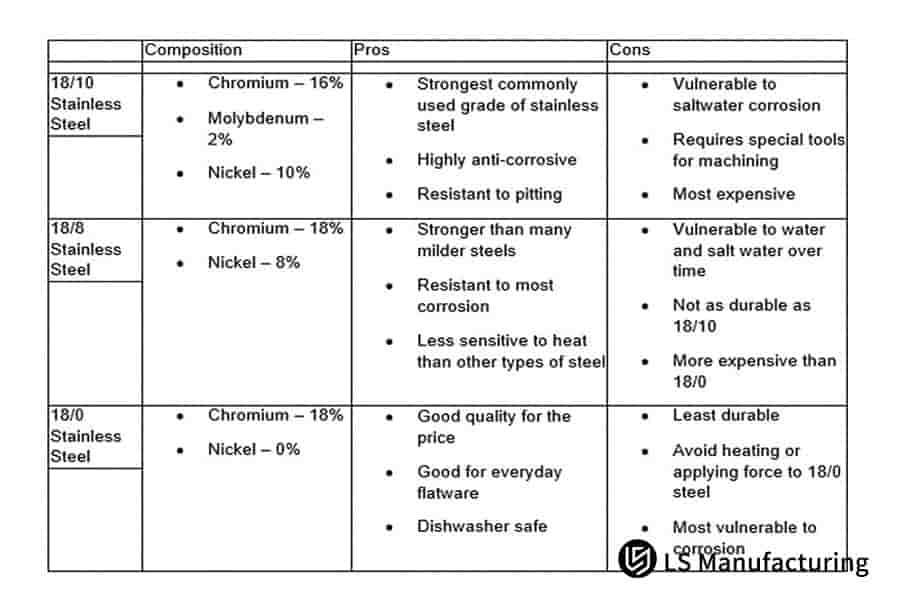

Grade selection is also of the utmost importance in succeeding in the area of producing a precision component. Resistance to corrosion, workability, and strength are highly complex regarding chromium, nickel, and carbon in the specific matters of the 18/8, 18/10, and 18/0 versions of metallic materials of the same kind. This foundational knowledge is key to effective stainless steel CNC machining services. The basic difference among the previously cited versions of the mentioned metal is as follows:

|

Grade |

Key Composition |

Primary Properties |

Ideal Application Scenarios |

|

18/8 (304) |

~18% Cr, ~8% Ni, Low C |

Corrosion-resistant, can be formed, and non-magnetic |

Kitchen utensils and equipment |

|

18/10 (316) |

~18% Cr, ~10% Ni, Mo added |

Extremely corrosion-resistant, particularly to chloride corrosion, and impact-resistant |

Medical, marine, and food service applications |

|

18/0 (430) |

~18% Cr, Low/No Ni, Higher C |

Magnetic, moderate corrosion resistance, moderate strength, excellent polishability |

Appliance parts and accessories, interior decorative items |

The combination made available by 18/8 is very good, the corrosion made available by 18/10 is excellent, and the economy encompasses 18/0 since this ferromagnetic material provides one advantage. To get professional advice and to manufacture your project with precision involves joining together with a reliable 18/8 stainless steel parts machining manufacturer. The reason being, we want your project to be real in a tangible and exemplary manner to express your custom stainless steel parts and quote.

What Are The Common Technical Challenges In Stainless Steel Processing?

Successfully machining stainless steel requires navigating its unique metallurgical properties. While strong and corrosion-resistant, these same traits present distinct hurdles that can compromise precision, efficiency, and cost. Understanding and proactively managing these challenges is the foundation of any reliable stainless steel CNC machining services program. The most common issues include work hardening, rapid tool wear, and thermal distortion, each demanding a targeted technical approach. Challenges and strategic mitigations:

|

Challenge |

Primary Cause |

Strategic Mitigation |

|

Work Hardening |

Work hardening in the cutting edge results in deformation strengthening. |

A specific strong and steady feed, combined with special tools. |

|

Rapid Tool Wear |

High alloyed toughness and abrasion resistance. |

Use high alloy coated carbide, optimize cooling. |

|

Thermal Distortion |

Low Thermal conduction absorbs and retains heat. |

Control cutting parameters, employ high-pressure coolant, step-machining. |

Overcoming these is critical to the optimization of dimensional stability, surface quality, and costs. It is a normalization process changed into a modern, custom stainless steel CNC machining solution. The only way to ensure that these are overcome to achieve an optimized product is by sourcing it from a multi-grade stainless steel parts machining supplier.

How To Select The Most Suitable Surface Treatment Process Based On Application Requirements?

A well-finished surface is a key requirement for optimized performance capabilities and aesthetic qualities of the stainless steel items. Finishing is mandatory and far-reaching in its effects concerning the corrosion resistance and cleanliness of the finished stainless steel items either directly or as a result of the machined items and components processed during our stainless steel CNC machining services. Options and applications of finishing of the stainless steel items:

- Electropolishing: The electrochemical process removes a thin layer of material, hence removing peaks to achieve a high-quality passivation layer of Chromium Oxide. The resultant finish from the process is bright, high polish, with high corrosion and chemical resistance properties, cleanable. Applications for the case include medical devices, food processing equipment, semiconductor wafers that require high level of cleanliness and purity. A high polish finish entails a good OEM precision stainless steel machining manufacturer.

- Passivation: Passivation is the chemical treatment of metal to remove the iron particles and form chromium oxide films on the metal surfaces. It does not affect the metal's appearance and size. The passivation of metal increases its natural corrosion-resistance properties. It is the most economical method used on the metal parts those are subjected to the low corrosion while functioning within building machinery and metal parts.

- Plating (Nickel/Chrome Plating): This involves the electro deposition of a thin metal layer upon the stainless steel part. This benefit basically enhances the hardness and resistance to wear of the part while, at the same time, giving the part a special look-such as the shiny look associated with the chrome finish. This special benefit can rather be looked upon as a mark or an indicator that the one-stop CNC machining supplier is able to furnish the part no matter the process done post-manufacturing.

- Bead Blasting and Brushing: These constitute the mechanical processes that are applied to give the glass a frosted effect. The bead blasted effect is of a non-reflective and textured finish, and it presents a satin effect. Fingerprints and small marks are completely hidden. The fingerprint effect also has a linear cut, which is an end result of the process involved. It can be used effectively in a building, products, and cases.

In coming up with the most appropriate surface treatment option, there has to be proper consideration of function, environment, and cost involved. Perhaps it will be the ultimate protection against corrosion, such as electropolishing. It will be important to make a decision to partner with the most trusted person in the field who will provide for your needs in stainless steel CNC machining services, which will make sure that your product gets the best machining work and the right advice on how to unlock its full potential through the subsequent surface treatments.

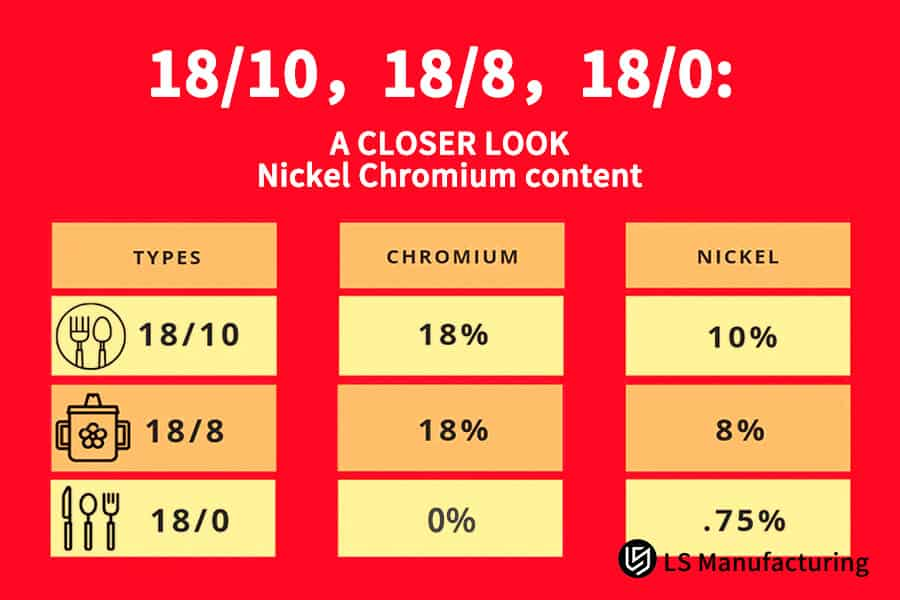

Figure 2: Comparison of chromium and nickel content in three types of stainless steel

What Are The Special Requirements For Stainless Steel Parts In The Medical Device Industry?

In the healthcare industry, the manufacturing of stainless steel parts needs the highest level of quality and processing requirements. In addition to having the parts machined with required precision like other parts, the part needs to meet very high biological and chemicals requirements. Let’s discuss the factors that make up the manufacturing of the part in the healthcare industry. Requirements and Standards:

Biocompatibility and Material Traceability

The starting point for these requirements is the use of approved biocompatible materials. It has also been mentioned that Grade 18/10 (316L) stainless steel must always be used if there is the chance, because it has highly successful anti-corrosion qualities and a low carbon content. A competent multi-grade stainless steel parts machining supplier should have full traceability according to ISO 10993 or approved biocompatibility.

Exceptional Surface Finish & Cleanability

Not having any single imperfection on the surface is the key in order to prevent the formation of bacteria. Electropolishing or similar processes are needed in order to attain the passive surface along with the Ra values. This associated cost makes it the need to determine the right costing of the 18/10 stainless steel machining service price.

Validation for Sterilization and Process Control

The components should withstand strong processes in the sterilization category like autoclave, gamma, or ETO sterilization. However, the components should not get damaged in the process. Conversely, there comes the need to validate the whole production cycle so that the cycle is capable of producing medical-grade components. This level of documented, controlled production is a core component of a comprehensive custom stainless steel parts and quote for medical applications.

Complete Quality Management and Documentation

Device History Record or DHR, Process Validation Report, or First Article Inspection Report is required. This is one utmost important point since the components are traceable. This is as important as hardware components when it comes to the approvals, according to FDA guidelines on Quality System Regulation or the EU Medical Device Regulation.

A necessary understanding of this kind amongst the required standards and verification needs, first the manufacturing partnerships practice according to specific needs mentioned in medical standards, with a particular focus on the knowledge range in the domains such as material science, precisely crafted components within the controlled environment, having a prime focus on the quality systems. This necessary need within the medical industry requires a partnering approach within specified domains such as medical.

Figure 3: LS Manufacturing Stainless Steel Selection Decision Guide: Matching Application Scenarios with Material Properties

How To Solve The Precision Machining Problem Of Stainless Steel Pump Bodies For Food Machinery?

Precision machining involved manufacturing food-grade stainless steel pump housing machined parts, which required technology specifications. This involved manufacturing parts needed in machinery. The parts required giving the best possible results with regard to sealing surface quality, in addition to cleanliness. This could not be realized in the conventional machining process. Below are the actual processes involved in LS Manufacturing to satisfy the needs of the food machinery corporation.

Customer Challenge

The customer was experiencing a problem pertaining to the leakage issues related to the pump assembly solution products provided by the firm. This is due to the inaccuracies present in the machining of the crucial surface of the seal provided by the supplier. Inaccuracy in the surface finish of the surface contributed to the failure of the seal created in the closure of the pump assembly solution products. This problem is related to the cleanliness and efficiency of the food lines.

LS Manufacturing Solution

The reasoning for choosing our material to be of quality 18/10 (316L) stainless steel lies in the distinct qualities the product has pertaining to corrosion resistance for food service uses. In addition to that, in order to improve the handling characteristic, taking into consideration stability, the machining process has been perfected so that warpage is removed. This integrated approach exemplifies the capabilities of an OEM precision stainless steel machining manufacturer.

Results and Value

The rate of production escalated to 98.5%, and the issue of leakage failure was completely erased. The rise in the value of the strength of the seal resulted in the extension of the life of the working pump by three times; thus, our client’s costs are considerably lower. In the above case, it is actually true that because of the expertise that our firm has concerning precision and the qualities that our materials always have, the costs of our clients are lower, coupled with the food safety standards that are always involved at the closing point of any given procedure in our firm concerning a custom stainless steel parts and quote.

The above success story clearly manifests that in any kind of problematic scenario in machining, purely depending on a solution based on the knowledge provided by a high-degree machining system is not an efficient solution and has to be achieved only through a complete knowledge level regarding materials, focusing on accuracy. It is at this point that any kind of compromise is simply not possible, and it is where an associate manufacturer, like an LS Manufacturing, steps into action.

Struggling with stainless steel machining challenges? Get expert solutions now.

What Are The Key Factors Affecting The Processing Cost Of Stainless Steel?

Information regarding the cost structure with regard to machining of stainless steel is very useful for budgetary work. These, which determine the total cost, are not described in terms of a single factor but a mixture that is determined by the factor labeled as “material considered.” Keycost drivers:

- Material Grade & Procurement: The basic cost also involves taking into consideration the raw material used. The superior type of 316/18-10 material is much more resistant to corrosion than type 304. It must be noted that material type and procurement quantity have a substantial impact the initial 18/10 stainless steel machining service price. The material for procurement should be selected in a manner that there is no over-design involved.

- Complexity of Design and Machinability: If there is high design complexity or deep cavity design, thin walled design, or close tolerance design, these necessarily involve spending much time in machining, thus thereby making it necessary to create these products by applying 5-axis machining. This is a core consideration in any custom stainless steel parts and quote, as complexity directly translates to machining hours and programming effort.

- Precision and Quality Assurance: The cost, in this case, is higher because the tolerance and service level of quality assurance are more precise. A higher level of precision in microns and lower machine speeds are required; besides, the secondary process may involve finishing and/or operations with CMM machines. Also, the level of detailed documentation and certification works, such as material certification and first article inspection, adds up to the project cost.

- Surface Finish and Secondary Operations: The cost of the surface finish/treatment could become part of the overhead mainly depending upon the nature of the surface finish that could range from the simplest de-burating operation to passivation or even the sophisticated electropolished surface finish. The other processes such as heat treatment, plating, and assembly could add to the cost. In other words, it would become relevant to keep the least surface finish required by the part in order to keep the cost of the stainless steel CNC machining services under control.

Cost management in machining stainless steel has to be undertaken with a comprehensive approach in mind, of course having to consider performance, economy, and quality requirements. For a precise custom stainless steel parts and quote, clearly define your requirements on tolerances, material, finish, and quality documentation to receive the most accurate and value-driven pricing.

How To Assess The Overall Capabilities Of A Stainless Steel Processing Supplier?

Your selection of the right partner for your project can literally mean the difference between success or failure. More attention is required when evaluating a project not only from the cost or financial side but also from other aspects of the project. It definitely makes a big difference if a supplier has very strong knowledge or expert understanding about a project area or sector. This template gives a check list of items to be assessed in a project partner. Key evaluation criteria:

Technical Infrastructure & Machining Expertise

One needs to evaluate the technical knowhow of the supplier regarding the availability of CNC machines, which should have the flexibility of being multi-axis. An experienced OEM precision stainless steel machining manufacturer should have the knowhow regarding the complexities associated with the usage of the cutting tools as well as the various types and complexities associated with the stainless steel being machined.

Quality Assurance Systems/Certifications

Technical expertise coupled with the presence of a sophisticated quality assurance system at the supplier’s end can actually act as the crucial key point, which should not at any point in time be compromised. One needs to do research on the quality certifications, usage of the right tools for inspection, traceability of the materials being utilized, which should meet your standards. Totally one-stop CNC machining supplier have the 'Impeccable quality assurance' system which verifies each part meticulously so as to meet your requirements.

Technical Team Skillset and Design For Manufacturing (DFM) Expertise

One should judge the skills of your technical teams at the design and programming teams' end, which play an important role in this juncture. One needs to evaluate the skills at the design and programming ends' support with the active interest in Design for Manufacturability. It is highly important to stick with the right pairing with the right amount of industry experience, wherein your partner or the supplier is the extended part of your organizations’ structure who brings the required skills at the design level thereby enhancing the design at the required manufacturing capabilities.

Industry Experience and Comprehensive Service Scope

Investigate the supplier’s proven track record in your specific sector, whether it's medical, aerospace, or automotive. A capable multi-grade stainless steel parts machining supplier will have relevant case studies. Furthermore, assess if they can handle the full scope, from prototyping to finishing and assembly, which streamlines your supply chain and ensures cohesive project management.

A thorough evaluation across these dimensions—technical capability, quality systems, team expertise, and relevant experience—is essential for identifying a partner that can ensure project success. Look for a supplier whose strengths align with your project's specific technical and quality demands. A partner that excels in these areas provides not just parts, but reliability, value engineering, and peace of mind throughout the manufacturing process.

What Is The Complete Service Process For Stainless Steel Processing Projects?

There are processes involved for the efficient machining of the stainless steel material. Starting from the concept phase to the concluding phase where the whole projects will be completed, there is work involved systematically in the creation of complex concepts to the design stages that will easily be feasible for the creation of products that will work efficiently. There are processes involved in this, and they include the following to ensure a reliable custom stainless steel CNC machining solution:

- Design for Manufacturing Analysis: As we initiate our process for manufacturing, the very first step towards this goal would be to analyze your needs, which in essence would entail a detailed definition of functional and material specifications for a component. We shall make a comparison of your manufacture ability analysis with the objective of recommending a design from where fruitful data can be acquired regarding cost as well as performance.

- Process Engineering & Digital Simulation: After the freezing step, there is an extremely detailed process engineering process. Process engineering pertains to the right execution of the CNC path in terms of tool movement, use of a special tool, as well as use of a fixture, in combination with simulation processing. Process engineering assists in the diagnosis of defects in terms of collisions as well as bending errors due to generation of heat before the beginning of metal removal processing.

- Accurate CNC Machining with In-Process Quality Verification: The nature of service offered in the service provided by the company is similar to the nature of service provided to our machinists in relation to the multi-axis CNC machining service provided in the production facility in our company. The nature of service offered in our company using the CNC machining service includes the following: The nature of service provided in the in-process quality verification in terms of the service offered.

- Final Quality Assurance, Finishing, and Delivered: Machining is followed by a comparison between the final product and the CAD design specification done by a Coordinate Measuring Machine, though other processes such as passivation, electropolishing, and plating would be involved depending on the design. Finishing involves the process of packaging and delivering the products and any other related documentation, which would include data concerning the material and quality of the product tested or inspected.

To conclude, in relation to machining, transparency, teamwork, and quality are central issues. It means that we apply our wisdom in applying the concept of integrated solution approach since they shall have been enjoying our custom stainless steel CNC machining solution in implementation of this approach and will come to understand that there is no better service than ours.

Figure 4: Performance comparison analysis table of three types of stainless steel

What Are The Future Development Trends Of Stainless Steel Processing Technology?

The requisite expertise in the use of advanced stainless steel alloys becomes the prerequisite of anyone involved in a custom stainless steel CNC machining solution, as the expertise in the machining of advanced steel would have been gained with the innovations in the cutting techniques of steel, which would have devised ways to handle the hardness of the advanced stainless steel at very high temperatures.

Community-Wide Smart Manufacturing and Optimization Based on AI

Smart manufacturing, based on the IoT, AI, and the use of the digital twin, will be the norm. The connected sensors on CNC machining centers would provide data to the predictive maintenance and adaptive process control, thus cutting the number of unscheduled downtimes. An OEM precision stainless steel machining manufacturer leading in this space will use AI to self-optimize machining parameters, ensuring peak efficiency and consistent, superior part quality.

Development of Hybrid/Additive Manufacturing Processes

There can be a combination or integration of the additive manufacturing processes, 3D Printing, and it can also be integrated into the existing processes which involve CNC machining, through the hybrid machine system, and it can also incorporate another new notion. There is also a possibility pertaining to the development of light-weighted components pertaining to SSC Stainless Steel, which also encompasses some designs that are not possible to conceptualize by undertaking a notion that includes CNC Machining.

Sustainable & Automated Manufacturing Commitment

While Sustainability is all about being environmentally friendly, reduced consumption of energy, generation of wastes, and coolant use, there should be a commitment to lights out manufacturing & automated manufacturing as well. The effect of the above on the supplier of the stainless steel CNC machining services should result in an environmentally friendly, stable, and inexpensive method of manufacture.

The use of technology in integrating the parts in order to meet the demands of technology and green technology will be the future in the machining of the stainless steel product. The future in the machining of the stainless steel product will involve smart materials, flexible materials, and green materials. The materials will achieve their futures through the power of vision in control and through hybrid technology by the flow process.

FAQs

1. Is 18/8 Stainless Steel Suitable for Food-Grade Applications?

This type of steel is fairly versatile, and thus it is used in different food processing operations because the fact is that an environment that is corrosion-resistant and clean is needed here. Electropolishing/passivation is an activity that is much recommended because of the intended smooth finish, cleanliness, and food security associated with its application. Its process is the creation of the chromium oxide passivation layer which inhibits the growth of bacteria—that is fairly helpful indeed.

2. Minimum Order Quantity for Precision Stainless Steel Machining?

We are prepared to accept orders from single prototype through to production, with no set minimums. The ability to do so, which comes naturally, could well be applied to stages of product development, to test before full-scale production.

3. What is the Standard Lead Time for Complex Stainless Steel Parts?

The normal lead time for delivery would be between 3 to 5 weeks depending on the complexity of the piece, the tolerance required, and the production schedules of existing orders. This service also includes expedited shipping for the production orders with higher priority towards meeting the specific time deadlines.

4. Can you provide complete material certification and quality documentation?

Well, yes, we do have complete documentation, which would include the certification or mill certificate, as well as process certification. Traceability Programs: Trace from material lot number to parts number. They are designed to audit on behalf of the customer.

5. How Does One Ensure Corrosion Resistance in Harsh Environments?

The strategy that will be adopted in our design will include the selection of the appropriate kind of 316L stainless steel that is to be used in the marine environment by creating the best possible finish, either by doing it yourself in the machining of the surface or eliminating the problems found on the surface using specialized finishes in the form of electropolishing.

6. What is done to retain precision in complicated stainless steel product parts?

Other advanced technologies are the development of CNC programming for multi-axis machines, fixuring for increased stiffness, as well as CMM in-process verification. The adaptive manufacturing system can take advantage of the properties that the materials have when they are loaded in order to keep the accuracy intact.

7. Can you expedite the delivery of urgent orders?

Of Course, yes! Because of the fact that we are flexible, urgent orders can also be done. The quick response team will definitely have the ability to adjust the schedule within the developed team using the special machine to help during the rush delivery.

8. What technical information is needed and would you like for collaboration on the first project?

The entire information about the design, hopefully 3D CAD, technical specifications, including the details of tolerance specification, surface finish, and samples/proto-types. This enables us the ability to discuss the details about the DFM so that the quotations for your projects are directly available.

Summary

The utilization in your performance functionality is impacted by the utilization in the stainless-steel parts. I would like to state that you would be asked to use a professional to machinate your parts. Since you are at the verge of applying the scientific concepts of material science, manufacturing technology, and quality assurance for your parts, I strongly believe that the additional value of your parts would be escalated. I assure you that your parts would be of high quality, durable, and cheap in price.

Would you look for a sincere partner who has accumulated success experience before in machining stainless steels? Come to the LS Manufacturing! Free material analysis and quotation service is given to ensure the absolute success of your project. Your project success or failure depends upon the utilization of the manufacturing technology and you are free to take the benefit of the manufacturing technology for completing your project.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.