CNC milling for custom manufacturing is most versatile among the ones listed above; however, the possible problem that can be created through production is budget as well as time constraints that may possibly go beyond due to the aspect that they may not be ready with production. Perhaps they may have designs with complexities in them.

This is a result of the divergence between design and production. In custom production and CNC machining, there is a possibility that the design professional is unaware of the process required in custom production. They will not be able to grasp the nuances of custom production, for instance, tool accessibility, setup difficulties, or secondary operations. Therefore, the typical review process will be missing the information required during optimization.

Custom Manufacturing CNC Milling: The Full Reference Guide

| Category | Key Consideration | Design/Process Impact | Cost & Time Factor |

|

Part Design |

Geometry Complexity |

Deep pockets, thin walls, sharp internal corners increase difficulty. |

High (more setups, special tools) |

|

Tolerances |

More precise CNC milling tolerances mean lower machining speeds with more inspections. |

High-the cost Raise Exponentially |

|

|

Feature Standardization |

Using standard hole sizes, tool radii reduce the need to build specialty tools. |

Lowers (reduces tooling/setup) |

|

|

Material |

Machinability |

Aluminum-easy, Stainless Steel-hard; Aluminum has highly machinable properties compared to Stainless Steel. |

Directly affects cycle time and tool cost |

|

Stock Form |

Blanks near net shape reduce scrap; economy with standard blanks. |

Cost of material & roughing time |

|

|

Process Planning |

Setup Strategy |

Single-setup designs minimize errors, while complex designs need several. |

High (fixturing and aligning time) |

|

Toolpath Optimization |

The optimized toolpath reduces air cutting time. |

Important (saves machine time) |

|

|

Supplier |

Technical Capability |

Matching part needs (e.g., 5-axis) to shop's equipment & expertise. |

Critical for feasibility & quality |

|

DFM Feedback |

Early input on design modifications for easier/cheaper production. |

Reduces cost & prevents rework |

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Now, it is true that tones of writing do exist on the subject of CNC milling, but very few are inscribed by the kind of people who are actively involved in this trade. This manual does not owe its origin to an immaculate setting but to the world itself, the workshop itself, precision being the buzzword that cannot be bargained over. This kind of understanding has developed itself from the battlegrounds of fighting against the tough alloys, the tough geometries, and the philosophy of perfection itself.

The key to our company's success is the successful implementation of our processes. Over the last decade, we have been able to deliver over 50,000 custom CNC machined parts. More importantly, each and every one of these parts, whether it be a part of a piece of medical equipment utilized to save a life or an aerospace fastener that has been subjected to considerable stress, has provided us with a practical learning experience. The ASTM International guidelines have been followed scrupulously.

Current knowledge is the knowledge which we apply in our daily operations in manufacturing. We know what to be known, the feeds and speeds that work well when one is working with the 316L stainless steel material as well as the procedures that one has to undertake in ensuring a perfect finish as required by the National Association for Surface Finishing (NASF).

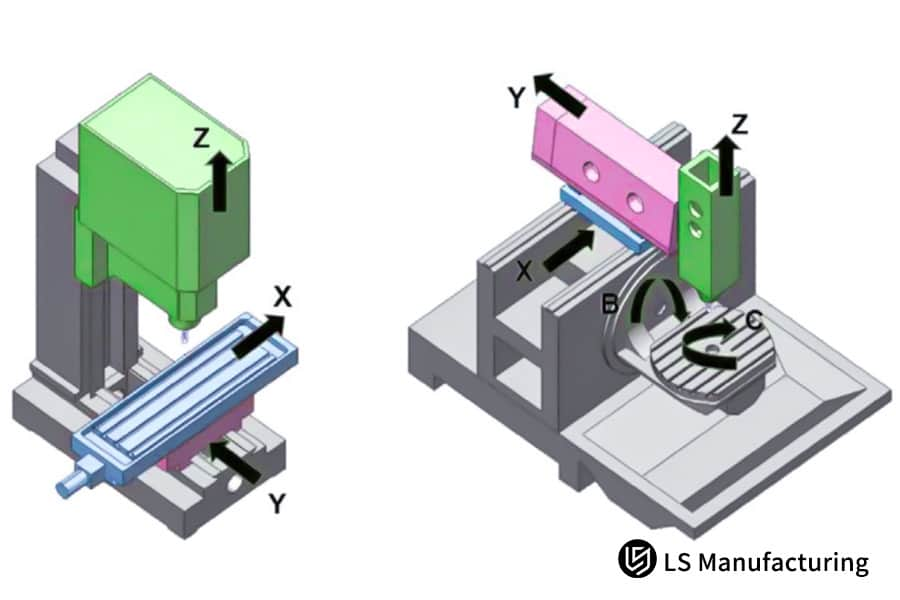

Figure 1: Designing parts for multi-axis CNC milling explained by LSManufacturing

Which Design Factors Have The Greatest Impact On CNC Milling Costs?

Awareness of the CNC milling cost factors is the secret to successfully implementing large price cuts. Although the final price is a single figure, it is the sum of a variety of interacting variables. Proper analysis of the machining cost analysis is the clue to understanding from where the greatest cuts can be made, not from the production line but from the earliest stages of the design itself, long before the first cutter ever touches the metal. The primary forces driving the costs in manufacturing cost control are:

- Cycle Time (Machine Utilization): This is often the single largest cost component. Every minute a part spends on the machine incurs costs. Factors that increase cycle time include complex 3D contours, excessive material removal, and unnecessarily tight tolerances that require slower, more precise machining passes.

- Part Geometry and Complexity: In any event, complexity is a realm where cost considerations are also certainly a factor. There would be a need for complex machines with longer time requirements when dealing with geometries involving deep pockets with sharp corner radii, walls which might be capable of vibrating, and geometries within those pockets which would require extension deep within the pocket.

- Material Selection And Waste: As stated earlier, apart from the cost involved in making a material selection for use, the other cost that is affected by the material selected is the machining cost effect. For instance, the use of robust material such as titanium implies that there will be heavy cutting, hence higher cutting cycle times. Furthermore, rather than the material cutting 80% of the material from solid stock, it would rather be ineffectively utilized in the design of an item that will cut 80% from near net shape material.

- Tolerances & Surface Finishes: The tolerances that exceed the functionally required value add to nearly half the cost. The reason is, instead of having a tolerance value of ±0.1 mm, it will have to be ±0.025 mm, which will cost ten times more. The reason is, if the surface that doesn't need polishing has to be polished or ground, it will take a long time.

In summary, effective manufacturing cost control begins with intelligent design. By focusing on designing for manufacturability, you directly influence the core CNC milling cost factors. A well-executed machining cost analysis that considers cycle time, complexity, and specifications from the start is the most powerful tool for how to design CNC milling parts that are both high-quality and cost-effective.

How To Achieve The Best Balance Between Cost And Performance Through Material Selection?

For optimal cost-performance balance of CNC machining processes, the process must also start with intelligent material selection optimization. One cannot always choose the material that possesses the best properties; it must be the material that possesses the best suitability for the performance of the functional requirement in an optimal manner in order to achieve the least cost of the project.

| Type of material | Cost Consideration | Machinability & Performance Note |

| Aluminum (e.g., 6061) | Lower material & machining cost. Excellent for economical material solutions. | High machinability, good strength-to-weight. Widely used for prototypes and enclosures. |

| Plastics (e.g., Delrin, PEEK) | Material cost varies; often lower machining cost. | Easy to machine; functional properties (e.g., chemical resistance, low friction) drive selection. |

| Mild & Tool Steels | Moderate material cost; higher machining cost than aluminum. | Good strength; used for molds, fixtures, and industrial parts. Balance of durability and cost. |

| Stainless Steels (e.g., 304, 316) | High cost due to the nature of the material and high machining costs. | Corrosion resistance is key. More abrasive, leading to faster tool wear and longer cycle times. |

| Titanium & Inconel | High cost of material & machining. | Used for maximum strength/weight or extreme temps. Difficult to machine, requiring specialized processes. |

In conclusion, the most effective CNC milling parts design considers manufacturability upfront. By collaborating with your manufacturing partner during the design phase, you can evaluate alternatives—such as using a pre-hardened steel instead of heat-treating a softer grade—to identify the most economical material solutions that deliver the necessary performance, achieving the ideal cost-performance balance.

Figure 2: Key design principles for economical custom CNC milled components by LS Manufacturing

What Kind Of Structural Design Can Effectively Reduce Processing Time?

Optimized structural designs at the strategic level, in actuality, represent one of the most optimized ways that help in achieving the objective of reduced machining time as well as the cost of production. In this given circumstance, the role of engineers in designing components with regard to manufacturability aims at reducing any complexity that eventually gives efficient machining solutions.

| Design Strategy | Implementation Example | Impact on Machining |

| Easy Geometry | Eliminate all curved surfaces by converting them into flat surfaces wherever feasible. | Simplified multi-axis tool paths and code. |

| Standardize Features | Use generic values for hole diameters, corner radii, and thread sizes | Reduces changes in tooling and potential error sources. |

| Prevent the creation of deep & narrow cavities | Adjust the pocket sizes so that they can be proportional concerning the tool sizes & capabilities. | Remove the need to utilize reach tooling & the associated slowness. |

| Unstable Fixturing Designs | Use parallel surfaces and bosses. | Easy to mount, easy to mount and then cut at high speed, and no vibration while cutting. |

| Eliminate Thin Walls & High Regions | Reinforce thin sections or design as separate assemblies. | Prevents chatter, reduces the need for light finishing passes, and improves accuracy. |

The bearing of an optimized structural design with the emphasis on both simplicity and standardization is the basis of the efficient machining solutions. One would argue that this proactive approach would help make sure that every single aspect of your custom CNC milling project did not only fulfill a given objective but had some inherent value with regard to being fast and cost-effective.

How Do Tolerance Design Affect Machining Costs And Quality?

The use of tolerance design optimization is critical in controlling quality and cost in manufacturing. Even though precision milling in manufacturing is of prime importance, each step above that has a very high cost factor. In trying to strike a precision-cost balance, it has to be determined where precision is functionally specified, where it is conventionally specified, and where it is functionally required. The impact of reasonable tolerance setting strategy can be profound in terms of both quality and cost:

Exponential Cost of Higher Tolerance Levels

It won’t be the same cost if the tolerance level is ±0.025mm or ±0.1mm. There would be an exponential cost if the tolerance levels are small, as the machines will run at slower speeds with the use of specialized equipment and even CMM measurements.

Machination Process and Cycle Time

Machinists, in this scenario, could find themselves in a situation whereby, in accordance with the tolerance limit, machinists are left to rely on safe machining conditions in a bid to meet this specified requirement without any variations at all. The effects in this case, considering the cyclic time of the resulting machined product, are significant and result in extra cost, as noted below. It is quite paradoxical to note that apart from contributing to this cost requirement, the scrap chances percentage is heightened due to variations in the tight limit of acceptability.

Function over Form

A reasonable tolerance setting should also take into consideration the function that the part performs when considering the tolerances. Areas of critical contact would necessitate tight tolerancing, while areas that require dimensions from a cosmetic and non-functional point of view may use standard tolerances, which in effect would reduce CNC milling costs.

In conclusion, an intelligent approach to tolerance design optimization is not about minimizing precision, but about applying it strategically. By conducting a functional analysis to define a reasonable tolerance setting for each feature, manufacturers can achieve the necessary precision-cost balance, ensuring part performance while actively working to reduce CNC milling costs and streamline production.

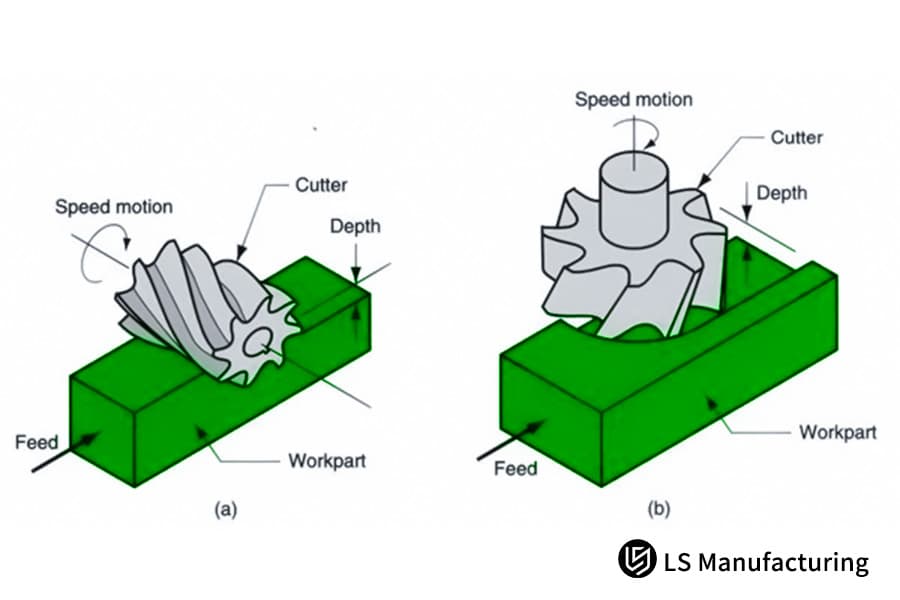

Figure 3: Comparing conventional and climb milling in CNC production methods by LS Manufacturing

How To Reduce Manufacturing Costs Through Standardized Design?

Implementing design standardization is a powerful yet often overlooked cost reduction strategy. In the context of CNC milling for custom manufacturing, standardization does not limit creativity but rather streamlines production by eliminating unnecessary variety. The core principle is to maximize the reuse of proven, efficient manufacturing elements. The advantages of standardization for both cost and reliability are significant:

Lesser Setup Time and Cost of Tooling

There would be vast standardization on far lower numbers of tooling patterns based on the sizes of the holes, corner radii, and types of threads in the shop that would fall into categories defined above. It would reduce the setup time of the tooling considerably, as it is one of the most important factors that impede the progress of a job. It would also be possible to buy quality tooling in bulk.

Improved Reliability of Process and Quality

The use of standard parameters would mean that machinists are able to count on standard speeds, feeds, and process performance. The knowledge created within the case would mean that the process would be closer to error elimination incurred with regard to the programming process. The reliability of the quality products being produced would thus be determined.

Simplification of Inventory and Procurement

This standardization in turn is further continued up to the stage of inventory of raw materials, i.e., the simplification of raw materials in terms of sizes of bar stock and plates to the simplified procurement of the standardized hardware parts in terms of hardware parts like screw, dowel pin, etc.

Minimizing Time-to-Market of New Designs

The conventional components of the sets of parts in the library facilitate designing on the part of the designer. This is brought about through the design of the component using building blocks that have been tested. This design procedure reduces the time utilized in this stage of producing prototypes. This is owing to an appropriate design of the parts based on knowledge of its processing.

Design standardization is one of the cost reduction strategy which can further be combined with CNC milling manufacturing facility to ensure efficiency. The concept is that instead of promoting diversities, the advantages of standardization, which include rapid manufacturing, cost-saving, precision, and ultimately an agile manufacturing company, can be achieved.

How Does The Choice Of Surface Treatment Affect The Total Cost?

Making decisions on surface finish selection is an ultimate step in achieving a cost-effective CNC milling design. These decisions are important in that they have a direct impact on strength, aesthetic functionality, and functionality capability of a given part. However, these decisions are not devoid of high levels of costs that are associated with them. A cost-effective cost optimization strategy in these choices would involve ensuring that the level of performance necessary in a part is aimed at being matched with its environment rather than selecting the strongest design unless its functionality is necessary. These decisions are arrived at through a clear comparison of treatment processes in a number of factors:

Cost of Processing vs. Performance Level

Although specialized processing like bead blasting and general anodizing is relatively less costly, it is found to be quite effective, keeping in mind that it is fulfilling its task of providing protective layers and polished finishes for low-performance products. Medium-level processing methods are averagely costly, and they are more durable and stronger. Very specialized processing methods, like electroless nickel electroplating and PTFE coating, are very costly.

Part geometry and pre-machining requirements

For electroplating processes, specific corner radii may be required to prevent the formation of plating pools and ensure uniform surface coating thickness. Processing requirements may include mask fabrication and surface microstructure values, both of which are measured by surface roughness Ra.

Consequences of Lead Time & Size of Batches

There are certain production operations that require a long lead time, and it can also be feasible to outsource the manufacturing of some components to third-party contractors, which would thereby add to the lead time by a few days. The high cost of painting can be standardized, making anodizing comparatively cheaper.

Functional Requirements Drive Selection

Material choice requires guidance from functional specifications. Is electric conductivity needed? In this specific circumstance, anodizing could not happen. Are you not affected by specific chemical materials? Is a material with lower friction on its surface needed? These questions must precede over-specification, hence identifying the most appropriate or cost-effective CNC milling design.

It would not be an incorrect statement to say that surface finish selection techniques along with an effective strategy is an integral part of cost optimization. Needs analysis related to surface finish techniques enable you to overlook unwanted cost expenditures, which would be helpful in making sure that the output maximizes value to its use.

Figure 4: Understanding CNC milling cutter processes for economical part production by LS Manufacturing

How To Conduct Manufacturability Analysis During The Design Phase?

A thorough manufacturability analysis is the most effective preventive action one can take to ensure a successful and efficient production process. A thorough examination in relation to design implementation well before design implementation is most effective in allowing one to eliminate problems prior to costly design changes or production line delays and is therefore at the heart of any successful step to reduce CNC milling costs. A systematic DFM inspection typically focuses on several critical areas of design risk assessment:

- Tool Accessibility and Feature Feasibility: This involves verifying that all internal corners, cavities, and undercuts can be reached by standard cutting tools. Features like deep, narrow slots or holes with a high length-to-diameter ratio may require special tooling or impossible machining angles, drastically increasing cost and complexity.

- Design for Stable Fixturing: The analysis evaluates whether the part geometry allows for secure and repeatable clamping during machining. Designs without adequate parallel faces or mounting points may require expensive custom fixtures, increase setup time, or risk part movement leading to scrap.

- Material and Geometry Suitability: This check assesses whether the chosen material and design are compatible. It identifies potential problems like excessive thin walls that could vibrate or distort, unnecessarily thick sections that waste material and machining time, or sharp internal corners that create stress concentrators and require smaller, less robust tools.

- Tolerance and Surface Finish Rationalization: It is an essential part of manufacturability analysis to investigate all specified tolerances and surface finishes. This should be done in order to question the dimensions specified but which are functionally specified and too tight, since these are major cost elements, and also to coordinate the surface finishes specified with the requirements rather than finishing the part at exorbitant costs with the sole intention of having an aesthetic surface finish.

In short, DFM inspection in its designing process can be considered a very proactive and highly positive approach. Its design risk assessment can turn any manufacturing process barrier into an optimized opportunity, and its final product is innovative, highly functional, economic to manufacture and produce at highly reduced CNC milling costs.

LS Manufacturing Automotive Parts Industry: Lightweight Design Optimization Of Engine Mounts

Within the LS Manufacturing success case, integrated engineering is a case study that exemplifies a method through which engineering is able to tackle major challenges presented by the car industry. Among these challenges, one is posed by an issue that arose with a Tier-1 supplier of parts used in cars, who requested a radical transformation in automotive parts optimization, that of an engine part.

Client Challenge

The traditional manufacturing process of the present engine mounting bracket and that which was being used in the client's vehicle involved machining steel. In this case, the approach was over-engineered because the end product would be heavier; this was a weakness of the engine concerning the efficiency of the vehicle. Secondly, it was wasteful as steel is quite expensive.

LS Manufacturing Solution

We began a full analysis of lightweight design and manufacturing processes. We substituted the material with a higher strength Aluminum alloy, from which we began. Subsequent to this, with a trade tool called topology optimization, we redistributed it to a more optimized shape with greater efficiency, where material would be subtracted from non-critical regions. Finally, through the quicker CNC machining of this complex shape.

Results & Value

In view of this, the results that have been realized in this project have been brilliant. This is on the grounds that the final component weighed 25% less, therefore impacting fuel mileage positively. More importantly, by incorporating material reduction, part design, and cost-effective machining techniques into this project, a 30% reduction in cost of manufacture was realized.

It shows that value can be created with a system level approach, such that the combination of lightweighting concepts, processes, and material understanding will result in outstanding component performance, cost, and sustainability. Therefore, the LS Manufacturing success case corporation inducts the corporation into a competitive advantage.

Need a detailed DFM analysis and quote on your components? Click here and share your requirement!

How To Collaborate With Manufacturers To Achieve The Best Cost-Effectiveness?

True cost-effectiveness optimization begins with strategic manufacturer collaboration. By partnering with your machining provider during the initial design phase, you can leverage their practical manufacturing experience before any models are finalized. This proactive engagement unlocks significant value and is one of the most impactful CNC milling design tips. The early participation value of your manufacturing partner is delivered through several key channels:

- Proactive DFM (Design for Manufacturability) Feedback: Engineers with direct machining experience can immediately identify features that are difficult, slow, or expensive to produce. They can suggest minor, non-critical geometry changes—like adjusting a wall thickness or corner radius—that dramatically simplify machining without affecting function.

- Material and Process Alternative Sourcing: A collaborative partner can suggest more readily available or cost-effective material grades that meet your specifications. They can also advise on whether a part would be more economical as a single CNC milled piece or as an assembly of simpler components, balancing machining cost with assembly labor.

- The Integration of Tooling & Fixturing Strategies: The first presentation gives the supplier the opportunity to formulate a strategy on how to best implement a fixturing & tooling solution. It could range from designing work holding fixtures with a focus on reducing set ups to designing changeover strategies that entail a spot tab positioner to position the item in a manner that makes it easier to work on.

- Effective Cost Forecasting and Risk Analysis: Since it will be possible to create a manufacturable design from the outset, it would mean that the manufacturer would be in a position to offer effective cost forecasting. Indeed, it will even enable effective budget understanding from an early stage and will definitely provide savings over costly changes at a later stage.

In order to be cost-effectiveness optimization, it is necessary that your CNC manufacturers are treated more like co-engineers than down-stream supplies. The value they can provide for your project through arly participation value your design philosophy so that your project ends up being founded on a manufacturability platform from early design concepts. Co-engineering is the final CNC milling design tips for manufacturability.

FAQs

1. How much can design optimization help in cutting costs, if at all?

In view of the complexity of the project and the degree of cost optimization available, cost saving of between 20% and 40% can be achieved by reasonable design optimization.

2. Will design optimization affect product performance?

Of course, professional design optimization is definitely an appropriate improvement with functionality maintained. We are going to conduct strict checks in order not to have any impact on functionality.

3. Is design optimization required in small-batch production?

The design optimization is valid for any number of batches. In a situation where there is a small number of batches, the design optimization will perform cost reduction.

4. How would you approach the process of carrying out an ROI analysis as part of design optimization?

We also incorporate a cost-benefit analysis within our report, whereby any investment required in the field of optimization and returns on investment will be determined in a way that helps in making decisions.

5. What materials would I need in order to go through the design optimization process?

The following need to be provided: 3D models, 2D plans, and technical specifications. This will allow us to carry out a complete manufacturability analysis.

6. How do I determine the feasibility of the optimized solution?

In addition, the correctness of our optimization technique is also verified with various techniques such as calculation of CAE, rapid prototyping, and finally producing the prototype.

7. Is there training available on the issue of design optimization?

We provide customized design optimization training for our partners to help their teams improve their design capabilities and achieve continuous improvement.

8. In what way is intellectual property protection achieved in the optimization method?

We follow strict confidentiality agreements. The intellectual properties of our optimisation solutions belong to you. Therefore, your competitive advantage is assured.

Summary

Through collaborative efforts in design optimization and manufacturing, it is possible to lower the cost of manufacture as well as the quality of the items manufactured. Through the extensive knowledge the organization has in the particular industry as well as employees who are experts, the organization provides complete solutions to the customers from the time of consultation until the time of manufacture.

Call or contact us today to receive a complimentary Design for Manufacturing report from our expert designers at LS Manufacturing, and let us assist you in examining and optimizing designs from a cost perspective related to their manufacture.

Skip the bottlenecks and we precision CNC milling parts for you, delivering fast, stable, and reliable results. Click to learn how our machining solutions can help you improve efficiency.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.